Professional Documents

Culture Documents

Prius Throttle

Prius Throttle

Uploaded by

Duy Kha0 ratings0% found this document useful (0 votes)

22 views12 pagesOriginal Title

220923_Prius_Throttle

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

22 views12 pagesPrius Throttle

Prius Throttle

Uploaded by

Duy KhaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

DTC | P0120 [Throttle / Pedal Position Sensor / Switch "A" Circuit Malfunction |

[DTC [P0121 [Throttle /Pedal Position Sensor / Switch "A" Circuit Range / Performance Problem

DTC | P0122 [Throttle / Pedal Position Sensor / Switch "A" Circuit Low Input |

DTC | P0123 [Throttle/ Pedal Position Sensor / Switch "A" Circuit High Input _|

DTC | P0222 _ [Throttle / Pedal Position Sensor / Switch "B" Circuit Low Input

DTC P0223 Throttle / Pedal Position Sensor / Switch "B" Circuit High Input

DIC | P2135 [Throttle / Pedal Pos

/oltage Correlation |

n Sensor / Switch "A" /"B"

DESCRIPTION

HINT:

+ These DTCs relate to the throttle position sensor.

The throttle position sensor is mounted on the throttle body assembly, and detects the opening angle of the

throttle valve. This sensor is a non-contact type. It uses Hall-effect elements in order to yield accurate signals

even in extreme conditions.

The throttle position sensor has 2 sensor circuits, each of which transmits a signal, VTAI and VTA2. VTA1 is

used to detect the throttle valve angle and VTA2 is used to detect malfunctions in VTA1. The sensor signal

voltages vary between 0 V and 5 V in proportion to the throttle valve opening angle, and are transmitted to the

VTA terminals of the ECM.

As the valve closes, the sensor output voltage decreases and as the valve opens, the sensor output voltage

increases. The ECM calculates the throttle valve opening angle according to these signals and controls the

throttle actuator in response to driver inputs. These signals are also used in calculations such as air fuel ratio

correction, power enrichment correction and fuel-cut control.

Line indicating VTA2 x 0.8

Sensor OuputVotage (V)

‘Magnet

ToNat

ad Avera

etl

q via

ae

ia) 0 Usabie Ranga a

(cHa.2 Magnet Trot Valve Opening Angle)

‘Thvotte Position Sensor ECM ‘HDG De see conteol

Note:

The throttle valve opening angle detected by the sensor

terminal VTA1 is exprossed 2s a percentage.

Features of sensor output:

Botween 10% and 22%:

rottie valve fully closed ‘The diference in voltage between VTAt and VTA2 x0.8

is approximatoly 1.11 V.

Betwoon 64% and 96%: Throitle valve fully open

Anproximately 18.6%: Fal sale angle (5.5°) (VTA2 «0.8 approximately equal to VTAT + 1.11 Vp

| Bre DTC Detection Condition Trouble Area |

No. |

+ Throttle position sensor (built into |

(Output voltage of VTA quickly fluctuates beyond lower throttle body assembly)

0120 |2nd upper malfunction thresholds for 2 seconds or more

(trp detection Logie S| ECM.

[Difference between VTAI and VTA2 voltages less than + Throttle position sensor (built into

throttle body assembly)

po121 8 V. ormore than 1.6 V for 2 seconds ‘© Throttle position sensor circuit

(1 trip detection logic) + ECM

I + Throttle position sensor (built into

‘Output voltage of VIAL 0.2 V or less for 2 seconds or throttle body assembly) |

poiz2 more |

+ Short in VTA1 circuit |

| trip detection logic)

om DTC Detection Condition Trouble Area

7 | Open in VC circuit ~

» ECM

‘+ Throttle position sensor (built into

throttle body assembly)

| © Open in VTAI circuit

Output voltage of VTA1 4.54 V or more for 2 seconds or

por2s more + Open in £2 circuit

(trip detection logic) + Short between VC and VTAI

circuits

+ ECM

fouput voltage of VTA2 quickly fluctuates beyond lower . — position sensor (built into

4 rottle body assembly)

0220 (ahd upper malfunction thresholds for 2 seconds or more

(( trip detection logic) = ECM

+ Throttle position sensor (built into

throttle body assembly)

