Professional Documents

Culture Documents

Oscillation Paper 2024 IOT Based

Oscillation Paper 2024 IOT Based

Uploaded by

Harshit RaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oscillation Paper 2024 IOT Based

Oscillation Paper 2024 IOT Based

Uploaded by

Harshit RaulCopyright:

Available Formats

IoT Based Wire Cutter and Stripper Machine

Sahil Swapnil Patil

UG Student, Department of Mechanical Engineering, Vidyavardhini College of Engineering & Technology, Vasai

401202, Mumbai University, Maharashtra, India

Harshit Raul

UG Student, Department of Mechanical Engineering, Vidyavardhini College of Engineering & Technology, Vasai

401202, Mumbai University, Maharashtra, India

Nishad Vyas

UG Student, Department of Mechanical Engineering, Vidyavardhini College of Engineering &Technology, Vasai

401202, Mumbai University, Maharashtra, India

Kamlesh Bachkar

Assistant Professor, Department of Mechanical Engineering, Vidyavardhini College of Engineering & Technology,

Vasai 401202, Mumbai University, Maharashtra, India

Abstract— In this Modern era, there are a lot of technological INTRODUCTION

improvements in wire cutting and stripping. The world is moving

rapidly towards an automated or smart mechanism. Although Nowadays, manual labor in underdeveloped small-scale

there are many systems, but there are some disadvantages in wire engineering industries has became a significant problem for

cutting and stripping which could operate on their own with a these industries. This may affect many companies resulting in

human interface. The conventional method of wire cutting and performance degradation and loss in efficiency. The company

stripping may not work efficiently in terms of human error, poor

owners also have to bear losses thus unable to reach their

performance and accuracy. When the wire being cut and stripped

manually, the worker tends to make mistakes when measuring the desired profit and goals. The implementation of automation can

wire as it may not be accurate. The continuous process of cutting solve this problem. IoT uses smart devices and the internet to

and stripping will hurt the worker’s wrist and might lead to a provide innovative solutions to various challenges and issues.

minor injury. In this project an IoT-based automatic cutter and An IoT-based wire cutter and stripper machine is a cutting-edge

stripper machine was developed to increase the wire cutting and

automation tool designed for precision wire processing tasks.

stripping performance. The machine is compared to the

conventional method of wire cutting and stripping on accuracy of An IoT-based automatic wire cutting andstripping machine has

measurement and time taken to finish all processes. With out a been discussed to achieve low cost-cutting and increase the

human interface, this machine only needs the input of wire length efficiency as well as the speed of the process. This machine

and quantity from the IoT application to operate. The process of combines traditional wire cutting and stripping functions with

wire cutting and stripping will be done automatically and Internet of Things (IoT) technology to enhance efficiency,

accurately. The machine has shown more accurate measurement

of wire and faster speed of cutting and stripping process accuracy, and remote monitoring capabilities. IoT integration

compared to conventional method by the subject. The machine allows users to control and monitor the machine remotely,

will certainly be helpful for small scale engineering industry that receive real-time data on wire processing, and even perform

does not have enough budget. This means that this machine predictive maintenance. This innovation streamlines wire

portable, convenient and easy to use processing operations in industries such as manufacturing,

Keywords— Wire cutting and Stripping Machine, Automatic electronics, and automotive, improving productivity and

Process, IoT application reducing human intervention

I. PROBLEM DEFINATION II. Process Flow Chart

The current wire cutting and stripping process in industrial In this project, the flowchart will give an overview of

and manufacturing settings involves manual labour , which is the steps in the process of automatic wirecutting and

time-consuming, labour-intensive and prone to inconsistency. stripping. The flowchart for process flow is illustrated

This process often leads to inefficiencies, increased production in Figure 2.

costs, and potential safety hazards for workers. There is a need

for an advanced wire cutter and stripper machine that utilizes

IoT (Internet of Things) technology to automate and enhance

wire cutting and stripping operations, resulting in improved

efficiency, accuracy, and worker safety.

