Professional Documents

Culture Documents

Intermiten Charging of Elctrical Collector

Intermiten Charging of Elctrical Collector

Uploaded by

chenghongwei2008Copyright:

Available Formats

You might also like

- Fuse Box Diagram Volkswagen Passat (B8 2015-2019)Document2 pagesFuse Box Diagram Volkswagen Passat (B8 2015-2019)slhkrh1905No ratings yet

- Calculating Cable Pulling TensionsDocument4 pagesCalculating Cable Pulling TensionsNilesh ButeNo ratings yet

- Winters PreviewDocument265 pagesWinters PreviewcqpresscustomNo ratings yet

- Yoga Nidra Masterclass Training Notes 1 PDFDocument4 pagesYoga Nidra Masterclass Training Notes 1 PDFMino Zo SydneyNo ratings yet

- Hussein 2017Document9 pagesHussein 2017Anonymous fqHGrbwxeFNo ratings yet

- Optimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesDocument9 pagesOptimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesU.B MujumdarNo ratings yet

- Single-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksDocument7 pagesSingle-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksNelson ParijósNo ratings yet

- Optimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesDocument9 pagesOptimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesAlexander López PadillaNo ratings yet

- Dhineshkumar 2018 J. Phys. Conf. Ser. 1000 012051Document11 pagesDhineshkumar 2018 J. Phys. Conf. Ser. 1000 012051Samyuktha S HariNo ratings yet

- Harmonic Reduction IEEE PaperDocument6 pagesHarmonic Reduction IEEE PaperRajasekaranViswaNo ratings yet

- Harmonic Detection Methods of Shunt Active PowerDocument7 pagesHarmonic Detection Methods of Shunt Active Poweroctober87No ratings yet

- Topic No. 3 Load CharacteristicsDocument11 pagesTopic No. 3 Load Characteristicsburnermike011323No ratings yet

- Design and Implementation of Single-Phase Hybrid Active Power Filter Controller-LibreDocument5 pagesDesign and Implementation of Single-Phase Hybrid Active Power Filter Controller-LibreDhivya NNo ratings yet

- Electrical Power and Energy Systems: Sajad Jashfar, Saeid EsmaeiliDocument13 pagesElectrical Power and Energy Systems: Sajad Jashfar, Saeid Esmaeilialessio8No ratings yet

- IREE Paper PDFDocument7 pagesIREE Paper PDFkavithaNo ratings yet

- Energy Balancing of Power System Considering Periodic Behavioral Pattern of Renewable Energy Sources and DemandsDocument18 pagesEnergy Balancing of Power System Considering Periodic Behavioral Pattern of Renewable Energy Sources and DemandsShameem SiddiqueNo ratings yet

- Wang 2012Document10 pagesWang 2012Itamar Peñaloza MoránNo ratings yet

- EE462 Second PartDocument27 pagesEE462 Second PartMusabNo ratings yet

- Conected Load 2222Document3 pagesConected Load 2222surajgedam044No ratings yet

- Chapter 04Document47 pagesChapter 04HassanKMNo ratings yet

- Introduction To Hydropower PresentationDocument167 pagesIntroduction To Hydropower Presentationpggopal_85No ratings yet

- Wibowo2014 r3Document6 pagesWibowo2014 r3Narendra YadavNo ratings yet

- التوافقيات في شبكات القوى الكهربيةDocument30 pagesالتوافقيات في شبكات القوى الكهربيةAbderahmanAkilaNo ratings yet

- 04 - The Influence of Electronic Loads Switching in The Reactive Flow of A Bus BarDocument6 pages04 - The Influence of Electronic Loads Switching in The Reactive Flow of A Bus BarKelvin Mendonça - WEANo ratings yet

- A New Approach To Wind EnergyDocument48 pagesA New Approach To Wind EnergySiva KulanjiNo ratings yet

