Professional Documents

Culture Documents

1426 Ec1942

1426 Ec1942

Uploaded by

Deipak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1426 Ec1942

1426 Ec1942

Uploaded by

Deipak HoleCopyright:

Available Formats

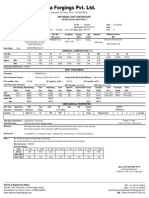

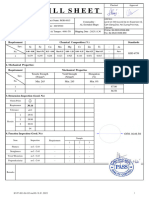

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC1842 Date : 10.10.2023

Invoice No.:WIF/EX/23-24/ Date :

P.O. No.: 4500795889 Line Item: 00040 PO Date : 11.09.2023 Spec. Ref.: M15030 Rev. : A

P.O.Ver.: 3

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

1426 BLANKING CAP FORGING 3253785 Rev G Forged 55.72 : 1 100 Nos. AISI 1040 EAF-LRF-VD-CCM

UNION 4 FIG 207 Normalized

& Shot - Aarti Steels Limited

Heat Code: MJR DU500002210 Rev B Blasted

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Grain Size

8832 0.43 0.79 0.24 0.003 0.013 6.5

Specn. Min. 0.37 0.60 0.15 - - 6

Max. 0.44 0.90 0.35 0.050 0.040 -

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Batch No. of N :- CY-916 Qty :- 100 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time

Ratio Temp. Hrs.

QTC 55.72 : 1 900⁰C 2 Hrs 40 Min

Forging 55.72 : 1 900⁰C 2 Hrs 40 Min

Specn. Min. --

Max. --

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C KSI KSI % % Temp. Requirement 1 2 3 Average

midwall of

thickest L 197, 197 Ambient 98.34 53.94 27.24 49.99 No impact specified in specification M15030 Rev A

section

235 HBW Max Spec. Min. 75.00 45.00 20.00 35.00

Max. - - - -

Test Piece Orientation:- Longitudinal NABL Lab Report No. :- G-23-676-P & G-23-677-P

Test Piece Size :- 6.25 mm Dia, 25 mm Gauge Length

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Dimensional Report

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

The above material meets the requirements of ASTM A788/A788M : 23

Forging Method- Closed Die Forging

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

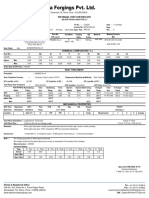

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC1842

P.O. No.:- 4500795889 Line Item: 00040 PO Date : 11.09.2023 Date : 10.10.2023

BLANKING CAP FORGING UNION 4 FIG

Item : Material : AISI 1040

207

Part No.: 3253785 Rev G Heat No. : 8832

Drawing No.: DU500002210 Rev B Ambient Temp : 27°C

Die No.: 1426 Hardness Range:- 235 HBW Max

Qty.: 100 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: CY-916 Sr No. 19/05/007

Reference Standard: ASTM E10 Machine Make: FSA

Load Applied: 3000 Kgs Calibration Agency: MM Engineers

Type of Penetrator: Dia 10 mm Carbide Ball Certificate No.:MME/CAL/337/23-24

Std Block Details: SH-2522/23 (Hardness value -184.8 HBW) Calibrated On: 07.08.2023

Entity Performing Test: WIF Sanaswadi Calibration Due On: 06.02.2024

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 07.10.2023

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

100 Nos. 174 - 197 HBW

Note : Hardness Checked on 10% of batch qty.

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Ajay Joshi (GM, MQC & HT)

F-HT-10 / Rev. 00 / 01-Apr-2016

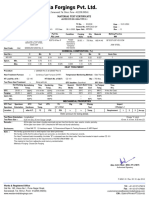

CERTIFICATE OF COMPLIANCE

Customer : TechnipFMC TC No.: EC1842

Date: 10.10.2023

Die No. : 1426 Heat Code : MJR

PO No : 4500795889 Line Item No : 00040

PO Qty : 100 Nos. Offer Qty. : 100 Nos.