Output voltage of VTA2 1.75 V or less for 2 seconds or + Short in VTA2 circuit

Po222 more

trip detection logic) + Open in VC circuit

+ ECM

+ Throttle position sensor (built into

throttle body assembly)

© Open in VTA2 circuit

(Output voltage of VTA2 4.8 V or more, and VTAL

poz23_ between 0.2 V and 2.02 V, for 2 seconds or more + Open in E2 circuit

(tip detection logic) + Short between VC and VTA2

circuits

+ ECM

‘Either condition (a) or (b) met (1 trip detection logic): «Short between VTAI and VTA2

P2135 (a) Difference between output voltages of VTAI and —_

VTA2 0.02 V or less for 0.5 seconds or more

Throttle position sensor (built into

DTC Detection Condition

[ pre Trouble Area

| No. Ss | _

| |(b) Output voltage of VTAT is 0.2 V or less, and VTA2 is | throttle body assembly)

11.75 V or less, for 0.4 seconds or more

+ ECM

MONITOR DESCRIPTION

P0120, P0122, P0123, P0220, P0222, P0223, P2135

‘The ECM uses the throttle position sensor to monitor the throttle valve opening angle. There are several checks

that the ECM performs to confirm the proper operation of the throttle position sensor.

+ A specific voltage difference is expected between the sensor terminals, VTAI and VTA2, for each

throttle valve opening angle. If the difference between VTAI and VTA2 is incorrect, the ECM interprets

this as a malfunction in the sensor circuit, and sets a DTC.

+ VTA1 and VTA2 each have a specific voltage range. If VTAI or VTA2 is outside the normal operating

range, the ECM interprets this as a malfunction in the sensor circuit, and sets a DTC.

+ VTA] and VTA2 should never be close to the same voltage level. If VTAI is within 0.02 V of VTA2,

the ECM determines that there is a short circuit in the sensor circuit, and sets a DTC.

Ifthe malfunction is not repaired successfully, a DTC is set 10 seconds after the engine is next started.

P0121

‘This sensor transmits two signals: VTAI and VTA2. VTAL is used to detect the throttle opening angle and

VTA2 is used to detect malfunctions in VTA1. The ECM performs several checks to confirm the proper

operation of the throttle position sensor and VTAI.

For each throttle opening angle, a specific voltage difference is expected between the outputs of VTAI and

VTA2. If the output voltage difference between the two signals deviates from the normal operating range, the

ECM interprets this as a malfunction in the throttle position sensor. The ECM illuminates the MIL and stores

the DTC.

If the malfunction is not repaired successfully, the DTC is stored 2 seconds after the engine is next started,

MONITOR STRATEGY

[ P0120: Throttle position sensor I range check (Chattering)

| P0121: Throttle position sensor rationality

Related DTCs lpon2:

|

P0123: Throttle position sensor 1 range check (High voltage)

Throttle position sensor 1 range check (Low voltage)

"P0220: Throttle position sensor 2 range check (Chaittering)

(P0222: Throttle position sensor 2 range check (Low voltage)

P0223: Throttle position sensor 2 range check (High voltage)

(P2135: Throttle position sensor range check (Correlation)

[Required Sensors/Components (Main) __[Throttle position sensor

iRequired Sensors/Components (Related) |-

[Frequency of Operation [Continuous

{2 seconds: P0120, P0122, P0123, P0220, P0222 and PO223

|Within 2 seconds: P0121

Duration

(0.5 seconds: P2135 Case 1

(0.4 seconds: P2135 Case 2

(MIL Operation Immediately |

[Sequence of Operation {None

TYPICAL ENABLING CONDITIONS

P0120, P0122, P0123, P0220, P0222, P0223, P2135:

[Monitor rans whenever following DTCs are not present None

[Either of the following conditions A or B is met E

[Power switch on (IG) 0.012 seconds or more |

[B. Electronic throttle actuator power ON

POI21:

[Monitor runs whenever following DTCs are not present [None

(Either of the following conditions A or Bis set E

|A. Power switch (on (iG)

'B. Electric throttle motor power ON

{Throttle position sensor malfunction (P0120, P0122, P0123, P0220, P0222, PO223, P2135) __Not detected