- Machine Learning Based Maximum Power Point Tracking in Tidal/Ocean Energy Conversion SystemDocument5 pagesMachine Learning Based Maximum Power Point Tracking in Tidal/Ocean Energy Conversion Systemoussama bouguerraNo ratings yet

- PG LecturesDocument414 pagesPG LecturesMUHAMMAD SHAHEERNo ratings yet

- Journal Rahma IREEDocument9 pagesJournal Rahma IREERahma AloulouNo ratings yet

- Power Quality Improvement With Shunt ActDocument5 pagesPower Quality Improvement With Shunt ActSergio QuirogaNo ratings yet

- Epeng 308-3Document55 pagesEpeng 308-3gwemeowenNo ratings yet

- Concept of Electrical TarrifsDocument4 pagesConcept of Electrical TarrifsAshutosh SoniNo ratings yet

- An Adaptive Hysteresis Band Current Controller For Shunt Active Power FilterDocument7 pagesAn Adaptive Hysteresis Band Current Controller For Shunt Active Power Filterherdal TedongmoNo ratings yet

- AR222s Week 1-5 ADocument138 pagesAR222s Week 1-5 AJOHANAH MICAH MARCOSNo ratings yet

- Allocation of Wind Capacity Subject To Long Term Voltage Stability ConstraintsDocument11 pagesAllocation of Wind Capacity Subject To Long Term Voltage Stability ConstraintsJoão PedroNo ratings yet

- MODULE-2-Economic Aspects-2Document20 pagesMODULE-2-Economic Aspects-2vivekNo ratings yet

- Load SheddingDocument5 pagesLoad SheddingAdhyartha KerafNo ratings yet

- Sundar Am 2014Document7 pagesSundar Am 2014Nikola DjordjevicNo ratings yet

- Performance Study of An Inverter: ArticleDocument6 pagesPerformance Study of An Inverter: Articlenjoku danielNo ratings yet

- Energies 16 01276 v2Document22 pagesEnergies 16 01276 v2arun kumarNo ratings yet

- Group5 Lab 07Document9 pagesGroup5 Lab 07FALSERNo ratings yet

- HWRE3141 Ch-3Document16 pagesHWRE3141 Ch-3kader ArefeNo ratings yet

- Optimum Design of The Current-Source Flyback Inverter For Decentralized Grid-Connected Photovoltaic SystemsDocument13 pagesOptimum Design of The Current-Source Flyback Inverter For Decentralized Grid-Connected Photovoltaic SystemsAaqib Ahmad QureshiNo ratings yet

- Energies 14 05626Document19 pagesEnergies 14 05626Jack ParedesNo ratings yet

- Reactive Power Compensation Technologies PDFDocument21 pagesReactive Power Compensation Technologies PDFTovar ArmandoNo ratings yet

- Harmonic Reduction in Multiplex Convertors by Triple-Frequency Current InjectionDocument5 pagesHarmonic Reduction in Multiplex Convertors by Triple-Frequency Current InjectionvmksamyNo ratings yet

- A Fuzzy - Logic Based Controller For Three Phase PWM Rectifier With Voltage Oriented Control StrategyDocument8 pagesA Fuzzy - Logic Based Controller For Three Phase PWM Rectifier With Voltage Oriented Control StrategyDRIS IDRISNo ratings yet

- Hourly Electricity Demand Response in The Stochastic Day-Ahead Scheduling of Coordinated Electricity and Natural Gas NetworksDocument10 pagesHourly Electricity Demand Response in The Stochastic Day-Ahead Scheduling of Coordinated Electricity and Natural Gas Networksmailsfree123No ratings yet

- The Reactive Power, Does It Important For UsDocument9 pagesThe Reactive Power, Does It Important For UsPiotr JuszczykNo ratings yet

- AKASH AUXILIARY CHARGEPUMP CMOS Startup Charge Pump With Body BiasDocument11 pagesAKASH AUXILIARY CHARGEPUMP CMOS Startup Charge Pump With Body Biasakashkumarswain213No ratings yet