Part No/ Rev : 3253785 Rev G Drg No / Rev : DU500002210 Rev B

Part Name : BLANKING CAP FORGING UNION 4 Serial No. : -

FIG 207

I. Material

A. Material Type : AISI 1040

B. Material Spec/ Rev. : As per Spec no : M15030 Rev No. A

C. Material Test Report No : Mill Heat No : 8832

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 8 Nos

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : CY-916 Process Spec : Q00025 Rev S

B. Process Name : QT

Heat Lot No. : NA Process Spec : NA

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

A. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

The above material meets the requirements of ASTM A788/A788M : 23

Sign with Stamp

Ajay Joshi (GM, MQC & HT)

You might also like

- T187400 - Heliosmart Technical SpecificationsDocument4 pagesT187400 - Heliosmart Technical Specificationsrudy repellinNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Astm 1776Document4 pagesAstm 1776Ruvini Buddhika Amarasinghe100% (1)

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- tc_amr (1)Document1 pagetc_amr (1)balaNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Inv 596 - 30.11.2023 - Emerson Sherman - 239 - 4780740520-01 - MTC 7336Document22 pagesInv 596 - 30.11.2023 - Emerson Sherman - 239 - 4780740520-01 - MTC 7336WHF MQCNo ratings yet

- Test Certificates W&HDocument1 pageTest Certificates W&HRonakNo ratings yet

- Inv 596 - 30.11.2023 - Emerson Sherman - 239 - 4780736807-01 - MTC 7334Document22 pagesInv 596 - 30.11.2023 - Emerson Sherman - 239 - 4780736807-01 - MTC 7334WHF MQCNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- Page 2 Tsi MTC 150x4 (MTC - 247)Document2 pagesPage 2 Tsi MTC 150x4 (MTC - 247)trayojam.rilNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- CBH-21-079 Flange Nut M4 WZP 8Document1 pageCBH-21-079 Flange Nut M4 WZP 8qualityNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- Heat No S13Document1 pageHeat No S13Siddharth ParmarNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- AaaDocument2 pagesAaaN ANo ratings yet

- MTC - 2046Document1 pageMTC - 2046tameem.p2023No ratings yet

- Test ReportDocument1 pageTest ReportSeptyadi NugrohoNo ratings yet

- 64-cbc Temp Controller Calibration CartificateDocument1 page64-cbc Temp Controller Calibration CartificateCustomer SupportNo ratings yet

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17No ratings yet

- Mill Sheet: Si Fe Cu MN MG CR ZN Ti - AL KSD 6759Document7 pagesMill Sheet: Si Fe Cu MN MG CR ZN Ti - AL KSD 6759Đạt NguyễnNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- Final Inspection ReportDocument1 pageFinal Inspection ReportC. M. JebinNo ratings yet

- A105 (VF863)Document1 pageA105 (VF863)Suli HartoNo ratings yet

- H151Document2 pagesH151KalpanaBansalNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- 1335 - Ec1904Document1 page1335 - Ec1904Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- Quotation Yoke WIFL Sanaswadi 201718Document4 pagesQuotation Yoke WIFL Sanaswadi 201718Deipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Al 111 2377-00 Rev 20 28-5-18Document2 pagesAl 111 2377-00 Rev 20 28-5-18Deipak HoleNo ratings yet

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocument2 pagesWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNo ratings yet

- Die No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDocument6 pagesDie No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDeipak HoleNo ratings yet

- WIF Laboratory Plan For 2019-2020Document30 pagesWIF Laboratory Plan For 2019-2020Deipak HoleNo ratings yet

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDocument8 pagesNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenNo ratings yet

- 1 s2.0 S0378517317310736 MainDocument13 pages1 s2.0 S0378517317310736 MaingabrielpoulsonNo ratings yet

- 1.1 Understanding WavesDocument24 pages1.1 Understanding WavesEzhas FauziNo ratings yet

- SWD Aci 530 11Document57 pagesSWD Aci 530 11Stephanie Miyata100% (2)

