Professional Documents

Culture Documents

KEX Basic Steps of Tire Repair

KEX Basic Steps of Tire Repair

Uploaded by

footloosebalakannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KEX Basic Steps of Tire Repair

KEX Basic Steps of Tire Repair

Uploaded by

footloosebalakannanCopyright:

Available Formats

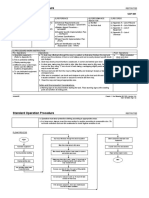

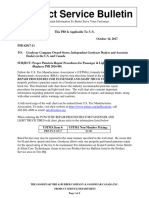

BASIC STEPS OF TIRE REPAIR

WARNING

Serious eye or ear injuries may result from not

The Three Basic Steps for Puncture Repairing are:

(1) removing the tire from the wheel for inspection and repair,

wearing adequate eye (goggles or face shields) (2) filling the injury to keep moisture out, and

and ear protection while repairing tires. (3) sealing the innerliner with a repair unit to prevent air loss.

1 EXTERNAL INSPECTION

Prior to demounting, check tire surface and

the valve for the source of the leak(s) by using

water or a soap solution. Mark the injured area

2 IINTERNAL EXAMINATION

Spread the beads and mark the puncture

with a tire crayon. Remove the nail or puncturing

object noting the direction of penetration. Probe

3 CLEANING

C

Clean the area around the puncture

thoroughly with a proper liner cleaner. Use a

clean cloth and/or scraper. Do not use gasoline

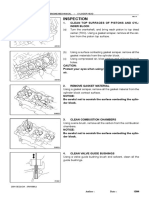

4 CLEAN INJURY CHANNEL

Use a proper hand reamer, carbide cutter, or

drill bit (1,200 rpm max.) to ream the puncture

channel from the inside of the tire to clean the

and totally deflate the tire. Then carefully remove the injury with a blunt awl to determine the - use may cause serious injury. This step serves injury. Remove steel wires protruding above the

the tire from the wheel to avoid further damage extent and direction of the injury and remove any to remove dirt and mold lubricants which can liner surface to prevent damage to the repair

to the tire, particularly to the bead area. Place on loose foreign material. Injuries exceeding ¼ must impair repair unit adhesion and contaminate unit.

a well-lighted spreader. not be repaired in other than a full-service repair buffing tools. Consult your local repair materials

facility. Inspect for any other internal damage. supplier for a proper cleaner.*

5 FILL INJURY

F

(Use compatible repair materials.)

Cement the puncture channel and fill the

injury from the inside of the tire with a suitable

6 REPAIR UNIT SELECTION

R

Center the repair unit over the injury and

outline an area larger than the unit, so buffing

will not remove the crayon marks. If multiple

7 BUFFING

B

To prevent contamination and preserve the

outline, buff within the marked area thoroughly

and evenly with a low speed (5,000 rpm max.)

8 CEMENTING

C

Apply chemical cement* according to repair

manufacturer’s procedures. Allow the cement to

dry thoroughly.

vulcanizing material or a rubber plug. Without repairs are made, repair units must not overlap. fine wire brush or gritted rasp. Buff to a smooth

stretching the plug cut the material off just Repair materials must be selected from those velvet surface (RMA #1 or #2 buffed texture**

above the inside tire surface. It is necessary to recommended for the construction (radial or for chemical vulcanizing repairs). Take care not

fill the injury to provide a backup for the repair bias) and tire inflation pressure. Some light truck to gouge the innerliner or expose casing fabric.

unit and to prevent rusting of the steel wires or

deterioration of fabric. For combination repair/

plug units skip this step.

tires operate at a higher inflation pressure than

passenger tires and require a different repair

unit. Consult your repair material supplier or tire

Remove any buffing dust with a vacuum cleaner.

CAUTION

Regardless of the type of repair

manufacturer for repair unit selection.

used, the repair must seal the

innerliner and fill the injury.

*Refer to information on the product

or manufacturer’s Material Safety Data

Sheet and follow guidelines for handling

9

and disposal.

10

**See RMA Shop Bulletin No. 29 available

from the address below.

Rubber Manufacturers Assocation

REPAIR UNIT APPLICATION For combination repair/plug units, pull FINAL INSPECTION 1400 K Street, N.W.

