Professional Documents

Culture Documents

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

Uploaded by

mohamed.moussa2506Copyright:

Available Formats

You might also like

- Typical AMSA Oral QuestionsDocument37 pagesTypical AMSA Oral Questionsrigel94% (17)

- Sample Documents For Crew EmploymentDocument45 pagesSample Documents For Crew EmploymentKrzysztof Majdzinski100% (2)

- Toll Management System Design PresentationDocument42 pagesToll Management System Design Presentationsarath71% (24)

- Shippers Seafood Carriage by Air Declaration June22Document1 pageShippers Seafood Carriage by Air Declaration June22Krishni DomahNo ratings yet

- Annual Surveys/intermediate Surveys/docking Surveys Survey ChecklistDocument13 pagesAnnual Surveys/intermediate Surveys/docking Surveys Survey Checklistthomaskurian777100% (1)

- AMSA Ship Initial Inspection ChecklistDocument13 pagesAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- Material Handling Control ProcedureDocument9 pagesMaterial Handling Control ProcedureBhisamS Salleh100% (2)

- Volvo d12Document18 pagesVolvo d12ANH LÊ67% (6)

- 15.vessel Safety Enforcement Inspections ChecklistDocument8 pages15.vessel Safety Enforcement Inspections ChecklistIan Kristian BelgicaNo ratings yet

- Vessel Inspection Checklist01Document2 pagesVessel Inspection Checklist01Prasanth Varrier100% (3)

- Survey Checklist For Ships Carrying Liquefied Gases in BulkDocument13 pagesSurvey Checklist For Ships Carrying Liquefied Gases in BulkAhmad Imran100% (2)

- Plipdeco Haulier Inspection ChecklistDocument2 pagesPlipdeco Haulier Inspection ChecklistHemas AvicennaNo ratings yet

- Owner's Manual: Downloaded From Manuals Search EngineDocument12 pagesOwner's Manual: Downloaded From Manuals Search EnginegragrNo ratings yet

- A Case Study of Southwest AirlinesDocument4 pagesA Case Study of Southwest AirlinesishmaelNo ratings yet

- COMDTINST M16672.2 Navigation Rules International InlandDocument220 pagesCOMDTINST M16672.2 Navigation Rules International Inlandeckster16No ratings yet

- DIY 2x72 Belt Grinder For Knife MakingDocument4 pagesDIY 2x72 Belt Grinder For Knife MakingJamespagan0% (1)

- ST Kitts & Nevis International Ship RegistryDocument11 pagesST Kitts & Nevis International Ship RegistrybthbidkesNo ratings yet

- Maintenance Guide CL (Lloyd's Reg. Cargo Vessels)Document22 pagesMaintenance Guide CL (Lloyd's Reg. Cargo Vessels)loai allamNo ratings yet

- Instructions To Maritime Cook Islands Inspector: Part A: General InformationDocument11 pagesInstructions To Maritime Cook Islands Inspector: Part A: General InformationMariyath Muraleedharan KiranNo ratings yet

- Documents - Pub LR Annual SurveysDocument13 pagesDocuments - Pub LR Annual SurveysMohammed Ahemd HassanNo ratings yet

- General Survey Report PDFDocument20 pagesGeneral Survey Report PDFEmmNo ratings yet

- Checklist 221225002317Document9 pagesChecklist 221225002317ocean trotter worldwideNo ratings yet

- Ship Certificates & Documents BookDocument74 pagesShip Certificates & Documents BookSherry GodwinNo ratings yet

- Annual, Docking, Intermediate SurveyDocument13 pagesAnnual, Docking, Intermediate Surveyargentum19619692No ratings yet

- Vessel Inspection Checklist - Last Updated 06.08.15Document3 pagesVessel Inspection Checklist - Last Updated 06.08.15Dadang KurniaNo ratings yet

- Survey ChecklistDocument17 pagesSurvey Checklistssshewale1988No ratings yet

- Amsa 249 Master Oral Exam ChecklistDocument4 pagesAmsa 249 Master Oral Exam ChecklistsdpojohnnyNo ratings yet

- SCV2 V2 December 2013 PDF FormatDocument30 pagesSCV2 V2 December 2013 PDF FormatNicandro PorcelliNo ratings yet

- Allianc - Foam AkbarDocument1 pageAllianc - Foam Akbarps projectNo ratings yet

- MZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Document24 pagesMZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Lj NecesitoNo ratings yet

- Mpa Vessel's ChecklistDocument2 pagesMpa Vessel's ChecklistmeridionalmototraverseNo ratings yet

- Certificates of Proficiency Requirement For SeafarersDocument10 pagesCertificates of Proficiency Requirement For SeafarershutsonianpNo ratings yet

- MLC Compliance Checlist Rev 0 30th Nov 18Document18 pagesMLC Compliance Checlist Rev 0 30th Nov 18Dini ANNo ratings yet

- Survey ChecklistDocument6 pagesSurvey ChecklistDIPIN PNo ratings yet

- Epirb Test Report - With LetterheadDocument1 pageEpirb Test Report - With LetterheadVarun K.JNo ratings yet

- Foreign Vessel Exam Book For Mtsa/Isps Code Compliance: United States Coast GuardDocument8 pagesForeign Vessel Exam Book For Mtsa/Isps Code Compliance: United States Coast GuardDiana MoralesNo ratings yet

- Onboard Routine Maintenance Check SheetDocument23 pagesOnboard Routine Maintenance Check SheetExpertise MlcsNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaPKNo ratings yet

- Tug and Barge Survey Report PDFDocument14 pagesTug and Barge Survey Report PDFDevi SamosirNo ratings yet

- AD-04 Certificate Status (New Format)Document8 pagesAD-04 Certificate Status (New Format)Rachit SharmaNo ratings yet

