Professional Documents

Culture Documents

Saic D 2023

Saic D 2023

Uploaded by

razzak.me.enggOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic D 2023

Saic D 2023

Uploaded by

razzak.me.enggCopyright:

Available Formats

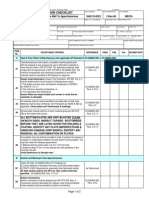

SAUDI ARAMCO ID/PIEU-30-April-2019 - REV.2019.04.00 (Standards Cutoff - April 30,2019) Rev.2019.04.

00 30-Apr-19

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of API Tank Plate Mat'l & Appurtenances SAIC-D-2023 29-Aug-19 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

A Shell & Floor Plates & Miscellaneous (Use applicable API Standard & 32-SAMSS-005 or 32-SAMSS-006)

The Tank Manufacturer shall submit a complete material specification with

the proposal.

The Tank Manufacturer may propose the use of alternative materials to

those that are listed in API STD 650. The alternative materials shall

comply with all the other requirements of API STD 650 and this

specification. The chemical compositions and mechanical properties of

non-ASTM materials shall be submitted to the Saudi Aramco Engineer for

32-SAMSS-005,

A1 approval.

Para. 4.1.2

Materials proposed by the Tank Manufacturer that are equivalent to those

specified in API STD 650 shall be approved by the Saudi Aramco

Engineer.0. The alternative materials shall comply with all requirements of

API STD 650 & 32-SAMSS-005.

Note: The materials equivalent to those specified in API STD 650 shall be

reviewed and approved by SA Engineer (The Chairman of vessel

standard committee)

Ensure Plates are impact tested (cert review) or verify that an

exemption is allowable:

Metal Temperature: The lowest of the following temperature values:

1) The lowest one-day mean atmospheric temperature (LODMAT) per

SAES-A-112, or 32-SAMSS-005,

A2

2) The minimum operating temperature, or Para. 3.6

3) The hydrostatic test temperature

API 650, Fig 4. 1 Provides — Minimum Permissible Design Metal

Temperature for Materials Used in Tank Shells without Impact Testing

All materials are clearly identified & provided with mill test certs. Materials

32-SAMSS-005,

A3 shall be alloy-verified by Tank Fabricator per SAES-A-206 as applicable.

Para. 4.1.3

Check plates mat'l thicknesses & markings.

Annular plate material shall be of same material group per API STD 32-SAMSS-005,

A4

650 as the lowest shell course. Para. 4.2.1.6

1-The drip ring shall be turn down at its outer diameter at a 45-degree

angle.

32-SAMSS-005,

A5 2-. The top of the drip ring and the top of the tank bottom edge projection

Para. 5.4.5

beyond the shell shall be coated with the same coating system used for

the first shell course of the tank in accordance with SAES-H-001.

The bottom side of the bottom plates shall be cleaned of all foreign matter

and grit-blast cleaned prior to being coated as specified in SAES-H-001

and placed in position for welding. 32-SAMSS-005,

A5

The topside surface of bottom plates, regardless whether Para. 7.1.7

coating is required or not,have been grit-blast cleaned (Surface

preparation shall be according to APCS-3 or APCS-113, as applicable) .

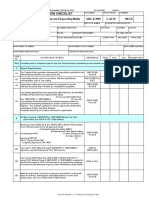

B Nozzles and Manways (Tank Appurtenances)

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

Utilize API Stds, 32-SAMSS-005 & IFC Drawings for:

A) Correct Material & Schedule/Thickness used

(Micrometer/caliper)

B1 B) PWHT & NDE Requirements (especially shop fabricated inserts) As Referenced

All shell nozzles shall be the API Low Type,

unless otherwise specified. (32-SAMSS-005, Para. 5.7.6.5)

Bottom Connections

When specified, bottom connections shall be designed in accordance with

32-SAMSS-005,

B2 API STD 650, Annex O.

Para. 5.8.2

Connections shall be fabricated from elbows; miter joints are prohibited.

Vortex breakers shall be provided for bottom connections.

Mixers supplied comply with following requirements verified from

Release documents or Final disposition report received with

mixture:

A) Number and type of mixers received are as specified on the Storage

Tank Data Sheet B)

Side-entry propeller mixers are designed, inspected, and tested in 32-SAMSS-005,

B3 accordance with 32-SAMSS-017. Para.

c) Nozzles for side-entry mixers shall be designed in accordance with API 5.8.11.5

STD 650 for manways. Supports for the mixer may be needed to maintain

stresses at the nozzle-to-shell junction within the allowable limits.

D) Jet-nozzle mixers shall not be used in tanks with internal floating roofs

on floats.

Bolting

A) Flange bolting material conforms to A193 Grade B7 bolts with A194

Grade 2H nuts.

B) All bolts and nuts used for anchorage shall be as specified on the

Storage Tank Data Sheet. They shall meet the following requirements: 32-SAMSS-005,

B4

1) Galvanized. Para. 4.7

2) Their diameters increased by 3.2 mm (1/16 in.) as a corrosion

allowance.

3) Their exposed parts top coated with an approved epoxy coating (e.g.,

APCS-26).

Gaskets

32-SAMSS-005,

B5 Gasket contact surfaces shall not be coated or painted.

Para. 11.6

Tank Appurtenances* Schedule & Orientations - Form 2696-ENG (Appurtenances consist of Nozzles & manways, Venting Devices,

C

Temperature Instruments, Level Gauging Systems, Sample Connections, and Stairways/Ladders/Platforms)

Check Appurtenances received (condition & specifications) against 32-

C1 32-SAMSS-005

SAMSS-005 Requirements & Form 2696-ENG for all items.