- New Rich Text DocumentDocument5 pagesNew Rich Text DocumentFaryal SiddiqueNo ratings yet

- A Practical Algorithm For Optimal Operation Management of Distribution Network Including Fuel Cell Power PlantsDocument19 pagesA Practical Algorithm For Optimal Operation Management of Distribution Network Including Fuel Cell Power PlantsFarouk KeniouNo ratings yet

- 05EEE - 2023 - Variable Load On Power SystemDocument31 pages05EEE - 2023 - Variable Load On Power SystemAmbadiNo ratings yet

- 04 - Planung - Einer - DL - Station - ALMIG - GB (NXPowerLite) (NXPowerLite)Document62 pages04 - Planung - Einer - DL - Station - ALMIG - GB (NXPowerLite) (NXPowerLite)Junaid AhmedNo ratings yet

- Ocean Engineering: Rishav Raj, R. Anandanarayanan, Suchithra Ravikumar, Prasad Dudhgaonkar, Abdus SamadDocument12 pagesOcean Engineering: Rishav Raj, R. Anandanarayanan, Suchithra Ravikumar, Prasad Dudhgaonkar, Abdus SamadAmelia Agista PutriNo ratings yet

- C.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurDocument13 pagesC.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurMohan KrishnaNo ratings yet

- Project Report On PLCDocument13 pagesProject Report On PLCkaran aroraNo ratings yet

- Charge While DrivingDocument6 pagesCharge While DrivingMạnh Hùng VũNo ratings yet

- H R e SystemDocument6 pagesH R e SystemMohitAgrawalNo ratings yet

- Design, Simulation and Implementation of A Self Oscillating Control Circuit To Drive Series Resonant Inverter Feeding A Brazing Induction FurnaceDocument7 pagesDesign, Simulation and Implementation of A Self Oscillating Control Circuit To Drive Series Resonant Inverter Feeding A Brazing Induction FurnaceSandeep SNo ratings yet

- 1 s2.0 S0038092X15005290 MainDocument15 pages1 s2.0 S0038092X15005290 MainZARINo ratings yet

- Unit 1 PSOCDocument16 pagesUnit 1 PSOCHari Narayanan ACNo ratings yet

- Module 1Document121 pagesModule 1merinfrancisNo ratings yet

- Power Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringFrom EverandPower Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringNo ratings yet

- Introduction to Electricity Supply and Regulation in IndiaFrom EverandIntroduction to Electricity Supply and Regulation in IndiaNo ratings yet

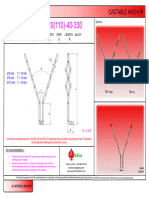

- Castable - Ancbor 3Document1 pageCastable - Ancbor 3chenghongwei2008No ratings yet

- Castable - Tancbor 4Document1 pageCastable - Tancbor 4chenghongwei2008No ratings yet

- Castable - Ancbor 1Document1 pageCastable - Ancbor 1chenghongwei2008No ratings yet

- New Suspension Burding SystemDocument1 pageNew Suspension Burding Systemchenghongwei2008No ratings yet

- TMEIC Cement Industry Brochure - A4Document24 pagesTMEIC Cement Industry Brochure - A4chenghongwei2008No ratings yet

- Raw Material FinenessDocument1 pageRaw Material Finenesschenghongwei2008No ratings yet

- Vertical Roller Mill ECSDocument1 pageVertical Roller Mill ECSchenghongwei2008No ratings yet

- Vertical Roller Mill For Raw MaterialsDocument1 pageVertical Roller Mill For Raw Materialschenghongwei2008No ratings yet

- Practice Quiz - Managing CollaborationDocument2 pagesPractice Quiz - Managing CollaborationMohamed RahalNo ratings yet

- Evolution of The Entertainment Ecosystem in India and Challenges AheadDocument78 pagesEvolution of The Entertainment Ecosystem in India and Challenges AheadAbhishek KumarNo ratings yet

