Professional Documents

Culture Documents

Method Statement For Pipes

Method Statement For Pipes

Uploaded by

xander1982Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Pipes

Method Statement For Pipes

Uploaded by

xander1982Copyright:

Available Formats

Method Statement

for Pipe Works

November 16, 2018

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Table of Contents

1. Scope of Work ........................................................................................................ 2

2. Storing and Handling the Pipes .............................................................................. 2

3. Handling, loading and unloading materials ............................................................ 3

4. Excavation of Trenches .......................................................................................... 4

5. Pipe Laying: Lowering to Trenches ..................................................................... 12

6. Breaking Road Surfaces/Paved Areas .................................................................. 14

7. Excavation in Non-Paved Areas ........................................................................... 14

8. Shoring and Supporting Sides of Trench Excavations ......................................... 15

9. Crossing of Utilities and Water Paths ................................................................... 19

10. Lowering Water Table .......................................................................................... 19

11. Disposing Excavated Materials ............................................................................ 21

12. Pipe Bedding & Types of Bedding ....................................................................... 21

13. Pipe Laying: Cutting – Jointing – Welding .......................................................... 22

14. Curves & Bends .................................................................................................... 32

15. Backfilling and Compaction of Trenches ............................................................. 32

16. Testing of Pipes during Installation ...................................................................... 34

17. Reinstatement of Surfaces Paved and Non-Paved Areas. .................................... 39

18. Safety .................................................................................................................... 40

19. Environmental Protection ..................................................................................... 41

20. Equipment and material ........................................................................................ 42

21. The forms to be submitted for test records. .......................................................... 50

November 16, 2018

1

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

1. Scope of Work

The scope of work includes storing of pipes, fittings and accessories, setting

out, preparation of site, arrangements for safety precautions, excavation of

trenches, laying pipes, jointing, backfilling, cleaning, testing and

connection between gravity and pressure systems.

2. Storing and Handling the Pipes

Pipes, fittings and accessories for the project shall be stored in the

Contractor yard in the store organized for every category: Corrugated pipes

HDPE of diameters 200 mm, 300 mm, 400 mm, 500 mm, 800 mm, 1000

mm and 1200 mm; pressure pipes HDPE of diameters OD110, OD140,

OD180, OD200, OD225,OD280, 0D315, OD355, OD400, OD450, OD500,

OD630, Manholes in different materials, size and fittings: concrete

manholes 1000 mm, 1200 mm, 1500 mm; plastic manholes 600 mm, 400

mm.

The site and its layout will be protected against physical damage to

components. The area will be of sufficient size to accommodate piping

components, to allow the handling of equipment to get around them, and to

have a relatively smooth, level surface free of stones, debris, or other

material that could damage pipe or components, or interfere with handling.

On the ground, layer of sand (between 10-20 cm) shall be installed to

prevent the contact of the material with stones or sharp elements. On top of

the sand layer, wood structure shall be placed to store every diameter of

pipes.

When unit packages are stacked, care shall be taken to ensure that the

weight of the upper units does not cause deformation to pipe in lower units.

Once the pipes are organized, they will be covered by plastic/tarpaulin

sheeting, out of any direct sunlight. Material in concrete will be placed

over the sand layer. Fittings will be kept inside of the package supplied in

the factory to prevent corrosion and other problems during the transport

and store period. Stock area and type of material shall be marked by signs.

November 16, 2018

2

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

All rubber joint rings and gaskets must be stored in a cool damp location in

black polythene sacks and shall not be distributed to the trench side for

installation until immediately prior to assembly. Rubber gaskets shall be

well lubricated prior to fitting to the pipes or couplings.

3. Handling, loading and unloading materials

Due to the length of pipes, (11.8m), bundle packs will be loaded and

unloaded by crane with loader with 4 supporting legs. Bands that are not

needed for immediately execution will be kept in the store of the

Contractor in the original conditions of the shipping from the factory.

In case of small diameters of pipe should been installed inside of the

excavation trench, the loading and offloading of them shall be done

manually. For bigger diameters, as 1000 mm and 1200 mm, wood support

could be use in order to prevent any accident with the personal inside of the

trenches and to protect the structure of the pipes.

November 16, 2018

3

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

4. Excavation of Trenches

Setting out

Before commencing the trench excavations for pipe laying, the path of the

new pipeline trace shall be pegged out accurately, as per the details of the

topographical (layout and longitudinal sections) drawings and the

preconstruction survey performed by the Contractor. In all cases,

gravitational pipes shall be controlled by optical level instrument in order

to guarantee the flow of the water. Once the bed of the trench is reached by

the excavation, levels and slope of the new pipes shall be checked and

adjusted according with the gravitational condition; critical points shall be

controlled on top of the joining between two pipe sections (every 11.8m).

Final levels of the gravitational pipes and pressure pipes will be presented

to the Engineer for approval before starting of backfilling activity.

Location of the lines shall be done by GPS RTK instrument and levels of

excavation shall be done by optical or electronic level.

Setting out pegs shall be executed by the surveying team of the sub-

contractor of the corresponding hydraulic area and revised by the

Contractor survey team.

Reference pegs shall be determinate for every street as a control point for

the execution of the works. These points shall have X, Y, Z coordinates in

the system defined in the contract and by the Engineer (UTM Zone37N).

Listing of coordinates and levels of each setting out shall be submitted to

the Engineer prior execution of the works.

If trial pit excavation is required by the Engineer, the Contractor will

perform this exploration with the intention to revise the material and detect

presence of possible utilities in the area.

In case that the street will not be totally closed for the construction works,

one traffic pass will be available for cars transient

November 16, 2018

4

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Steps of the excavation:

The method of excavation is shown schematically in scheme 1.

Step 1:

In the first step, the main pipeline between 2 manholes will be constructed.

After setting out of the corresponding line to excavate, the suitable

machine (excavator or backhoe) will be located above it. This machine will

excavate the trench in straight alignment and moving in reverse. Material

extracted from the excavation trench will be evaluated, then placed in

parallel to the alignment or rejected for backfilling.

In case material is suitable for backfilling, it will be offloaded at least 60

cm from the edge of the new trench for posterior backfilling of the trench.

Alternately, the excavator (of 360-degree) will unload excavated material

to the loading truck if the material is not appropriate for backfilling and

send it to the dumpsite area.

The tees for house connections will be installed in the main pipeline during

the first stage.

Step 2

The house connections of one side of the road will be assembled.

Step 3

After appropriate traffic control signalisation the house connections of the

second side of the toad will be joint.

Material extracted from the excavation trench will be evaluated, then

placed in parallel to the alignment or rejected for backfilling and sent to the

dumpsite area.

In case that excavated material should be transported, covered trucks will

be used to prevent dust and depositing loose materials on the road during

hauling.

In case that bed of the final level inside of the trench shows a cohesive soil

or not suitable base, the excavation will go deeper in a magnitude of 10 to

November 16, 2018

5

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

15 cm in order to replace and compact a suitable material to guarantee the

geometry and stability of the new sewage pipe.

This new layer will be trim by manual procedure to create the correct slope

on the alignment.

Depth of excavation will be controlled every 12 m length (average) in

order to maintain the corresponding slopes.

All trenching will have vertical sides unless otherwise permitted or ordered

by the Engineer.