II. PROBLEM OBJECTIVE

The main goal of the project is to construct a fully

functioning prototype of an automatic wire cutter & stripper

machine .

The main objective are listed below:

➢ • An interactive user interface

➢ • An option for the user to decide wire length

➢ • An option for the user to decide the number of wires that

the machine should cut

➢ • Be able to handle a wide range of wire diameters

➢ • Be compact

➢ To enhanced safety and cost savings

III. Material and Method Figure 2: Process flow chart of the machine

This section will present the methodology used to III. Overall Machine Setup

develop the proposed IoT-based automatic wirecutting

and stripping machine. The first subsection will present All the component’s connections are combined in

the overall block diagram of the machine, followed by this setup. Figure 3 shows the machine setup of this

the flow chart of the process and finally the details of the project. The components include I2C 16x2 LCD

setup display, stepper motor, 2 servo motors, metal

I. Block Diagram extruder, Node MCU ESP32 and motor driver

A4988. Plywood is used as a base for the device to sit

The main criteria in most of the projects are inputs, control unit on. Plywood is cheap, strong enough to hold the

and outputs. The input of this project is the value in the IoT device and easy to use. A handheld cutter is used to

application. The control unit is Node MCU ESP32 and the

output are LCD display, stepper motor and servo motors. Figure

cut and strip the wire. The spool is used to store the

1 shows the block diagram of this project wire, which will be inserted into the metal extruder.

3D-printed parts are used to hold the motors and

cutter

A4988 Servo

NodeMCU

Metal Cutter and

Figure 1: Block diagram of IoT-based wire cutting and stripping machine

Spool of Stepper Servo

16x2

I2C

Figure 3: Machine setup

IV. METHODOLOGY II. WORKING

The fundamental need of IoT wire cutting and stripping is User Input: Through a mobile app (connected via the Node

to cut and strip the wire of required length in required number MCU's Wi-Fi) or physical buttons, the user specifies the

of pieces, without work, proficiently. So we chose to make a

venture named ‘IoT based wire cutting and stripping machine. desired wire length and stripping distance.

For that we concluded a few determinations given beneath. Like

to cut required length of wire, The breadth of wire ought to be Wire Feeding: The Node MCU sends control signals to the

consequently movable. The spool is given to store wire stock, stepper motor driver. The stepper motor rotates precisely,

Guide tubes are given to keep wire in straight heading. For feeding the wire through the metal extruder at a controlled rate

making of the IoT wire cutting machine we will follow this based on the desired length.

method underneath - So we, right off the bat, chose to cause a

virtual plan of the task and afterward we to finish that a last plan

for project. The human undertakings in electrical wiring are Stripping Mechanism: The Node MCU sends a signal to the

high and the material used for the gathering of the wires is servo motor driver. The servo motor positions the cutting plier

costly. Appropriately it should be used truly. Subsequently, this at the designated stripping distance from the wire end.

endavour is proposed to want to restrict the human undertakings

and to avoid the wastage of the wires. This system can Cutting Operation: The Node MCU triggers the servo motor

definitively gauge wire length and cutting machine can cut wire

to close the cutting plier, precisely severing the wire at the

into number of pieces.

programmed length.

Steps performed in project:

• Power supply is ON, using +5V supply. Process Monitoring: The Node MCU can monitor various

• Input is given by IoT App to the microcontroller. The aspects like motor movement, completion signals, and

required length of wire to be cut is given as input to potential errors. The user can view the process status and any

the microcontroller, which then provides information errors on the display or mobile app.

to the LCD for display.

• The microcontroller interfaces with the motor driver, Data Storage:

and both motors start to operate.

The Node MCU can be programmed to store data like

• Firstly, the motor where the spool of wire is placed on

the shaft rotates for a particular time, according to the processed wires, lengths, and any errors in its internal

specified duration of rotation. memory or cloud storage for future reference and analysis

• As the wire is unwound from the spool of the wire, it

moves through the conveyor belt to the cutting area.

