Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsJsa 36 - Ppu Shed

Jsa 36 - Ppu Shed

Uploaded by

golusinghdataCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Full Download Ebook Ebook PDF Linne Ringsruds Clinical Laboratory Science Concepts Procedures and Clinical Applications 8th Edition PDFDocument48 pagesFull Download Ebook Ebook PDF Linne Ringsruds Clinical Laboratory Science Concepts Procedures and Clinical Applications 8th Edition PDFlillian.palmer175100% (53)

- PalmTherapy Program Your Mind by Moshe ZwangDocument751 pagesPalmTherapy Program Your Mind by Moshe Zwangjules6294100% (7)

- BORB Birmingham Object Recognition BatteryDocument5 pagesBORB Birmingham Object Recognition BatteryAnaaaerobios0% (1)

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho86% (7)

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDocument6 pages03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu Niveriya100% (1)

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002100% (1)

- UntitledDocument201 pagesUntitledCsongor KicsiNo ratings yet

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat80% (5)

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- A Completed Example of Long Term Planning Cambridge Primary Science Guide p.16 17Document2 pagesA Completed Example of Long Term Planning Cambridge Primary Science Guide p.16 17Omar A. Mohammad100% (1)

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- DewateringDocument1 pageDewateringChandruNo ratings yet

- JSA. Confined Space EntryDocument3 pagesJSA. Confined Space EntrySwaroop Cherry67% (3)

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- 04 HVAC Panel Installation & Electrical Job.Document4 pages04 HVAC Panel Installation & Electrical Job.Himanshu Niveriya100% (1)

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- AGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMDocument1 pageAGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMArslanNo ratings yet

- Jobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding WorkDocument4 pagesJobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding Workuttam mishraNo ratings yet

- Cable Laying &termination HIRADocument66 pagesCable Laying &termination HIRAPRIYESH . K. PRIYANNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Job Safety Analysis: Date:02-05-2022Document3 pagesJob Safety Analysis: Date:02-05-2022Mohammad HussainNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- JSEADocument2 pagesJSEAIndermohan MehtaNo ratings yet

- JHA For Temp Structure ErectionDocument1 pageJHA For Temp Structure Erectiongullipalli srinivasa raoNo ratings yet

- Job Safety Analysis: Date:27-05-2022Document2 pagesJob Safety Analysis: Date:27-05-2022Mohammad HussainNo ratings yet

- Solar HandbookDocument36 pagesSolar HandbookAkash Kumar SuryawanshiNo ratings yet

- Cement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsDocument1 pageCement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Fall - Protection - Plan - Rev - 001 (1) (AutoRecovered)Document17 pagesFall - Protection - Plan - Rev - 001 (1) (AutoRecovered)NonhleNo ratings yet

- Jsa CPBDocument3 pagesJsa CPBmd maroofNo ratings yet

- Job Safety Analysis Report: DG Lifting & InstallationDocument2 pagesJob Safety Analysis Report: DG Lifting & Installationvijay kumar singh100% (2)

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- 49 Switch Board - Panel ErectionDocument4 pages49 Switch Board - Panel ErectionvasudevanmNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- Chapter 2 Hazard and Control MeasuresDocument3 pagesChapter 2 Hazard and Control MeasuresArul PrasaadNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Job Activity Hazard Effect Control MeasuresDocument2 pagesJob Activity Hazard Effect Control Measuresperquino oasan100% (1)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Mahalasa Aduit Compliance ReportDocument22 pagesMahalasa Aduit Compliance Reporthimansukumar biswalNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Toaz - Info 5 Jsa Rebar Cutting Amp Bending PRDocument2 pagesToaz - Info 5 Jsa Rebar Cutting Amp Bending PRthennarasuNo ratings yet

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Carpentry Works 20.09.2020Document11 pagesCarpentry Works 20.09.2020Amit BhattNo ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- Job Hazard Analysis Breaker InstallationDocument1 pageJob Hazard Analysis Breaker InstallationIsraelNo ratings yet