The trench will be of sufficient width to easily and safely allow operations

necessary for the laying and jointing of pipes, fittings and placing and

compaction of backfill material, following the Table 1 (presented below) of

the contract, however excavation width should be maintain between

manhole and manhole.

DN Trench depth, m Clear trench width, m

100 < 1.00 0.55

100 ≥ 1.00 to ≤ 1.75 0.80

100 ≥ 1.75 to ≤ 4.00 0.90

100 > 4.00 1.00

150 < 1.00 0.60

150 ≥ 1.00 to ≤ 1.75 0.80

150 ≥ 1.75 to ≤ 4.00 0.90

150 > 4.00 1.00

200 < 1.00 0.65

200 ≥ 1.00 to ≤ 1.75 0.80

200 ≥ 1.75 to ≤ 4.00 0.90

200 > 4.00 1.00

300 < 1.00 to ≤ 4.00 0.90

300 > 4.00 1.00

400 For all depths 1.20

500 For all depths 1.35

600 For all depths 1.40

700 For all depths 1.50

800 For all depths 1.80

900 For all depths 1.90

1000 For all depths 2.00

November 16, 2018

6

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

DN Trench depth, m Clear trench width, m

1100 For all depths 2.10

1200 For all depths 2.25

The variation should be according with the slope in the bed of each trench,

in the depth.

When the depth of the trench overpass the limit allow for the width the

section shall increase the corresponding dimension in the next section

(manhole to manhole).

Shoring boxes will be installed in section when the depth is more than 1.5

m. See chapter 8 for details on shoring method.

Pipe trenches shall be free of surface or ground water by shoring depth

installation and/or dewatering.

Depth excavation will be indicated by signs and limited by “not crossing

tape” along the geometry of the trenches.

House connection trench will be done by manual procedure and transversal

to the edge of the pipe collector in the shaft along the street.

Typical sections for asphalt, gravel and ballast roads are shown hereafter in

sections 1, 2 and 3 respectively.

November 16, 2018

7

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

8

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

9

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

10

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Scheme1

November 16, 2018

11

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

The general diagram of the pressure pipe works construction steps is shown

below.

5. Pipe Laying: Lowering to Trenches

Pipes will be lowered by using a proper lifting mechanism like cranes,

winches, tripods etc. with guided lifting mechanism for due care on slow

movement.

Before any new pipe is lowered into the trench the plug will be provided or

installed at the end of the last pipe laid and the new pipe shall be carefully

lowered into the trench. Each pipe and fitting shall be laid true to

alignment, curve and gradient in accordance with drawings or as directed

by the Engineer.

November 16, 2018

12

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Pipes are to be laid on minimum acceptable grades, with consideration also

to the anticipated and potential number of connections.

All pipes will be cleaned in the connection circular area and prepared with

lubricant between the two sections to be assembled.

The dishwashing detergent will be used as a lubricant. Using the standard

soft soap (green soap) will help to achieve a good lubricating effect.

For small diameter, connection will be done by manual pushing verifying

the alignment and levelling of the sewage pipe inside the trench or by

suitable manual assembly devices to be provided by the manufacturer of

the pipes.

For bigger diameters (> 400mm), vertical wood will be placed in the

opposite extreme of the pipe section to be connected and pushed by the

hydraulic arm of the suitable machine (Excavator or Backhoe)

For the previous proceed smaller diameter pipe will be cutted and

introduced in the opposite side to be connected (spigot), and then vertical

wood should be installed as contact surface against the machine. This in

order to protect the pipe to be joint with the prior pipe section.

Lowering of the pressure pipes to trench without shoring will be done after

welding of the pipes to one pipeline of approximately 50 m and cautious

descending of the pipeline to the trench.

November 16, 2018

13

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Lowering of the pressure pipes to the trenches with shoring will be done by

different methods depending of the soil stability:

If the soil is stable, the lowering of approximately 50 m welded

pipeline will be done by alternatively rising of one element of

shoring and lowering the appropriate length of the pipe. The

operation is carried out with 2 cranes.

If the soil is not stable, the lowering of the welded pipeline will be

done by manipulating of the struts of the shoring and cautious

descending of the appropriate length of the pipeline.

The third method will be applied is trailing the welded pipe in the

bottom of the trench using special wheels for pipes.

6. Breaking Road Surfaces/Paved Areas

Asphalt and concrete pavements will be removed as necessary to perform

reconstruction. The limits of removal will be saw cut. When the required

installation will be constructed new asphalt and concrete pavements will be

placed to match the original. Breaking of roads will be done with the prior

approval of the relevant authorities in accordance with their specifications

or guidelines. Wherever applicable, diamond wheel road breakers or cutters

will be used to straight cut of the sides of the marked pipe trenches. Base

and sub-base of the roads will be excavated with due care to minimise the

collapse of damage to the balance portions of the roads.

7. Excavation in Non-Paved Areas

Particular regard will be taken to the safety of the livestock in the working

area and will ensure that all open excavations, access routes and slopes

arising from the operations are adequately barricaded and protected.

Stacking of excavated material along the sides of the trenches will be

permitted of there would not be objections from the relevant parties or

from the respective landowners.

November 16, 2018

14

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

8. Shoring and Supporting Sides of Trench Excavations

The sides of all trench excavations will be effectively support. The

materials used for shoring will be strong enough to cater lateral earth

pressures and vibratory impacts due to dynamic loading.

A strutting system will be used for depths < 6 m and wooden trench

support will be applied where needed. The width of trenches should be

carried out according to dimensions and type of pipes as shown in sections

1, 2, 3 and table 1.

Excavation shall be carried out nearly to the lines and levels which are

specified on the Drawings or as instructed by the Engineer.

The Contractor will take all possible precautions to prevent slips in

excavations and embankments and to protect and support structures, which

may be endangered.

Thereby the works will commence:

Depending on the road conditions

o Cutting the asphalt where the road is asphalted,

o Removal of gravel where the road is gravelled.

Digging the bitumen layers of gravel and laying it aside on the approved

dumps.

Shoring will be used where the depth of the trench is higher than 1.5 m

Pipe trenches are to be excavated as narrow as practicable and shall not be

widened by scraping or loosening materials from the side. Every effort

shall be made to keep the side of the trenches firm and undisturbed until

backfilling has been completed and consolidated.

November 16, 2018

15

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Depending on the land stability, depth of the trench, gauge of the pipes that

will be laid and the level of ground waters, the corresponding system of

strutting will be applied, in accordance with the necessities.

System components are produced of steel and they are heavy both as

individual components and as a whole.

It will consists of two steel prefabricated panels with shafts or struts. The

struts are with joint and they bend when they join to the side panels,

enabling in such a way independent propulsion of each of them.

Installation into the trench is performed either gradually (the walls of

trench are strutted all the time) with the bucket of dredger or after digging,

depending on the soil conditions.

November 16, 2018

16

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

17

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

System of strutting

November 16, 2018

18

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

9. Crossing of Utilities and Water Paths

Care will be taken to avoid damage to existing utilities such as pipelines,

cables, etc. If found necessary, temporary supports will be provided to

those utilities.

While undertaking the excavation across rivers or man-made water paths,

care will be taken to allow at least base flows for a short period with

minimum disturbance to water paths. If applicable, diversion of water paths

will be done with the approval of the relevant authorities.

10. Lowering Water Table

For safe and proper construction, the groundwater level in the trench should

be kept below the pipe invert. This will be accomplished by well points and

pumps placed in the trench.

