Professional Documents

Culture Documents

T013482001V0F1

T013482001V0F1

Uploaded by

haseebrazvi1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T013482001V0F1

T013482001V0F1

Uploaded by

haseebrazvi1Copyright:

Available Formats

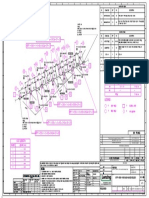

UP -------------------- STANDARD DETAIL REFERENCE DRAWINGS

| BILL OF MATERIAL |

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

-------------------- CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

AWAY AWAY

N PT NPD INSULATION DETAILS FOR HOT PIPING

INSULATION DETAILS FOR COLD PIPING

AA-036911

AA-036913

NO DESCRIPTION (IN) CMDTY CODE QTY INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

-- PIPE ----------- -- ----- ---- ---

----

TOWARD TOWARD

1 PIPE 1.450" (36.83 MM) WELDED, BE ASTM 36 P_6CA2PX-8 23.148 M

A671 GR.CC65 CL.22, EFW, (NACE

DOWN

MR-0175/ISO 15156 + HIC RESISTANCE),

ASME B36.10M NOTES

1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

FITTINGS FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

-------- 2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

2 90 DEG LR ELBOW 1.450" (36.83 MM) 36 E_6CA1P6-8 3 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

WELDED, BW, ASTM A420 GR.WPL6, W, 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

(NACE MR-0175/ISO 15156 + HIC

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION

RESISTANCE), ASME B16.9 01-SAMSS-10.

3 45 DEG LR ELBOW 1.450" (36.83 MM) 36 EA_6CA1P6-8 1

6. GASKET ALLOWANCE PER SPEC

WELDED, BW, ASTM A420 GR.WPL6, W,

7. PIPING MATERIAL IS PER BOM

(NACE MR-0175/ISO 15156 + HIC

PIPE SIZE SCHEDULE SPECIFICATION

RESISTANCE), ASME B16.9

FLANGES

-------

4 FLANGE CLASS 600, 1.450" (36.83 MM) WN, 36 F_6CA1P823 1

RF ASTM A350 GR.LF2 CL.1, (NACE

MR-0175/ISO 15156), ASME B16.47 8. WELDING STRESS RELIEF - YES NO

CONT.ON SERIES A

PER SAES-W-011 TABLE 17.6.2.1

100% X-RAY SPOT X-RAY 01-SAMSS-10

56"-P-1742-6CA2P06- _01 9. TESTING SHOP HYDROSTATIC TEST - YES NO

GASKETS THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

/ B53 FLANGED. HYDROSTATIC TEST PRESSURE PER HYDROTEST DIAGRAM

-------

012939-001 5 4.5 MM THK GASKETS SPIRAL-WOUND, SS316 36 G6_3CE1P2 1 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING

DWG. NO. BA-752422 WINDINGS, FLEXIBLE GRAPHITE FILLED, SPECIFICATION SAES-L-105 CLASS 6CA2P06 .

ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

WITH CARBON STEEL OUTER RING AND

56"NS E 134714

SS316 INNER RING, ASME B16.20, ASME 11. INSULATION

N 402102 B16.47 SERIES A, CL 600 INSULATION TYPE & THK. ON DWG. PP 40MM

12. TIE-IN LOCATIONS AND DETAILS SHALL BE FIELD VERIFIED BEFORE START OF WORK.

EL.117881

BOLTS 13. FOR SMALL BORE LINES (UPTO 1-1/2") DIMENSIONS, ROUTING & SUPPORTING SHALL

36"-P-0001-6CA2P06 ----- BE FIELD ADJUSTED.

56X36"NS 6 BOLTING ASTM A320 GR.L7M STUD BOLTS, 2 1/2 B_XCSXP3 28 14. ALL DIMENSIONS AND COORDINATES ARE IN MM. CONTRACTOR TO FIELD VERIFY ALL

SEMI-FINISHED HEAVY PATTERN, ASTM DIMENSIONS PRIOR TO CONSTRUCTION.