- Vessel Inspection ChecklistDocument2 pagesVessel Inspection ChecklistIbrahim KashmNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaDimosNo ratings yet

- Surfer Vessel Inspection Form - V2Document12 pagesSurfer Vessel Inspection Form - V2VICTORNo ratings yet

- Survey Report FormDocument28 pagesSurvey Report FormJavier Rayleigh100% (2)

- Barge Insurance FormDocument12 pagesBarge Insurance FormAnonymous ycFeyuLAtNo ratings yet

- AMSA579 - Application For NS VesselDocument3 pagesAMSA579 - Application For NS Vesselinmran.gNo ratings yet

- Masters OralsDocument107 pagesMasters OralsKiran Krishnamoorthy100% (2)

- Chief Mate Oral Examination Checklist: (Aide Memoire)Document2 pagesChief Mate Oral Examination Checklist: (Aide Memoire)Shahrior MahmudNo ratings yet

- VA Ramp Safety Observation Checklist - SafetyCultureDocument10 pagesVA Ramp Safety Observation Checklist - SafetyCultureshabaneethuaeNo ratings yet

- IMSBC Flow ChartDocument1 pageIMSBC Flow ChartMahesh Singh100% (1)

- Vessel Safety Check (VSC)Document2 pagesVessel Safety Check (VSC)Douglas PassarelliNo ratings yet

- SWP05 - Form 06Document10 pagesSWP05 - Form 06ahmedNo ratings yet

- List of Ship CertificateDocument3 pagesList of Ship CertificateBrian PhamNo ratings yet

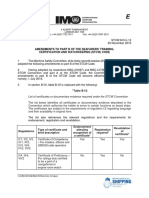

- Amendments To Part B of The Seafarers' Training, Certification and Watchkeeping (STCW) CodeDocument3 pagesAmendments To Part B of The Seafarers' Training, Certification and Watchkeeping (STCW) CodearmanNo ratings yet

- Annual, Docking, Intermediate SurveyDocument29 pagesAnnual, Docking, Intermediate SurveyAjay Singh100% (1)

- Questions For Interview - ANSWEREDDocument4 pagesQuestions For Interview - ANSWEREDalbaraka.shippingNo ratings yet

- Equipment Test Mooring and Lifting Equipmenty NavalDocument1 pageEquipment Test Mooring and Lifting Equipmenty NavalPingarilhoNo ratings yet

- USCG Foreign VSL Exam Booklet MTSA-ISPS ComplianceDocument9 pagesUSCG Foreign VSL Exam Booklet MTSA-ISPS CompliancePricop Marius OctavianNo ratings yet

- VDR 01-2012Document3 pagesVDR 01-2012Ndipo BecklyNo ratings yet

- Certification and Class Reports: Checklist Based On PSC DeficienciesDocument16 pagesCertification and Class Reports: Checklist Based On PSC DeficienciesVengat VenkitasamyNo ratings yet

- 2020 002 AMSA Pre Arrival CkecklistDocument6 pages2020 002 AMSA Pre Arrival Ckecklistdominic dmelloNo ratings yet

- s04.s4 - Material - Maritime Regulations - Documentation IIDocument38 pagess04.s4 - Material - Maritime Regulations - Documentation IILAWRENCE OLIVER ESPINOZA VALDERRAMANo ratings yet

- 19425-Lge-Rigel X-30507.Document9 pages19425-Lge-Rigel X-30507.aripinetijaswanthNo ratings yet

- O.okeniyi - R. 2021Document3 pagesO.okeniyi - R. 2021HenryNo ratings yet

- Masters OralsDocument74 pagesMasters Oralsssabih75No ratings yet

- Encyclopaedia of International Aviation Law: Recueil Des Textes De Lois Relatifs AFrom EverandEncyclopaedia of International Aviation Law: Recueil Des Textes De Lois Relatifs ANo ratings yet

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- 61f93 Ats2015 Exhibitorlistfloor AnDocument45 pages61f93 Ats2015 Exhibitorlistfloor AnkumarneerajNo ratings yet

- DIAGRAMA-ventanas Electricas SparkevDocument3 pagesDIAGRAMA-ventanas Electricas SparkevHarvey LaresNo ratings yet

- LO: How Do We Represent Journeys On A Distance - Time GraphDocument23 pagesLO: How Do We Represent Journeys On A Distance - Time GraphMarta Carbajosa Fernandez Carbajosa FernandezNo ratings yet

- AMD DEL: Sen / Anubhav MR AI0835Document1 pageAMD DEL: Sen / Anubhav MR AI0835Nisha SagarNo ratings yet

- MAN Maxicosi Mobi 2011 LR ENSVNOFI PDFDocument56 pagesMAN Maxicosi Mobi 2011 LR ENSVNOFI PDFAnonymous NM63QfBNo ratings yet

- Biology For CAPE Unit 1 Chapter 3 Answers PDFDocument8 pagesBiology For CAPE Unit 1 Chapter 3 Answers PDFGerrald RamoutarNo ratings yet

- F.O Based Thermal Power PlantDocument98 pagesF.O Based Thermal Power PlantMuhammad AsifNo ratings yet

- Transas ECDIS BrochureDocument20 pagesTransas ECDIS Brochureahlee08No ratings yet

- Suspension Control System: SectionDocument32 pagesSuspension Control System: SectionzhenyupanNo ratings yet

- BhagalpurDocument11 pagesBhagalpurshailesh37100% (1)

- The TVS GroupDocument9 pagesThe TVS GroupSanjeev KumarNo ratings yet

- NG ExistingDocument2 pagesNG ExistingdeepdixitNo ratings yet

- The Hippie Lieutenant: Vietnam "War" RemembrancesDocument101 pagesThe Hippie Lieutenant: Vietnam "War" RemembrancesAnthony St. John100% (1)