A wellpoint is a small-diameter, closely-spaced shallow well, which offers

a highly versatile method of groundwater control where drawdown

requirements onsite are shallow. Wellpoints are pumped using a specialist

surface vacuum pump and are particularly effective in fine-graded soils.

Wellpoint dewatering also has the advantage of having a comparatively

quick installation time, making it ideal for Poti's dynamic site, where many

metres of pipe can be laid in a single shift.

Each wellpoint will consist of a small diameter riser pipe, with a slotted

filter at the base, and the wellpoint pump is connected to the header main

pipe. The wellpoint pump creates a partial vacuum in the header main,

which draws up the water so that it can be discharged at a designated point.

Wellpoints will be installed parallel to the pipeline trench.

November 16, 2018

19

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

..

November 16, 2018

20

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

11. Disposing Excavated Materials

Excavated material which is not required for or is unsuitable for re-use in

the Works will be disposed of offsite. Materials to be disposed will be

removed from the site and ultimately disposed.

12. Pipe Bedding & Types of Bedding

Unless unsuitable soil is encountered, trenches will be excavated to 100

mm below the barrel of the pipe and prepared conforming to the following.

On the trench bottom sand bedding will be laid to a compacted thickness of

100 mm. For rock, the sand bedding shall be 150 mm.

If the foundation beneath the pipe is unsuitable (potentially expansive

material, soft, unstable soil), it will be removed to a minimum depth of 150

mm and replaced with appropriate material.

The bedding will be compacted to 95% of the standard maximum dry

density.

November 16, 2018

21

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Bedding type will be decided in accordance with the findings of the

investigation of soil logs of the pipe traces or after excavation of the

trenches.

Before placing the bedding material, the excavated surface will be properly

levelled and trimmed with manual means and will be compacted with

vibratory compactors to ensure stabilized foundation for pipes.

Boulders, loose particles and other impurities will be removed before

compaction and will be wetted if necessary.

Prior to pipe laying it will be ensured that the pipe bedding is in conformity

to the invert levels of the pipe traces as specified in the drawings and free

from foreign materials, boulders, sharp edges etc.

If local material is not suitable, bedding material will be imported to the

site.

13. Pipe Laying: Cutting – Jointing – Welding

Pipe shall be cut by means of saws, power driven abrasive wheels or pipe

cutters, which will produce a square cut. No wedge-type roller cutters will

be permitted.

The sharp edge of the cut surface shall be smoothed manually or by power

operated grinders.

Butt fusion welding will be used for joining the high density polyethylene

pipes. Butt fusion jointing involves the fusion of two pipe ends together in

a machine manufactured for the fusion of HDPE pipes which prepare the

pipe ends, heat them and bring them together under pressure to form a

homogeneous weld. The joint is fully end load resistant and is at least as

strong as the parent pipe. Pipe to be joined should be kept levelled prior to

jointing.

Connection of the pipes to WAVIN manholes:

Installation guide for installation of manholes and connection of the pipes

to WAVIN manholes is described in Annexes 1 and 2.

November 16, 2018

22

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

1. Manholes installation

The manholes TEGRA 600 will be installed according to Annex 1.

The manholes SX 400 will be installed according to Annex 2.

2. Connection of the pipes to TEGRA 600 and SX 400.

Each socket of the base of TEGRA 600 is supplied with the sealing.

3. PE adaptors will be installed inside the socket of the WAVIN base (see

items 6, 7, 8, 9 of the Material List in Chapter 20) according to the

appropriate diameters.

4. The corrugated pipes will be inserted to the PE adaptors.

5. The house connections to WAVIN manholes will be done via PE

adaptor DN 150 (see item 5 of the Material List of the Chapter 20).

Manholes and fitting Assembly:

1. Connection between manhole of Wavin SX 400 and the piping system

November 16, 2018

23

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

The connections between manhole of Wavin SX 400 and the piping system

will be done by means of special connector PE DN 160 as shown below:

2. Connection between manhole of Wavin Tegra 600 and the piping

system

The connection between manhole of Wavin Tegra 600 and the piping

system will be done by means of special connectors PE DN 200/315/400

as shown below:

November 16, 2018

24

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

25

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

3. Connection between house connections and manhole of Wavin Tegra

600

November 16, 2018

26

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

The connection between house connection and manhole of Wavin Tegra

600 will be done by means of special connectors PP as shown below:

November 16, 2018

27

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Sewer House Connections (SHC):

1. Size of SHC

SHCs for residential services are of 150 mm.

2. Connection of the SHC to the Mainline Sewer of the diameter of

200/300 mm

Connection from the SX 400 to the Mainline Sewer will be arranged by

direct connection to the mainline as shown in the scheme below:

3D View

November 16, 2018

28

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Plan

Section

November 16, 2018

29

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

3. Connection of the SHC to the Mainline Sewer of the diameter 400 mm

and more

Connection from the SX 400 to the Mainline Sewer of big diameter (400

mm and more will be arranged by collecting sewer from the houses by

mini-system of 150 mm and connecting to the Main Pipe only in the

Manholes as shown in the scheme below.

3D View

November 16, 2018

30

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Plan

November 16, 2018

31

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Section

14. Curves & Bends

The bends will be the same wall thickness as the joining pipes executed

according to DIN 2605. Radius 1.5 x D.

15. Backfilling and Compaction of Trenches

Bedding around mains and service laterals is to be thoroughly compacted

by hand-operation or by approved mechanical compactor, avoiding damage

to the new laid pipework.

No backfilling of trenches will be done until the pipes to be covered have

been inspected.

Marker tapes will be laid 0.25 m above the top of the pipes but not deeper

than 0.70 m below GL, to indicate buried wastewater gravity pipes or

pressure pipes. The tape will include all required information (see sample

of tape in picture below).

November 16, 2018

32

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

The trenches will be refilled using suitable material selected from the

excavation. Soil free from stones greater than 2.5 cm in size called soft

material will be deposited in 15 cm layers and thoroughly rammed working

alternately on either side of the pipe until the filling has been carried out at

least 30 cm above the top of the pipe.

Medium and heavy compacting equipment may first be used after a

minimum covering compacted height of 1.0 m has been achieved.

The coarse filling will be carried out to the level at which surface

reinstatement is to commence.

All compaction will be by hand-operated, plate-type, vibratory, or other

suitable hand-tampers in areas not accessible to larger rollers or

compactors. Extreme care will be taken to avoid damage to conduits, pipes,

and any appurtenances.

November 16, 2018

33

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Where necessary adjustment of the moisture content of the refill material

will be done in order to execute the compaction according with proctor

reference.

Compaction around the pipe – and especially below and around the

corrugated HDPE pipes - shall be by hand-operated compacting plate-type,

vibratory or other suitable hand tampers and adjust the moisture content of

the refill material where necessary, to assure that all voids are filled.

Backfill will be compacted to a dry density of not less than 90% of the

maximum dry density in general and or at least to suit the following

requirements depend upon the location of the backfill.

One compaction test for each working day backfilling of trenches is carried

out or agreed upon with the Engineer.

At least one official test for compaction jointly with the relevant road

authorities will be done for every 500 m of pipe laying along the roadways.

Backfilling materials will be according to the lab results presented in

Annex 3.