- Pit Cleaning HSE ProfessionalsDocument1 pagePit Cleaning HSE ProfessionalsSamadov 13No ratings yet

- Hot Work Jsa - Safetymgmtstudy-1-1Document1 pageHot Work Jsa - Safetymgmtstudy-1-1imdadullahhseNo ratings yet

- Hot Work JSA - SAFETYMGMTSTUDY PDFDocument1 pageHot Work JSA - SAFETYMGMTSTUDY PDFMohammed AlshehhiNo ratings yet

- Hot work JSA - SAFETYMGMTSTUDY-1Document1 pageHot work JSA - SAFETYMGMTSTUDY-1imdadullahhseNo ratings yet

- 12 - Method Statement For Steel Structure ErectionDocument5 pages12 - Method Statement For Steel Structure ErectionidzwanNo ratings yet

- 4 - Og Gedi Car Shes A 0003Document4 pages4 - Og Gedi Car Shes A 0003jonartapado2No ratings yet

- X Rigging, Lifting & HoistingDocument141 pagesX Rigging, Lifting & HoistinggolusinghdataNo ratings yet

- JSA 26 - Magnetic Particle Inspection (MPI)Document1 pageJSA 26 - Magnetic Particle Inspection (MPI)golusinghdataNo ratings yet

- X Suspended Work BasketsDocument26 pagesX Suspended Work BasketsgolusinghdataNo ratings yet

- JSA 49-Rev.01Erection of Spool Using by Rope PulleyDocument2 pagesJSA 49-Rev.01Erection of Spool Using by Rope PulleygolusinghdataNo ratings yet

- X Powered EquipmentDocument41 pagesX Powered EquipmentgolusinghdataNo ratings yet

- JSA 45 - Valve BoxupDocument18 pagesJSA 45 - Valve BoxupgolusinghdataNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- JSA 43 - Tightening of Water LineDocument1 pageJSA 43 - Tightening of Water LinegolusinghdataNo ratings yet

- JSA 18-Rev.02 - GroutingDocument2 pagesJSA 18-Rev.02 - GroutinggolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- JSA 37-Rev.01 - RADIOGRAPHY TESTDocument1 pageJSA 37-Rev.01 - RADIOGRAPHY TESTgolusinghdataNo ratings yet

- JSA 15-Rev.02 - Fabrication (OSBL)Document3 pagesJSA 15-Rev.02 - Fabrication (OSBL)golusinghdataNo ratings yet

- F-INO-04 Records of Training ImpartedDocument2 pagesF-INO-04 Records of Training ImpartedgolusinghdataNo ratings yet

- JSA 17-Rev.01 - Flange Tightening JobDocument2 pagesJSA 17-Rev.01 - Flange Tightening JobgolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- F-INO-05 Training Evaluation SheetDocument3 pagesF-INO-05 Training Evaluation SheetgolusinghdataNo ratings yet

- What Can You Do To Prevent AccidentsDocument1 pageWhat Can You Do To Prevent AccidentsgolusinghdataNo ratings yet

- Construction Fall Protection QuizDocument1 pageConstruction Fall Protection QuizgolusinghdataNo ratings yet

- F-INO-03 Training Need IdentificationDocument1 pageF-INO-03 Training Need IdentificationgolusinghdataNo ratings yet

- WRENCHESDocument1 pageWRENCHESgolusinghdataNo ratings yet

- Safety Flash 10 - Crane Hoist Wire Rope Dead End FailedDocument1 pageSafety Flash 10 - Crane Hoist Wire Rope Dead End FailedgolusinghdataNo ratings yet

- Safety Flash 35 Man Basket Fell From HeightDocument1 pageSafety Flash 35 Man Basket Fell From HeightgolusinghdataNo ratings yet