TYPICAL MALFUNCTION THRESHOLDS

P0120

[VTAI voltage (0.2 V or less, or 4.54 V ot more

P0121

[Either of the following conditions is set EF

Difference of throttle position sensor voltage between VTAI and (VTA2 x 0.8) |Higher than 1.6 V

Difference of throttle position sensor voltage between VTAI and (VTA2 x 0.8) [Lower than 0.8 V

P0122

[VTAI voltage [0.2 Vor less _

P0123

\VTAI voltage (4.54 V or more

P0220

[Either of the following conditions is met [AoB — __|

[A. VTA2 voltage [1.75 V or less |

[B. All of the following conditions are met |

((a) VTA2 voltage 4.8 V or more

(b) VTAI voltage (0.2 V or more, and 2.02 V or less

‘P0222

iVTA2 voltage — [1.75 V or less |

P0223

|VTA2 voltage when VTAI 0.2 V or more, and 2.02 V or less [4.8 V or more |

P2135 Case 1

[Difference between VTAI and VTA2 voltages [0.02 V or less

P2135 Case 2

[VAI voltage (0.2 Vor less

[75 V or less

NT OPERATING RANGE

[VTAI voltage 02104.54V

[VTA2 voltage 1.751048V

CONFIRMATION DRIVING PATTERN

Released

tating

Power Suitch on (16)

1, Connect the Techstream to the DLC3.

2. Tur the power switch on (IG) and turn the Techstream on.

3. Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure) EEE.

4. Turn the power switch off and wait for 30 seconds.

5. Tum the power switch on (IG) and turn the Techstream on [A].

6

1.

8

9.

;. Put the engine in inspection mode BEM

. Start the engine.

. With the vehicle stationary, fully depress and release the accelerator pedal [B].

). Idle the engine for 2 seconds or more [C].

10. Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

11. Read the DTC [D]

12. If'a DTC is output, the system is malfunctioning,

HINT:

Ifa DTC is not output, perform the following procedure.

13, Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

14, Input the DTC: P0120, P0121, P0122, P0123, P0220, P0222, P0223 or P2135.

15, Check the DTC judgment result.

Techstream

1

"i Description

[ioe | esr

© DTC judgment completed

NORMAL System normal

|

rT ‘0 DTC judgment completed a

ABNORMAL System abnormal

INCOMPLETE ‘© DTC judgment not completed

Tochstream, ij Description

Display | P

| o Perform driving pattern after confirming DTC enabling conditions

[ "| © Unableto performDTC judgment

UNKNOWN 0 Number of DTCs which do not fulfill DTC preconditions has reached ECU

memory limit

HINT:

© Ifthe judgment result shows ABNORMAL, the system has @ malfunction.

© Ifthe judgment result shows NORMAL, the system is normal.

‘© If the judgment result shows INCOMPLETE or UNKNOWN, perform steps [B] and [C] again.

16. Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

17. Check the judgment result.

HINT:

© Ifthe judgment result shows ABNORMAL, the system has @ malfunction.

© Ifthe judgment result shows NORMAL, the system is normal.

18. Ifthe test result is INCOMPLETE or UNKNOWN and no DTC is output, perform a universal trip and

check for permanent DTCs MEE.

HINT:

© Ifa permanent DTC is output, the system is malfunctioning.

© Ifno permanent DTC is output, the system is normal.

FAIL-SAFE

‘When any of these DTCs, as well as other DTCs relating to electronic throttle control system malfunctions, are

set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator, and

the throttle valve is returned to a 5.5° throttle angle by the return spring. The ECM stops the engine and the

vehicle can be driven using solely the hybrid system. If the accelerator pedal is depressed firmly and gently, the

vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the power switch is then turned off.

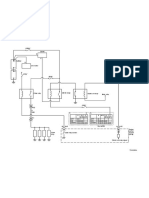

WIRING DIAGRAM

04

‘Trrotle Postion Sensor (Bult Into Throttle Body Assembly) =

©2

vr

vraz

028 ECM

+: Shielded

INSPECTION PROCEDURE

HINT:

DTC P0121 is stored when the voltages output from VTAI and VTA2 are not consistent with the

characteristics of the sensors. Therefore, check the Freeze Frame Data when this DTC is output. Use the

following formula to confirm relative fluctuations in voltage.