15. FOR INTERNAL LINED PIPE, LINING SHALL BE DONE AFTER SPOOL FABRICATION

A194 GR.7M, W/2 HEAVY HEX NUTS,

& COMPLETION OF ALL HOT WORKS.

480.0MM BOLT LENGTH

S9 S7 16. FOR GALVANIZED PIPE, GALVANIZING SHALL BE DONE AFTER SPOOL FABRICATION

56"NS PIPE SUPPORTS

& COMPLETION OF ALL HOT WORKS.

IS01-36 SH02-B-36-450-LT-4

1 -------------

7 PIPE SUPPORT 36 SH02-B-36-450-LT-4 2 SPOOLS TO BE FABRICATED BY VENDOR

2 S8 NO. WEIGHT NO. WEIGHT

MARK NO. SIZE MARK NO. SIZE

PIECES LBS PIECES LBS

28 WA01-36-500-LT 8 PIPE SUPPORT 36 WA01-36-500-LT 2

92

9 PIPE SUPPORT 36 IS01-36 2

2

28

1

09

S9 S7

1

IS01-36

1

SH02-B-36-450-LT-4

3253

SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

62

3 53 NO.

PIECES

MARK NO. SIZE

NO.

PIECES

MARK NO. SIZE

45? 1

2 1986

91 19 F4 G5 B6

32 86 36

0 "N

59 S

17 7991

8

462

1 S8 EL.112641 CONT.ON

.1

EL SHT 2

WA01-36-500-LT

E 152304

REFERENCE DRAWINGS

N 390965

EL.112641 DWG. CONTROL FOR J.O. 10-12862-0001 TD-718027

PIPING PLAN BA-752286

HYDROTEST DIAGRAM TA-011931001

REVISION VALIDATION

THIS REVISION NO. IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

0F1

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

10-12862-0001-029

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

FAW LAK ASD AHB

06/12/23 06/12/23 06/12/23 06/12/23

REV.NO.DATE REVISION DESCRIPTION

0F1 06/12/23 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-12862-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

STRESS SYSTEM (SYS-) 004

PIPING CLASS 6CA2P06 SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

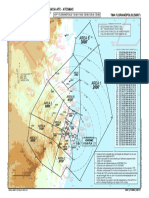

P & ID No. BA-747591001 ISO 36"-P-0001-6CA2P06-B97

ISO

OPER/DESN PRESS.(psig) 1011 / 1305

INLET & GAS TREATMENT SHAYBAH

OPER/DESN TEMP.( F) 140 / 230

INLET FACILITIES

FLUID PHASE VAPOR

MODULE NO: SHAYBAH SAUDI ARABIA

PAINT SPEC (APCS-) 1D

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

LINE ID B97-P-0001-B97-01

B97 L TB-013482 001 0F1

Saudi Aramco 5994 ENG. (09/03)

RESTRICTED VECTOR CADD-05

18/03/2024 16:50:55 Wison

You might also like

- WMS Basecourse Aggregate B TrialDocument10 pagesWMS Basecourse Aggregate B Trialdyaharsya100% (1)

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Lifting Plan For PC Spun Pile 400 10 UP Crawler Crane 55 TonDocument11 pagesLifting Plan For PC Spun Pile 400 10 UP Crawler Crane 55 Tonwahyu widartoNo ratings yet

- An Experimental Study On The Properties of Concrete After Partial Replacement of Fine Aggregates With Waste Tyre Crumb RubberDocument25 pagesAn Experimental Study On The Properties of Concrete After Partial Replacement of Fine Aggregates With Waste Tyre Crumb RubberSelva Prakash100% (1)

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- TB 661291 001Document1 pageTB 661291 001Khalid OnlyNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- TB-659651-003 Rev 0F1Document1 pageTB-659651-003 Rev 0F1Khalid OnlyNo ratings yet

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- TB-659770-002 Rev 0F1Document1 pageTB-659770-002 Rev 0F1Khalid OnlyNo ratings yet