- BOOK LIST MU LibraryDocument13 pagesBOOK LIST MU LibraryJohn ThNo ratings yet

- Different InjuriesDocument2 pagesDifferent InjuriesJailian NagpiingNo ratings yet

- Dis Advantages of AbortionDocument5 pagesDis Advantages of AbortionAziil LiizaNo ratings yet

- Linking Words ActivitiesDocument3 pagesLinking Words ActivitiesSebastian Montaño RodriguezNo ratings yet

- Moh Exam Questions (10-7-18)Document9 pagesMoh Exam Questions (10-7-18)Subhajit SahaNo ratings yet

- TeksolDocument5 pagesTeksolniki fitraNo ratings yet

- Outcomes of Radioactive Iodine Versus Surgery For The Treatment of Graves' Disease - A Systematic Review and Meta AnalysisDocument9 pagesOutcomes of Radioactive Iodine Versus Surgery For The Treatment of Graves' Disease - A Systematic Review and Meta AnalysisGestne AureNo ratings yet

- SN MCQ Block IDocument12 pagesSN MCQ Block Iطال الإنتظارNo ratings yet

- Vitamin and Mineral Requirements in Human NutritionDocument361 pagesVitamin and Mineral Requirements in Human Nutritionpeny7No ratings yet

- Movement Disorders Types - Mayo ClinicDocument1 pageMovement Disorders Types - Mayo ClinicdrrajmptnNo ratings yet

- Last Child in The Woods - Overview - Richard LouvDocument1 pageLast Child in The Woods - Overview - Richard LouvGengjiaqi CHANGNo ratings yet

- Exercise Nutrition Learning Guide 2023Document17 pagesExercise Nutrition Learning Guide 2023AlexNo ratings yet

- Heymann & Tulloch (2006) Implantable Devices As Orthodontic AnchorageDocument12 pagesHeymann & Tulloch (2006) Implantable Devices As Orthodontic AnchorageDominikaSkórkaNo ratings yet

- Speaking Sample Test 5 (Dentistry)Document2 pagesSpeaking Sample Test 5 (Dentistry)Jia SunNo ratings yet

- Nike and Child LabourDocument8 pagesNike and Child LabourLorraine ChenNo ratings yet

- Voucher No: 125244/2023 - 30/03/2023: Reference No. For The Hotel: 9153573473984 / 1484479948Document4 pagesVoucher No: 125244/2023 - 30/03/2023: Reference No. For The Hotel: 9153573473984 / 1484479948Григорий ПавловNo ratings yet

- What Is PTH?: Parathyroid Hormone (PTH) TestDocument4 pagesWhat Is PTH?: Parathyroid Hormone (PTH) TestHariNo ratings yet

- Golden RetrieverDocument8 pagesGolden Retrieverpacho87No ratings yet

- Ringkasan Pendidikan GiziDocument73 pagesRingkasan Pendidikan GiziisrofahNo ratings yet

- SIP Report FinalDocument65 pagesSIP Report FinalChetan DubeyNo ratings yet

- DLL Mapeh Q 3 WK2 Health StraightDocument6 pagesDLL Mapeh Q 3 WK2 Health StraightEdelyn UnayNo ratings yet

- Full Ebook of Cardiopulmonary Bypass 3Rd Edition Florian Falter Online PDF All ChapterDocument69 pagesFull Ebook of Cardiopulmonary Bypass 3Rd Edition Florian Falter Online PDF All Chapterjustinesmedt868100% (5)

- Anthracnose Disease of Walnut - A ReviewDocument9 pagesAnthracnose Disease of Walnut - A ReviewIJEAB JournalNo ratings yet

- Lawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesDocument11 pagesLawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesABC News 4No ratings yet

- Use A Single Space 12-Point Font When Writing. Your Assignment Should Be About 1100+ WordsDocument7 pagesUse A Single Space 12-Point Font When Writing. Your Assignment Should Be About 1100+ WordsRaman RandhawaNo ratings yet