The tire must be in a relaxed position when the plug through the injury until the repair (For tube-type tires be sure to use a properly Washington, DC 20005-2403

the repair unit is installed. (Do not spread the just reaches the liner, then stitch. Remove repaired or new tube to replace a damaged tube.)

beads excessively.) If applicable, install the unit and discard the protective covering. Follow After remounting and inflating, the tire, both

so that the alignment is correct. Center the repair manufacturer’s recommendations for further beads, the repair, and the valve must be checked

unit over the injury and stitch down thoroughly installation instructions. with water or a soap solution to detect leaks. If

with a stitching tool, working from the center the tire continues to lose air, it must be removed

out. Being careful not to stretch the plug, cut the from the wheel for complete reinspection.

material flush with the outer tread surface.

These Procedures are limited to tread area only.

Speed Ratings – Tire Manaufacturer should be consulted for its individual repair policy.

NEVER repair tires worn to treadwear indicators (2/32" remaining tread depth).

NEVER repair tires with a tread puncture larger than ¼". Injuries larger than ¼" or

with exposed fabric must be refered to a full-service repair facility.

NEVER substitue an inner tube for a permissible or non-permissible repair.

NEVER perform an outside-in tire repair (on the wheel).

NEVER disregard Tire Mounting Safety Warnings.

KEX Tire Repair • 119 Rockland Ave, Northvale, NJ 07647 • Phone: (888) 395-1KEX (1539) • www.KexTireRepair.com

You might also like

- 18807330-Same Solaris 30-40-50 Workshop Service Repair ManualDocument430 pages18807330-Same Solaris 30-40-50 Workshop Service Repair ManualHottuning Bruno Ribeiro100% (2)

- TSG DL420-5 (950106-01976e) 20170629 PDFDocument606 pagesTSG DL420-5 (950106-01976e) 20170629 PDFTony Rouillon75% (4)

- Daily Plant Inspection ChecklistDocument1 pageDaily Plant Inspection Checklist8460272421No ratings yet

- BHT-206B3-CR&O Vol 2Document7 pagesBHT-206B3-CR&O Vol 2Benito PalmaNo ratings yet

- Method Statement GRP MANHOLES REPAIR AND INSTALLATION OF EXTENSION RINGS PDFDocument19 pagesMethod Statement GRP MANHOLES REPAIR AND INSTALLATION OF EXTENSION RINGS PDFbryan100% (1)

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFDocument2 pagesChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- SOP 001 Dust MoppingDocument2 pagesSOP 001 Dust MoppingMade GileeNo ratings yet

- Replacement: - Front Brake PadDocument2 pagesReplacement: - Front Brake PadMiguel AngelNo ratings yet

- psb2017 11 Tire Repair Auto LT TruckDocument2 pagespsb2017 11 Tire Repair Auto LT TruckfootloosebalakannanNo ratings yet

- 33-590011-1 - Section 5Document3 pages33-590011-1 - Section 5Fábio FariaNo ratings yet

- Repair Airbag: Shandong Nanhai Airbag Engineering Co., LTDDocument6 pagesRepair Airbag: Shandong Nanhai Airbag Engineering Co., LTDRandy CernaNo ratings yet

- CFA Sample Method Statement:: Resin Injection Anchors - in ConcreteDocument2 pagesCFA Sample Method Statement:: Resin Injection Anchors - in ConcreteansarisaeedNo ratings yet

- Chapter 3-Section 3.2-Cylinder BlockDocument46 pagesChapter 3-Section 3.2-Cylinder BlockNikkikumar MaisuriyaNo ratings yet

- MI 434 - Auxiliary Generator Model A-8102Document16 pagesMI 434 - Auxiliary Generator Model A-8102Jesse BarnettNo ratings yet

- Sealant Instructions 50ccDocument1 pageSealant Instructions 50ccValerio CadedduNo ratings yet

- JLR 18 39 10 - 1E - Land Rover Anti-Corrosion GuidelinesDocument1 pageJLR 18 39 10 - 1E - Land Rover Anti-Corrosion GuidelinesmunNo ratings yet

- HR 12 Ee BRDocument13 pagesHR 12 Ee BRКонстантин ДубенкоNo ratings yet

- 103 Cyl BoringDocument4 pages103 Cyl BoringDmitrolv DmitrolvNo ratings yet

- Adjustable Ckoke (Not Cortec) SOPDocument10 pagesAdjustable Ckoke (Not Cortec) SOPAmer RehanNo ratings yet

- Vipal Manual Reparos para Pneus 2019 IngDocument118 pagesVipal Manual Reparos para Pneus 2019 IngAgro SipotNo ratings yet

- NOTE: The Chrome (Silver) Ring Should Be: ! CautionDocument4 pagesNOTE: The Chrome (Silver) Ring Should Be: ! CautionLeon Jaime Velasquez CardenasNo ratings yet

