Professional Documents

Culture Documents

Ror Plant Layout

Ror Plant Layout

Uploaded by

gopal sapkotaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ror Plant Layout

Ror Plant Layout

Uploaded by

gopal sapkotaCopyright:

Available Formats

Sapkotaggopal051@gmail.

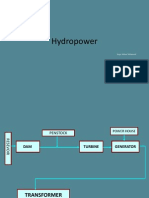

com Hydropower plant layour

Layout & Components of Typical ROR Type Hydropower Plant

Source: Vivek Dhakal, https://www.dhakalvivek.com.np/2023/06/layout-of-typical-

ROR-type-hydropower-plant.html

Components of Typical ROR Type Hydropower Plant

The general layout and components of hydropower plants may differ based on

the types of hydroelectric project. A general layout of typical ROR type hydropower

plants constructed in Nepal is shown in figure above in schematic form. The name

of each components is listed below:

10/30/2023 11:26 AM 1|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

1. Headworks Components

The diversion headwork is constructed in a hydro power plant so as to divert

necessary amount of sediment free water into a waterway. A diversion headwork

may consist of following components:

Weir / Spillway

Undersluice / Scouring sluice

Divide wall

Flood wall

Side Intake

Bed Sluice

Gravel Trap

Gravel Trap Side Spillway

Approach Culvert / Approach Canal

Settling Basin

Head Pond

2. Headrace Waterway

It is a long watercourse or passage that conveys water from headworks component

to the a surge chamber or a forebay. The flow in the waterway may be either open

channel or pipe flow. The structure in waterway may be one of the following types:

Headrace Tunnel

Headrace Canal

Headrace Pipe

3. Surge Tank / Surge Chamber

The chamber provided in between headrace pressure conduit and steeply sloping

penstock pipes with a purpose to minimize the effect of water hammer is called surge

tank. If the the waterway in headrace is of open channel type instead of pressurized

system, forebay is installed in place of surge tank.

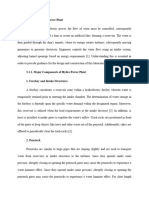

4. Penstock

It is a steel pipe that supplies water from surge chamber to the turbines placed inside

powerhouse. Penstock pipe operates under very high water pressure.

5. Anchor Block and Saddle Support

10/30/2023 11:26 AM 2|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

These are the structures that provide supports to the penstock pipe. Anchor

blocks are provided at the bends where as saddle supports are provided in between

the anchor blocks at regular spacing.

6. Powerhouse

It is a building which consists of different hydromechanical and electromechanical

equipment in which hydraulic energy is converted into mechanical energy by

turbines and the generators convert mechanical energy into electrical energy.

7. Tailrace Culvert / Tailrace Canal

Tailrace is a water channel constructed in the downstream of hydroelectric

powerhouse in order to discharge water back to the river or other water bodies safely.

DETAILED NOTES on ROR Plant BY:

Civil Works Guidelines for MICRO-HYDROPOWER IN NEPAL, BPC

Hydroconsult

Components of micro-hydro schemes Although no two micro-hydro sites are

similar, all of them require specific common components of different dimensions to

convey the stream water to the power generation units and back into the stream.

These components are shown in Figure 1.1. The civil components are briefly

discussed below:

1. HEADWORKS Structures at the start of the scheme are collectively called the

headworks. In micro-hydro schemes, the headworks always include the diversion

weir, intake and gravel trap. A spillway and a settling basin are also usually at the

headworks.

2. DIVERSION WEIR A diversion weir is a low structure (small dam) placed

across the river which diverts some of the river flow into the hydropower scheme.

The weir can be of permanent, semi permanent or temporary nature.

10/30/2023 11:26 AM 3|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

3. INTAKE This is at the riverbank upstream from the diversion weir where water

is initially drawn into a conduit (canal or a pipe). Usually a flow control structure

and a coarse trashrack are incorporated at the intake

4. INTAKE CANAL Generally the gravel trap is sited away from the intake at some

downstream location to protect it from flood and to provide sufficient flushing head.

If such an arrangement is made in the project layout, then an intake canal will convey

the flow that enters in the intake to the gravel trap. Whenever possible, provision for

a spillway should be made immediately downstream of the intake so that excess flow

during the flood season can be spilt back into the river. This will improve the settling

efficiency of the gravel trap as only the desired flow reaches this structure. However,

care should be taken to site the spillway such that flood flow will not re-enter to the

waterways system via the spill way instead of spilling the excess water. Though the

intake canal is steeper than the headrace canal, sometimes both types of canals are

referred to as "headrace canal."