- Erection Materials: DetailDocument1 pageErection Materials: DetailMohammed Omer AliNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- TB-659631-001 Rev 0F2Document1 pageTB-659631-001 Rev 0F2Khalid OnlyNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- 6012-Storage ShedDocument5 pages6012-Storage ShedTigermarinerNo ratings yet

- Smwsasbt CPG SWD Tu000 MS PKG 070801Document11 pagesSmwsasbt CPG SWD Tu000 MS PKG 070801MassimilianoTerenziNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- Asfa Roma 400606 PS02Document1 pageAsfa Roma 400606 PS02joeripaNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Asfa Roma 400699 PS02Document1 pageAsfa Roma 400699 PS02joeripaNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24622 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24622 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- 3 Conn. To 306F-851A/TSTCR2 2 in RFFE 300 G1 B2 SA1 306TEDocument1 page3 Conn. To 306F-851A/TSTCR2 2 in RFFE 300 G1 B2 SA1 306TESunil Kumar GuptaNo ratings yet

- Smwsasbt CPG STM Sn100 MB PKG 030701 (Se)Document48 pagesSmwsasbt CPG STM Sn100 MB PKG 030701 (Se)MassimilianoTerenziNo ratings yet

- 1778 4601 TH DWG 003e 4Document1 page1778 4601 TH DWG 003e 4Asyifa AldanaNo ratings yet

- Maxwell DTJC 3015-01 G.A. (Double Wheel)Document1 pageMaxwell DTJC 3015-01 G.A. (Double Wheel)CHIRAG PATELNo ratings yet

- Girder DWGDocument1 pageGirder DWGAKILESH RAONo ratings yet

- Department of Agrarian Reform R-3Document86 pagesDepartment of Agrarian Reform R-3abadfredNo ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Drive ManualDocument85 pagesDrive ManualsudhakarraomNo ratings yet

- Welding Joint: NorthDocument1 pageWelding Joint: Northrio arthabintekNo ratings yet

- Starbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendDocument56 pagesStarbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendMmr Pré MoldadosNo ratings yet

- 1778 4601 TH DWG 003J 1Document1 page1778 4601 TH DWG 003J 1Asyifa AldanaNo ratings yet

- TURK PLAST (UPVC) 01-02-2021 OutstationDocument1 pageTURK PLAST (UPVC) 01-02-2021 OutstationicrcgisNo ratings yet

- 005 WPK005-R-2019-RT (AMA Appr) PDFDocument14 pages005 WPK005-R-2019-RT (AMA Appr) PDFMarcus AntoniusNo ratings yet

- Consumption of Rake Items For 2023-24 (DOOR)Document1 pageConsumption of Rake Items For 2023-24 (DOOR)Sovan ChakrabortyNo ratings yet

- SBXF TMA FlorianópolisDocument1 pageSBXF TMA Florianópolisazx72No ratings yet

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- J-22 Magnetic Particle Inspection Report No.59Document1 pageJ-22 Magnetic Particle Inspection Report No.59Yousab CreatorNo ratings yet

- General Notes: Nashville BMWDocument1 pageGeneral Notes: Nashville BMWAli KhalafNo ratings yet

- Access Service View: (YYYY/MM/DD) (YYYY/MM/DD)Document2 pagesAccess Service View: (YYYY/MM/DD) (YYYY/MM/DD)RubenNo ratings yet

- H2S Removal Unit: NotesDocument1 pageH2S Removal Unit: NotesHsein WangNo ratings yet

- Composition (PPM) Part No Part Name Material Result Report No. Nama Supplier Tahun ReleaseDocument1 pageComposition (PPM) Part No Part Name Material Result Report No. Nama Supplier Tahun ReleaseZacky Al MubaroqNo ratings yet

- Hvac Standard DetailsDocument3 pagesHvac Standard DetailsVaisakh C&TNo ratings yet

- Appendix I List of Attached Conceptual & Reference Drawings PTS-20WM319Document13 pagesAppendix I List of Attached Conceptual & Reference Drawings PTS-20WM319Durgaprasad RyaliNo ratings yet