- Diesel Engine Crankshaft DisassemblyDocument15 pagesDiesel Engine Crankshaft DisassemblyAnshar NaraNo ratings yet

- 7 - Simulations and PFDsDocument23 pages7 - Simulations and PFDsIslam SolimanNo ratings yet

- Accomplishment Report Pinagtigasan KinderDocument12 pagesAccomplishment Report Pinagtigasan KinderMay Anne AlmarioNo ratings yet

- Full Data AnalysisDocument627 pagesFull Data AnalysisMyMinecrafter97No ratings yet

- Excel Project AssignmentDocument5 pagesExcel Project AssignmentJayden RinquestNo ratings yet

- Chapter 7 - Non Verbal CommunicationDocument7 pagesChapter 7 - Non Verbal CommunicationCarolyn NacesNo ratings yet

- What Is CommunicationDocument4 pagesWhat Is CommunicationsamsimNo ratings yet

- Actuator DX PDFDocument6 pagesActuator DX PDFFelix Enrique MoratayaNo ratings yet

- The Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronDocument23 pagesThe Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronNanasaheb PatilNo ratings yet

- Checklist Information Security Policy ImplementationDocument18 pagesChecklist Information Security Policy Implementationbaye omar SoceNo ratings yet

- HFLD Literature ReviewDocument5 pagesHFLD Literature ReviewMuhammad AamirNo ratings yet

- VBA Water 6.09 Temperature Pressure Relief Valve Drain LinesDocument2 pagesVBA Water 6.09 Temperature Pressure Relief Valve Drain LinesgaryNo ratings yet

- Khidmat - The ServiceDocument6 pagesKhidmat - The ServiceAjay Prakash VermaNo ratings yet

- Nakshtra Swami and BhramanDocument12 pagesNakshtra Swami and Bhramansagar_m26100% (1)

- Designing Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingDocument7 pagesDesigning Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingdjinxdNo ratings yet

- New Record TDocument2 pagesNew Record Tapi-309280225No ratings yet

- GA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0Document1 pageGA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0esteban muñozNo ratings yet

- GA Standard PPT (Cooling N Staging) .PGIDocument23 pagesGA Standard PPT (Cooling N Staging) .PGIBasit AbdulNo ratings yet

- Willis, John Ral - Slaves and Slavery in Muslin Africa - The Servuile State PDFDocument211 pagesWillis, John Ral - Slaves and Slavery in Muslin Africa - The Servuile State PDFTheCremaNo ratings yet

- Variables, Validity & ReliabilityDocument42 pagesVariables, Validity & ReliabilityNsem Rao100% (1)

- Data Warehouse Slide3Document43 pagesData Warehouse Slide3Kai EnezhuNo ratings yet

- Water Flow Meter South AfricaDocument2 pagesWater Flow Meter South AfricaH2oNetNo ratings yet

- Printable Article Synthetic Materials Making Substances in The LabDocument2 pagesPrintable Article Synthetic Materials Making Substances in The LabJoshua BrewerNo ratings yet

Intermiten Charging of Elctrical Collector

Intermiten Charging of Elctrical Collector

Uploaded by

chenghongwei2008Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intermiten Charging of Elctrical Collector

Intermiten Charging of Elctrical Collector

Uploaded by

chenghongwei2008Copyright:

Available Formats

Item

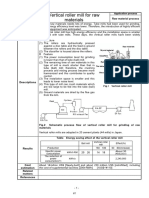

Intermittent charging of electric Application process

dust collector Raw material process

The conventional electric dust collectors use the continuous charging method.

However, the intermittent charging method was developed to save energy and is now

Background being implemented.

To meet the following demand for more efficient electric dust collectors, the pulse

charging method was developed and is now being implemented.

The intermittent charging method uses a waveform (semi-pulses) thinned out from the

output of the continuous charging method periodically. Thinning out the output saves

power. In addition, the dust collection efficiency is said to be a bit superior to that of the

continuous charging method and the alteration cost is not high because only the control

device of the continuous charging method should be altered.