16. Testing of Pipes during Installation

The tests required will be carried out continuously during the installation of

pipes and fittings. Tests will be carried out in accordance with EN 1610 or

equal testing standards. Tests carried out will be documented in reports that

will be presented for approval of the Engineer.

The Contractor will furnish all equipment and materials for making the

tests. Each pipeline shall be tested before backfilling. All pipes are to be

clean and empty at the time of testing. Tests will be performed in the

presence of the Engineer.

Gravity pipes

Gravity pipes will be tested by air test in accordance with the requirements

of the standard.

November 16, 2018

34

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

The Contractor will plug all pipe outlets with suitable plugs, and brace each

plug securely where needed.

Air shall be pumped in slowly to the pipe until a pressure of 100 mm water

gauge is indicated on a manometer connected to the system. After the

internal pressure of 100 mm water gauge is obtained, 5 minutes shall be

allowed for the air temperature to stabilize within the pipe.

Air may be added to restore the pressure to 100 mm water gauge. During a

further period of 5 min, the pressure shall not fall below 75 mm water

gauge without further pumping.

Infiltration test for gravity pipes

An infiltration test for gravity pipes will be performed. The upper ends of

the sewer and service connections will be closed sufficiently to prevent the

entry of water and pumping of groundwater will be discontinued until the

groundwater surface reaches its natural level before beginning the

infiltration test.

The dewatering system will be stopped, but not be removed until the

infiltration test has been successfully completed or as otherwise permitted

by the Engineer.

The infiltration will not exceed 6 litres per millimetre diameter per

kilometre per day of the portion of sewer being tested, including the length

of service connection entering that section

The total length tested in one section shall not exceed 400 m in length.

Pressure pipes

Pressure pipes will be tested by water test in accordance with the

requirements of the standard.

After the pipe has been laid, all newly laid pipe or any valve section thereof

shall be subjected to a hydrostatic pressure of at least 1.5 times the working

pressure at the point of testing, Each valve section of pipe will be slowly

filled with water, and the specified test pressure (based on the elevation of

the lowest point of the line or section under test and corrected to the

elevation of the test gauge) shall be applied by means of a pump connected

November 16, 2018

35

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

to the pipe. Valves will not be operated in either the opening or closing

direction at differential pressures above the rated pressure. The test

pressure shall not exceed the rated pressure of the valves when the pressure

boundary of the test part includes closed, resilient-seated gate valves or

butterfly valves. It is a good practice to allow the system to stabilize at the

test pressure before conducting the leakage test.

Stop ends will be provided. They may be jointed to the pipe to be tested by

means of a standard coupling or other method approved by the Engineer.

Reliable thrust blocks or temporary anchorage will be provided to hold the

stop ends in place against the test pressure.

The pressure in the pipeline should be raised steadily until the site test

pressure is reached in the lowest part of the section. This pressure should

be maintained, by pumping if necessary, for a period of 1 hour. The pump

should then be disconnected and no further water permitted to enter the

pipeline for a period of 1 hour. At the end of this period, the original

pressure should be restored, by pumping and the loss measured by drawing

off water from the pipeline until the pressure reached at the end of the test

is reached again.

Before applying the specified test pressure, air shall be expelled completely

from the section of piping under test. If permanent air vents are not located

at all high points, corporation cocks shall be installed at such points so that

the air can be expelled as the line is filled with water. After all the air has

been expelled, the corporation cocks shall be closed and the test pressure

applied. At the conclusion of the pressure test, the corporation cocks shall

be removed and plugged or left in place.

Water required for pressure testing shall be free from impurities and of

such a quality that will not pollute or injure pipelines.

Manholes

Manholes and inspection chamber will be tested with water. Test pressure

will correspond to a filling height to approximately 10 cm below the

reference level. The reference level of manhole is the top edge of the taper

or of the chamber unit below cover slab. The testing time shall be 30 min.

November 16, 2018

36

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

the test requirement is satisfied if the variation of volume of water during

the test not greater than 0,40 l/m2/

Test equipment

1. Bourdon type manometer

November 16, 2018

37

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

2. Piston compressor

3. Centrifugal compressor

November 16, 2018

38

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

4. Positive displacement pump

5. Balloons plugs

17. Reinstatement of Surfaces Paved and Non-Paved

Areas.

All surfaces of roads, fields, paths, gardens, verges, etc. which are affected

by the works will be temporary restored in the first instance and

permanently reinstated in the second instance when the ground has

consolidated fully.

In the case of roads and streets, the surface shall be mechanically rolled

during the progress of the work as often as may be necessary to consolidate

the filling and keep the surface fit for traffic, suitable material being added

to all places which have sunk or become rough.

Permanent reinstatement of concrete or asphalt roads will be made until the

ground has consolidated permanently and until sanction to do so is received

from the Engineer. It will be carried out conforming to the specification for

roads specified applicable to the type of road to be reinstated.

November 16, 2018

39

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

18. Safety

Every hydraulic zone shall have its own graphic plan showing the

demarcation and the order of the execution of the works. In this drawing

the Contractor will indicate the traffic deviation, the distribution of the

material (from excavation trenches), the arrangement of warning signs, the

arrangement of the “do not crossing tapes”, and the fences if applicable.

The Contractor will present the filled and signed form for each house

connection, in the corresponding format with the notification of works and

the approval of the location in the area with the coordinates for the house

connection (manhole Ø 400 mm).

In every street, the execution of house connection will be done only in one

side of the street (left or right) in order to allow controlled traffic,

transporting of material and access to the parking of the existing houses.

Once the pipe from the house connection is joined to the corresponding

gravity pipe, the open trench will be backfilled with previous approval of

the Engineer. Then, excavation for house connection in the other side of

the street will start. In this way, impact on the community shall be

minimized.

All signs and traffic warning signals will be kept clean and legible at all

times and to be repositioned as the work progresses.

When persons are required to enter trenches, 1.20 m or more in depth, an

adequate mean of exit, such as a ladder or steps, will be provided and

located.

Additional precautions, by way of shoring and bracing, will be taken to

prevent slides or cave-ins when trenches are dug in locations adjacent to

backfilled areas or are subjected to vibration from road traffic, the

operation of machinery, or any other sources. Cross braces or trench jacks

will be placed in horizontal position, be spaced vertically, and be secured

to prevent sliding, falling or kick-outs.

During the excavation and backfilling activities no personal shall be

allowed inside of the existing trenches.

When supported material or shoring panels are being removed, no personal

shall be allowed inside of the trenches during their lifting.

November 16, 2018

40

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

19. Environmental Protection

The Contractor will take all reasonable steps to protect the environment

(both on and off the Site) and to limit damage and nuisance to people and

property resulting from pollution, noise and other results or his operations.

Where trench excavation for pipe laying is carried out, the Contractor will

assume full responsibility for protection of environment during his

operation. Surrounding structures, service lines. drains etc have to be

carefully protected up to the maximum possible extent to minimize injury

or any kind of damage to third parties.

Before commencing excavation, the Contractor will contact all the

responsible owners of such services within the work area and confirm the

existence, position or status of such utilities and keep an authorized record

on them. It will also receive from the local utilities companies the location

of the existing infrastructures in the area and will keep their record

Existing utilities and opened drainage will be protected to prevent their

damage or contamination caused by the execution of the works.

Photographical or video recording will be registered during the

preconstruction survey to use in case of any claim from the owners of the

existing utilities and houses affected by the construction process.