• After that, the second motor where the cutting foil is

placed starts to run, and thus the wire is cut as per the

user's requirement

I. DESIGN AND ASSEMBLY

Fig 6. Circuit Diagram

Fig 4. Solidworks design of setup

Fig 5. Experimental setup

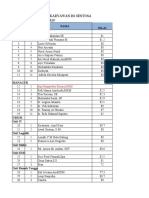

8.36 -5.92 4.12

CH1 CH2 CH3

8.32 -5.96 4.12

8.51 -5.84 4.04

8.32 -5.96 4.12

8.32 -6.12 4.12

8.47 -5.88 4.16

8.24 -6.12 4.04

8.47 -5.88 4.2

8.36 -5.92 4.12

8.24 -6.16 4.08

8.32 -5.96 4.08

8.36 -6 4.08

8.39 -6 4.08

8.32 -6.08 4.12

8.39 -6 4.08

8.28 -5.92 .04

8.39 -5.92 4.08

8.43 -6 4.08

8.39 -5.96 4

8.47 -5.84 4.12

8.16 -6.12 4

8.43 -5.84 4.16

8.59 -5.77 4.12

8.39 -6 4.168.32

8.47 -5.84 4.12

8.39 -5.81 4.08

8.36 -5.96 4.04

8.39 -5.92 4.08

8.32 -5.96 4.08

8.47 -5.84 4.08

8.36 -6.04 4

8.43 -5.88 4.12

8.43 -6 4.16

8.32 -5.81 4.04

8.39 -5.96 4.08

8.43 -6 4.16

8.39 -5.96 4.08

8.39 -5.88 4.04

8.39 -5.92 4.12

8.39 -5.96 4.08

8.39 -5.96 4.08

8.39 -5.88 4.12

8.43 -5.92 4.08

8.47 -5.77 4.12

8.36 -5.96 4

8.39 -5.88 4.16

8.36 -6.04 4.04

8.43 -5.88 4.08

8.39 -5.88 4.08

8.43 -5.88 4.12

8.51 -5.84 4.16

8.36 -5.92 4.08

8.36 -5.96 4.12

8.36 -5.96 4.04

8.36 -5.96 4.04

8.39 -6 4.12

8.43 -5.92 4.04

8.47 -5.84 4.08

8.39 - -6

5.968.28 8.39 -5.88 4.16

8.43 -5.88 4 8.39 -6 4.2

8.51 -5.81 4.12 8.36 -5.88 4.08

8.36 -5.92 4.04 8.39 -5.84 4.08

8.39 -6 4.08 8.43 -5.77 4.08

8.43 -5.96 4.08 8.55 -5.88 4.2

8.47 -5.84 4.12 8.36 -5.92 4.12

V. RESULT

REFERENCES

Figure: Result of the cutting and stripping of the wire [1] S. Narendra Patil, “Design and development of Automatic

Wire Cutting Machine: A case studyin small scale industry,”

International Journal for Research in Applied Science and

EngineeringTechnology, vol. V, no. III, pp. 951–956, 2017.

[2] Rubman, M., Lorenz, M., Gerbert, P., Waldner, M., Justus,

J., Engel, P., & Harnisch, M. Industry 4.0: The future of

productivity and growth in manufacturing industries. Boston

consulting group, 9(1), 54-89, 2015.

[3] J. M. Davila Delgado, L. Oyedele, A. Ajayi, L. Akanbi, O.

Akinade, M. Bilal, and H. Owolabi,“Robotics and automated

systems in construction: Understanding industry-specific

challenges for adoption,” Journal of Building Engineering,

vol. 26, p. 100868, 2019.

[4] Z. Fatima, M. H. Tanveer, Wasee mullah, S. Zardari, L. F.