Jsa 36 - Ppu Shed

Jsa 36 - Ppu Shed

Uploaded by

golusinghdata0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

JSA 36 - PPU SHED

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views2 pagesJsa 36 - Ppu Shed

Jsa 36 - Ppu Shed

Uploaded by

golusinghdataCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

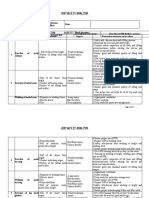

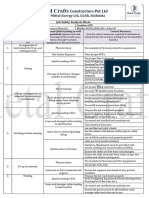

Job Safety Analysis

Metal Crafts Constructors Pvt. Ltd.

JSA Sheet No.

Main Activity Making of PPU Catalyst unloading shed.

Plant & Location PPU Reactor Area.

Sl. Sub Activities Hazards (Both Existing as well Control Measures.

No. (List the tasks required to as potential) Against each task (List the control measures required to eliminate or minimize

perform the activity in the list the hazards that could the risk of injury arising from the identified hazard.)

sequence they are carried cause injury/damage to people,

out equipment or the

environment.

Unloading of material 1. use TPI certified & healthy condition lifting tools & Tackles

trailer required for making

Injury to person while 2. Use guide rope to control the movement of lifting load.

1 shed.( Material Beam,

unloading the material

Channel purlin, scaffold 3. Use guide rope to control the movement of lifting the load.

material etc.)

4. Use mandatory PPE's for all workers.

5. K- 10 hydra for this purpose.

6. K-10 Hydra operator will work under the instruction of

banks man.

1. Scaffold to be erected by experienced & trained erector.

Fall of person, material 2. Lift the scaffolding with the help of good condition PP rope.

2 Erection of scaffolding

3. Movement of People in the area to be restricted by physical

barication. &while lifting the pipes no one should stand below

or inside the barricade.

4. Use full body harness.

contact injury (physical injury )

5. Use mandatory PPE's for all workers.

with the material

Lifting of material with 1. Person carrying out the activity will stand on certified

crane for making the scaffold.

3 fall hazard

structure for shed of 18

Mtr height. 2. Follow control measures mentioned in sub activity no.01&2.

3. All hot works should be carried out in hot work booth.

Cutting, grinding, fit up & Fire Hazards

4. Provide Running fire water hose with hand control branch.

4 welding of the bracket

with the existing column. provide 2 no of 10 kg fire extinguisher near the hot work both

.

5. tools used for the activity should e carried out in hot booth.

fall of materials 6. Follow all control measures mention in the sub activity 1&2.

Electrocution by grinding 7. Use inspected & certified tools & machines

machine & welding machine. 8. Ensure the all cables are in good condition and free form

cut and joints & provide ELCB with the connection.

Lift the purlin (Chanel) 1. Maintain distance from lifting loads.

5 length of 8 mtr having Personal Injury

2. Use guide ropes for lifting the loads.

weight 200 kg.

3. Guide rope holding person should be at least 1 mtr away

from the lift load.

4. Maintain housekeeping at working platform.

Bolting of purlin (Chanel)

6 fall of materials 1. Follow control measures mentioned in sub activity no 05.

with bracket.

2. Follow control measures mentioned in sub activity no .05.

fixing of supporting rod in-

between two purlin having

7 fall of materials 1. follow control measures mentioned in sub activity no.06

length of 1.4 mtr(bolt

fixing

lifting of steel sheet from 2. use mandatory PPE's

ground & Cladding of steel Cut injury

3. Cladding metal will be lift with the help of rope & hook by

8 shed with purlin (Chanel) tightening with all four side use guide rope .

by drilling )

fall of materials 4. follow control measures mentioned in sub activity no.06

Electrocution by drilling 5. use good condition(inspected & certified drilling M/C with

machine ELCB in line

Note: For hot job activities - use certified & healthy condition tools, Machines & provide ELCB with the electric connection.