5. GRAVEL TRAP This is a basin (pond) close to the intake where gravel and other

coarse materials are trapped and then removed. In the absence of this structure gravel

can settle along the gentler section of the headrace or in the settling basin.

6. SETTLING BASIN This is also a basin where sand and other fine suspended

particles present in the river water are settled and then removed. If allowed to enter

the penstock, such particles would abrade the penstock pipe and the turbine and

hence shorten their operational lives.

7. HEADRACE This is a canal or a pipe that conveys the water from the headworks

to the forebay structure. The headrace alignment is usually on even to gently sloping

ground; a headrace pipe is generally not subject to significant hydraulic pressure.

Sometimes the canal stretch from the intake structure to the gravel trap is also

referred to as the ‘Intake Canal”. This section of the canal is generally steeper than

the headrace canal downstream as it needs to convey the gravels along with

discharge from the intake to the gravel trap. Similarly, the canal stretch from the

gravel trap to the settling basin is also referred to as the “Approach Canal”. This

section of the canal is also steeper than the headrace downstream as it needs to

convey sediments along with the discharge. However, the slope of the approach

canal can be lower than that of the intake canal, i.e., a less sloped area is required to

convey suspended sediments than gravels. In these guidelines, the entire canal (or

pipe) stretch from the intake to the forebay is referred to as the headrace.

10/30/2023 11:26 AM 4|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

8. FOREBAY This is a tank at the entrance to the penstock pipe. The forebay tank

allows for flow transition from open channel to pressure flow, maintains

submergence depth for the penstock pipe to avoid vortex formation and provides

storage when there are flow fluctuations in the turbine. It can also serve as a final

settling basin. In fact, sometimes the settling basin and the forebay structures are

combined together. An overflow spillway should always be provided in the forebay

structure to allow spilling of the entire flow in case of emergency plant closure and

excess flow in case of excessive load fluctuations.

9. SPILLWAYS AND ESCAPES Spillways are openings in headrace canals that

divert excess flow and only allow the design flow downstream. Note that some

literature may use the terms spill weir or overflow to refer to the spillway. Escapes

are similar in structure but their function is to divert flows from the headrace canals

in case the downstream sections get blocked (in case of a landslide).

10. CROSSINGS These are structures that convey the flow over streams, gullies or

across unstable terrain subject to landslides and erosion. Aqueducts, super passage,

culverts and suspended crossings are examples of such structures.

11. PENSTOCK This is a pipe that conveys water under pressure from the forebay

to the turbine. The penstock pipe usually starts where the ground profile is steep.

Some times a long penstock could be laid from headwork to the power house if the

topography is suitable (e.g., alignment is suitable for a penstock alignment right from

the intake). In such project layout a forebay is constructed at the headworks area and

is combined with the settling basin.

12. ANCHOR BLOCK An anchor block (thrust block) is an encasement of a

penstock designed to constrain the pipe movement in all direction. Anchor blocks

are placed at all sharp horizontal and vertical bends, since there are forces at such

bends that will tend to move the pipe out of alignment. Anchor blocks are also

required to resist axial forces in long straight sections of penstock.

13. SUPPORT PIER Support piers (also called slide blocks or saddles) are

structures that are used along straight runs of exposed penstock pipe (between anchor

blocks), to prevent the pipe from sagging and becoming overstressed. They need to

resist all vertical forces such as the weight of the penstock pipe and water. However,

they should allow movement parallel to the penstock alignment which occurs during

thermal expansion and contraction processes.

10/30/2023 11:26 AM 5|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

14. POWERHOUSE This is a building that accommodates and protects the electro

mechanical equipment such as the turbine, generator and may include agro-

processing units. The electro-mechanical equipment in the powerhouse converts the

potential and kinetic energy of water into electrical energy.

15. TAILRACE This is a channel or a pipe that conveys water from the turbine

(after power generation) back into the stream; generally the same stream from which

water was initially withdrawn.