Naz, H. Khadim, N. Ahmed, and M.Tahir, “Production plant

WIRE NO MEASURMENT, and warehouse automation with IOT and industry 5.0,”

mm AVERAGE, Applied Sciences, vol. 12, no. 4, p. 2053, 2022.

mm

[5] T. Pulainthran and Jais Bin Lias, “IoT Based Smart Pet

1 8.6

Cage”, EEEE, vol. 3, no. 1, pp. 053– 061, Jun. 2022.

2 8.6 [6] S. Kumar, P. Tiwari, and M. Zymbler, “Internet of things is a

8.6 revolutionary approach for future technology enhancement:

3 8.6 A Review,” Journal of Big Data, vol. 6, no. 1, 2019.

4 8.6

[7] Pravin raj A/L Chandran and Jais Lias, “Banana Quality

Managing System”, EEEE, vol. 2, no. 1, pp. 123-130, April.

2022

VI. CONCLUSION

This project is an IoT-based automatic wire cutting and

stripping machine that can be controlled using a

smartphone application. The machine will certainly be

helpful for small-scale engineering industry that does not

have enough budget or big production of wire. As stated in

the first objective, it only requires the user input value for

the length and the quantity of the wire. All the processes

are automated and work efficiency compared to the

conventional method. This will reduce human error and

increase efficiency and accuracy, which is stated in the

second objective. With wireless communication in mind,

the user does not even have to stay near or at the machine

as they can operatethe machine wirelessly. This means that

this machine is portable, convenient and easy to use.

You might also like

- M4140 Application NoteDocument12 pagesM4140 Application Noteupt vadodara100% (1)

- Design and Development of Robotic Arm For Cutting Tree PDFDocument10 pagesDesign and Development of Robotic Arm For Cutting Tree PDFHamza HebNo ratings yet

- Night Patrol RobotDocument10 pagesNight Patrol RobotBlack Hat100% (1)

- Handy-Tig 210 AcdcDocument80 pagesHandy-Tig 210 AcdcEdin Edin100% (1)

- International Journal of Research Publication and Reviews: Ravindra, Abhijeet Bharat Girmal, Aniket, Ms - SoundatteDocument2 pagesInternational Journal of Research Publication and Reviews: Ravindra, Abhijeet Bharat Girmal, Aniket, Ms - SoundatteasasinghNo ratings yet

- Automatic Metal Sheet Cutting MachineDocument2 pagesAutomatic Metal Sheet Cutting MachinekothandapaniNo ratings yet

- Irjet V5i3717 PDFDocument5 pagesIrjet V5i3717 PDFlenchoNo ratings yet

- Multipurpose Robotic ArmDocument7 pagesMultipurpose Robotic ArmIJRASETPublicationsNo ratings yet

- Design and Development of SPM For Nut SortingDocument8 pagesDesign and Development of SPM For Nut SortingIJRASETPublicationsNo ratings yet

- Final Report 01Document13 pagesFinal Report 01Fozan AzeemNo ratings yet

- Fin IrjmetsDocument4 pagesFin IrjmetsSILENCENo ratings yet

- Drawing Robot: Keyur Jain, Akash Nair, Prof. Shikha SinghDocument5 pagesDrawing Robot: Keyur Jain, Akash Nair, Prof. Shikha Singhhasan alsarrafNo ratings yet

- Development and Integration of Laser Sensor Tracking System in Robotic Arm For Path Correction During Welding OperationDocument9 pagesDevelopment and Integration of Laser Sensor Tracking System in Robotic Arm For Path Correction During Welding OperationIAES International Journal of Robotics and AutomationNo ratings yet

- Design and Analysis of Automatic ForkliftDocument6 pagesDesign and Analysis of Automatic ForkliftIJRASETPublicationsNo ratings yet

- Iotbasedtransmissionlinefault PDFDocument5 pagesIotbasedtransmissionlinefault PDFsanjay ANo ratings yet