JSA done by:

Name Designation signature Date

You might also like

- Full Download Ebook Ebook PDF Linne Ringsruds Clinical Laboratory Science Concepts Procedures and Clinical Applications 8th Edition PDFDocument48 pagesFull Download Ebook Ebook PDF Linne Ringsruds Clinical Laboratory Science Concepts Procedures and Clinical Applications 8th Edition PDFlillian.palmer175100% (53)

- PalmTherapy Program Your Mind by Moshe ZwangDocument751 pagesPalmTherapy Program Your Mind by Moshe Zwangjules6294100% (7)

- BORB Birmingham Object Recognition BatteryDocument5 pagesBORB Birmingham Object Recognition BatteryAnaaaerobios0% (1)

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho86% (7)

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDocument6 pages03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu Niveriya100% (1)

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002100% (1)

- UntitledDocument201 pagesUntitledCsongor KicsiNo ratings yet

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat80% (5)

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- A Completed Example of Long Term Planning Cambridge Primary Science Guide p.16 17Document2 pagesA Completed Example of Long Term Planning Cambridge Primary Science Guide p.16 17Omar A. Mohammad100% (1)

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- DewateringDocument1 pageDewateringChandruNo ratings yet

- JSA. Confined Space EntryDocument3 pagesJSA. Confined Space EntrySwaroop Cherry67% (3)

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- 04 HVAC Panel Installation & Electrical Job.Document4 pages04 HVAC Panel Installation & Electrical Job.Himanshu Niveriya100% (1)

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- AGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMDocument1 pageAGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMArslanNo ratings yet

- Jobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding WorkDocument4 pagesJobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding Workuttam mishraNo ratings yet

- Cable Laying &termination HIRADocument66 pagesCable Laying &termination HIRAPRIYESH . K. PRIYANNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Job Safety Analysis: Date:02-05-2022Document3 pagesJob Safety Analysis: Date:02-05-2022Mohammad HussainNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- JSEADocument2 pagesJSEAIndermohan MehtaNo ratings yet

- JHA For Temp Structure ErectionDocument1 pageJHA For Temp Structure Erectiongullipalli srinivasa raoNo ratings yet

- Job Safety Analysis: Date:27-05-2022Document2 pagesJob Safety Analysis: Date:27-05-2022Mohammad HussainNo ratings yet

- Solar HandbookDocument36 pagesSolar HandbookAkash Kumar SuryawanshiNo ratings yet

- Cement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsDocument1 pageCement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Fall - Protection - Plan - Rev - 001 (1) (AutoRecovered)Document17 pagesFall - Protection - Plan - Rev - 001 (1) (AutoRecovered)NonhleNo ratings yet

- Jsa CPBDocument3 pagesJsa CPBmd maroofNo ratings yet

- Job Safety Analysis Report: DG Lifting & InstallationDocument2 pagesJob Safety Analysis Report: DG Lifting & Installationvijay kumar singh100% (2)

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- 49 Switch Board - Panel ErectionDocument4 pages49 Switch Board - Panel ErectionvasudevanmNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- Chapter 2 Hazard and Control MeasuresDocument3 pagesChapter 2 Hazard and Control MeasuresArul PrasaadNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Job Activity Hazard Effect Control MeasuresDocument2 pagesJob Activity Hazard Effect Control Measuresperquino oasan100% (1)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Mahalasa Aduit Compliance ReportDocument22 pagesMahalasa Aduit Compliance Reporthimansukumar biswalNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Toaz - Info 5 Jsa Rebar Cutting Amp Bending PRDocument2 pagesToaz - Info 5 Jsa Rebar Cutting Amp Bending PRthennarasuNo ratings yet

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Carpentry Works 20.09.2020Document11 pagesCarpentry Works 20.09.2020Amit BhattNo ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- Job Hazard Analysis Breaker InstallationDocument1 pageJob Hazard Analysis Breaker InstallationIsraelNo ratings yet