- My FerrariDocument11 pagesMy FerrariManuel Alcayde BolañosNo ratings yet

- Application of Variable Speed Drive (VSD) in Electrical Motor Energy SavingDocument8 pagesApplication of Variable Speed Drive (VSD) in Electrical Motor Energy SavingTenzin JamtshoNo ratings yet

- Igi DPRDocument137 pagesIgi DPRNivedita AggarwalNo ratings yet

- Atr72 QBDocument65 pagesAtr72 QBraiday8490% (10)

- Extension: The City of The FutureDocument2 pagesExtension: The City of The Futurebenilde bastidaNo ratings yet

- CM 03 - Cargo Handling Risk AssessmentDocument3 pagesCM 03 - Cargo Handling Risk AssessmentDmitriy100% (1)

- Kenya PVoCDocument2 pagesKenya PVoCkevotooNo ratings yet

- Sh70 Orec Tondeuse Debroussailleuse Vue EclateeDocument23 pagesSh70 Orec Tondeuse Debroussailleuse Vue EclateeArctic SilverNo ratings yet

- Tadano TM Zr500xlDocument6 pagesTadano TM Zr500xlRafael Durio EtgarNo ratings yet

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

Uploaded by

mohamed.moussa2506Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

TDL-018r4 Annex 1 - IMMARBE Self-Inspection Checklist - Unlocked (1) 1

Uploaded by

mohamed.moussa2506Copyright:

Available Formats

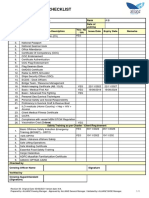

IMMARBE

Annex 1 -Self-Inspection Checklist

The Belize Administration requires the Owners/ISM Operators to provide their Master’s with the Self-

Inspection Checklist which is to be submitted to IMMARBE as per MMN-19-006r3 along with the

current crew list.

Maridive-232 IMO NO: 9327970

SHIP NAME:

GROSS TONNAGE: 3787

TYPE: DSV Date of submission: 27/03/2024

Name of ISM Company: MARIDIVE CO.

SUEZ - EGYPT

Port(s) to be called:

CERTIFICATES & DOCUMENTATION

Valid & Correctly Endorsed

(as applicable)

Certificate YES NO N/A

Flag Registry Certificate YES

Radio Station License YES

Safe Manning Certificate YES

Bunker Certificate YES

Class Certificate YES

Cert. of Insurance or other Financial Security in respect of civil Liability for

Nairobi International Convention on the removal of wrecks YES

International Tonnage Certificate (ITC ‘69) YES

International Load Line Certificate (ILLC) YES

Cargo Ship Safety Construction Certificate (CSSCC) YES

Cargo Ship Safety Equipment Certificate (CSSEC) YES

Cargo Ship Safety Radio Certificate (CSSRC) YES

International Oil Pollution Prevention Certificate (IOPPC) YES

International Sewage Pollution Prevention Certificate (ISPPC) YES

Annex 1 – IMMARBE Self-Inspection Checklist 1 TDL-018r4

International Air Pollution Prevention Certificate (IAPPC) YES

International Energy Efficiency Certificate (IEEC) YES

Chemical Fitness Certificate N/A

Gas Fitness Certificate N/A

Grain Loading Certificate N/A

Document of Compliance with the Special Requirements for Ships Carrying

Dangerous Goods

N/A

Certificate of Inspection of Crew Accommodation (CICA) N/A

Safety Management Certificate (SMC) YES

Document of Compliance (DOC) YES

International Ship Security Certificate (ISSC) YES

Maritime Labour Certificate (MLC) YES

Long Range Identification Tracking (LRIT) YES

Antifouling System Statement of Compliance (AFS-SoC) YES

Ballast Water Management Statement of Compliance (BWMC-SoC) YES

Carriage of Solid Bulk Cargoes Certificate N/A

Exemption Certificate(s) if any YES

STCW

Addressed

ITEM YES NO N/A

Crew on board is in accordance with the requirements as per Safe Manning

Certificate

YES

Master, deck officers, engineer officers and ratings have a Certificate of

competence available

YES

Officers’ licenses have endorsements by the Flag Administration as appropriate YES

Crew members have a valid medical examination Certificate YES

New crew members on board are familiar with their duties, responsibilities, and

the safety equipment YES

Rest hours documentation of the crew duly signed and readily available YES

Table of working hours is posted and is easily accessible YES

Seafarers with security duties possess security training YES

Annex 1 – IMMARBE Self-Inspection Checklist 2 TDL-018r4

HULL

Addressed

ITEM YES NO N/A

Ship’s side shell plates without damage and excessive wastage (as far as visible) NO

Bulwarks, handrails, and cat walks without signs of damage and excessive wastage NO

Cargo holds structure without damages and excessive wastage (e.g. bulkheads,

frames, brackets, tank tops etc.)

