Professional Documents

Culture Documents

040 K - Underground Utility Protection During Excavation

040 K - Underground Utility Protection During Excavation

Uploaded by

meeshu1133Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

040 K - Underground Utility Protection During Excavation

040 K - Underground Utility Protection During Excavation

Uploaded by

meeshu1133Copyright:

Available Formats

RAJASTHAN OIL DEVELOPMENT PROJECT

SPEARHEADING HEALTH, SAFETY & ENVIRONMENTAL

Underground Utility Expossure & Protection During

Excavation

In response to the recent Hi-Po incident related to damaged underground utilities during excavation at AWP

involving inadequate protection & supervision for the exposed underground utilities such as Electrical cable

FOC cable etc. necessity has been felt to educate the work force on potential risk of damaging underground

facilities (especially HT electrical Cables) while performing excavation and trenching activities.

In Cairn Projects we routinely perform excavations for construction activities. Never forget or ignore the

potential hazards associated with excavation work and follow the procedures and safe work practises.

Excavation Inspection Tag

Common Excavation Hazards

Damage to underground utilities (electrical, FOC Cables, Pipe lines etc.

Damage to adjoining or existing structure

Excavation cave-in & collapse

Being hit, or crushed by machinery

Fall in to excavation, Electrocution, Engulfment, Asphyxiation

Aerial View of Incident Location Exposed pipeline provided Exposed cable provided

additional support to avoid sagging additional sleeve protection

Control measures

Mark the area of excavation and arrange the resource as per the depth of the excavation.

Conduct underground survey (Using Scanner and / Trial pit) and identify the underground facilities.

Obtain work permit and excavation certificate. Implement all PTW control measures and JSA.

Don’t perform mechanical excavation within 1m radius of identified underground facility.

Perform mechanical excavation only if work permit is permitted to do so.

A close supervision shall be provided for all excavation activates.

Continuous and effective supervision should be carried out for identified underground Cables, Pipes etc.

All identified cables and pipeline shall be protected properly with additional sleeve or any other means.

Any excavation more than 1.2 meter deep must be adequately supported on the sides by proper slopping /

benching / shoring or shielding for personnel protection.

Stability of adjacent structure need to be ensured and provide adequate support for the same if required.

Excavations deeper than 1.5m shall be considered as ‘Confined Space Entry” and comply with relevant

controls. Such as entry certificate & gas test etc.

Excavated material should be kept at least 1m away from the top edge of excavation.

Ensure safe means of access and entry / exit for excavations deeper than 600 mm

No heavy equipment, vehicle is permitted near to the edge of the excavated area.

Provide adequate cave-in and collapse protection for all excavations edges. (Sloping, Shoring etc..)

Excavated area shall be barricaded by hard barricading and installed sign boards.

As a part of identified fatal risks, excavation safety training is mandatory for all exposed personnel.

Expose underground utilities route completely before starting any mechanical excavation.

Bulletin Dec. 2018

You might also like

- Excavation PlanDocument8 pagesExcavation PlanNajim Habib100% (2)

- Method Statement - Excavation Works (Scribd)Document9 pagesMethod Statement - Excavation Works (Scribd)Joseph NGNo ratings yet

- Risky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateDocument12 pagesRisky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateqerat88No ratings yet

- Accident & Incidents Investigation TechniquesDocument1 pageAccident & Incidents Investigation TechniquesNeog RupakNo ratings yet

- Excavation TrainingDocument60 pagesExcavation TrainingFahad Abdul HaqNo ratings yet

- Working On HeightDocument4 pagesWorking On Heightmansoor hussainNo ratings yet

- Jerp Safety Manual 12. Safety in Excavation WorkDocument4 pagesJerp Safety Manual 12. Safety in Excavation WorkMd SakibNo ratings yet

- Excavation Hazards and Control MeasuresDocument22 pagesExcavation Hazards and Control MeasuresJick Micheal Jm100% (3)

- Safety Orientation For Excavation WorkersDocument8 pagesSafety Orientation For Excavation WorkersHaroonAbdulRahimNo ratings yet

- SOP Excavation and PermittingDocument4 pagesSOP Excavation and PermittingTengku & Wan ResourcesNo ratings yet

- Module 3 Ise KtuDocument35 pagesModule 3 Ise Ktuvcb57xbtd5No ratings yet

- Excavation Shoring and Protection ProcedureDocument7 pagesExcavation Shoring and Protection ProcedureREBAA HatemNo ratings yet

- Trenching and Excavation SafetyDocument6 pagesTrenching and Excavation SafetySn AhsanNo ratings yet

- Excavation WorksDocument8 pagesExcavation WorkspradheepNo ratings yet

- SIBIssue March 13-Special IssueDocument5 pagesSIBIssue March 13-Special Issuekirandevi1981No ratings yet

- Safe Test Pit ExcavationsDocument2 pagesSafe Test Pit Excavationsdp_paulNo ratings yet