November 16, 2018

41

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

20. Equipment and material

Equipment list:

No. Equipment Name Specification / Photo

1 Wheel excavator VOLVO EC-250, 1.2 m3 - 25 ton

2 Mini excavator KOMATSU PC 35 MR-2,

CATERPILLAR 304

November 16, 2018

42

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Equipment Name Specification / Photo

3 Backhoe loader VOLVO BL 61B, 0.65 m3 - 1 m3

4 Bobcat Bobcat S70, 343, S 530

5 Auto-crane KAMAZ KC-55713-5B, 6x6, 25 ton, up to 32

meters.

6 Crane truck 1. KAMAZ 53229, 24 ton.

2. MERSEDES BENZ ATEGO 950,50 18 ton.

November 16, 2018

43

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Equipment Name Specification / Photo

7 Dump truck KAMAZ 53229, 15 ton.

SHACMAN SX3317DT306G, 44 ton.

8 Trailer truck SCANIA R124LA4X2NA 420.

RENAULT MAGNUM440.

9 Bus UAZ 39629

10 Car Mitsubishi Pajero, Mitsubishi Delica, Nissan

Titan, Opel Combo.

11 Generators 75, 50, 11, 6 KW

12 Hand Compactor EY20-3L

13 Compactor GCAAH-3927027

November 16, 2018

44

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Equipment Name Specification / Photo

14 Compaction test

equipment

15 Compaction test

equipment

14 GPS Leica GNNS08

15 Total station Leica TS06

16 Welding machine

November 16, 2018

45

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Material List:

No. Material Name Photo

1 HDPE PRESSURE PIPE

2 HDPE CORRUGATED PIPE

3 PE 45° Corrugated TEE

4 PE 90 ° ELBOW

5 PE ADAPTOR DN 150

November 16, 2018

46

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Material Name Photo

5 PE ADAPTOR FOR THE

CONCRETE MANHOLES

6 PE ADAPTOR 200 FOR

WAVIN TEGRA 600

November 16, 2018

47

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Material Name Photo

7 PE ADAPTOR 315 FOR

WAVIN TEGRA 600

November 16, 2018

48

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Material Name Photo

8 PE ADAPTOR 400 FOR

WAVIN TEGRA 600

November 16, 2018

49

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

No. Material Name Photo

9 Proposed connector PE for SX

400, DN 160

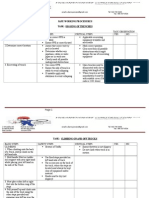

21. The forms to be submitted for test records.

The following forms will be submitted for various test records:

Act of hidden works

Act of compaction

Pressure pipe test form

Sewer line Air Test form

Manhole test form

All forms are presented in Annex 4.

November 16, 2018

50

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Annexes

November 16, 2018

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Annex 1:

Installation guide for installation of WAVIN manholes Tegra 600 and

connection of the pipes to the manholes

November 16, 2018

Non-Entry Chamber Tegra 600

Installation guide

Installation guide

1. Level the bottom of the trench and remove 2. Place the chamber base on the sand bed- 3. It is recommended to backfill the trench at

large and sharp stones. Prepare a non- ding. Connect sewer piping and adjust the an- least 30 cm above the top surface of the

compacted sand bedding 10 cm high. gle of pipe connection precisely (adjustment sewer pipe. Cover with backfill and com-

range: +/- 7.5º). Level out the top of the cham- pact, layer by layer.

ber base.

4. Cut the DN600 corrugated shaft pipe 5. Fix the sealing ring delivered with the base 6. As the sealing ring fixed on the corrugated

either manually or mechanically to fit the in the lowest groove (hollow part) between pipe is profiled, its position must be in line

required height of the chamber. the outer ribs of the corrugated shaft pipe. with a drawing on the label.

7. Base socket must be cleaned and lubrica- 8. Backfill the trench layer by layer. Compact Note! Compact the ground around the cham-

ted to make the installation of corrugated layers of backfill uniformly along the entire ber gradually and in accordance with technical

pipe easier. circumference of the inspection chamber. design observing guidelines included in PN-

Soil must be compacted adequately to the ENV 1046. Be careful and do not cause the

current ground and water conditions as

ovalization of the chamber. During the assembly

well as the future external load. It is recom-

process pay particular attention to maintain

mended to compact the soil at the mini-

mum SPD level (Standard Proctor Density) density during the works (e.g. while removing

of: shoring) and after completing the chamber (se-

• SPD 90% in green areas, curing the backfill against loosening e.g. by wa-

• SPD 95% in roads with limited traffic shing out fine fractions). The method of carrying

load, earthworks must be in accordance with regula-

• SPD 98% in roads with heavy traffic tions included in PN EN 16 10:2002.

load.

In the case of high ground water level, it is

recommended to increase the degree of

soil compaction to the minimum level of

95% Proctor (SPD) for the first case, and

98% Proctor (SPD) for the second case.

PHONE FAX E-MAIL

58 +48 61 891 10 00 +48 61 891 10 11 kontakt_pl@wavin.pl

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Telescopic Riser

Wavin Tegra 600

Installation guide Tegra 600

Clean the riser and the corrugated shaft pipe with a cloth.

1) Fix the sealing in the first groove of the corrugated pipe.

2) Lubricate the seal and the corrugated shaft pipe.

3) Connect the grating or cover with the telescopic pipe

4) Fix the cast iron cover

November 16, 2018

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

November 16, 2018

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Annex 2:

Installation guide for installation of WAVIN manholes SX ø400 and

connection of the pipes to the manholes

November 16, 2018

Non-Entry Chambers Ø425, Ø400 and Ø315

Installation guide

Installation guide

1. As inspection chambers are small in size, 2. Place the base horizontally on the non-com- 3. Cut the corrugated shaft pipe to fit the re-

there is no need to extend trenches above pacted sand bedding 5-10cm high (levelling quired height of the chamber on the con-

the minimum trench dimensions required to layer on the trench bottom). As-dug material struction site, using a hand saw.

install sewer piping. Individual elements are may be used as the bedding, backfill and si- Remember to cut in the middle of corruga-

very light and may be handled and installed defill, provided that it meets all requirements tion hill, not in corrugation valley!

by one person. specified for sand beddings, backfill and si-

defill materials. While levelling the base out,

remember about the build-in slope of the ba-

se bottom of 1.5%. In straight-flow bases, an

arrow indicates the correct direction of sewa-

ge flow.

4. Fix the sealing ring at the lowest groove 5. Clean and lubricate the base socket. (use only 6. Backfill the chamber with a loose material;

between the outer ribs of the corrugated professional lubricates approved for rubber the material must be easy to compact.

shaft pipe. seals and plastics). Fix the shaft pipe in the Backfill layers must be uniformly spread

base socket and push home. This connection around the shaft pipe. Compact the backfill

is tight. The cap removed from the base soc- in layers (layer thickness: up to 30cm). Soil

ket must be fixed on top of the corrugated pi- must be compacted adequately to current

pe to protect it against contamination during conditions in the location, as well as exi-

subsequent work-in-progress. sting or expected external loads. It is re-

commended to compact the soil at the mi-

nimum SPD level (Standard Proctor

Density) of SPD 92% for green areas, SPD

95% for paved areas with limited traffic lo-

ad, and SPD 98% for roads with heavy

traffic loads. In the case of high ground wa-

ter level (above the chamber bottom level) it

is recommended to adopt a stricter instal-

lation regime and increase the degree of

soil compaction – one level up.

