Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

42 viewsPost-Tensioning Manual 6TH EDITION

Post-Tensioning Manual 6TH EDITION

Uploaded by

langley.zhu.cnCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Brick Cladding To Steel Framed Buildings - CommentryDocument59 pagesBrick Cladding To Steel Framed Buildings - Commentryalaa4altaie100% (1)

- Design of MSE Walls at Pile Supported AbutmentsDocument15 pagesDesign of MSE Walls at Pile Supported AbutmentsLjubomir JocicNo ratings yet

- Base Plate and Anchor Rod Design 2nd PDFDocument8 pagesBase Plate and Anchor Rod Design 2nd PDFAmol JdvNo ratings yet

- Guide To Fixings For GRC CladdingDocument55 pagesGuide To Fixings For GRC CladdingThompson Lai100% (4)

- ACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresDocument16 pagesACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresnoijpNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Jsa For ScaffoldingDocument3 pagesJsa For Scaffoldingsoubhagya100% (4)

- Steel ConstructionsDocument23 pagesSteel ConstructionsdanmertzNo ratings yet

- Joints in Concrete BuildingsDocument8 pagesJoints in Concrete BuildingsHossam Al-Dein Mostafa Helmy100% (1)

- Deflection Considerations in Two-Way Reinforced CoDocument13 pagesDeflection Considerations in Two-Way Reinforced CoHamid HassanzadaNo ratings yet

- Portal Frame Footings and Slab - 4ed - bk180Document12 pagesPortal Frame Footings and Slab - 4ed - bk180NivarNo ratings yet

- Location of WallsDocument14 pagesLocation of WallsEr Sourav DasNo ratings yet

- Traduccion AciDocument6 pagesTraduccion AcifelipeNo ratings yet

- Variations in Position of Columns and SlabsDocument13 pagesVariations in Position of Columns and SlabsuserinterestedNo ratings yet

- C StructuralComponents CateDocument3 pagesC StructuralComponents Cateimde2No ratings yet

- Camber Considerations: Lawrence A. Kloiber, PE, and Susan B. Burmeister, PEDocument5 pagesCamber Considerations: Lawrence A. Kloiber, PE, and Susan B. Burmeister, PEalberto rosadoNo ratings yet

- 3 Other Design RequirementDocument2 pages3 Other Design RequirementRajan_2010No ratings yet

- Some Aspects of The Design of Face Loaded Slender Precast Concrete Wall Panels - SESOC Journal Vol29 No2 Sep 2016Document2 pagesSome Aspects of The Design of Face Loaded Slender Precast Concrete Wall Panels - SESOC Journal Vol29 No2 Sep 2016junhe898No ratings yet

- Flat Slab (Efficient Construction)Document4 pagesFlat Slab (Efficient Construction)tanhh5678No ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!esgsNo ratings yet

- Composite and Steel Construction CompendiumDocument3 pagesComposite and Steel Construction CompendiumΤε ΧνηNo ratings yet

- 1.2.5 Initial Estimation of Member Dimensions: N N N N N N N NDocument7 pages1.2.5 Initial Estimation of Member Dimensions: N N N N N N N NSuman.SNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 26Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 26behnam fallahNo ratings yet

- ASSESSMENT REPORT NDocument9 pagesASSESSMENT REPORT NMudassur HussainNo ratings yet

- KEYSTONE-GSRW Retaining WallsDocument24 pagesKEYSTONE-GSRW Retaining WallsIsti HaryantoNo ratings yet

- Measures To Mitigate Cracks in Reinforced Concrete StructuresDocument8 pagesMeasures To Mitigate Cracks in Reinforced Concrete StructuresLee TaiNo ratings yet

- Measures To Mitigate Cracks in Reinforced Concrete StructuresDocument4 pagesMeasures To Mitigate Cracks in Reinforced Concrete StructuresNiraj ShindeNo ratings yet

- 2001 08 VaryaniDocument2 pages2001 08 Varyaniraj_anu130% (1)

- Code of Practice For Structural Use of Concrete - HK - 1987Document68 pagesCode of Practice For Structural Use of Concrete - HK - 1987nebojsadj6411100% (1)

- 01. HTU Structural Design CommentsDocument4 pages01. HTU Structural Design CommentsElias DefalgnNo ratings yet

- Hollow Core SpecificationsDocument19 pagesHollow Core SpecificationsShivanan SinghNo ratings yet

- Constructability of Embedded Steel Plates in CIP ConcreteDocument7 pagesConstructability of Embedded Steel Plates in CIP ConcreteimranNo ratings yet