- Excavation SafetyDocument31 pagesExcavation SafetyPageduesca RouelNo ratings yet

- Excavations - Construction Safety Topics - HSEDocument5 pagesExcavations - Construction Safety Topics - HSETehman SiddiquiNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Week 20 Underground Services and ExcavationDocument1 pageWeek 20 Underground Services and Excavationpl_rajaNo ratings yet

- ExcavationDocument24 pagesExcavationAhmed ImranNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresrjavillarNo ratings yet

- Excavation SafetyDocument3 pagesExcavation SafetyJenise PhillipsNo ratings yet

- NCP - 22Document13 pagesNCP - 22chettriranjanNo ratings yet

- 30.01.23 MS For Excavation of Trial Pit - Trench - R1 - From GLCPL - FinalDocument8 pages30.01.23 MS For Excavation of Trial Pit - Trench - R1 - From GLCPL - FinalsuratNo ratings yet

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranNo ratings yet

- Electrical Safety by PAUL CEDDocument25 pagesElectrical Safety by PAUL CEDDharfan ApriantoNo ratings yet

- Protecting Underground Cables & Services: Pe Cu57Document11 pagesProtecting Underground Cables & Services: Pe Cu57SABIR KHANNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Excavation SafetyDocument41 pagesExcavation SafetyGerald Paul SumagpaoNo ratings yet

- JSA ExcavationDocument6 pagesJSA Excavationkermech21607100% (1)

- Method Statement Store: Editable Documents CatalogDocument1 pageMethod Statement Store: Editable Documents CatalogBAWA ALEXNo ratings yet

- Risk Involved in Construction Works.Document10 pagesRisk Involved in Construction Works.Shaibal AhmedNo ratings yet

- Shamrock Ground DisturbanceDocument85 pagesShamrock Ground DisturbanceTerry PenneyNo ratings yet

- Excavations and TrenchesDocument2 pagesExcavations and TrenchesSiewkuan LeeNo ratings yet

- 1 Excavations and TrenchesDocument2 pages1 Excavations and TrenchesAruNo ratings yet

- Trenching and Excavation SafetyDocument5 pagesTrenching and Excavation SafetyAnge JuanNo ratings yet

- ExcavationDocument9 pagesExcavationabidNo ratings yet

- Basrah Water Supply Improvement Project: FulltechDocument17 pagesBasrah Water Supply Improvement Project: FulltechAhmad MohammadNo ratings yet

- Working in Excavations ProcedureDocument16 pagesWorking in Excavations Procedurejanel norbeNo ratings yet

- KOC SA 026 Excavation ProcedureDocument9 pagesKOC SA 026 Excavation ProcedureFathyNo ratings yet

- ExcavationDocument18 pagesExcavationBogdan-Gabriel SchiopuNo ratings yet

- Risk and Personnel SafetyDocument16 pagesRisk and Personnel SafetyCamille Andrea SequitinNo ratings yet

- 1 Excavation Safety Work Method and ProcedureDocument7 pages1 Excavation Safety Work Method and Procedureankesh anand100% (1)

- Ali Mousa and Sons ContractingDocument46 pagesAli Mousa and Sons ContractingSajid ShahNo ratings yet

- EXC Training 02Document41 pagesEXC Training 02Burdang PinoyNo ratings yet

- Excavation and Trenching TrainingDocument59 pagesExcavation and Trenching TrainingJohn Ervin AgenaNo ratings yet

- Prevention Plan For Excavation Works Presentation ArabicDocument45 pagesPrevention Plan For Excavation Works Presentation ArabicnounoulekNo ratings yet

- Norseman Directional Drilling Safe Work PracticeDocument6 pagesNorseman Directional Drilling Safe Work PracticeZYS ConstructionNo ratings yet

- 2750 - MS For Cable Crossing Under ORPIC PipelinesDocument6 pages2750 - MS For Cable Crossing Under ORPIC PipelinesGeeks PondNo ratings yet

- Trench and Excavation Safety Guide: I. Policy A. PurposeDocument21 pagesTrench and Excavation Safety Guide: I. Policy A. PurposeForum PompieriiNo ratings yet

- Construction Safety Guidelines No.9 Excavation: Prior To Excavation Barricade The Area Display NoticesDocument1 pageConstruction Safety Guidelines No.9 Excavation: Prior To Excavation Barricade The Area Display Noticestp101267No ratings yet

- Excavations - Health and Safety AuthorityDocument8 pagesExcavations - Health and Safety AuthorityaneethavilsNo ratings yet

- Safety in Excavation Work: Structural Stability During ExcavationsDocument4 pagesSafety in Excavation Work: Structural Stability During ExcavationsRutuja ShikhareNo ratings yet

- Excavation and TrenchingDocument2 pagesExcavation and Trenchingfebin febiNo ratings yet

- Excavation Safety Policy: City of LincolnDocument11 pagesExcavation Safety Policy: City of LincolnMianNo ratings yet