- Second MergedDocument48 pagesSecond MergedRandhir JhaNo ratings yet

- CNC PlotterDocument9 pagesCNC Plotterankurmondal2000No ratings yet

- Minor PublicationsDocument20 pagesMinor Publications20-311 AkhilNo ratings yet

- Design and Fabrication of Polar Cnc-2D-PrinterDocument25 pagesDesign and Fabrication of Polar Cnc-2D-PrinterLovely AtchuthNo ratings yet

- Semi - Outer Thread Cutting MachineDocument4 pagesSemi - Outer Thread Cutting MachineTechnico TechnocratsNo ratings yet

- Industrial Automation Using Modern Controls MonitoDocument6 pagesIndustrial Automation Using Modern Controls MonitoSucii AnggraiiniiNo ratings yet

- Raju T - (1AJ19CS036) Internship REPORTDocument39 pagesRaju T - (1AJ19CS036) Internship REPORTharikach2208No ratings yet

- Prototype Wireless Controller System Based On Raspberry Pi and Arduino For Engraving MachineDocument7 pagesPrototype Wireless Controller System Based On Raspberry Pi and Arduino For Engraving MachineChahiMouhcineNo ratings yet

- IJCRT22A6112Document7 pagesIJCRT22A6112tamannakouser1812No ratings yet

- Design of Agv With Mobile Communication: ArticleDocument6 pagesDesign of Agv With Mobile Communication: ArticleHo Van RoiNo ratings yet

- SMT Solar and Automation TechnologyDocument26 pagesSMT Solar and Automation TechnologyNitin PanwarNo ratings yet

- Irjet V5i11169Document13 pagesIrjet V5i11169Sumardi Sadi FT UMTNo ratings yet

- 1.1 Objectives: Mini CNC PlotterDocument42 pages1.1 Objectives: Mini CNC Plotteryashwanth M V100% (1)

- Low Cost Iot Based Mini Inverter: (Peer-Reviewed, Open Access, Fully Refereed International Journal)Document9 pagesLow Cost Iot Based Mini Inverter: (Peer-Reviewed, Open Access, Fully Refereed International Journal)georgeNo ratings yet

- Prototyping of Mini CNC Milling Machine Using MicrocontrollerDocument12 pagesPrototyping of Mini CNC Milling Machine Using MicrocontrollerAye Chan AungNo ratings yet

- Design and Analysis of Surveillance RobotDocument8 pagesDesign and Analysis of Surveillance RobotIJRASETPublicationsNo ratings yet

- Jornal IjaertDocument9 pagesJornal IjaertVarun SharmaNo ratings yet

- 1 s2.0 S2214785322059521 MainDocument9 pages1 s2.0 S2214785322059521 MainfelipeNo ratings yet

- WAR Field Spying Robot: January 2018Document6 pagesWAR Field Spying Robot: January 2018Chemudupati SunilNo ratings yet

- Microcontroller Based Automatic GateDocument12 pagesMicrocontroller Based Automatic GateAndyNo ratings yet

- G-Code Controlled 2D Robotic Plotter: December 2017Document4 pagesG-Code Controlled 2D Robotic Plotter: December 2017hasan alsarrafNo ratings yet

- Flower Knitting Machine: International Research Journal of Engineering and Technology (IRJET)Document3 pagesFlower Knitting Machine: International Research Journal of Engineering and Technology (IRJET)aruljeromeNo ratings yet

- Main ReportDocument46 pagesMain Reportkrish4allindians100% (3)

- Nabish 1Document24 pagesNabish 1nabishadnanansariNo ratings yet

- Result Paper On IOT Based Induction Motor Speed Control and Parameter MonitoringDocument8 pagesResult Paper On IOT Based Induction Motor Speed Control and Parameter MonitoringIJRASETPublicationsNo ratings yet

- The Electricity Billing System Over IOTDocument7 pagesThe Electricity Billing System Over IOTIJRASETPublicationsNo ratings yet