- PDS - Bituthene Application (January 2014 Replaces April 2012)Document2 pagesPDS - Bituthene Application (January 2014 Replaces April 2012)Sphesihle MagubaneNo ratings yet

- TSB - RF Drain CleaningDocument8 pagesTSB - RF Drain Cleaningpetej.publicscribdNo ratings yet

- Care and MaintenanceDocument15 pagesCare and MaintenanceJeff LeeNo ratings yet

- Camshaft GearDocument10 pagesCamshaft GearJuan Antonio Ochoa PadronNo ratings yet

- Valve Lapping PDFDocument3 pagesValve Lapping PDFAmy Hull100% (1)

- MikunisbnDocument4 pagesMikunisbnIdan VaronNo ratings yet

- Standard Practices Airplane Finish Care Maintenance PracticesDocument28 pagesStandard Practices Airplane Finish Care Maintenance PracticesWalter TorenaNo ratings yet

- PT Level II G GULF-AILDocument8 pagesPT Level II G GULF-AILkingstonNo ratings yet

- Strain Gauge InstallationDocument5 pagesStrain Gauge InstallationAnonymous UoHUagNo ratings yet

- Inspection: 1. Clean Cylinder BlockDocument7 pagesInspection: 1. Clean Cylinder Blockdolphi_742078No ratings yet

- Group 4-Cylinder BlockDocument48 pagesGroup 4-Cylinder BlockNikkikumar MaisuriyaNo ratings yet

- 530 PDFDocument39 pages530 PDFЕгорNo ratings yet

- NTB02 068Document4 pagesNTB02 068PMNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoNo ratings yet

- Parte 5 Md200Document22 pagesParte 5 Md200samuelNo ratings yet

- RTS TG M78Document9 pagesRTS TG M78woosah1234No ratings yet

- PB9900Document4 pagesPB9900Jan SoukupNo ratings yet

- Amt Owner's ManualDocument8 pagesAmt Owner's ManuallrolindoNo ratings yet

- Pavement Management System Text BookDocument26 pagesPavement Management System Text BookGoutham AthemNo ratings yet

- Corrosion Severity Inspection Compliance: © 2016 Cessna Aircraft CompanyDocument2 pagesCorrosion Severity Inspection Compliance: © 2016 Cessna Aircraft CompanyFran GaritaNo ratings yet

- Cap562 5Document206 pagesCap562 5DavidGarcíaNo ratings yet

- Standard DS-1 Fourth Edition, Volume 3 - ADDENDUM 6 Applies To First, Second and Third PrintingDocument15 pagesStandard DS-1 Fourth Edition, Volume 3 - ADDENDUM 6 Applies To First, Second and Third PrintingJ Edinson NavarroNo ratings yet

- DS-1 4th Ed - Volume 3 - Addendum 6 (09DEC2016) PDFDocument15 pagesDS-1 4th Ed - Volume 3 - Addendum 6 (09DEC2016) PDFisrael11288No ratings yet

- Cylinder Bloc InspectionDocument7 pagesCylinder Bloc InspectionYannick de WalqueNo ratings yet

- Geared Coupling Manual PDFDocument5 pagesGeared Coupling Manual PDFSatNo ratings yet

- HDBIDocument5 pagesHDBIkevlar315No ratings yet

- Iom-1 2 21Document4 pagesIom-1 2 21chris110No ratings yet

- Proposal of Epoxy Coating - Lotte-Titan - Material WarehouseDocument10 pagesProposal of Epoxy Coating - Lotte-Titan - Material Warehouseirawan tataNo ratings yet

- MP 7503 Duracion de PartesDocument15 pagesMP 7503 Duracion de PartesRICHARD ALBERTO NARVA ORTIZNo ratings yet

- General Information: With Mechanically Actuated InjectorDocument12 pagesGeneral Information: With Mechanically Actuated InjectorChardy Jarith Piragua AlvaradoNo ratings yet

- BOQ & Methodolgy of RepairsDocument2 pagesBOQ & Methodolgy of Repairsswapnil gandhiNo ratings yet

- Premier Butyl Tape System IFU DENSODocument4 pagesPremier Butyl Tape System IFU DENSOChuck AnsphilNo ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- Camisa de CilindroDocument16 pagesCamisa de CilindroFelipe CarranzaNo ratings yet

- Up150 38BDocument40 pagesUp150 38BRamKS80100% (3)

- LG Wheels and BrakesDocument34 pagesLG Wheels and Brakesmarcos torresNo ratings yet