- DN 32 Connection ArchiDocument40 pagesDN 32 Connection ArchiAjit SinghNo ratings yet

- Ibc DeflectionDocument3 pagesIbc Deflectiongraziella njeimNo ratings yet

- Concrete Chapter 6Document144 pagesConcrete Chapter 6bryexplorerNo ratings yet

- C StructuralDesign NGDocument3 pagesC StructuralDesign NGHafiz SaeedNo ratings yet

- MortarlessDM AS3700 Part1 Section 1 140601Document8 pagesMortarlessDM AS3700 Part1 Section 1 140601jonnypremNo ratings yet

- Tolleranze PCIDocument20 pagesTolleranze PCIkurtainNo ratings yet

- Solutions: Practical SDocument5 pagesSolutions: Practical SArjun Chitradurga RamachandraRaoNo ratings yet

- Design of Unstiffened Extended Single Plate Shear ConnectionsDocument14 pagesDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasNo ratings yet

- AISC Trusses 03Document7 pagesAISC Trusses 03sugi zhuangNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Reinforcement Congestion in CIP Concrete CI - 12 22Document11 pagesReinforcement Congestion in CIP Concrete CI - 12 22JAZPAKNo ratings yet

- Erection ManualDocument20 pagesErection ManualJose Arthur AbellaNo ratings yet

- Needham Connections PDFDocument11 pagesNeedham Connections PDFjeddijNo ratings yet

- Pile Cap DesignDocument12 pagesPile Cap DesignBhaskar Jyoti Das100% (2)

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Time-dependent Behaviour and Design of Composite Steel-concrete StructuresFrom EverandTime-dependent Behaviour and Design of Composite Steel-concrete StructuresNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- 2006 Fire Resitant Gypsum ManualDocument28 pages2006 Fire Resitant Gypsum Manuallangley.zhu.cnNo ratings yet

- Infinity BrochureDocument30 pagesInfinity Brochurelangley.zhu.cnNo ratings yet

- Epicore MSR Design ManualDocument68 pagesEpicore MSR Design Manuallangley.zhu.cnNo ratings yet

- MilitaryHandbook AluminumStructuresCompositeStructuresStructuralPlasticsandFiber ReinforcedCompositesDocument35 pagesMilitaryHandbook AluminumStructuresCompositeStructuresStructuralPlasticsandFiber ReinforcedCompositeslangley.zhu.cnNo ratings yet

- Rendering Fat Screw PressDocument2 pagesRendering Fat Screw Presssofiane mokhtariNo ratings yet

- Von Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622Document2 pagesVon Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622edielNo ratings yet

- Uma 120 MBHDocument24 pagesUma 120 MBHSergio Cataño GaleanoNo ratings yet

- Pakistan Steel Marketing DepartmentDocument5 pagesPakistan Steel Marketing DepartmentHamid NaveedNo ratings yet

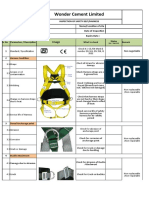

- Safety Harness ChecklistDocument2 pagesSafety Harness ChecklistTilak RajNo ratings yet

- P 726 ED tcm135 566229 PDFDocument11 pagesP 726 ED tcm135 566229 PDFВасилий ЗотовNo ratings yet

- Air Refrigeration SystemDocument29 pagesAir Refrigeration SystemSumit KumarNo ratings yet

- Catalog For Clamps For Clamp Hub ConnectionsDocument17 pagesCatalog For Clamps For Clamp Hub ConnectionsDavid OrtegaNo ratings yet

- Maneurop® Reciprocating Compressors: MT/MTZDocument34 pagesManeurop® Reciprocating Compressors: MT/MTZLevi Lr'sNo ratings yet

- Bosch Cordless Screwdriver GSR 120 PDFDocument60 pagesBosch Cordless Screwdriver GSR 120 PDFNsrdn AlloyNo ratings yet

- Thermo King Parts Manual CF-II M53 (uPA+) - P PDFDocument93 pagesThermo King Parts Manual CF-II M53 (uPA+) - P PDFSerhiiNo ratings yet

- Design Drawings PV Pump Sizing ReportsDocument117 pagesDesign Drawings PV Pump Sizing ReportsafeworkNo ratings yet

- CEC 409 EXAMi 2022Document5 pagesCEC 409 EXAMi 2022Abdullahi MuhammadNo ratings yet