10/30/2023 11:26 AM 6|Page

Sapkotaggopal051@gmail.com Hydropower plant layour

10/30/2023 11:26 AM 7|Page

You might also like

- Civil Works Guidelines For Micro Hydropower in NepalDocument185 pagesCivil Works Guidelines For Micro Hydropower in Nepaljayusman100% (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Water Power EngineeringDocument14 pagesWater Power EngineeringSAMIM100% (1)

- Modern Land Drainage PDFDocument443 pagesModern Land Drainage PDFStephanie Angel0% (1)

- Hydro Power PlantsDocument7 pagesHydro Power PlantsKyambadde Francisco100% (1)

- Function of Components of DamsDocument8 pagesFunction of Components of DamsAmber AliNo ratings yet

- Hydropower WCSDocument36 pagesHydropower WCSKathiravan ParameswaranNo ratings yet

- Hydrology and Water Resource Managment: Principle Components of Hydroelectric Power PlantDocument23 pagesHydrology and Water Resource Managment: Principle Components of Hydroelectric Power PlantmseaNo ratings yet

- The Elements of Hydroelectric Power Plant Are As FollowsDocument8 pagesThe Elements of Hydroelectric Power Plant Are As FollowsDanial DanialNo ratings yet

- Main Elements of Hydroelectric Power PlantDocument14 pagesMain Elements of Hydroelectric Power PlantYimam AlemuNo ratings yet

- PPE Expriment No-01Document9 pagesPPE Expriment No-01Aasawari Mahagaonkar100% (1)

- Chapter 1Document9 pagesChapter 1Prashant JoshiNo ratings yet

- The Elements of Hydroelectric Power Plant Are As FollowsDocument10 pagesThe Elements of Hydroelectric Power Plant Are As FollowsmorolosusNo ratings yet

- CanalsDocument19 pagesCanalsFemeena P-vNo ratings yet

- Canal Outlets and Canal RegulationsDocument22 pagesCanal Outlets and Canal RegulationssatyaNo ratings yet

- 11.2 Chapter 2 FinalDocument19 pages11.2 Chapter 2 FinalPhoo PhooNo ratings yet

- Power of WaterDocument60 pagesPower of WaterAdnan MehmoodNo ratings yet

- Hyd Structures of Small Hydro PowerDocument12 pagesHyd Structures of Small Hydro PowerKhanNo ratings yet

- Conduits, Intake, Power House and AccessoriesDocument29 pagesConduits, Intake, Power House and Accessorieshussen belewNo ratings yet

- 1 Hydro Power PlantDocument5 pages1 Hydro Power PlantBlancCanvasNo ratings yet

- Exp 2Document8 pagesExp 2HR HabibNo ratings yet

- Hydraulic Structures For Flow Diversion and Storage Reservoir Outlet WorksDocument23 pagesHydraulic Structures For Flow Diversion and Storage Reservoir Outlet WorksAliyyi JamaalNo ratings yet

- Water Power Engg.Document78 pagesWater Power Engg.Chintu Dabang ChintuNo ratings yet

- Hydraulic Structures For Flow Diversion and StorageDocument25 pagesHydraulic Structures For Flow Diversion and StorageEndless LoveNo ratings yet

- Irrigation Structures Modulical DesignDocument26 pagesIrrigation Structures Modulical DesignIssa DrdrNo ratings yet

- Components of DamsDocument37 pagesComponents of DamsAmanuel AzemeteNo ratings yet

- Wre Part IDocument8 pagesWre Part ISajed AbdulrahmanZaiNo ratings yet

- Electric Power Generation NotesDocument64 pagesElectric Power Generation NotesnikhilNo ratings yet

- Report On Spillways Funcution Location and Componants: ReservoiDocument8 pagesReport On Spillways Funcution Location and Componants: Reservoisakshi pawarNo ratings yet

- Chapter - 06 Civil Engineering Structure - DPR - 7.5 MW-5.12.20Document36 pagesChapter - 06 Civil Engineering Structure - DPR - 7.5 MW-5.12.20nira365No ratings yet

- HydroPower Plant 3Document15 pagesHydroPower Plant 3alamdar.hussainNo ratings yet

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power PlantAdrian Ray Ayam100% (1)

- Practical Training RestDocument35 pagesPractical Training RestĎąŕ BäbăřNo ratings yet

- Fluid MachineDocument53 pagesFluid MachineVineet K. MishraNo ratings yet

- HydalDocument26 pagesHydalPrathap VuyyuruNo ratings yet

- Chapter 4Document22 pagesChapter 4Yasin Mohamed BulqaazNo ratings yet

- Hydroelectric Power PlantDocument2 pagesHydroelectric Power PlantMamta SinghNo ratings yet