The reduction of dust collection efficiency of electric dust collector became unsatisfying

as coal ashes and other wastes having great electric resistance and fine particles of

submicron-level diameters were used in greater amount. Under these circumstances,

the pulse charging method was implemented to save power and improve the dust

collection efficiency.

The pulse charging method uses a voltage waveform where pulses are superposed on

a DC voltage. The DC voltage, pulse voltage, and period are controlled.

This method costs higher than the others.

Descriptions As of 1996, 120 systems use continuous charging, 21 systems use intermittent

charging, and 16 systems use pulse charging in Japan.

Intermittent charging Pulse charging

Voltage Voltage

Time Time

Current Current

Time Time

Continuous Intermittent

Pulse Charging

Charging Charging

Power Saving Ratio by Power

Results 100 65 45

Effect Consumption(%)

Dust Collection Ratio by Dust Collection

100 110 150

Capacity Efficiency(%)

1) Conversion to the intermittent charging method: 0.8 to 1.6 million US$ (electrical

Cost

equipment only) [1US$=¥110]

estimation 2) Conversion to the pulse charging method: 2.3 to 4.5 million US$ [1US$=¥110]

Related

matters

Reference

-8-

74

You might also like

- Fuse Box Diagram Volkswagen Passat (B8 2015-2019)Document2 pagesFuse Box Diagram Volkswagen Passat (B8 2015-2019)slhkrh1905No ratings yet

- Calculating Cable Pulling TensionsDocument4 pagesCalculating Cable Pulling TensionsNilesh ButeNo ratings yet

- Winters PreviewDocument265 pagesWinters PreviewcqpresscustomNo ratings yet

- Yoga Nidra Masterclass Training Notes 1 PDFDocument4 pagesYoga Nidra Masterclass Training Notes 1 PDFMino Zo SydneyNo ratings yet

- Hussein 2017Document9 pagesHussein 2017Anonymous fqHGrbwxeFNo ratings yet

- Optimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesDocument9 pagesOptimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesU.B MujumdarNo ratings yet

- Single-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksDocument7 pagesSingle-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksNelson ParijósNo ratings yet

- Optimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesDocument9 pagesOptimal Charge Pattern For The High-Performance Multistage Constant Current Charge Method For The Li-Ion BatteriesAlexander López PadillaNo ratings yet

- Dhineshkumar 2018 J. Phys. Conf. Ser. 1000 012051Document11 pagesDhineshkumar 2018 J. Phys. Conf. Ser. 1000 012051Samyuktha S HariNo ratings yet

- Harmonic Reduction IEEE PaperDocument6 pagesHarmonic Reduction IEEE PaperRajasekaranViswaNo ratings yet

- Harmonic Detection Methods of Shunt Active PowerDocument7 pagesHarmonic Detection Methods of Shunt Active Poweroctober87No ratings yet

- Topic No. 3 Load CharacteristicsDocument11 pagesTopic No. 3 Load Characteristicsburnermike011323No ratings yet

- Design and Implementation of Single-Phase Hybrid Active Power Filter Controller-LibreDocument5 pagesDesign and Implementation of Single-Phase Hybrid Active Power Filter Controller-LibreDhivya NNo ratings yet

- Electrical Power and Energy Systems: Sajad Jashfar, Saeid EsmaeiliDocument13 pagesElectrical Power and Energy Systems: Sajad Jashfar, Saeid Esmaeilialessio8No ratings yet

- IREE Paper PDFDocument7 pagesIREE Paper PDFkavithaNo ratings yet

- Energy Balancing of Power System Considering Periodic Behavioral Pattern of Renewable Energy Sources and DemandsDocument18 pagesEnergy Balancing of Power System Considering Periodic Behavioral Pattern of Renewable Energy Sources and DemandsShameem SiddiqueNo ratings yet

