Professional Documents

Culture Documents

Classifier

Classifier

Uploaded by

chenghongwei2008Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classifier

Classifier

Uploaded by

chenghongwei2008Copyright:

Available Formats

Item

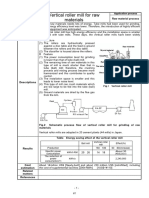

Classification of powder returned Application process

from raw material separator Raw material process

When raw materials are ground in a closed circuit by a double-rotator mill, grids remain

Background

underground in the second chamber for fine grinding, lowering the grinding efficiency.

The cause of this phenomenon is that grids contained in the separator returned power

directly enters the second chamber. To separate grids from the returned powder and

return them to the first chamber for coarse grinding, a simple grid screen (classifier)

was installed at the return chute of the separator. The grids and coarse powder were

ground with large balls. The ball diameter of the second chamber can be made small

because only fine powder is returned to the room.

Grid screen

To EP Fine

Coarse

powder powder

Descriptions

Refined powder First Second

chamber chamber

Raw materials

Double-rotator mill

Fig. Classification of returned powder by double-rotator mill

The work for removing grids from the second chamber can be mitigated. The decrease

Results

of power consumption rate is not remarkable but below 1 kWh per ton of raw materials.

Cost

18,000 to 36,000 US$ per system [1US$=¥110]

estimation

Related

matters

Reference

-5-

71

You might also like

- Sintered Metal BushDocument5 pagesSintered Metal Bush124swadeshiNo ratings yet

- Mega Yarn Dyeing Mills LTDDocument12 pagesMega Yarn Dyeing Mills LTDmd iqbal hossainNo ratings yet

- PYROLITIC OIL POWER SYSTEM 12MWeDocument39 pagesPYROLITIC OIL POWER SYSTEM 12MWeMurat CengizNo ratings yet

- Austin Et Al-1990-Particle & Particle Systems CharacterizationDocument6 pagesAustin Et Al-1990-Particle & Particle Systems CharacterizationLuis Verdugo GallegosNo ratings yet

- Equipment and Their SpecificationsDocument5 pagesEquipment and Their SpecificationsJohn SmithNo ratings yet

- Pro Lab-7 by NoorDocument4 pagesPro Lab-7 by Noornoor.fatimaNo ratings yet

- Topic 3 Mechanical PulpingDocument41 pagesTopic 3 Mechanical PulpingGhina MauliaNo ratings yet

- Executive Summary English Dinanath 11112020Document18 pagesExecutive Summary English Dinanath 11112020Piyush SahuNo ratings yet

- Vertical Roller Mill PregrindingDocument1 pageVertical Roller Mill Pregrindingchenghongwei2008No ratings yet

- Description of The EquipmentDocument4 pagesDescription of The EquipmentHarshil TejaniNo ratings yet

- Experiment 01 Layout of Mineral Processing LaboratoryDocument7 pagesExperiment 01 Layout of Mineral Processing LaboratoryBialNo ratings yet

- Comparsion Statement For Bitument Paint: A Commercial TermsDocument2 pagesComparsion Statement For Bitument Paint: A Commercial TermsPanruti S SathiyavendhanNo ratings yet

- Reactive Powder ConcreteDocument12 pagesReactive Powder Concretebudi nayobiNo ratings yet

- ECOFOR For Cement Mill - Intensification of Dry Grinding Processes by Using The ECOFOR' DeviceDocument4 pagesECOFOR For Cement Mill - Intensification of Dry Grinding Processes by Using The ECOFOR' DeviceAntonNo ratings yet

- Information Archieve - 2-3-2020Document15 pagesInformation Archieve - 2-3-2020Mizanul HoqueNo ratings yet

- Fuel Filtration & Coalescer Housing AssembliesDocument4 pagesFuel Filtration & Coalescer Housing AssembliesYesid FigueroaNo ratings yet

- Welspun Ec PCB PDFDocument40 pagesWelspun Ec PCB PDFraghuarjunNo ratings yet

- Case - Studies (Compatibility Mode)Document18 pagesCase - Studies (Compatibility Mode)VRUSHABHNo ratings yet

- Kinetics of Fine Wet Grinding in A Laboratory Ball Mill: M. Yekeler, A. Ozkan, L.G. AustinDocument5 pagesKinetics of Fine Wet Grinding in A Laboratory Ball Mill: M. Yekeler, A. Ozkan, L.G. AustinDirceu NascimentoNo ratings yet

- Very Important Notes For Purchasing Managers in Cement FactoryDocument32 pagesVery Important Notes For Purchasing Managers in Cement FactoryLa KubaisiNo ratings yet

- Vertical Roller Mill SP 3Document1 pageVertical Roller Mill SP 3chenghongwei2008No ratings yet

- Adobe Scan 19 Nov 2022Document1 pageAdobe Scan 19 Nov 2022Sunitha SasiNo ratings yet

- JK Paper Limited HeheDocument34 pagesJK Paper Limited HehematushriNo ratings yet

- BVF3184 Topic 6 - Industrial Visit - Boiler Operation, Maintenance, Problems TrobleshootingDocument68 pagesBVF3184 Topic 6 - Industrial Visit - Boiler Operation, Maintenance, Problems TrobleshootingwidadNo ratings yet