- Procedure For LPT TestDocument4 pagesProcedure For LPT Testdyke_enggNo ratings yet

- Chap - 21 Drill-In FluidsDocument46 pagesChap - 21 Drill-In FluidspaimanNo ratings yet

- Visual-000spanish Connec SLSFDocument5 pagesVisual-000spanish Connec SLSFOscar Gomez GonzalezNo ratings yet

- Centrifugal Pumps: DescriptionDocument8 pagesCentrifugal Pumps: Descriptionudrogono2No ratings yet

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDocument14 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakNo ratings yet

- RM-12 Radial Earthmover Tire RepairDocument12 pagesRM-12 Radial Earthmover Tire RepairdadankikiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Jason Claunch: Professional ExperienceDocument3 pagesJason Claunch: Professional ExperienceJason ClaunchNo ratings yet

- Trigger 29er & Trigger 26er.: Owner'S Manual SupplementDocument38 pagesTrigger 29er & Trigger 26er.: Owner'S Manual SupplementLeonardo FariasNo ratings yet

- 700Series5to10Ton ManDocument20 pages700Series5to10Ton ManStiven PeñaNo ratings yet

- Manual: Servicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R 9250Document141 pagesManual: Servicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R 9250Augusto Oliveira100% (2)

- Series 40 - M46 Tandem Variable Pumps: Service ManualDocument44 pagesSeries 40 - M46 Tandem Variable Pumps: Service Manualleogerguz100% (1)

- TM1526 John Deere 300A Auger Platform, 300 Grass Seed Special Technical ManualDocument6 pagesTM1526 John Deere 300A Auger Platform, 300 Grass Seed Special Technical ManualtteelsarsNo ratings yet

- Refitting The ClutchDocument5 pagesRefitting The ClutchRudi HeriantoNo ratings yet

- Formato Removal & Installation Mando Final y Freno de Servicio 994HDocument3 pagesFormato Removal & Installation Mando Final y Freno de Servicio 994HJuanNo ratings yet

- White Black Elegant Modern Corporate CV ResumeDocument1 pageWhite Black Elegant Modern Corporate CV ResumeCyline Manon-ogNo ratings yet

- Travel Drives - : Translation of Original Operating and Installation InstructionsDocument41 pagesTravel Drives - : Translation of Original Operating and Installation InstructionsJijin ThomasNo ratings yet

- Rs04501reach StackerDocument395 pagesRs04501reach StackerAlexander Simanca Candela100% (2)

- 3090 KubotatDocument119 pages3090 KubotatArie GolfNo ratings yet

- Operator'S: ManualDocument50 pagesOperator'S: ManualStelian CrisanNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- Service Axle - Manual: Edition 10/2015 Original Allied Form #: 80-1155Document133 pagesService Axle - Manual: Edition 10/2015 Original Allied Form #: 80-1155sudaryantoNo ratings yet

- Nissan Leaf 2014 Workshop Manual - General PrecautionsDocument3 pagesNissan Leaf 2014 Workshop Manual - General PrecautionsyogapostNo ratings yet

- M/D Totco'": Technical Manual LpiiiimrDocument10 pagesM/D Totco'": Technical Manual LpiiiimrLuis Eduardo Albarracin Rugeles100% (1)

- Engine Removal, Disassembly, Inspection and In-Chassis Repairs ObjectivesDocument2 pagesEngine Removal, Disassembly, Inspection and In-Chassis Repairs Objectivesltoloane_59788557No ratings yet

- Temporary Revision Number Chapter/ Section Date: M250 - C30 Series Operation and MaintenanceDocument2 pagesTemporary Revision Number Chapter/ Section Date: M250 - C30 Series Operation and MaintenanceJosé Edwin RoldánNo ratings yet

- Electro Magnetic DentDocument20 pagesElectro Magnetic Dentflorea_ctinNo ratings yet

- 311 Range Tramming: Maintenance ManualDocument28 pages311 Range Tramming: Maintenance ManualjoseNo ratings yet

- Bandit Manual - 3500T FMDocument80 pagesBandit Manual - 3500T FMRonaldNo ratings yet

- English Grammar: Samuel LizardoDocument3 pagesEnglish Grammar: Samuel LizardoSamuel Lizardo Lopez100% (1)

- Cost Exercise 8-3Document2 pagesCost Exercise 8-3HarunNo ratings yet

- F2e WB3 Unit02Document4 pagesF2e WB3 Unit02Angelina SalasNo ratings yet

- CAUSATIVE Have SMT DoneDocument3 pagesCAUSATIVE Have SMT DoneBex TasicNo ratings yet