REMARKS:

NOTES:

REFERENCE DOCUMENTS:

1. 32-SAMSS-005, Manufacture of Atmospheric Tanks, 19 September 2018

2. API 650, Welded Steel Tanks for Oil Storage, ELEVENTH EDITION,March 2013 w/ addendum 1 September 2014

3. SAES-D-100, Design Criteria of Atmospheric & Low-Pressure Tanks (22 January 2019)

4. Schedule Q, Contractor's Quality Requirement, Project Specific

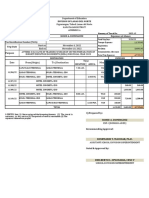

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 pagesSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- SAIC-L-2112 Rev 7Document7 pagesSAIC-L-2112 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saic K 4008Document3 pagesSaic K 4008Dusngi MoNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- Saic H 2011Document2 pagesSaic H 2011zuknesedriNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-K-4008 Hvac Metal Duct, Hangers and Supports and Insulation ReceivingDocument8 pagesSaudi Aramco Inspection Checklist: SAIC-K-4008 Hvac Metal Duct, Hangers and Supports and Insulation ReceivingshahzadaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- SAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFDocument2 pagesSAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic - K-4008Document7 pagesSaic - K-4008Bander Al–kouhlaniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Document2 pagesSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke mohaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 347 804 2501 Op Manual Nov07Document91 pages347 804 2501 Op Manual Nov07Luis MironNo ratings yet

- Verbal Section Reading CompDocument35 pagesVerbal Section Reading CompBasharat AliNo ratings yet

- Employees' Health Insurance and Pension (Shakai Hoken 社会保険)Document2 pagesEmployees' Health Insurance and Pension (Shakai Hoken 社会保険)Putri HalinNo ratings yet

- VRF E Series (R) 1111Document4 pagesVRF E Series (R) 1111ShuFai LiNo ratings yet

- Combined SpecsheetDocument1 pageCombined SpecsheetApurva PatelNo ratings yet

- Livne-Ofer Et Al. - (2019 - AMJ) - Perceived Exploitative and Its ConsequecesDocument30 pagesLivne-Ofer Et Al. - (2019 - AMJ) - Perceived Exploitative and Its Consequeces李佩真No ratings yet

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDocument17 pages15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- BT138FDocument7 pagesBT138FMiloud ChouguiNo ratings yet

- 1 - Tell Me Something About Yourself in BriefDocument5 pages1 - Tell Me Something About Yourself in BriefPAWAN KUMARNo ratings yet

- Nios II IntroductionDocument91 pagesNios II IntroductionRajan VermaNo ratings yet

- Central Asian Survey: To Cite This Article: Thomas H. Johnson & Matthew C. Dupee (2012) : Analysing The New TalibanDocument16 pagesCentral Asian Survey: To Cite This Article: Thomas H. Johnson & Matthew C. Dupee (2012) : Analysing The New Talibannagendrar_2No ratings yet

- Brokerage: What Does BRS and LRS Mean in Indian Real Estate: 7 AnswersDocument3 pagesBrokerage: What Does BRS and LRS Mean in Indian Real Estate: 7 AnswersnarayanaNo ratings yet

- Buy Ultimate Fantasy Real Sex Doll Bianca in IndiaDocument1 pageBuy Ultimate Fantasy Real Sex Doll Bianca in Indiapy2f5ypmpsNo ratings yet

- CE 323 - Engineering Management Case Study No. 6: Submitted By: Roger F. Villaruel, JRDocument4 pagesCE 323 - Engineering Management Case Study No. 6: Submitted By: Roger F. Villaruel, JRGEr JrvillaruElNo ratings yet

- Developing ASP - Net MVC Web Applications (70-486)Document11 pagesDeveloping ASP - Net MVC Web Applications (70-486)khundaliniNo ratings yet

- Even Semester 2023-24 Student Attendance Report Less Than 75% As On 19.02.2024Document449 pagesEven Semester 2023-24 Student Attendance Report Less Than 75% As On 19.02.2024Prithvi RastogiNo ratings yet

- Amado VDocument1 pageAmado Vェヌエクサ ーNo ratings yet

- School Principal ItineraryDocument3 pagesSchool Principal ItineraryKaren S. RoblesNo ratings yet

- Ted Nelson - Computer Lib - Dream Machine PDFDocument132 pagesTed Nelson - Computer Lib - Dream Machine PDFgmtinwinslienl12No ratings yet

- 5Q0765RTDocument10 pages5Q0765RTFuadNo ratings yet

- Resume - 2 ProjectDocument2 pagesResume - 2 Projectapi-357163581No ratings yet

- 2nd Sem Previous Yr. Question Papers (5 Subjects)Document44 pages2nd Sem Previous Yr. Question Papers (5 Subjects)Muhammed Muktar0% (1)

- Procédure de Test de L'afficheur LED EB004Document2 pagesProcédure de Test de L'afficheur LED EB004FantomasNo ratings yet

- Cloud Computing Lab ManualDocument57 pagesCloud Computing Lab ManualAdvithNo ratings yet

- Calculo de Bus BarraDocument8 pagesCalculo de Bus BarraJohn AnguloNo ratings yet

- 1.EE 563 SyllabusDocument3 pages1.EE 563 SyllabusMohammad Reza RajatiNo ratings yet

- INtroduction To ErgonomicsDocument103 pagesINtroduction To Ergonomicsnurjamima96No ratings yet

- Strategic Leadership Primer PDFDocument75 pagesStrategic Leadership Primer PDFAbdul Jabbar100% (1)

- Merivaara Futura Plus 8381 Junior Manual ServiceDocument40 pagesMerivaara Futura Plus 8381 Junior Manual ServiceDanniel SchaafNo ratings yet

- Forms: WWMS (Waste Water Management SystemDocument3 pagesForms: WWMS (Waste Water Management SystemAkram KhanNo ratings yet