- JournalDocument8 pagesJournalVarun SharmaNo ratings yet

- PLC Installation On Inner Ring Bore SHG Grinding MachineDocument5 pagesPLC Installation On Inner Ring Bore SHG Grinding MachineEditor IJRITCCNo ratings yet

- Iot Based Industrial Automation IJERTCONV5IS01099Document4 pagesIot Based Industrial Automation IJERTCONV5IS01099PARTH BirajdarNo ratings yet

- 1optimization of Micro-WireDocument33 pages1optimization of Micro-WireAman BansalNo ratings yet

- Final Copy of Line Follower RobotDocument10 pagesFinal Copy of Line Follower RobotPhạm Tành ĐồngNo ratings yet

- Contact Less Tachometer IJERTCONV6IS13194Document3 pagesContact Less Tachometer IJERTCONV6IS13194poornarithikNo ratings yet

- EDM Lab ReportDocument12 pagesEDM Lab ReportAli Hassan100% (1)

- BookchapterDocument25 pagesBookchapterprabhakaranNo ratings yet

- Design and Fabrication of 3-Axis CNC Milling Machine: AbstractDocument5 pagesDesign and Fabrication of 3-Axis CNC Milling Machine: AbstractMohammedsaleemNo ratings yet

- Smart Hair Salon Management System: IarjsetDocument4 pagesSmart Hair Salon Management System: IarjsetRakshitha RNo ratings yet

- V15I5090Document3 pagesV15I5090tariq qureshiNo ratings yet

- Matlab Colour Sensing RobotDocument5 pagesMatlab Colour Sensing Robotwaqas67% (3)

- IOT Based Arm RobotDocument6 pagesIOT Based Arm RobotIJRASETPublicationsNo ratings yet

- Design and Implementation of MicrocontrollersDocument6 pagesDesign and Implementation of MicrocontrollersmarcloubonNo ratings yet

- Automatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopDocument3 pagesAutomatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopSANAPA TEJASWININo ratings yet

- 32 Power NCDocument10 pages32 Power NCArnold RosenbergNo ratings yet

- Accurate and Cost-Effective Mini CNC Plotter: Sara Raad Qasim Haider Mohammad Mustafa FalahDocument6 pagesAccurate and Cost-Effective Mini CNC Plotter: Sara Raad Qasim Haider Mohammad Mustafa FalahRamleelakal OfficialNo ratings yet

- Indore Institute of Science and Technology A Training Report On "Internet of Things"Document49 pagesIndore Institute of Science and Technology A Training Report On "Internet of Things"Abhishek GuptaNo ratings yet

- Prasoon Raj - 1709131099 - ReportDocument41 pagesPrasoon Raj - 1709131099 - ReportPAWAN TIWARI100% (1)

- Welding Robot Using ArduinoDocument13 pagesWelding Robot Using ArduinoBeer BhadraNo ratings yet

- Control Engineering PDFDocument164 pagesControl Engineering PDFsanthoshramrNo ratings yet

- 6, 8,10,12,16 CHANNEL Mic/Line Mixer Owners Manual: Caution: AttentionDocument15 pages6, 8,10,12,16 CHANNEL Mic/Line Mixer Owners Manual: Caution: AttentionBrix MatacsilNo ratings yet

- MRG 512-PRO PQ Flex: Mobile Universal Measurement DeviceDocument9 pagesMRG 512-PRO PQ Flex: Mobile Universal Measurement DeviceLuciaNo ratings yet

- Kpi 2020Document7 pagesKpi 2020jemi rieNo ratings yet

- Siemens Thermostat RDS120Document16 pagesSiemens Thermostat RDS120Roudy J. MhawasNo ratings yet

- Wire Code Identification: Color Code Color Color Code Color Tracer Wire Color Code ChartDocument8 pagesWire Code Identification: Color Code Color Color Code Color Tracer Wire Color Code ChartLuis Antonio Velazquez OlguinNo ratings yet