N/A

Hatch cover arrangements including gaskets in good condition to close weather

tight, without signs of wastage

YES

All closing appliances in good working condition YES

Ventilators and air pipes including any closing appliances properly working

without signs of damage or wastage and able to close air-tight

YES

Closing devices of all sounding pipes properly working YES

Weather tight doors and small access hatches in good condition and close

weathertight

YES

Draft marks and Plimsoll marks painted in different colour NO

Plimsoll marks permanently marked on hull in accordance with the Load Line

Certificate

NO

MACHINERY & POLLUTION PREVENTION

Addressed

ITEM YES NO N/A

Electric cable arrangements properly installed and insulated (no loosing wires) YES

Light covers properly fixed YES

Around the electrical main switchboard is provided an insulation mat YES

Engine room in clean condition YES

Main propulsion system is working properly YES

Auxiliary engine and power system including 100% power redundancy working

properly

YES

Emergency generator arrangement for immediate supply of electrical power

working properly

YES

Jacketed piping system on high pressure fuel lines properly installed and alarms

working

YES

Exhaust and vapour pipes properly insulated YES

Engine alarm arrangements working properly YES

All engines and piping systems free of leakage YES

Anchoring equipment in good condition YES

Mooring ropes in good condition YES

Oily water separation system in good working condition together with testing

arrangements and the crew is familiar with the system and its use

YES

15ppm alarm and stopping arrangements in good working condition YES

Annex 1 – IMMARBE Self-Inspection Checklist 3 TDL-018r4

Piping arrangements in good condition (no signs of damage and/or corrosion) YES

Bilges and other machinery areas free of excessive oil YES

Oil record book is updated, entries are correct and periodically signed by the

Master (codes used are correct and tanks listed as per IOPP Certificate)

YES

Manuals for tankers, chemical tankers, and gas carriers available on board N/A

SOPEP available and approved onboard (includes updated communication data of

Focal Point List as per IMO)

YES

Sewage treatment plant in good working conditions YES

SMPEP available on board (for ships certified to carry Noxious Liquid substances

in bulk) with updated Focal Point List

N/A

Garbage is collected and separated in closable bins as required and garbage record

book entries are correct

YES

Onboard readily available proof that while navigating in restricted areas low

sulphur fuel is used N/A

Crew is familiar with the sewage system and the treatment plan. Necessary

drawings available on board

YES

LIFE SAVING APPLIANCES

Addressed

ITEM YES NO N/A

Lifeboats with all parts in good condition without wastage, blocks and release

mechanisms properly maintained, and the crew is familiar with safe use of N/A

launching and release gear

Lifeboat inventory complete and in good condition with dates of expiration for

pyrotechnics and foodstuff rations recorded and not outdated N/A

Rescue boats complete and in proper condition with the inventory stored as

required

YES

Lifeboat/rescue boat engines in good working condition and starting easily YES

Life rafts and launching arrangements in good working condition and properly

marked

YES

Hydrostatic release for the rafts correctly connected and not outdated YES

Equipment for embarkation for additional life raft available (raft at the bow) N/A

Launching arrangements for rescue boats and life rafts including limit switches in

good condition and without wastage YES

Annual thorough examination of the launching appliances and on-load release

gear has been carried out and relevant documentation available onboard

YES

Embarkation ladders including their shackles and pad eyes on deck in good

condition

YES

Wire falls of all launching/recovery arrangements in good condition and renewed

as required

YES

Lifebuoys (including reflective tape, correct ship’s name/home port and lights

with non-outdated batteries or smoke signals) available in sufficient amount and YES

in good condition

“Heavy” lifebuoy (4.5kg) attached to the smoke/light buoy at bridge wings in a

free fall arrangement

YES

Lifejackets (including whistles plus lights and non-outdated batteries) found in

good condition and sufficient amount as per Certificate. Additional lifejackets YES

available on board

Annex 1 – IMMARBE Self-Inspection Checklist 4 TDL-018r4

Line throwing appliances complete with expiration dates of the pyrotechnic units YES

Parachute distress signals available on board in sufficient quantities and in good

condition with expiration dates not outdated, found on the bridge in an YES

appropriate containment which is marked appropriately

Immersion suits (including lights and special attachments) available for all

personnel onboard and stored in good condition. Additional suits available at YES

remote working stations as required

Emergency illumination at all survival craft stations sufficiently working also

illuminating the ship’s side and the instructions posted

YES

Lifeboat release and retrieval system comply with paragraphs 4.4.7.6.4 to

4.4.7.6.6 of the LSA Code, as amended by resolution MSC.320(89) and relevant N/A

documentary evidence can be found on board

FIRE FIGHTING APPLIANCES

Addressed

ITEM YES NO N/A

Fire main piping and all hydrants in good condition without signs of corrosion or

wastage and without soft patches. Also, couplings and valves free of leakages

YES

Fire pumps including prime mover in engine room in good working condition and

with sufficient delivery of water pressure

YES

Emergency fire pump including prime mover in proper working condition with

sufficient suction and delivered water pressure. Also, exhaust lines properly YES

insulated

Fire stations (including equipment of hoses, nozzles, spanners) in good condition.

More specifically, nozzle spray adjustments workable and hoses without YES

deterioration

Portable fire extinguishers available on board in good condition as per Fire &

Safety Plan (due dates for required servicing recorded and not outdated)

YES

Fireman’s outfit available in required number and good condition (i.e. complete

with helmet, clothes, lifeline, lamp, and other required requisites)

YES

Breathing apparatuses in good condition and ready to use with bottles including

spare bottles filled

YES

Fixed firefighting systems for engine room and cargo spaces in good working

condition (e.g. filling status of gas bottles or foam tanks)

YES

CO2 room properly locked and the key readily available YES

Fire detection arrangements properly working at all detection points YES

Fire extinguishing arrangement in paint locker as required in place and in proper

working condition

YES

Fire dampers and ventilation closing appliances (e.g. gaskets, handles, screws and

other) in good working condition. Fire flaps inside trunks checked and closing YES

properly

Fire doors closing properly using their automatic closing devices and not fitted

with holdbacks

YES

Quick closing devices for tank shut-off and emergency stop of pumps and fans in

good working condition

YES

Emergency Escape Breathing Devices (EEBDs) available in required amount (plus

additional training units) and distributed as per fire plan within superstructure YES

and engine room and under full pressure

International shore connection including reduces piece with appropriate bolds

and nuts available as per Fire & Safety plan

YES

Annex 1 – IMMARBE Self-Inspection Checklist 5 TDL-018r4

NAVIGATION

Addressed

ITEM YES NO N/A

Nautical publications including pilot books, list of lights, sailing directions, tide

tables, code of signals, IAMSAR books used for the next voyage updated to the YES

latest available amendments /corrections

Nautical charts to be used for the next intended voyage updated to the latest

available Notice to Mariners (if applicable ECDIS system updated to latest YES

amendments)