7. If cast-iron covers with telescopic pipe or 8. Lubricate the sealing ring and fix the cover.

corrugated pipe are used, fix the sealing Align the position of the top part of the gra-

ring delivered with the pipes at the highest ting or cover with the level of the surroun-

groove between the valley of the corruga- ding area.

ted pipe. Connect the grating or cover with

the telescopic pipe (snap-in-place mecha-

nical connection).

INSPECTION CHAMBERS AND MANHOLES Product catalogue – April 2012

Inspection Chambers and Manholes

www.wavin.pl 93

Non-Entry Chambers Ø425, Ø400 and Ø315

Installation guide/The solution

Installation of the “in-situ” connector

In situ connectors are designed for “on-site” making additional When connections are made in existing and operating sewer

channel connections above a base (on the height of corruga- network, dig a trench along the entire circumference of the

ted pipe). pipe and after the connection is completed, precisely com-

pact the soil around it, in accordance with chamber installation

guidelines.

1. Use special drill saw to cut an opening in 2. Install a special seal in the opening and lu- 3. Such “in-situ” connector is ready to place a

the corrugated pipe. Clean and polish bricate it. Put special “in-situ” socket in the smooth-wall, PVC sewer pipe inside it.

sharp edges of the opening. opening.

Backdrop chambers

When the sewer system with diameter up to 0,4m is to be located chamber shaft by using in-situ connector (ø110 or ø160). When the

within area of large level differences (the pitch between 0,5m-4,0m) it sewer supply pipe diameter is bigger than 160mm the connection

is necessary to install a backdrop chamber, which can be made with to Tegra 425, shaft pipe is made according to the way shown in the

the downpipe either inside or outside of the manhole. picture. The downpipe is led as the standard backdrop connection

by using the vertical pipe or the pipe at the angle of 45º.

In the case of non-entry chambers, in this Tegra 425, it is not neces-

sary to install the downpipe. Connection can be made directly to the

Sediment chambers (gullies)

Elements of inspection chambers: ø315, ø400 and ø425 may Alternatively, choose ready-to-use solution of the ø315 and 425

be also used to construct gullies with sediment chambers for rain water chamber presented in this catalogue.

storm-water house drains. In order to do so, instead of the pre- It is possible to connect additional sludge basket under the gully

formed base - use PP cover/bottom, a section of corruga- (cf. pages 90 and 67)

ted pipe and grating (of B125 or D400class) presented in this

Optionally an additional sludge basket may be installed under

catalogue.

the gully.

The outlet may be installed at any height of the corrugated pipe

on the construction site, using special “in situ” connectors.

PHONE FAX E-MAIL

94 +48 61 891 10 00 +48 61 891 10 11 kontakt_pl@wavin.pl

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Annex 3:

Backfilling materials

November 16, 2018

You created this PDF from an application that is not licensed to print to novaPDF printer (http://www.novapdf.com)

You created this PDF from an application that is not licensed to print to novaPDF printer (http://www.novapdf.com)

You created this PDF from an application that is not licensed to print to novaPDF printer (http://www.novapdf.com)

You created this PDF from an application that is not licensed to print to novaPDF printer (http://www.novapdf.com)

Construction of Sewerage Systems in Poti

Method Statement for Pipe Works

Annex 4:

Forms of Acts and Tests

November 16, 2018

Sewage System in Poti / Act of Hidden Works

foTis kanalizaciis sistema / faruli samuSaoebis aqti

1.Manhole and Pipe data

1.Webis da milis monacemi

Start Date/daw. TariRi End Date/das. TariRi

LINE /xazi Asphalted/Not Asphalted

SECTION BETWEEN /seqcia Soris

Manhole No. /Wa N. Manhole No./ Wa N.

X: Y: X: Y:

GL: GL:

IL: IL:

Depth/siRrme Depth/siRrme

Type/tipi F S REC Type/tipi F S REC

Base/baza: {type.code} Base/baza: {type.code}

Rings/ rgolebi: {q-ty, length, code} Rings/ rgolebi: {q-ty, length, code}

plastic Pipe Length/plast. rgolis sigrZe plastic Pipe Length/plast. rgolis sigrZe

conus/konusi: {code} conus/konusi: {code}

adaptor/adaptori: {code} adaptor/adaptori: {code}

Cover Type/xufis tipi

additional excavation for dewatering /sketch/ dametebiTi eqskavacia dehidrataciisTvis/eskizi/

HDPE corrugated pipe DN

L=

HDPE gofrirebuli mili DN

Liquid Soil Gravel Drainage Sand Under/above pipe Backfilling-Trench soil

Txevadi miwa xreSis drenaJi baliSi milis qveS ukuCayra

Ground Water Water Pumping Gravel Under the Asphalt Backfilling-Ballast

miwisqveSa wyali wylis amotumbva xreSi asfaltis qveS ukuCayra balasti

Trial Pits Volume excavation

Length

Width

Depth

SUB-CONTRACTOR/sab-kontraqtori CONTRACTOR/kontraqtori ENGINEER/inJineri

date/TariRi: date/TariRi: date/TariRi:

{name} {name} {name}

{signature} {signature} {signature}

Sewage System in Poti / Test of compaction

foTis kanalizaciis sistema / faruli samuSaoebis aqti

1.Manhole and Pipe data

1.Webis da milis monacemi

Start Date/daw. TariRi End Date/das. TariRi

LINE /xazi Asphalted/Not Asphalted

SECTION BETWEEN /seqcia Soris

Pressure pipe zone. P.S / wneviani milis zona. s.s

Y: X: Y:

GL: GL:

IL: IL:

Depth/siRrme Depth/siRrme

Type/tipi F S REC Type/tipi F S REC

Bend/muxli Bend/muxli

adaptor/adaptori adaptor/adaptori: {code}

additional excavation for dewatering /sketch/ dametebiTi eqskavacia dehidrataciisTvis/eskizi/

Pressure pipe OD

L=

wneviani mili OD

Liquid Soil Gravel Drainage Sand Under/above pipe Backfilling-Trench soil

Txevadi miwa xreSis drenaJi baliSi milis qveS ukuCayra

Ground Water Water Pumping Gravel Under the Asphalt Backfilling-Ballast

miwisqveSa wyali wylis amotumbva xreSi asfaltis qveS ukuCayra balasti

datkepnis Sedegebi/Compression Results

Chainage Geometry Compaction

Sand bedding, Bottom

qviSis fena, qveda

Sand bedding, Above

qviSis fena, zeda

ukuCayra

Backfilling

SUB-CONTRACTOR/sab-kontraqtori CONTRACTOR/kontraqtori ENGINEER/inJineri

date/TariRi: date/TariRi: date/TariRi:

{name} {name} {name}

{signature} {signature} {signature}

Pressure Pipe Test Form

Poti

Test Date: Contractor/Superintendent:

Project Name:

City Project Number: Engineer/inspector

Location:

Test Parameters

Required test pressure:

Test starting time:

Test ending time

Test duration (ending – starting time)

Test Equipment – Pressure Gauge

Type

Pressure range

Calibration date

Results

Pressure test:

Satisfactory/Unsatisfactory

Remarks:

Sewer Line Low Pressure Air Test Form

Poti

Test Date: Contractor/Superintendent:

Project Name:

City Project Number: Engineer/inspector

Location:

Plan Upstream Start End

Upstream Downstream Downstream Start End Pass or

Sheet Sta. Pressure Pressure

manhole manhole Sta. Number Time Time fail

Number Number (psi) (psi)

Manhole Water Test Form

Poti

Test Date: Contractor/Superintendent:

Project Name:

City Project Number: Engineer/inspector

Location:

Initial level Final level Water

Plan Sheet Manhole Sta. Start Pass or

(m from End Time (m from addition

Number number Number Time fail

surface ) surface) (l/m2)

You might also like

- METHOD STATEMENT FOR TOILET (Temporary) CONSTn.23.3.23Document21 pagesMETHOD STATEMENT FOR TOILET (Temporary) CONSTn.23.3.23vinayp talpadaNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Method Statement For Installation of PVC PipesDocument13 pagesMethod Statement For Installation of PVC PipesChathura Dharmasena100% (3)

- Method Statement Sheet PilingDocument9 pagesMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- Drift Work MethodologyDocument8 pagesDrift Work MethodologyTheodore Teddy Kahi100% (3)

- Example Method StatementDocument9 pagesExample Method StatementMuhammadWazimAkramNo ratings yet

- Method Statement For Pipe Laying Along Road Shoulder - Edurapotha 2Document2 pagesMethod Statement For Pipe Laying Along Road Shoulder - Edurapotha 2BMWGNo ratings yet

- Penstock Erection Procedure - SUHEPDocument7 pagesPenstock Erection Procedure - SUHEPPrasanta Malla0% (1)

- Method Statment - Concrete Pour SoGDocument3 pagesMethod Statment - Concrete Pour SoGMuhammad Zafar Iqbal100% (1)

- DD Env 1994-1-1-1994Document161 pagesDD Env 1994-1-1-1994xander198267% (3)

- Majnoon Sour Gas Treatment Facility Project: MGP1-GP2-CPC-LA-7880-1501 003Document32 pagesMajnoon Sour Gas Treatment Facility Project: MGP1-GP2-CPC-LA-7880-1501 003mohammedNo ratings yet

- Method StatementDocument3 pagesMethod StatementmemekenyaNo ratings yet

- Mos - RPR Pipe JackingDocument11 pagesMos - RPR Pipe Jacking7e1a8821No ratings yet

- Check List For Foundation OHE - 001 - Rev - 00Document4 pagesCheck List For Foundation OHE - 001 - Rev - 00Varadharajalu Gopal100% (2)

- Method Statement For Slab On GradeDocument3 pagesMethod Statement For Slab On Grademustafa75% (4)

- Method Statement UG GRE R 3 PDFDocument46 pagesMethod Statement UG GRE R 3 PDFRashid Kayum50% (2)

- Guniting Slope, Ed.1, Rev.0Document8 pagesGuniting Slope, Ed.1, Rev.0Andrei Radu100% (2)

- 2.MS For Relocation of SewerageDocument9 pages2.MS For Relocation of Seweragechandar70No ratings yet

- Method Statement: Personnel and Site OrganizationDocument6 pagesMethod Statement: Personnel and Site OrganizationМаринаNo ratings yet

- microtrenchDocument2 pagesmicrotrenchAhmed FahmyNo ratings yet

- BorronDocument6 pagesBorronEl Charasquiada CharroNo ratings yet

- Ek 29 Boru Hattı Montaj Uygulama Planı (Pipeline Erection Method Statement) ÖrneğiDocument6 pagesEk 29 Boru Hattı Montaj Uygulama Planı (Pipeline Erection Method Statement) ÖrneğiMohamed100% (1)

- Coating PipeDocument16 pagesCoating PipeHanderi MattjikNo ratings yet

- WMS - Pipe Laying OutsideDocument4 pagesWMS - Pipe Laying OutsideLasandu WanniarachchiNo ratings yet

- Pipe CoatingDocument51 pagesPipe CoatingAndy ChongNo ratings yet

- Pipeline Coating ProcessDocument34 pagesPipeline Coating Processzenisler100% (2)

- Pipe Laying MetodeDocument27 pagesPipe Laying MetodeMochamad SafarudinNo ratings yet

- MOS - PipeBridge SG SebatangDocument13 pagesMOS - PipeBridge SG Sebatang7e1a8821100% (1)

- Method Statment For Diverted Vally Water-Realigned Access Road-N301Document7 pagesMethod Statment For Diverted Vally Water-Realigned Access Road-N301vinayp talpadaNo ratings yet

- Trench Excavation, Backfilling & RR 03.09.2018Document19 pagesTrench Excavation, Backfilling & RR 03.09.2018Civil EngineerNo ratings yet

- Op-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Document3 pagesOp-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Garry Yan DiazNo ratings yet

- Going Trenchless HistoryDocument3 pagesGoing Trenchless HistoryJoyce Wm Wong100% (2)

- Method Statement For Installation of GRE PipingDocument11 pagesMethod Statement For Installation of GRE Pipingmichaelnicodemus93No ratings yet

- I. Methodology of ConstructionDocument21 pagesI. Methodology of ConstructionDominique DominiqueNo ratings yet

- Appendix F Pipeline Construction Schedule and Tasks: Temporary Fence InstallationDocument5 pagesAppendix F Pipeline Construction Schedule and Tasks: Temporary Fence InstallationMd Izzuddin OmarNo ratings yet

- Concrete WorksDocument4 pagesConcrete WorksmrameshceNo ratings yet

- Method Statement - Concreting WorkDocument4 pagesMethod Statement - Concreting WorkArnold Roy ManaloNo ratings yet

- Trench Excavation_Backfilling and RR Uploaded on 08-08-2022Document17 pagesTrench Excavation_Backfilling and RR Uploaded on 08-08-2022m fathul alyNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 35270 446041633Document12 pagesT Proc Notices Notices 040 K Notice Doc 35270 446041633Amjad aliNo ratings yet

- GRP Installation UndergroundDocument46 pagesGRP Installation UndergroundRajiv R'n'bNo ratings yet

- Section 819 Microtunneling and Pipe-Jacked TunnelsDocument22 pagesSection 819 Microtunneling and Pipe-Jacked TunnelsthowchinNo ratings yet

- S TR CIVIL OHL (Rev.0 2018) 1648785693296Document33 pagesS TR CIVIL OHL (Rev.0 2018) 1648785693296Vimala PonnusamyNo ratings yet

- Installation Manual - Safdal RTP Products - Rev03 - 2023.02.14Document40 pagesInstallation Manual - Safdal RTP Products - Rev03 - 2023.02.14Oscar MoraNo ratings yet

- Channel Formwork ProcessDocument17 pagesChannel Formwork ProcessScribdTranslationsNo ratings yet

- C.1 Method Statement For Pipeline Maintenance and Emergency RepairsDocument17 pagesC.1 Method Statement For Pipeline Maintenance and Emergency Repairsagbon johnNo ratings yet

- Pipe LayingDocument14 pagesPipe Layingfrancis pacaigueNo ratings yet

- PCC Slab Full Depth Repair MethodologyDocument4 pagesPCC Slab Full Depth Repair Methodologypascua.jpmNo ratings yet

- Microtunneling Pipe Jacking Construction Specification PDFDocument16 pagesMicrotunneling Pipe Jacking Construction Specification PDFadalcayde2514No ratings yet