- A High Frequency SIMULINK Model For PMSMDocument6 pagesA High Frequency SIMULINK Model For PMSMBook4AllNo ratings yet

- SF 400 Electronic Weighing Machine Scale ManualDocument13 pagesSF 400 Electronic Weighing Machine Scale ManualMILTON ELIASNo ratings yet

- KSKDocument197 pagesKSKAnonymous qIGu372No ratings yet

- MATLAB Simscape Model of An Alkaline ElectrolyserDocument9 pagesMATLAB Simscape Model of An Alkaline ElectrolyserAbdelaziz EL GHZIZALNo ratings yet

- Conventional Vs Addressable Fire Alarm SystemsDocument1 pageConventional Vs Addressable Fire Alarm SystemssaturnengNo ratings yet

- Varitrans P41058D1 CatalogDocument24 pagesVaritrans P41058D1 CatalogdikochchNo ratings yet

- Traction Power System Study For Metro North RailroadDocument20 pagesTraction Power System Study For Metro North RailroadmoisesramosNo ratings yet

- 480RGB X 864 Dot, 16.7M Color, With Internal GRAM, TFT Mobile Single Chip DriverDocument320 pages480RGB X 864 Dot, 16.7M Color, With Internal GRAM, TFT Mobile Single Chip Drivernio58No ratings yet

- FQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CDocument5 pagesFQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CAndrew NazarovNo ratings yet

- Optimizador Tigo TS4-A-O Hasta 700W - Ficha TécnicaDocument2 pagesOptimizador Tigo TS4-A-O Hasta 700W - Ficha Técnicaalfonso muroNo ratings yet

- ENL GatewayDocument2 pagesENL GatewaycelsohernandoNo ratings yet

- Modifying An IC735 For The 630m BandDocument9 pagesModifying An IC735 For The 630m BandJuan Carlos AbasoloNo ratings yet

- UD10 Dettronics Gas Detector Data SheetDocument2 pagesUD10 Dettronics Gas Detector Data SheetmuthuNo ratings yet

- VarioLED Flex NIKE HD5 SVW9271025 IP67Document8 pagesVarioLED Flex NIKE HD5 SVW9271025 IP67jerin1365No ratings yet

- Eliminate Problematic and Momentary Relay Actions: Qualitrol 909Document4 pagesEliminate Problematic and Momentary Relay Actions: Qualitrol 909AbdulJabbarSethar50% (2)

- Kingston 10 25 2023 EMMC04G MT32 01G10 v1 2-3359335Document24 pagesKingston 10 25 2023 EMMC04G MT32 01G10 v1 2-3359335ManunoghiNo ratings yet

- Suggested Retail Price List of General Wiring & Cables: STANDARD PACK - Imperial Sizes HALF PACK - Imperial SizesDocument1 pageSuggested Retail Price List of General Wiring & Cables: STANDARD PACK - Imperial Sizes HALF PACK - Imperial SizesATL ZOT PROJECTNo ratings yet

- PEE Unit-4 NotesDocument37 pagesPEE Unit-4 Notes322103312181 SAI ANAND MEDAPATINo ratings yet

- Amps X 100 BESS-01-Bus (Nom. KV 0.48, Plot Ref. KV 0.48)Document1 pageAmps X 100 BESS-01-Bus (Nom. KV 0.48, Plot Ref. KV 0.48)Tosikur RahmanNo ratings yet

- 978 1 5275 5585 3 SampleDocument30 pages978 1 5275 5585 3 SampleDongo DanielNo ratings yet

- List of Allowed Non-Programmable CalculatorsDocument4 pagesList of Allowed Non-Programmable CalculatorsLorenz Esperon BorromeoNo ratings yet

- BPA121 EngDocument14 pagesBPA121 Engสมภพ หลวงภักดีNo ratings yet