- Figure 1. Diversion Weir at Solu KholaDocument25 pagesFigure 1. Diversion Weir at Solu KholaKrishna KafleNo ratings yet

- Constituents of Hydro-Electric Power Station: Fig. 3 Protecting Devices of PenstockDocument4 pagesConstituents of Hydro-Electric Power Station: Fig. 3 Protecting Devices of PenstocksmitajanaNo ratings yet

- Critical Review of Stilling Basin Models For Pipe Outlet WorksDocument4 pagesCritical Review of Stilling Basin Models For Pipe Outlet WorksInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hydropower Project Summary by TeslaDocument31 pagesHydropower Project Summary by TeslaLuthfi NaufalNo ratings yet

- CH - 5 Bottom Outlets (Compatibility Mode)Document63 pagesCH - 5 Bottom Outlets (Compatibility Mode)zelalemniguseNo ratings yet

- SpillwayDocument18 pagesSpillwaykmahesh92No ratings yet

- Lecture 20 - Spillways 03.04.2021Document5 pagesLecture 20 - Spillways 03.04.2021Morio MosoroNo ratings yet

- Chapter 6 Dam and Spillways2Document48 pagesChapter 6 Dam and Spillways2Mahmoud I. Mahmoud100% (1)

- Hydropower in NepalDocument19 pagesHydropower in NepalVivek GyawaliNo ratings yet

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power Plantk rajendraNo ratings yet

- 1.2-II-gl For Planning The Projects On Canal FallsDocument8 pages1.2-II-gl For Planning The Projects On Canal FallsRanjeetKumarNo ratings yet

- HYDRODocument4 pagesHYDROTelleNo ratings yet

- Hydropower SurveyDocument37 pagesHydropower Surveybhattharish799No ratings yet

- Kaplan ProjectDocument39 pagesKaplan Projectmahmoudlotfy309No ratings yet

- Canal Headworks HeadworkDocument6 pagesCanal Headworks HeadworkPhacku MiaNo ratings yet

- Flood Gates and Pumping StationDocument10 pagesFlood Gates and Pumping StationTin VillalbaNo ratings yet

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsFrom EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Tunnels & Caverns: Looking Back at Forty Years in Underground Construction & EstimatingFrom EverandTunnels & Caverns: Looking Back at Forty Years in Underground Construction & EstimatingNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Elect MC 1 Chap-2 Lecture-8Document12 pagesElect MC 1 Chap-2 Lecture-8gopal sapkotaNo ratings yet

- SCR NotesDocument21 pagesSCR Notesgopal sapkotaNo ratings yet

- Class Note On RectifierDocument32 pagesClass Note On Rectifiergopal sapkotaNo ratings yet

- Electrical Measurements UpdatedDocument55 pagesElectrical Measurements Updatedgopal sapkotaNo ratings yet

- 3.1 Sensors and TransducersDocument14 pages3.1 Sensors and Transducersgopal sapkotaNo ratings yet

- MultiplesDocument1 pageMultiplesgopal sapkotaNo ratings yet

- पाठ्रम New Kharidar Syllabus in PDF New Nayab Subba Syllabus 2078 in PDF New Section Officer Syllabus in PDF Nayab Subba Model Questions 2078 in PDF Section Officer Model Question 2078 in PDFDocument7 pagesपाठ्रम New Kharidar Syllabus in PDF New Nayab Subba Syllabus 2078 in PDF New Section Officer Syllabus in PDF Nayab Subba Model Questions 2078 in PDF Section Officer Model Question 2078 in PDFgopal sapkotaNo ratings yet

- Grounding and Shielding Techniques 4th EditionDocument3 pagesGrounding and Shielding Techniques 4th Editiongopal sapkotaNo ratings yet

- Project ManagementDocument23 pagesProject Managementgopal sapkotaNo ratings yet

- SIP Sustainable Drainage SolutionDocument5 pagesSIP Sustainable Drainage SolutionElyNo ratings yet

- 04 GWMR GDR Suthersan Et Al 2015Document7 pages04 GWMR GDR Suthersan Et Al 2015Fabiano Rodrigues dos SantosNo ratings yet