- Excavation SafetyDocument2 pagesExcavation SafetyMirza S. BaigNo ratings yet

- ER420 - MS of G.I Pipe Crossing - r0Document12 pagesER420 - MS of G.I Pipe Crossing - r0Wr ArNo ratings yet

- Erosion in Geomechanics Applied to Dams and LeveesFrom EverandErosion in Geomechanics Applied to Dams and LeveesStephane BonelliNo ratings yet

- Asghar - Resume - KDocument2 pagesAsghar - Resume - Kmeeshu1133No ratings yet

- Hassam CV OnlyDocument2 pagesHassam CV Onlymeeshu1133No ratings yet

- Olcp 01Document1 pageOlcp 01meeshu1133No ratings yet

- INVOICEDocument2 pagesINVOICEmeeshu1133No ratings yet

- Mazhar q.5b January 24Document4 pagesMazhar q.5b January 24meeshu1133No ratings yet

- A Hybrid Machine Learning Method For Image ClassificationDocument15 pagesA Hybrid Machine Learning Method For Image Classificationindex PubNo ratings yet

- Endemic Bird Areas (EBA) : Restricted-RangeDocument4 pagesEndemic Bird Areas (EBA) : Restricted-RangeRifani SabranNo ratings yet

- Shady Othman Nour El Deen: Doha, QatarDocument3 pagesShady Othman Nour El Deen: Doha, QatarHatem HusseinNo ratings yet

- GCP CarbonBudget 2023 Slides v1.0-2-1Document94 pagesGCP CarbonBudget 2023 Slides v1.0-2-1YULIANTONo ratings yet

- Excel Charts 2019Document159 pagesExcel Charts 2019the4rinaNo ratings yet

- Đáp Án C A The Growth of Bike-Sharing Schemes Around The WorldDocument4 pagesĐáp Án C A The Growth of Bike-Sharing Schemes Around The WorldThu An TranNo ratings yet

- H O Solutions: Hydroelectric Power Project: ObjectiveDocument2 pagesH O Solutions: Hydroelectric Power Project: ObjectiveImman Ray Loriezo AguilarNo ratings yet

- Calibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceDocument2 pagesCalibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceSAKKARIN TURATHAMNo ratings yet

- Aclm ReportDocument3 pagesAclm Reportabdulhadee naimNo ratings yet

- Hindus Acknowledge The Law of KarmaDocument3 pagesHindus Acknowledge The Law of KarmaAnil Kumar BNo ratings yet

- Mechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsDocument21 pagesMechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsTestingAccNo ratings yet

- Types of Communication Session 7Document4 pagesTypes of Communication Session 7supratimloveNo ratings yet

- Annals Change FinalDocument92 pagesAnnals Change FinalandriNo ratings yet

- Gy4006 L6 Gis 2023Document39 pagesGy4006 L6 Gis 2023Karrie ChambersNo ratings yet

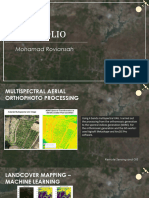

- Mohamad Roviansah's Remote Sensing and GIS PortfolioDocument12 pagesMohamad Roviansah's Remote Sensing and GIS PortfolioJi BayNo ratings yet

- Q1 - W7 - LP - ST DOQUEDocument5 pagesQ1 - W7 - LP - ST DOQUEMylene PastranaNo ratings yet

- Inoculum BestDocument6 pagesInoculum BestSabarishNo ratings yet

- Programs of Non-Government OrganizationsDocument27 pagesPrograms of Non-Government OrganizationsPhili-Am I. OcliasaNo ratings yet

- Space Law Seminar BharatDocument26 pagesSpace Law Seminar BharatBharat JoshiNo ratings yet

- CW Module 1-Lesson 3-Figures of SpeechDocument15 pagesCW Module 1-Lesson 3-Figures of SpeechNelia RuizNo ratings yet

- Consumer Buying BehaviorDocument15 pagesConsumer Buying BehaviorpogsNo ratings yet

- ITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableDocument24 pagesITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableHilman NurzenNo ratings yet

- Chapitre 10 Flow Nets 1Document22 pagesChapitre 10 Flow Nets 1Yulia Yunita KNo ratings yet

- Syed Asad AbbasDocument1 pageSyed Asad AbbasAsad AbbasNo ratings yet

- 09.1 Carey - Cultural ApproachDocument16 pages09.1 Carey - Cultural ApproachOneness EnglishNo ratings yet

- GlitchDocument4 pagesGlitchGréta KovácsNo ratings yet

- Chapter 3, Solution 97CDocument6 pagesChapter 3, Solution 97CkarenNo ratings yet

- AspirinDocument34 pagesAspirinAyoub AinaneNo ratings yet

- A Slurry Consolidation Method For Reconstitution of Triaxial SpecimensDocument10 pagesA Slurry Consolidation Method For Reconstitution of Triaxial SpecimensandreaNo ratings yet