- 2430-3-DIN-Piggable Piping Systems Part 3 Trial Pigging (Prior To Commissioning)Document2 pages2430-3-DIN-Piggable Piping Systems Part 3 Trial Pigging (Prior To Commissioning)dgkmurtiNo ratings yet

- Engin EngDocument5 pagesEngin EngAbhimanyu SinghNo ratings yet

- 2web OppeningDocument3 pages2web OppeningHozaifaNo ratings yet

- Curriculum Vitae: (Piping Engineer)Document3 pagesCurriculum Vitae: (Piping Engineer)oil hguNo ratings yet

- MATH Timber Design and Construction MethDocument4 pagesMATH Timber Design and Construction MethJeth Verdejo RiveroNo ratings yet

- 8a Homework Unit 1 Imię I NazwiskoDocument2 pages8a Homework Unit 1 Imię I NazwiskoAgnieszka Wieteczka WietechaNo ratings yet

- Ti Spec FedStd H28 1969Document2 pagesTi Spec FedStd H28 1969Nick TsikasNo ratings yet

- Surebind 3 Service ManualDocument106 pagesSurebind 3 Service ManualFatema NasreenNo ratings yet

- Beam Clamp - Universal - Tiger LiftingDocument2 pagesBeam Clamp - Universal - Tiger LiftingYADAGIRI REDDYNo ratings yet

- 8564 - KNT-WNT-0172-X-P - XL - Rev 5 - STR - 15-Oct-2021 - Rev 0 - 202110193052Document15 pages8564 - KNT-WNT-0172-X-P - XL - Rev 5 - STR - 15-Oct-2021 - Rev 0 - 202110193052NanankNo ratings yet

- XXXXXX Hydac Blasenspeicher GBDocument8 pagesXXXXXX Hydac Blasenspeicher GBManuel AvendanoNo ratings yet

- Teh 375a PDFDocument27 pagesTeh 375a PDFomarNo ratings yet

- Catalog Pasx 710Document65 pagesCatalog Pasx 710Drew Reaz100% (1)

- 1969 6 EngDocument15 pages1969 6 EngTateNo ratings yet

- Pressue CompensatorDocument2 pagesPressue CompensatorMahmud MaherNo ratings yet

- FS-C5350DN ECOSYS-P6030cdn: Parts ListDocument38 pagesFS-C5350DN ECOSYS-P6030cdn: Parts ListangevilessNo ratings yet

Post-Tensioning Manual 6TH EDITION

Post-Tensioning Manual 6TH EDITION

Uploaded by

langley.zhu.cn0 ratings0% found this document useful (0 votes)

42 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

42 views4 pagesPost-Tensioning Manual 6TH EDITION

Post-Tensioning Manual 6TH EDITION

Uploaded by

langley.zhu.cnCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Chapter 6 Detailing And Construction Procedures For Buildings

DETAILING AND CONSTRUCTION PROCEDURES FOR BUILDINGS

6.1 GENERAL should be clearly shown on the structural drawings and

carefully inspected during all stages of construction.

The primary emphasis of this chapter is on detailing and Building owners should be made aware that some move-

construction procedures for buildings with unbonded ten- ment is expected at joints over the life of the structure.

dons. Some of the material presented is also applicable to

buildings with bonded tendons and other applications. Structural elements that cannot be isolated from floor

These applications may require specialized considerations movements must be designed and detailed to absorb the

beyond the scope of this chapter, Additional information movements. There are four factors that contribute to the

on construction of post-tensioned buildings is available in shortening of cast-in-place post-tensioned floors:

the PTI Field Procedtrres Manual for Unbonded Single Elastic shortening due to pre-compression

Strand tendon^.^.' Creep shortening due to pre-compression

Shrinkage of concrete

6.2 DESIGN ISSUES

Temperature variation

6.2.1 Information on Structural Drawings It is important for the designer to understand the effect of

floor shortening on the various components of the struc-

The project construction documents typically include ture and account for it in the design.

design drawings and specifications from all of the disci-

plines involved. The design drawings indicate the scope

6.2.3 Measures to Mitigate Restraint Cracking

of the project and give sufficient detail for the contractor

to estimate the work and produce detailed installation1 Floor shortening can cause cracking of both the floor slabs

shop drawings. and the vertical supporting elements. Although it may be

In general, the structural drawings show the geometry of impossible to completely eliminate cracking, it can be sig-

all elements of the structure and the required non-pre- nificantly reduced by taking appropriate steps during

stressed as well as post-tensioned reinforcing. For post- design. Some techniques that can be used to mitigate

tensioned slabs, the designer typically specifies the effec- restraint cracking are discussed in this section.