- Housing Infrastructure and Services: Social Infrastructure and FacilitiesDocument24 pagesHousing Infrastructure and Services: Social Infrastructure and Facilitiesgitansh tyagiNo ratings yet

- Water Supply Problems and SolutionsDocument8 pagesWater Supply Problems and SolutionsNobody100% (2)

- Water: Water Pollution in A Densely Populated Megapolis, DhakaDocument13 pagesWater: Water Pollution in A Densely Populated Megapolis, DhakaMd abdul karimNo ratings yet

- Design of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana StateDocument6 pagesDesign of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana Statedeepak kumarNo ratings yet

- Interior Services - Ii: Plumbing and SanitationDocument17 pagesInterior Services - Ii: Plumbing and Sanitationrose2006No ratings yet

- 05 ProblemsDocument13 pages05 ProblemsZahid Rahman50% (2)

- River Basin ProcessesDocument16 pagesRiver Basin Processes3alliumcourtNo ratings yet

- WER 301 - Chapter 3 - Sewer - M1 Sanitary Sewer - 2Document41 pagesWER 301 - Chapter 3 - Sewer - M1 Sanitary Sewer - 2Zithulele TreatwellNo ratings yet

- Sanitary and Drainage Layout Water Line Layout: Two-Storey Residential Building Kristianne Mari C. TyDocument1 pageSanitary and Drainage Layout Water Line Layout: Two-Storey Residential Building Kristianne Mari C. TyJimwell ManaloNo ratings yet

- Restoration of Polluted Lakes - 29-12-2016.Ppt (Autosaved)Document145 pagesRestoration of Polluted Lakes - 29-12-2016.Ppt (Autosaved)Sugumar BalasubramaniamNo ratings yet

- Use of Ground Chickpea As Bio-Coagulant in Surface Water TreatmentDocument5 pagesUse of Ground Chickpea As Bio-Coagulant in Surface Water TreatmentMD Najmul HossanNo ratings yet

- Case Study - Coca Colas Conflict - FinalDocument11 pagesCase Study - Coca Colas Conflict - FinalKristine Joy LaboneteNo ratings yet

- Korapani DamDocument2 pagesKorapani DamPriyaranjan SahooNo ratings yet

- MIS Booklet June 2020 - 04Document22 pagesMIS Booklet June 2020 - 04Nita HadzihamzaNo ratings yet

- Cavite West Point College: Operational Performance of Purified Water Refilling Stations in Maragondon, CaviteDocument18 pagesCavite West Point College: Operational Performance of Purified Water Refilling Stations in Maragondon, CaviteZejkeara ImperialNo ratings yet

- Turning Ver A New Leaf: Green InfrastructureDocument5 pagesTurning Ver A New Leaf: Green InfrastructureFernando MoreiraNo ratings yet

- University of Gondar Hydraulic and Water Resources EngineeringDocument54 pagesUniversity of Gondar Hydraulic and Water Resources Engineeringismail abibNo ratings yet

- Reverse OsmosisDocument16 pagesReverse Osmosismochamad iwanNo ratings yet

- Jadual Present FYPDocument24 pagesJadual Present FYPfarid_23101531No ratings yet

- Socio-Economic Impacts of Solar Pumping System in Term of Local Job and Value Creation in EgyptDocument110 pagesSocio-Economic Impacts of Solar Pumping System in Term of Local Job and Value Creation in EgyptJessa ArgabioNo ratings yet

- FM CPD AW11 DISCHARGE PERMIT APPLICATION FORM NewDocument2 pagesFM CPD AW11 DISCHARGE PERMIT APPLICATION FORM Newallen alegreNo ratings yet

- The Boring Company Wastewater Disposal PermitDocument8 pagesThe Boring Company Wastewater Disposal PermitMaria MeranoNo ratings yet

- TLE-Agri Crop Production Three: Learning Area Grade Level Seven/Eight Quarter DateDocument5 pagesTLE-Agri Crop Production Three: Learning Area Grade Level Seven/Eight Quarter DateÁthymosNo ratings yet

- SewageDocument7 pagesSewageChandra KanthNo ratings yet

- Gess 205Document9 pagesGess 205balajiNo ratings yet

- Prezentacija Za GermanijaDocument20 pagesPrezentacija Za GermanijamgjorNo ratings yet

- Revision - Public FacilitiesDocument5 pagesRevision - Public FacilitiesonlymotieNo ratings yet