System for correcting all nautical publications on board has been developed YES

Passage plan from berth to berth available on board YES

Navigational instruments (e.g. radar, echo sounder etc.) in proper condition YES

Steering gear including rudder angle indicator as well as emergency steering gear

including switch-over devices in good operating condition and the steering gear YES

alarm functioning. Also, instructions for switch-over handling posted in vicinity

Daylight shapes in operational condition YES

Daylight signalling lamp and the independent power supply in good operational

condition

YES

Automatic position indicator (e.g. GPS) available on board and in good condition YES

Communication systems between bridge - engine room and bridge – steering gear

room is provided and working properly

YES

NAVTEX receiver in good working condition and spare paper is available YES

Echo sounder in good working condition YES

Magnetic steering compass in good working condition and properly visible from

steering position. Spare magnetic compass (if provided) in good working YES

condition. Lastly, updated calibration table available

VDR (or S-VDR) installed correctly onboard and connected to respective devices YES

AIS system installed and constantly switched on YES

LRITS in good working condition and test documentation onboard as required YES

Navigational equipment verified is as required in the Safety Record “Form E” YES

RADIO EQUIPMENT

Addressed

ITEM YES NO N/A

GMDSS transmitting and receiving equipment components including sources of

energy in proper working condition

YES

Radio operator assigned onboard is familiar with cancellation procedures for false

distress alarms

YES

Radio logbook is kept as required and includes records of tests YES

Portable VHF handheld radios for survival craft including batteries with spares/

recharger are in good working condition.

YES

Antenna systems without any signs of corrosion or damage YES

Radar Transponders in satisfying working condition and ready to be used in case of

emergency. Also, they are serviced in accordance with manufacturer’s YES

requirements by shore service

Annex 1 – IMMARBE Self-Inspection Checklist 6 TDL-018r4

Freefall boat arrangement (if onboard) is fitted with one Radar transporter within

the freefall lifeboat

N/A

EPIRB is correct and float free position. The life date of battery and hydrostatic

release valid

YES

EPIRB test certificate readily available YES

Radio publications and manuals updated on board YES

Radio License on board valid YES

Reserve sources of energy (batteries) properly maintained and in working

condition

YES

SAFETY

Addressed

ITEM YES NO N/A

Working language of the ship established and recorded in the logbook YES

Updated fire & safety plans posted in accommodation alleyways clearly readable

and show a sign of approval. One copy if the plan is stored in marked and weather YES

tights container outside the accommodation area

SOLAS training manuals available, with specific instructions for the appliances

installed onboard and written in the working language

YES

Instruction manuals for onboard maintenance of life-saving appliances available

and understood by all crew members. Regular maintenance has been recorded

YES

A plan or program of maintenance is readily available YES

Operating instructions for lifesaving appliances posted on scene and under

emergency lighting. Instructions written in a language understood by all crew YES

members

Table of life saving signals poster on the bridge YES

Drills for firefighting, abandon ship, rescue boat operation and oil spill fighting

YES

have been carried out satisfactorily and the dates are recorded in the logbook

Muster list is updated and written in the working language of the ship. Substitutes

for key personnel are included and the muster list is posted on the bridge, in YES

engine control room and accommodation spaces

Paint materials stored inside the designated paint locker only YES

Escape ways accessible, free of obstructions and properly illuminated YES

IMO symbols properly used for marking escape ways and locations of emergency

equipment

YES

Pilot ladders and related boarding arrangements clean and in good condition YES

Crew working on the bridge is familiar with the steering gear switch-over

procedures and with the use of emergency steering device

YES

Key engine crew is familiar with emergency power arrangements YES

Key persons for firefighting are familiar with starting emergency fire pump YES

Designated lifeboat/rescue boat crew is familiar with starting the engines YES

Public alarm systems as for general alarm are working properly YES

Engineer’s alarm of unmanned machinery system is working properly YES

Annex 1 – IMMARBE Self-Inspection Checklist 7 TDL-018r4

ISM

Addressed

ITEM YES NO N/A

Crew is familiar with the company’s safety and environmental protection policy YES

ISM manual is readily available on board YES

All documentation available onboard is written in a language understood by the

crew

YES

Senior ship officers can identify the “designated person” YES

Procedures and data are available and updated to establish contact with shore

management

YES

Programs for drills and training have been set-up and recorded YES

Familiarization records of new crew members are available onboard YES

Master can show his overriding authority YES

Non-conformities have been reported to the company and corrective actions have

been taken by the company YES

Maintenance routine and records are readily available onboard. YES

A copy of the DOC with the endorsement for the latest office audit is available

onboard

YES

Cyber risk assessment completed and the management Plan available on board YES

ISPS

Addressed

ITEM YES NO N/A

Arrangements in place for controlling access to the ship for persons/going the next

port

YES

Personnel responsible for controlling access to the ship is familiar with its duties YES

Arrangements are in place to secure and control restricted areas specified in the

SSP

YES

All entrances leading to restricted areas of the ship ready to be closed or secured YES

Security Equipment maintained and tested as specified in the SSP YES

MLC, 2006

Addressed

ITEM YES NO N/A

All seafarers on board have signed a Seafarers’ Employment Agreement (SEA) with

the ship-owner and an original copy is provided to each seafarer

YES

The SEA and CBA is in English language in case the ship is engaged in

international voyages.