Features of sensor output:

VTA2x 0.

is approximately equal to VTAI + 1.11 V

VTAIL: Throttle Position No, 1

VTA2: Throttle position No. 2

IfDTC P0121 is output, proceed to "CHECK HARNESS AND CONNECTOR (THROTTLE

POSITION SENSOR - ECM)":

Read freeze frame data using the Techstream. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

‘warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction,

PROCEDURE

{ 1. [CHECK HARNESS AND CONNECTOR (THROTTLE POSITION SENSOR - ECM)

(2) Disconnect the throttle body assembly connector.

4

(b) Disconnect the ECM connector.

(©) Measure the resistance according to the value(s) in the table below,

Standard Resistance (Check for Open):

‘Tester Connection Condition —[ Specified Condition

[D4-5 (VC) - D28-88 (VCTA) [Always Below &

[B46 (VTA) - D28-90 (VTA) [Always [Below 1 2

[D4-4 (VTA2)- D28-89(VTA2) [Always [BlwI2 ss

[D4-3 (2) - D28-111 (ETA) [Always [Below 19

Standard Resistance (Check for Short):

Tester Connection ion | Specified Condition

|D4-5 (VC) or D28-88 (VCTA) - Body ground [Always {10 k@ or higher

[D4-6 (VTA) or D28-90 (VTA) - Body ground (Always

(D4-4 (VTA2) or D28-89 (VTA2) - Body ground a [Always

‘Text in Illustration

(to Throttle Body Assembly)

io view of wire hamess connector

‘1

[Front view of wire hamess connector

2

(ECM)

(@) Reconnect the throttle body assembly connector.

(© Reconnect the ECM connector.

NG)>REPAIR OR REPLACE HARNESS OR CONNECTOR (THROTTLE POSITION SENSOR - ECM)

OK

Vv

| 2. [INSPECT ECM (VC VOLTAGE)

“4

(a) Disconnect the throttle body assembly connector.

@ ((GesuEe

\

ve

(b) Tum the power switch on (IG).

(©) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

[ Tester Connection Condition Specified Condition

[D4-5 (VC) - D4-3 2) Power switch on (IG) 45 t055V

Text in Illustration

[Front view of wire harness connector

"1

(to Throttle Body Assembly)

(d) Reconnect the throttle body assembly connector,

NGP>REPLACE ECM.

OK

¥

REPLACE THROTILE BODY ASSEMBLY

(a) Replace the throttle body assembly MEE

NEXT

bd

[CHECK WHETHER DTC OUTPUT RECURS (THROTTLE POSITION SENSOR DTCS)

(a) Connect the Techstream to the DLC3.

(b) Tum the power switch on (IG).

(©) Turn the Techstream on.

@ Clear the DTCs IEEE

(e) Put the engine in inspection mode EEG.

(f Start the engine.

(g) Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

(h) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(i Read the DTCs.

Result:

[ Result | Proceed to

[DTCPO120, P0121, P0122, P0123, P0220, P0222, P0223 and/or P2135 is output lA

[DTCis not output -

END.

REPLACE ECM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Digest A3Document16 pagesDigest A3Duy KhaNo ratings yet

- Tsjj0181e PDFDocument1 pageTsjj0181e PDFDuy KhaNo ratings yet

- Tshk0014e PDFDocument1 pageTshk0014e PDFDuy KhaNo ratings yet

- Tsjj0181e PDFDocument1 pageTsjj0181e PDFDuy KhaNo ratings yet

- TSUZ0008EDocument1 pageTSUZ0008EDuy KhaNo ratings yet

- Idle Up Switch Idling Selector Switch Idle Down Switch Mode Map Switch 0 Mode Map Switch 1 Mode Map Switch 2Document1 pageIdle Up Switch Idling Selector Switch Idle Down Switch Mode Map Switch 0 Mode Map Switch 1 Mode Map Switch 2Duy KhaNo ratings yet

- TSHK0025Document1 pageTSHK0025Duy KhaNo ratings yet

- StarterDocument1 pageStarterDuy KhaNo ratings yet

- Idle Up Switch Idling Selector Switch Idle Down Switch Mode Map Switch 0 Mode Map Switch 1 Mode Map Switch 2Document1 pageIdle Up Switch Idling Selector Switch Idle Down Switch Mode Map Switch 0 Mode Map Switch 1 Mode Map Switch 2Duy KhaNo ratings yet