- Pit Cleaning HSE ProfessionalsDocument1 pagePit Cleaning HSE ProfessionalsSamadov 13No ratings yet

- Hot Work Jsa - Safetymgmtstudy-1-1Document1 pageHot Work Jsa - Safetymgmtstudy-1-1imdadullahhseNo ratings yet

- Hot Work JSA - SAFETYMGMTSTUDY PDFDocument1 pageHot Work JSA - SAFETYMGMTSTUDY PDFMohammed AlshehhiNo ratings yet

- Hot work JSA - SAFETYMGMTSTUDY-1Document1 pageHot work JSA - SAFETYMGMTSTUDY-1imdadullahhseNo ratings yet

- 12 - Method Statement For Steel Structure ErectionDocument5 pages12 - Method Statement For Steel Structure ErectionidzwanNo ratings yet

- 4 - Og Gedi Car Shes A 0003Document4 pages4 - Og Gedi Car Shes A 0003jonartapado2No ratings yet

- X Rigging, Lifting & HoistingDocument141 pagesX Rigging, Lifting & HoistinggolusinghdataNo ratings yet

- JSA 26 - Magnetic Particle Inspection (MPI)Document1 pageJSA 26 - Magnetic Particle Inspection (MPI)golusinghdataNo ratings yet

- X Suspended Work BasketsDocument26 pagesX Suspended Work BasketsgolusinghdataNo ratings yet

- JSA 49-Rev.01Erection of Spool Using by Rope PulleyDocument2 pagesJSA 49-Rev.01Erection of Spool Using by Rope PulleygolusinghdataNo ratings yet

- X Powered EquipmentDocument41 pagesX Powered EquipmentgolusinghdataNo ratings yet

- JSA 45 - Valve BoxupDocument18 pagesJSA 45 - Valve BoxupgolusinghdataNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- JSA 43 - Tightening of Water LineDocument1 pageJSA 43 - Tightening of Water LinegolusinghdataNo ratings yet

- JSA 18-Rev.02 - GroutingDocument2 pagesJSA 18-Rev.02 - GroutinggolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- JSA 37-Rev.01 - RADIOGRAPHY TESTDocument1 pageJSA 37-Rev.01 - RADIOGRAPHY TESTgolusinghdataNo ratings yet

- JSA 15-Rev.02 - Fabrication (OSBL)Document3 pagesJSA 15-Rev.02 - Fabrication (OSBL)golusinghdataNo ratings yet

- F-INO-04 Records of Training ImpartedDocument2 pagesF-INO-04 Records of Training ImpartedgolusinghdataNo ratings yet

- JSA 17-Rev.01 - Flange Tightening JobDocument2 pagesJSA 17-Rev.01 - Flange Tightening JobgolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- F-INO-05 Training Evaluation SheetDocument3 pagesF-INO-05 Training Evaluation SheetgolusinghdataNo ratings yet

- What Can You Do To Prevent AccidentsDocument1 pageWhat Can You Do To Prevent AccidentsgolusinghdataNo ratings yet

- Construction Fall Protection QuizDocument1 pageConstruction Fall Protection QuizgolusinghdataNo ratings yet

- F-INO-03 Training Need IdentificationDocument1 pageF-INO-03 Training Need IdentificationgolusinghdataNo ratings yet

- WRENCHESDocument1 pageWRENCHESgolusinghdataNo ratings yet

- Safety Flash 10 - Crane Hoist Wire Rope Dead End FailedDocument1 pageSafety Flash 10 - Crane Hoist Wire Rope Dead End FailedgolusinghdataNo ratings yet

- Safety Flash 35 Man Basket Fell From HeightDocument1 pageSafety Flash 35 Man Basket Fell From HeightgolusinghdataNo ratings yet