YES

The SEA signed between the seafarer and the shipowner includes all the

requirements of Regulation 2.1, Standard A2.1.4 as well as national requirements YES

of the flag State

The SEA includes a clause for early termination of contract that should not be less

than seven days

YES

Annex 1 – IMMARBE Self-Inspection Checklist 8 TDL-018r4

The wages of each seafarer(s) engaged on board the ship are paid in accordance

with the SEA and CBA, as applicable

YES

Each seafarer is provided with monthly statement of account that includes the

monthly wage, additional payments, deductions, and applied exchange rates. The YES

monthly account does not indicate any unauthorized deductions

A table of shipboard working arrangements for all position, Hours of work and rest

are signed by the Master (or a person authorized by the Master) and the seafarer; YES

and are available for each seafarer engaged on board the ship

The muster and drills are carried out at times that minimize the disturbance of rest

periods and fatigue

YES

All seafarers engaged on board the ship are entitled to repatriation after a

maximum 12-month period, in case of termination of the agreement for justified

reasons or when they cannot carry out their duties on board due to illness, injury

YES

etc. (refer to the SEA that should state the provisions for repatriation)

Copy of the Financial security for repatriation (Regulation 2.5) and Financial

security relating to shipowner's liability (Regulation 4.2) can be found on board YES

and is easily accessible to seafarers

DMLC Part II in compliance with MLC 2006, as amended in 2018 YES

The accommodation spaces are clean and provided with proper lighting and

sufficient drainage

YES

Sanitary facilities are hygienic and reasonable standard of comfort are met YES

The galley is clean, hygienic and in good condition YES

Spaces used for the storage of food are clean, hygienic and in good condition YES

The ship is provided with sufficient amount of drinking water and food of

nutritional value, quality, and variety for the number of crew members on board

YES

The seafarer assigned a ship’s cook is over 18 years of age, trained, qualified and

food competent according to the requirements of the flag State

N/A

For ships with less than 10 seafarers, the seafarers assigned for handling and

processing food in the galley is adequately trained or instructed in areas including YES

food and personal hygienic as well as handling and storage of food onboard

All seafarers are provided free of charge with health protection and medical care

(including essential dental care) relevant to their duties

YES

The ship is equipped with sufficient Personal Protective Equipment and all

seafarers engaged on board are familiar with it

YES

All seafarers on board the ship have a copy of the complaint procedure YES

OTHER REQUIREMENTS

Addressed

ITEM YES NO N/A

Ballast Water Management Plan (BWMP) available and approved onboard YES

Ballast Water Management Record Book (BWMRB) available and updated

onboard

YES

Ballast Water Management Treatment System (BWMS) available and operational

onboard

N/A

Shipboard Emergency Efficiency Management Plan (SEEMP) available and

approved onboard YES

Compliance with MARPOL Annex VI Regulation 22A – Data Collection System for

fuel oil consumption of ships

YES

Statement of Compliance in accordance with the Hong Kong Convention or

European Union Ship Recycling Regulation (EU-SRR) available on board

YES

Annex 1 – IMMARBE Self-Inspection Checklist 9 TDL-018r4

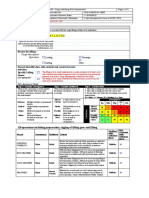

If any of the items outlined in this checklist are not in good working condition or found not

incompliance, the crew should take appropriate steps for a corrective action to be implemented prior

to arrival into port. Please contact IMMARBE Head Office through inspections@immarbe.com for

further assistance.

DEFICIENCIES

vessel at DRY DOCK for some hull port side repair under class supervision

NOTE 1: Tokyo MOU ships shall submit the Self Inspection Checklist (SIC) the first 5

days of each month. All other vessels operating outside the Tokyo MOU are to submit

their SIC by the 15th of each month.

NOTE 2: A full photo report (Hull, Main Deck, Mooring Stations, Cargo Spaces,

Navigational Bridge, Accommodations, Engine Room, Machinery Spaces, etc.) must

be submitted on quarterly basis (January, April, July, and October). At least two

photos per area with the date inserted in each photo.

NOTE 3: Any deficiency found should be supported by a photo or any other type of

evidence.

Annex 1 – IMMARBE Self-Inspection Checklist 10 TDL-018r4

NOTE 4: Crew list (use 'FAL FORM 5 IMMARBE' only) needs to be attached as

required in STCW items and submitted on a monthly basis.

NOTE 5: Next ports to be called are required in order for IMMARBE to confirm the

current trading area of its fleet.

The undersigned Master and DPA verify the abovementioned items and declare that all

information completed is the true condition of the Vessel.

Walied Salama

Gad

Master Name and Signature: DPA Name and Signature:

Vessel seal to be stamped:

Annex 1 – IMMARBE Self-Inspection Checklist 11 TDL-018r4

You might also like

- Typical AMSA Oral QuestionsDocument37 pagesTypical AMSA Oral Questionsrigel94% (17)

- Sample Documents For Crew EmploymentDocument45 pagesSample Documents For Crew EmploymentKrzysztof Majdzinski100% (2)

- Toll Management System Design PresentationDocument42 pagesToll Management System Design Presentationsarath71% (24)

- Shippers Seafood Carriage by Air Declaration June22Document1 pageShippers Seafood Carriage by Air Declaration June22Krishni DomahNo ratings yet

- Annual Surveys/intermediate Surveys/docking Surveys Survey ChecklistDocument13 pagesAnnual Surveys/intermediate Surveys/docking Surveys Survey Checklistthomaskurian777100% (1)

- AMSA Ship Initial Inspection ChecklistDocument13 pagesAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- Material Handling Control ProcedureDocument9 pagesMaterial Handling Control ProcedureBhisamS Salleh100% (2)

- Volvo d12Document18 pagesVolvo d12ANH LÊ67% (6)