- Wang 2012Document10 pagesWang 2012Itamar Peñaloza MoránNo ratings yet

- EE462 Second PartDocument27 pagesEE462 Second PartMusabNo ratings yet

- Conected Load 2222Document3 pagesConected Load 2222surajgedam044No ratings yet

- Chapter 04Document47 pagesChapter 04HassanKMNo ratings yet

- Introduction To Hydropower PresentationDocument167 pagesIntroduction To Hydropower Presentationpggopal_85No ratings yet

- Wibowo2014 r3Document6 pagesWibowo2014 r3Narendra YadavNo ratings yet

- التوافقيات في شبكات القوى الكهربيةDocument30 pagesالتوافقيات في شبكات القوى الكهربيةAbderahmanAkilaNo ratings yet

- 04 - The Influence of Electronic Loads Switching in The Reactive Flow of A Bus BarDocument6 pages04 - The Influence of Electronic Loads Switching in The Reactive Flow of A Bus BarKelvin Mendonça - WEANo ratings yet

- A New Approach To Wind EnergyDocument48 pagesA New Approach To Wind EnergySiva KulanjiNo ratings yet

- Machine Learning Based Maximum Power Point Tracking in Tidal/Ocean Energy Conversion SystemDocument5 pagesMachine Learning Based Maximum Power Point Tracking in Tidal/Ocean Energy Conversion Systemoussama bouguerraNo ratings yet

- PG LecturesDocument414 pagesPG LecturesMUHAMMAD SHAHEERNo ratings yet

- Journal Rahma IREEDocument9 pagesJournal Rahma IREERahma AloulouNo ratings yet

- Power Quality Improvement With Shunt ActDocument5 pagesPower Quality Improvement With Shunt ActSergio QuirogaNo ratings yet

- Epeng 308-3Document55 pagesEpeng 308-3gwemeowenNo ratings yet

- Concept of Electrical TarrifsDocument4 pagesConcept of Electrical TarrifsAshutosh SoniNo ratings yet

- An Adaptive Hysteresis Band Current Controller For Shunt Active Power FilterDocument7 pagesAn Adaptive Hysteresis Band Current Controller For Shunt Active Power Filterherdal TedongmoNo ratings yet

- AR222s Week 1-5 ADocument138 pagesAR222s Week 1-5 AJOHANAH MICAH MARCOSNo ratings yet

- Allocation of Wind Capacity Subject To Long Term Voltage Stability ConstraintsDocument11 pagesAllocation of Wind Capacity Subject To Long Term Voltage Stability ConstraintsJoão PedroNo ratings yet

- MODULE-2-Economic Aspects-2Document20 pagesMODULE-2-Economic Aspects-2vivekNo ratings yet

- Load SheddingDocument5 pagesLoad SheddingAdhyartha KerafNo ratings yet

- Sundar Am 2014Document7 pagesSundar Am 2014Nikola DjordjevicNo ratings yet

- Performance Study of An Inverter: ArticleDocument6 pagesPerformance Study of An Inverter: Articlenjoku danielNo ratings yet

- Energies 16 01276 v2Document22 pagesEnergies 16 01276 v2arun kumarNo ratings yet

- Group5 Lab 07Document9 pagesGroup5 Lab 07FALSERNo ratings yet

- HWRE3141 Ch-3Document16 pagesHWRE3141 Ch-3kader ArefeNo ratings yet

- Optimum Design of The Current-Source Flyback Inverter For Decentralized Grid-Connected Photovoltaic SystemsDocument13 pagesOptimum Design of The Current-Source Flyback Inverter For Decentralized Grid-Connected Photovoltaic SystemsAaqib Ahmad QureshiNo ratings yet

- Energies 14 05626Document19 pagesEnergies 14 05626Jack ParedesNo ratings yet

- Reactive Power Compensation Technologies PDFDocument21 pagesReactive Power Compensation Technologies PDFTovar ArmandoNo ratings yet

- Harmonic Reduction in Multiplex Convertors by Triple-Frequency Current InjectionDocument5 pagesHarmonic Reduction in Multiplex Convertors by Triple-Frequency Current InjectionvmksamyNo ratings yet