- Tel No.: 0141-2721966, Fax No.: 0141-2721919, Email: Mail@ruidp - Gov.in, Web Site: WWW - Ruidp.gov - inDocument4 pagesTel No.: 0141-2721966, Fax No.: 0141-2721919, Email: Mail@ruidp - Gov.in, Web Site: WWW - Ruidp.gov - inPrasenjit DeyNo ratings yet

- Trench Preparation Excavation and Backfill Method Statement For Electric Undergr 2024-02-13 07 - 31 - 03Document16 pagesTrench Preparation Excavation and Backfill Method Statement For Electric Undergr 2024-02-13 07 - 31 - 03Tomas Casillas-GerenaNo ratings yet

- Detailed Specifications - EarthworkDocument10 pagesDetailed Specifications - EarthworkKishan KumarNo ratings yet

- Method Statement For Installation & Hydrotest of GRP & Upvc PipesDocument19 pagesMethod Statement For Installation & Hydrotest of GRP & Upvc PipesBAVA M.HNo ratings yet

- MS-E-02 Installation of Electrical Manhole & Underground PipeDocument8 pagesMS-E-02 Installation of Electrical Manhole & Underground PipeTan Chek Yau100% (1)

- Method Statement Concrete PouringDocument4 pagesMethod Statement Concrete PouringSmart ShivaNo ratings yet

- Department of Public Works and HighwaysDocument10 pagesDepartment of Public Works and HighwaysAnthony TangNo ratings yet

- Work MethodDocument22 pagesWork MethodQianlei ZhuNo ratings yet

- Method Statement Egostino Services LTDDocument10 pagesMethod Statement Egostino Services LTDajie denzelNo ratings yet

- Method of Statement (ELECTRICAL) - PONAMI APARTMENTDocument5 pagesMethod of Statement (ELECTRICAL) - PONAMI APARTMENTNaing Win TunNo ratings yet

- Priced Bill of Quantities: The Existing Driveway StructureDocument12 pagesPriced Bill of Quantities: The Existing Driveway StructuremideladNo ratings yet

- Technical Specifications of Tubewell WorksDocument13 pagesTechnical Specifications of Tubewell WorksLeng Chai100% (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Turkish ComprehensiveDocument6 pagesTurkish Comprehensivexander1982No ratings yet

- Brn3c2af41c072e 053265Document66 pagesBrn3c2af41c072e 053265xander1982No ratings yet

- ABUMN Post Asset TransferDocument17 pagesABUMN Post Asset Transferxander1982No ratings yet

- Sap 2000Document102 pagesSap 2000xander1982No ratings yet

- AQUAPANEL Cement Board Outdoor Datasheet 0817Document3 pagesAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982No ratings yet

- Datasheet Lantern Technology ID 369Document4 pagesDatasheet Lantern Technology ID 369xander1982No ratings yet

- SolaMAXSERIES REV5 PDFDocument2 pagesSolaMAXSERIES REV5 PDFxander1982No ratings yet

- Datasheet Monitoring AIS Web PDFDocument4 pagesDatasheet Monitoring AIS Web PDFxander1982No ratings yet

- Paledi 11kV Cable - Design, 27 April 21, Rev 0Document16 pagesPaledi 11kV Cable - Design, 27 April 21, Rev 0Farney BellamyNo ratings yet

- PIU-SULTANPUR File No - 1624Document15 pagesPIU-SULTANPUR File No - 1624Purvanchal Expressway P-5678No ratings yet

- Trenwa Trench Catalog 2012 PDFDocument54 pagesTrenwa Trench Catalog 2012 PDFgormankungNo ratings yet

- FOC - Laying OGCDocument13 pagesFOC - Laying OGCjahanzaibNo ratings yet

- Archaeological Excavation at Mellor. 2002Document36 pagesArchaeological Excavation at Mellor. 2002digitalpastNo ratings yet

- المواصفات الفنية لاعمال شبكات المياه والصرف الصحيDocument214 pagesالمواصفات الفنية لاعمال شبكات المياه والصرف الصحيmanar rafikNo ratings yet

- WP contentuploads202008UHDE Specs - Section 1 - Earth Work PDFDocument1 pageWP contentuploads202008UHDE Specs - Section 1 - Earth Work PDFBAWA ALEXNo ratings yet

- Excavation and Trenching ChecklistDocument8 pagesExcavation and Trenching Checklistpatrick chegeNo ratings yet

- Perspective Review On Subsea Jet Trenching Technology and ModelingDocument27 pagesPerspective Review On Subsea Jet Trenching Technology and ModelingJeff QinNo ratings yet

- Woodlands, Staunton Archaeological Watching Brief, APAC. LTDDocument46 pagesWoodlands, Staunton Archaeological Watching Brief, APAC. LTDAPAC LtdNo ratings yet

- Method Statement For Foul Sewer Network - R04Document28 pagesMethod Statement For Foul Sewer Network - R04muhammedpmubarakNo ratings yet

- Is Code For Exploration of ShaftsDocument20 pagesIs Code For Exploration of Shaftslokesh aggarwalNo ratings yet

- Email HDC Installation Instructions Patio or Pool HIGHDocument4 pagesEmail HDC Installation Instructions Patio or Pool HIGHRogie TolentinoNo ratings yet

- Deadman Anchor Quick Guide Low ResDocument2 pagesDeadman Anchor Quick Guide Low ResmohsenNo ratings yet

- More Random Encounters RemasteredDocument34 pagesMore Random Encounters RemasteredjavandarNo ratings yet

- P6022MAB.000.51S.004a01 - FDH JV HSE HandbookDocument42 pagesP6022MAB.000.51S.004a01 - FDH JV HSE HandbookbabjihanumanthuNo ratings yet

- Pipe Layingmanual 2012 EditionDocument127 pagesPipe Layingmanual 2012 EditionSharon LambertNo ratings yet

- Excavation and Trench SafetyDocument7 pagesExcavation and Trench SafetyKarim KachourNo ratings yet

- U4-SY-109-L1000028 (Rev.L)Document14 pagesU4-SY-109-L1000028 (Rev.L)arbazNo ratings yet

- OSHJ-CoP-08 Safe Excavation Version 1 EnglishDocument17 pagesOSHJ-CoP-08 Safe Excavation Version 1 EnglishsajinNo ratings yet

- Hira Gaurd HouseDocument14 pagesHira Gaurd HouseNagadevan GovindanNo ratings yet

- GF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedDocument3 pagesGF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedsureshNo ratings yet

- Safe Working ProcedureDocument23 pagesSafe Working ProcedureBea MokNo ratings yet

- Wagon and Horses, Bishop's StortfordDocument32 pagesWagon and Horses, Bishop's StortfordWessex ArchaeologyNo ratings yet

- Active FaultDocument5 pagesActive Faultelka prielaNo ratings yet

- Sor BLD 2013Document201 pagesSor BLD 2013తేజ చొల్లంగిNo ratings yet

- QQS Valuation No 8 - 22-08-2016Document16 pagesQQS Valuation No 8 - 22-08-2016Francois EhlersNo ratings yet

- 12-4 Utility TrenchesDocument3 pages12-4 Utility TrenchesAbderrahmaneTemhachetNo ratings yet

- Is 1200 20 1981 PDFDocument11 pagesIs 1200 20 1981 PDFvaibhav suryavanshiNo ratings yet