- FM-200 - 068-007 SHT of 1 Installation & Mounting DetailsDocument1 pageFM-200 - 068-007 SHT of 1 Installation & Mounting DetailsAhmed SweetNo ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- Kent STructural Engineer JobDocument1 pageKent STructural Engineer Jobhaseebrazvi1No ratings yet

- Material Submittal LogDocument19 pagesMaterial Submittal LogJericFuentes100% (1)

- CC Road Karnataka Nagepalli-WEDocument79 pagesCC Road Karnataka Nagepalli-WEVannurSwamyNo ratings yet

- Building MaterialsDocument45 pagesBuilding MaterialsWyncie CariñoNo ratings yet

- 2.0 Cegeotech2 Lec m1 (Intro)Document19 pages2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaNo ratings yet

- Conbextra Cable GroutDocument4 pagesConbextra Cable Groutm.basim.technitalNo ratings yet

- NEW Atlanta Permaline 2019Document2 pagesNEW Atlanta Permaline 2019gregNo ratings yet

- Resume Paulo PolisticoDocument2 pagesResume Paulo PolisticoVienna Eleize PortillanoNo ratings yet

- Sca 4 IDocument324 pagesSca 4 IPoorna AbeywardanaNo ratings yet

- Chabane Hadj Mohammed QAQC/ NDT Inspector: Since Sep 2020Document3 pagesChabane Hadj Mohammed QAQC/ NDT Inspector: Since Sep 2020med chabaneNo ratings yet

- #10 VHB SGT-APT Design SummaryDocument2 pages#10 VHB SGT-APT Design SummarySenthil KumarNo ratings yet

- Corrosion Performance of Weathering Steel Structures: Iht: IhtDocument6 pagesCorrosion Performance of Weathering Steel Structures: Iht: IhtagungbasNo ratings yet

- PT Argo TuhuDocument22 pagesPT Argo TuhuWulan EgidiaNo ratings yet

- MR SmallDocument42 pagesMR SmallDeepti100% (1)

- CRSI Technical Note - Stainless Steel RebarDocument8 pagesCRSI Technical Note - Stainless Steel Rebaralum_91No ratings yet

- Cico ProfileDocument109 pagesCico ProfileDjelloul BadroNo ratings yet

- Boq - Fencing EstimateDocument2 pagesBoq - Fencing EstimateAugustine Believe100% (4)

- ESP SURVEY PROGRAMME FOR ALL SHIPS v13.1 2021Document28 pagesESP SURVEY PROGRAMME FOR ALL SHIPS v13.1 2021Elang ANo ratings yet

- Planbar 1/1/2019 Hotfix: Precast Software Engineering GMBHDocument5 pagesPlanbar 1/1/2019 Hotfix: Precast Software Engineering GMBHAnliNo ratings yet

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pages84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoNo ratings yet

- SOR Volume 2 BuildingDocument266 pagesSOR Volume 2 Buildingpankajsamiksha0% (1)

- Boq 1Document13 pagesBoq 1raja MNo ratings yet

- DRA Sholinganallur Terrace Electrical Layout1Document1 pageDRA Sholinganallur Terrace Electrical Layout1J.KANIMOZHI SURIYANo ratings yet

- Renaissance Architecture: History of Architecture-IVDocument34 pagesRenaissance Architecture: History of Architecture-IVVanshika DograNo ratings yet

- Roof ArchitionalDocument124 pagesRoof ArchitionalRusscel MarquesesNo ratings yet

- 07 42 13 Mcelroy Metal MCPDocument15 pages07 42 13 Mcelroy Metal MCPMelvin SanchezNo ratings yet

- Operation and Maintenance Manual Gooseneck GN 30 TSDocument17 pagesOperation and Maintenance Manual Gooseneck GN 30 TSGioeNo ratings yet

- Model BKR Premium Cement Retainer - Mechanical SetDocument1 pageModel BKR Premium Cement Retainer - Mechanical SetCarlos HolguinNo ratings yet