- BOOK LIST MU LibraryDocument13 pagesBOOK LIST MU LibraryJohn ThNo ratings yet

- Different InjuriesDocument2 pagesDifferent InjuriesJailian NagpiingNo ratings yet

- Dis Advantages of AbortionDocument5 pagesDis Advantages of AbortionAziil LiizaNo ratings yet

- Linking Words ActivitiesDocument3 pagesLinking Words ActivitiesSebastian Montaño RodriguezNo ratings yet

- Moh Exam Questions (10-7-18)Document9 pagesMoh Exam Questions (10-7-18)Subhajit SahaNo ratings yet

- TeksolDocument5 pagesTeksolniki fitraNo ratings yet

- Outcomes of Radioactive Iodine Versus Surgery For The Treatment of Graves' Disease - A Systematic Review and Meta AnalysisDocument9 pagesOutcomes of Radioactive Iodine Versus Surgery For The Treatment of Graves' Disease - A Systematic Review and Meta AnalysisGestne AureNo ratings yet

- SN MCQ Block IDocument12 pagesSN MCQ Block Iطال الإنتظارNo ratings yet

- Vitamin and Mineral Requirements in Human NutritionDocument361 pagesVitamin and Mineral Requirements in Human Nutritionpeny7No ratings yet

- Movement Disorders Types - Mayo ClinicDocument1 pageMovement Disorders Types - Mayo ClinicdrrajmptnNo ratings yet

- Last Child in The Woods - Overview - Richard LouvDocument1 pageLast Child in The Woods - Overview - Richard LouvGengjiaqi CHANGNo ratings yet

- Exercise Nutrition Learning Guide 2023Document17 pagesExercise Nutrition Learning Guide 2023AlexNo ratings yet

- Heymann & Tulloch (2006) Implantable Devices As Orthodontic AnchorageDocument12 pagesHeymann & Tulloch (2006) Implantable Devices As Orthodontic AnchorageDominikaSkórkaNo ratings yet

- Speaking Sample Test 5 (Dentistry)Document2 pagesSpeaking Sample Test 5 (Dentistry)Jia SunNo ratings yet

- Nike and Child LabourDocument8 pagesNike and Child LabourLorraine ChenNo ratings yet

- Voucher No: 125244/2023 - 30/03/2023: Reference No. For The Hotel: 9153573473984 / 1484479948Document4 pagesVoucher No: 125244/2023 - 30/03/2023: Reference No. For The Hotel: 9153573473984 / 1484479948Григорий ПавловNo ratings yet

- What Is PTH?: Parathyroid Hormone (PTH) TestDocument4 pagesWhat Is PTH?: Parathyroid Hormone (PTH) TestHariNo ratings yet

- Golden RetrieverDocument8 pagesGolden Retrieverpacho87No ratings yet

- Ringkasan Pendidikan GiziDocument73 pagesRingkasan Pendidikan GiziisrofahNo ratings yet

- SIP Report FinalDocument65 pagesSIP Report FinalChetan DubeyNo ratings yet

- DLL Mapeh Q 3 WK2 Health StraightDocument6 pagesDLL Mapeh Q 3 WK2 Health StraightEdelyn UnayNo ratings yet

- Full Ebook of Cardiopulmonary Bypass 3Rd Edition Florian Falter Online PDF All ChapterDocument69 pagesFull Ebook of Cardiopulmonary Bypass 3Rd Edition Florian Falter Online PDF All Chapterjustinesmedt868100% (5)

- Anthracnose Disease of Walnut - A ReviewDocument9 pagesAnthracnose Disease of Walnut - A ReviewIJEAB JournalNo ratings yet

- Lawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesDocument11 pagesLawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesABC News 4No ratings yet

- Use A Single Space 12-Point Font When Writing. Your Assignment Should Be About 1100+ WordsDocument7 pagesUse A Single Space 12-Point Font When Writing. Your Assignment Should Be About 1100+ WordsRaman RandhawaNo ratings yet