- A Fuzzy - Logic Based Controller For Three Phase PWM Rectifier With Voltage Oriented Control StrategyDocument8 pagesA Fuzzy - Logic Based Controller For Three Phase PWM Rectifier With Voltage Oriented Control StrategyDRIS IDRISNo ratings yet

- Hourly Electricity Demand Response in The Stochastic Day-Ahead Scheduling of Coordinated Electricity and Natural Gas NetworksDocument10 pagesHourly Electricity Demand Response in The Stochastic Day-Ahead Scheduling of Coordinated Electricity and Natural Gas Networksmailsfree123No ratings yet

- The Reactive Power, Does It Important For UsDocument9 pagesThe Reactive Power, Does It Important For UsPiotr JuszczykNo ratings yet

- AKASH AUXILIARY CHARGEPUMP CMOS Startup Charge Pump With Body BiasDocument11 pagesAKASH AUXILIARY CHARGEPUMP CMOS Startup Charge Pump With Body Biasakashkumarswain213No ratings yet

- New Rich Text DocumentDocument5 pagesNew Rich Text DocumentFaryal SiddiqueNo ratings yet

- A Practical Algorithm For Optimal Operation Management of Distribution Network Including Fuel Cell Power PlantsDocument19 pagesA Practical Algorithm For Optimal Operation Management of Distribution Network Including Fuel Cell Power PlantsFarouk KeniouNo ratings yet

- 05EEE - 2023 - Variable Load On Power SystemDocument31 pages05EEE - 2023 - Variable Load On Power SystemAmbadiNo ratings yet

- 04 - Planung - Einer - DL - Station - ALMIG - GB (NXPowerLite) (NXPowerLite)Document62 pages04 - Planung - Einer - DL - Station - ALMIG - GB (NXPowerLite) (NXPowerLite)Junaid AhmedNo ratings yet

- Ocean Engineering: Rishav Raj, R. Anandanarayanan, Suchithra Ravikumar, Prasad Dudhgaonkar, Abdus SamadDocument12 pagesOcean Engineering: Rishav Raj, R. Anandanarayanan, Suchithra Ravikumar, Prasad Dudhgaonkar, Abdus SamadAmelia Agista PutriNo ratings yet

- C.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurDocument13 pagesC.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurMohan KrishnaNo ratings yet

- Project Report On PLCDocument13 pagesProject Report On PLCkaran aroraNo ratings yet

- Charge While DrivingDocument6 pagesCharge While DrivingMạnh Hùng VũNo ratings yet

- H R e SystemDocument6 pagesH R e SystemMohitAgrawalNo ratings yet

- Design, Simulation and Implementation of A Self Oscillating Control Circuit To Drive Series Resonant Inverter Feeding A Brazing Induction FurnaceDocument7 pagesDesign, Simulation and Implementation of A Self Oscillating Control Circuit To Drive Series Resonant Inverter Feeding A Brazing Induction FurnaceSandeep SNo ratings yet

- 1 s2.0 S0038092X15005290 MainDocument15 pages1 s2.0 S0038092X15005290 MainZARINo ratings yet

- Unit 1 PSOCDocument16 pagesUnit 1 PSOCHari Narayanan ACNo ratings yet

- Module 1Document121 pagesModule 1merinfrancisNo ratings yet

- Power Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringFrom EverandPower Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringNo ratings yet

- Introduction to Electricity Supply and Regulation in IndiaFrom EverandIntroduction to Electricity Supply and Regulation in IndiaNo ratings yet

- Castable - Ancbor 3Document1 pageCastable - Ancbor 3chenghongwei2008No ratings yet

- Castable - Tancbor 4Document1 pageCastable - Tancbor 4chenghongwei2008No ratings yet

- Castable - Ancbor 1Document1 pageCastable - Ancbor 1chenghongwei2008No ratings yet