- Torsional PendDocument2 pagesTorsional PendDR.P.V.Kanaka RaoNo ratings yet

- 2001 Darendeli - Normalized Shear Modulus and Damping PHD ThesisDocument395 pages2001 Darendeli - Normalized Shear Modulus and Damping PHD ThesisEderEnzoTapiaBañezNo ratings yet

- Helmholtz Free Energy: Ideal Gas (Ig)Document10 pagesHelmholtz Free Energy: Ideal Gas (Ig)ClaudioTRodriguesNo ratings yet

- 05.thermodynamics. Entropy - Free Energy of GibbsDocument52 pages05.thermodynamics. Entropy - Free Energy of GibbsRoseman TumaliuanNo ratings yet

- Physics VocabularyDocument4 pagesPhysics Vocabularyapi-309597212No ratings yet

- Overcoming Paint Film DefectsDocument7 pagesOvercoming Paint Film DefectsMahmood H NaqviNo ratings yet

- Electrodeposition PDFDocument4 pagesElectrodeposition PDFcb gNo ratings yet

- Helwany - Applied Soil Mechanics With ABAQUS ApplicationsDocument398 pagesHelwany - Applied Soil Mechanics With ABAQUS ApplicationsFélix Michael Hernandez LópezNo ratings yet

- Compiled P4 (M1)Document116 pagesCompiled P4 (M1)Roshaan Ashraf0% (1)

- Exercise-4 Part - 1: Single Option Correct Type: Newton's Laws of MotionDocument23 pagesExercise-4 Part - 1: Single Option Correct Type: Newton's Laws of MotionDebraj SahaNo ratings yet

- X-Ray: Presented By:-Mohit ChebaDocument20 pagesX-Ray: Presented By:-Mohit ChebaMohit ChebaNo ratings yet

- Jim Hansen - Buried ArcDocument22 pagesJim Hansen - Buried ArcJeff MNo ratings yet

- Ada 324990Document394 pagesAda 324990marwan shawqiNo ratings yet

- J Powtec 2020 04 047Document63 pagesJ Powtec 2020 04 047BISWAJEET BEHERANo ratings yet

- Physics Class 11 DerivationDocument4 pagesPhysics Class 11 Derivation1234raoshabNo ratings yet

- Ice Microfluidics Ice As Size Tunable Separation Field and Physicochemical Nature of Freeze Concentrated Solutions Arinori InagawaDocument35 pagesIce Microfluidics Ice As Size Tunable Separation Field and Physicochemical Nature of Freeze Concentrated Solutions Arinori Inagawapeter.big740100% (3)

- TINSLEY ZX70-90 Series Guide Datasheet V3Document7 pagesTINSLEY ZX70-90 Series Guide Datasheet V3manu mcNo ratings yet

- Some Basic Principle of MagnetismDocument2 pagesSome Basic Principle of MagnetismAce Matthew100% (1)

- Design of Water Supply For PlumbingDocument23 pagesDesign of Water Supply For PlumbingssgjmlimNo ratings yet

- Bionanocomposite: Vikram Singh Vikash Kumar Sunil Kumar Akshay PadghanDocument14 pagesBionanocomposite: Vikram Singh Vikash Kumar Sunil Kumar Akshay PadghanVikram KulriaNo ratings yet

- 12. Atoms: Rutherford's α-particle scattering experiment - When α-particlesDocument6 pages12. Atoms: Rutherford's α-particle scattering experiment - When α-particlesĐřăğøøñ ĞãmîñğNo ratings yet

- Unit 19: They'Re in The Park: Part 1: Theory English Pronunciation VietnameseDocument8 pagesUnit 19: They'Re in The Park: Part 1: Theory English Pronunciation Vietnamesenguyen lynNo ratings yet

- Gratings & Cycle RacksDocument31 pagesGratings & Cycle Rackswawan setiawanNo ratings yet

- 覆膜机quotation vacuum membrane press machineDocument7 pages覆膜机quotation vacuum membrane press machiner HariNo ratings yet