- 15.vessel Safety Enforcement Inspections ChecklistDocument8 pages15.vessel Safety Enforcement Inspections ChecklistIan Kristian BelgicaNo ratings yet

- Vessel Inspection Checklist01Document2 pagesVessel Inspection Checklist01Prasanth Varrier100% (3)

- Survey Checklist For Ships Carrying Liquefied Gases in BulkDocument13 pagesSurvey Checklist For Ships Carrying Liquefied Gases in BulkAhmad Imran100% (2)

- Plipdeco Haulier Inspection ChecklistDocument2 pagesPlipdeco Haulier Inspection ChecklistHemas AvicennaNo ratings yet

- Owner's Manual: Downloaded From Manuals Search EngineDocument12 pagesOwner's Manual: Downloaded From Manuals Search EnginegragrNo ratings yet

- A Case Study of Southwest AirlinesDocument4 pagesA Case Study of Southwest AirlinesishmaelNo ratings yet

- COMDTINST M16672.2 Navigation Rules International InlandDocument220 pagesCOMDTINST M16672.2 Navigation Rules International Inlandeckster16No ratings yet

- DIY 2x72 Belt Grinder For Knife MakingDocument4 pagesDIY 2x72 Belt Grinder For Knife MakingJamespagan0% (1)

- ST Kitts & Nevis International Ship RegistryDocument11 pagesST Kitts & Nevis International Ship RegistrybthbidkesNo ratings yet

- Maintenance Guide CL (Lloyd's Reg. Cargo Vessels)Document22 pagesMaintenance Guide CL (Lloyd's Reg. Cargo Vessels)loai allamNo ratings yet

- Instructions To Maritime Cook Islands Inspector: Part A: General InformationDocument11 pagesInstructions To Maritime Cook Islands Inspector: Part A: General InformationMariyath Muraleedharan KiranNo ratings yet

- Documents - Pub LR Annual SurveysDocument13 pagesDocuments - Pub LR Annual SurveysMohammed Ahemd HassanNo ratings yet

- General Survey Report PDFDocument20 pagesGeneral Survey Report PDFEmmNo ratings yet

- Checklist 221225002317Document9 pagesChecklist 221225002317ocean trotter worldwideNo ratings yet

- Ship Certificates & Documents BookDocument74 pagesShip Certificates & Documents BookSherry GodwinNo ratings yet

- Annual, Docking, Intermediate SurveyDocument13 pagesAnnual, Docking, Intermediate Surveyargentum19619692No ratings yet

- Vessel Inspection Checklist - Last Updated 06.08.15Document3 pagesVessel Inspection Checklist - Last Updated 06.08.15Dadang KurniaNo ratings yet

- Survey ChecklistDocument17 pagesSurvey Checklistssshewale1988No ratings yet

- Amsa 249 Master Oral Exam ChecklistDocument4 pagesAmsa 249 Master Oral Exam ChecklistsdpojohnnyNo ratings yet

- SCV2 V2 December 2013 PDF FormatDocument30 pagesSCV2 V2 December 2013 PDF FormatNicandro PorcelliNo ratings yet

- Allianc - Foam AkbarDocument1 pageAllianc - Foam Akbarps projectNo ratings yet

- MZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Document24 pagesMZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Lj NecesitoNo ratings yet

- Mpa Vessel's ChecklistDocument2 pagesMpa Vessel's ChecklistmeridionalmototraverseNo ratings yet

- Certificates of Proficiency Requirement For SeafarersDocument10 pagesCertificates of Proficiency Requirement For SeafarershutsonianpNo ratings yet

- MLC Compliance Checlist Rev 0 30th Nov 18Document18 pagesMLC Compliance Checlist Rev 0 30th Nov 18Dini ANNo ratings yet

- Survey ChecklistDocument6 pagesSurvey ChecklistDIPIN PNo ratings yet

- Epirb Test Report - With LetterheadDocument1 pageEpirb Test Report - With LetterheadVarun K.JNo ratings yet

- Foreign Vessel Exam Book For Mtsa/Isps Code Compliance: United States Coast GuardDocument8 pagesForeign Vessel Exam Book For Mtsa/Isps Code Compliance: United States Coast GuardDiana MoralesNo ratings yet

- Onboard Routine Maintenance Check SheetDocument23 pagesOnboard Routine Maintenance Check SheetExpertise MlcsNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaPKNo ratings yet

- Tug and Barge Survey Report PDFDocument14 pagesTug and Barge Survey Report PDFDevi SamosirNo ratings yet

- AD-04 Certificate Status (New Format)Document8 pagesAD-04 Certificate Status (New Format)Rachit SharmaNo ratings yet

- Vessel Inspection ChecklistDocument2 pagesVessel Inspection ChecklistIbrahim KashmNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaDimosNo ratings yet

- Surfer Vessel Inspection Form - V2Document12 pagesSurfer Vessel Inspection Form - V2VICTORNo ratings yet

- Survey Report FormDocument28 pagesSurvey Report FormJavier Rayleigh100% (2)

- Barge Insurance FormDocument12 pagesBarge Insurance FormAnonymous ycFeyuLAtNo ratings yet

- AMSA579 - Application For NS VesselDocument3 pagesAMSA579 - Application For NS Vesselinmran.gNo ratings yet

- Masters OralsDocument107 pagesMasters OralsKiran Krishnamoorthy100% (2)

- Chief Mate Oral Examination Checklist: (Aide Memoire)Document2 pagesChief Mate Oral Examination Checklist: (Aide Memoire)Shahrior MahmudNo ratings yet

- VA Ramp Safety Observation Checklist - SafetyCultureDocument10 pagesVA Ramp Safety Observation Checklist - SafetyCultureshabaneethuaeNo ratings yet