- New Suspension Burding SystemDocument1 pageNew Suspension Burding Systemchenghongwei2008No ratings yet

- TMEIC Cement Industry Brochure - A4Document24 pagesTMEIC Cement Industry Brochure - A4chenghongwei2008No ratings yet

- Raw Material FinenessDocument1 pageRaw Material Finenesschenghongwei2008No ratings yet

- Vertical Roller Mill ECSDocument1 pageVertical Roller Mill ECSchenghongwei2008No ratings yet

- Vertical Roller Mill For Raw MaterialsDocument1 pageVertical Roller Mill For Raw Materialschenghongwei2008No ratings yet

- Practice Quiz - Managing CollaborationDocument2 pagesPractice Quiz - Managing CollaborationMohamed RahalNo ratings yet

- Evolution of The Entertainment Ecosystem in India and Challenges AheadDocument78 pagesEvolution of The Entertainment Ecosystem in India and Challenges AheadAbhishek KumarNo ratings yet

- Diesel Engine Crankshaft DisassemblyDocument15 pagesDiesel Engine Crankshaft DisassemblyAnshar NaraNo ratings yet

- 7 - Simulations and PFDsDocument23 pages7 - Simulations and PFDsIslam SolimanNo ratings yet

- Accomplishment Report Pinagtigasan KinderDocument12 pagesAccomplishment Report Pinagtigasan KinderMay Anne AlmarioNo ratings yet

- Full Data AnalysisDocument627 pagesFull Data AnalysisMyMinecrafter97No ratings yet

- Excel Project AssignmentDocument5 pagesExcel Project AssignmentJayden RinquestNo ratings yet

- Chapter 7 - Non Verbal CommunicationDocument7 pagesChapter 7 - Non Verbal CommunicationCarolyn NacesNo ratings yet

- What Is CommunicationDocument4 pagesWhat Is CommunicationsamsimNo ratings yet

- Actuator DX PDFDocument6 pagesActuator DX PDFFelix Enrique MoratayaNo ratings yet

- The Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronDocument23 pagesThe Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronNanasaheb PatilNo ratings yet

- Checklist Information Security Policy ImplementationDocument18 pagesChecklist Information Security Policy Implementationbaye omar SoceNo ratings yet

- HFLD Literature ReviewDocument5 pagesHFLD Literature ReviewMuhammad AamirNo ratings yet

- VBA Water 6.09 Temperature Pressure Relief Valve Drain LinesDocument2 pagesVBA Water 6.09 Temperature Pressure Relief Valve Drain LinesgaryNo ratings yet

- Khidmat - The ServiceDocument6 pagesKhidmat - The ServiceAjay Prakash VermaNo ratings yet

- Nakshtra Swami and BhramanDocument12 pagesNakshtra Swami and Bhramansagar_m26100% (1)

- Designing Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingDocument7 pagesDesigning Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingdjinxdNo ratings yet

- New Record TDocument2 pagesNew Record Tapi-309280225No ratings yet

- GA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0Document1 pageGA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0esteban muñozNo ratings yet

- GA Standard PPT (Cooling N Staging) .PGIDocument23 pagesGA Standard PPT (Cooling N Staging) .PGIBasit AbdulNo ratings yet

- Willis, John Ral - Slaves and Slavery in Muslin Africa - The Servuile State PDFDocument211 pagesWillis, John Ral - Slaves and Slavery in Muslin Africa - The Servuile State PDFTheCremaNo ratings yet

- Variables, Validity & ReliabilityDocument42 pagesVariables, Validity & ReliabilityNsem Rao100% (1)

- Data Warehouse Slide3Document43 pagesData Warehouse Slide3Kai EnezhuNo ratings yet

- Water Flow Meter South AfricaDocument2 pagesWater Flow Meter South AfricaH2oNetNo ratings yet

- Printable Article Synthetic Materials Making Substances in The LabDocument2 pagesPrintable Article Synthetic Materials Making Substances in The LabJoshua BrewerNo ratings yet