- Charcoal Briquette Production Line 2-3tonDocument32 pagesCharcoal Briquette Production Line 2-3tonБат-Эрдэнэ ЭрдэнэчулуунNo ratings yet

- Firewood Logs Firewood Logs: Charcoal Briquettes Charcoal BriquettesDocument6 pagesFirewood Logs Firewood Logs: Charcoal Briquettes Charcoal BriquettesJosephine ChirwaNo ratings yet

- Raw Material Grinding & StorageDocument24 pagesRaw Material Grinding & StorageMadhuNo ratings yet

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- BR - WEEE - 1804 - EN - high-180409 العمليات بشكل عام مخطط من الشركهDocument3 pagesBR - WEEE - 1804 - EN - high-180409 العمليات بشكل عام مخطط من الشركهmoheedNo ratings yet

- Coal Beneficiation TechnologyDocument5 pagesCoal Beneficiation TechnologyChandan Das100% (1)

- Desta Tesfay (Labour Cost)Document47 pagesDesta Tesfay (Labour Cost)Mehari GebreyohannesNo ratings yet

- Desta Tesfay (Material Cost)Document49 pagesDesta Tesfay (Material Cost)Mehari GebreyohannesNo ratings yet

- Cocoa Beans Crusher WinnowerDocument1 pageCocoa Beans Crusher WinnowerFernando GarciaNo ratings yet

- 05 - Optimization Barite ProcessingDocument13 pages05 - Optimization Barite ProcessingharrywrmNo ratings yet

- Ficha Tecnica Vibrador LM2Document1 pageFicha Tecnica Vibrador LM2Henry PCNo ratings yet

- Rate Analysis SheetDocument5 pagesRate Analysis SheetGsUpretiNo ratings yet

- Vertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsDocument16 pagesVertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsRahul RoyNo ratings yet

- Manufacturing ReportDocument22 pagesManufacturing ReportR Sailesh ae18b011No ratings yet

- Design Mix M 30 PPC - CP2659-41Document2 pagesDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- Pet Nylon IonDocument2 pagesPet Nylon Ionkvbg1980No ratings yet

- Area Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Document7 pagesArea Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Zohaib AhmedNo ratings yet

- Geometrija Zobnikov - Gradivo Za Vaje 2014-15Document6 pagesGeometrija Zobnikov - Gradivo Za Vaje 2014-15Dejan MitrovićNo ratings yet

- Size Reduction Heat Transfer AnaChem EditedDocument6 pagesSize Reduction Heat Transfer AnaChem EditedEquipment DesignNo ratings yet

- He 185 Ya Lfe AsDocument61 pagesHe 185 Ya Lfe AsPavan kalyan UramduruNo ratings yet

- Application OF Iron Waste IN Geotechnical EngineeringDocument15 pagesApplication OF Iron Waste IN Geotechnical EngineeringAntariksha NayakNo ratings yet

- Cement Milling Part 2 (Training)Document6 pagesCement Milling Part 2 (Training)Husni BasharudinNo ratings yet

- Pembangunan Pabrik Pembuatan Agregat Perkerasan JalanDocument12 pagesPembangunan Pabrik Pembuatan Agregat Perkerasan JalanRiston BelMan SidabutarNo ratings yet

- PEQS-Sent To HSEDocument1 pagePEQS-Sent To HSEAMIRNo ratings yet

- Overview of Cement Manufacturing 09.06.21Document39 pagesOverview of Cement Manufacturing 09.06.21Abhishek Michael ChandNo ratings yet

- 4010e Polyester Continuous ProcessDocument8 pages4010e Polyester Continuous Processanil kapadiaNo ratings yet

- Nano HVOFThermicoDocument43 pagesNano HVOFThermicohirafarooq2000No ratings yet

- 23 Waste Plastics 2Document23 pages23 Waste Plastics 2revolvevijaya123No ratings yet

- Christian PfeifferDocument22 pagesChristian Pfeifferreddy426935No ratings yet

- HW No 2-S2015Document1 pageHW No 2-S2015NourAldin AbuSalehNo ratings yet

- Substitute of Coke BreezeDocument3 pagesSubstitute of Coke BreezeArjun Chetri BhandariNo ratings yet

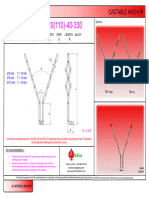

- Castable - Ancbor 3Document1 pageCastable - Ancbor 3chenghongwei2008No ratings yet

- Castable - Tancbor 4Document1 pageCastable - Tancbor 4chenghongwei2008No ratings yet

- Castable - Ancbor 1Document1 pageCastable - Ancbor 1chenghongwei2008No ratings yet

- Intermiten Charging of Elctrical CollectorDocument1 pageIntermiten Charging of Elctrical Collectorchenghongwei2008No ratings yet

- TMEIC Cement Industry Brochure - A4Document24 pagesTMEIC Cement Industry Brochure - A4chenghongwei2008No ratings yet

- New Suspension Burding SystemDocument1 pageNew Suspension Burding Systemchenghongwei2008No ratings yet

- Vertical Roller Mill ECSDocument1 pageVertical Roller Mill ECSchenghongwei2008No ratings yet

- Raw Material FinenessDocument1 pageRaw Material Finenesschenghongwei2008No ratings yet

- Vertical Roller Mill For Raw MaterialsDocument1 pageVertical Roller Mill For Raw Materialschenghongwei2008No ratings yet