- IMSBC Flow ChartDocument1 pageIMSBC Flow ChartMahesh Singh100% (1)

- Vessel Safety Check (VSC)Document2 pagesVessel Safety Check (VSC)Douglas PassarelliNo ratings yet

- SWP05 - Form 06Document10 pagesSWP05 - Form 06ahmedNo ratings yet

- List of Ship CertificateDocument3 pagesList of Ship CertificateBrian PhamNo ratings yet

- Amendments To Part B of The Seafarers' Training, Certification and Watchkeeping (STCW) CodeDocument3 pagesAmendments To Part B of The Seafarers' Training, Certification and Watchkeeping (STCW) CodearmanNo ratings yet

- Annual, Docking, Intermediate SurveyDocument29 pagesAnnual, Docking, Intermediate SurveyAjay Singh100% (1)

- Questions For Interview - ANSWEREDDocument4 pagesQuestions For Interview - ANSWEREDalbaraka.shippingNo ratings yet

- Equipment Test Mooring and Lifting Equipmenty NavalDocument1 pageEquipment Test Mooring and Lifting Equipmenty NavalPingarilhoNo ratings yet

- USCG Foreign VSL Exam Booklet MTSA-ISPS ComplianceDocument9 pagesUSCG Foreign VSL Exam Booklet MTSA-ISPS CompliancePricop Marius OctavianNo ratings yet

- VDR 01-2012Document3 pagesVDR 01-2012Ndipo BecklyNo ratings yet

- Certification and Class Reports: Checklist Based On PSC DeficienciesDocument16 pagesCertification and Class Reports: Checklist Based On PSC DeficienciesVengat VenkitasamyNo ratings yet

- 2020 002 AMSA Pre Arrival CkecklistDocument6 pages2020 002 AMSA Pre Arrival Ckecklistdominic dmelloNo ratings yet

- s04.s4 - Material - Maritime Regulations - Documentation IIDocument38 pagess04.s4 - Material - Maritime Regulations - Documentation IILAWRENCE OLIVER ESPINOZA VALDERRAMANo ratings yet

- 19425-Lge-Rigel X-30507.Document9 pages19425-Lge-Rigel X-30507.aripinetijaswanthNo ratings yet

- O.okeniyi - R. 2021Document3 pagesO.okeniyi - R. 2021HenryNo ratings yet

- Masters OralsDocument74 pagesMasters Oralsssabih75No ratings yet

- Encyclopaedia of International Aviation Law: Recueil Des Textes De Lois Relatifs AFrom EverandEncyclopaedia of International Aviation Law: Recueil Des Textes De Lois Relatifs ANo ratings yet

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- 61f93 Ats2015 Exhibitorlistfloor AnDocument45 pages61f93 Ats2015 Exhibitorlistfloor AnkumarneerajNo ratings yet

- DIAGRAMA-ventanas Electricas SparkevDocument3 pagesDIAGRAMA-ventanas Electricas SparkevHarvey LaresNo ratings yet

- LO: How Do We Represent Journeys On A Distance - Time GraphDocument23 pagesLO: How Do We Represent Journeys On A Distance - Time GraphMarta Carbajosa Fernandez Carbajosa FernandezNo ratings yet

- AMD DEL: Sen / Anubhav MR AI0835Document1 pageAMD DEL: Sen / Anubhav MR AI0835Nisha SagarNo ratings yet

- MAN Maxicosi Mobi 2011 LR ENSVNOFI PDFDocument56 pagesMAN Maxicosi Mobi 2011 LR ENSVNOFI PDFAnonymous NM63QfBNo ratings yet

- Biology For CAPE Unit 1 Chapter 3 Answers PDFDocument8 pagesBiology For CAPE Unit 1 Chapter 3 Answers PDFGerrald RamoutarNo ratings yet

- F.O Based Thermal Power PlantDocument98 pagesF.O Based Thermal Power PlantMuhammad AsifNo ratings yet

- Transas ECDIS BrochureDocument20 pagesTransas ECDIS Brochureahlee08No ratings yet

- Suspension Control System: SectionDocument32 pagesSuspension Control System: SectionzhenyupanNo ratings yet

- BhagalpurDocument11 pagesBhagalpurshailesh37100% (1)

- The TVS GroupDocument9 pagesThe TVS GroupSanjeev KumarNo ratings yet

- NG ExistingDocument2 pagesNG ExistingdeepdixitNo ratings yet

- The Hippie Lieutenant: Vietnam "War" RemembrancesDocument101 pagesThe Hippie Lieutenant: Vietnam "War" RemembrancesAnthony St. John100% (1)

- My FerrariDocument11 pagesMy FerrariManuel Alcayde BolañosNo ratings yet

- Application of Variable Speed Drive (VSD) in Electrical Motor Energy SavingDocument8 pagesApplication of Variable Speed Drive (VSD) in Electrical Motor Energy SavingTenzin JamtshoNo ratings yet

- Igi DPRDocument137 pagesIgi DPRNivedita AggarwalNo ratings yet

- Atr72 QBDocument65 pagesAtr72 QBraiday8490% (10)

- Extension: The City of The FutureDocument2 pagesExtension: The City of The Futurebenilde bastidaNo ratings yet

- CM 03 - Cargo Handling Risk AssessmentDocument3 pagesCM 03 - Cargo Handling Risk AssessmentDmitriy100% (1)

- Kenya PVoCDocument2 pagesKenya PVoCkevotooNo ratings yet

- Sh70 Orec Tondeuse Debroussailleuse Vue EclateeDocument23 pagesSh70 Orec Tondeuse Debroussailleuse Vue EclateeArctic SilverNo ratings yet

- Tadano TM Zr500xlDocument6 pagesTadano TM Zr500xlRafael Durio EtgarNo ratings yet