tive prestress force per linear foot in the slab and the

tendon profile for each design strip. Total effective force 6.2.3.1 Planning Layout .of Restraining Members

and tendon profile is typically specified for post-tensioned

The most effective method of preventing restraint cracks is

beams. Fig. 6.1 shows a plan for a post-tensioned slab. In

to ensure that columns and walls are correctly located. Stiff

addition to the floor plan, the licensed design professional

elements such as shear walls should be located at, or near,

is also expected to provide sufficient detail on the drawings

points of zero expected movement. Fig. 6.2 shows examples

to illustrate the intent of the design. Section 6.4 shows

of both favorable and unfavorable wall arrangements. Cracks

some of the commonly used details and standard notes for

sometimes develop in the slab in the vicinity of shear walls,

post-tensioned construction. Post-tensioning fabricators

even if they are favorably located. Aalami et. al.6.286.3

provide

frequently have experienced structural designers on staff

recommendations regarding additional non-prestressed rein-

who review the structural drawings and produce shop

forced that should be provided in order to control cracking.

drawings that address construction and stressing sequence.

Fig. 6.16 shows a possible detail of this reinforcement.

6.2.2 Floor Shortening and Restraint Cracking

6.2.3.2 Expansion Joints

If it is not adequately addressed in design and construction,

Slabs of irregular plan geometry are particularly suscepti-

floor shortening can be a source of distress in both the

ble to cracking. Fig. 6.3 shows a small slab area appended

structural and non-structural elements. Restraint can occur

to a larger rectangular region. An expansion joint can be

due to the stiffness of the columns or other stiff lateral load

added between the two slab sections to create a structural

resisting elements such as shear walls, foundation walls,

separation. Restraint forces are minimized because each

and non-structural elements that are not temporarily or

slab is allowed to move independently towards its respec-

permanently isolated from the structure.

tive location of zero expected movement. If an expansion

Restraint to floor shortening is a major source of cracking joint cannot be provided, the effect of potential shortening

and distress in post-tensioned structures. Non-structural and movements between stiff elements must be investi-

elements should be isolated from the structure by means of gated and additional reinforcing provided as necessary to

joints and physical separations. Joint and separation details minimize apparent cracking.

PLL

s 6 u ! ~ a ~doys

a J O ~~ z . PUP

9 zz.9 's6!j '01 Jeietl 'qels ABM-OM~

pua -auO J O ~uald 6u!ura~jeldues ~'9.6!4

Chapter 6 Detailing And Construction Procedures For Buildings

6.2.3.3 Closure Strips

Closure strips are temporary slab separations that allow

different sections of a slab to move independently until the

closure strip concrete is placed and the adjacent slab sec-

tions are connected. In order to be effective in mitigating

restraint cracks, closure strips must remain open long

\--POINT OF Z E ~

enough for a sufficient amount of the slab shortening to MOVEMENT

have occurred. Additional information on shortening cal-

culations and detailing requirements are available in Sec- (a) Favorable Arrangement o f Shear Walls

tion 2.8 in the reference Design, Construction and Mainte-

nance of Cast-in-Place Post-Tensioned Concrete Parking

Struct~res.~.~ If the construction schedule or other consid-

erations do not allow a closure strip to remain open for the

required time, an expansion joint should be considered.

Fig. 6.15 shows typical reinforcing for a closure strip.

6.2.3.4 Expansion Joint and Closure Strip Spacing

Guidelines

The following general limitations on the lengths between

closure strips and expansion joints are recommended,

unless other details or methods are specified to mitigate

cracking caused by restraint to shortening: (b) Unfavorable Arrangement o f Shear Walls

If the slab length is less than 250 feet, no closure

strip or expansion joint is necessary. Fig. 6.2 Arrangement of Restraining Elements

For slab lengths between 250-325 feet, provide one

centrally located closure strip.

If the slab length is between 325 and 400 feet, consider

using two closure strips open for at least 60 days.

For slabs greater than 400 feet an expansion joint is

recommended.

These guidelines may need to be modified for locations

with significant temperature changes. In addition, it is

assumed that the slab is regular in shape and stiff elements

such as shear walls are favorably located near points of SF

P! RATION

CTURAL

-

zero expected movement. As already discussed, plan loca-

tion of stiff elements and geometry of the slab play an

important role in the determination of.expansion joint and

POINT OF ZERO

closure strip location. MOVEMENT

6.2.3.5 Special Movement Details

In some cases, details can be developed to allow some

movement of the floor slab relative to its supporting ele-

ments. This helps to relieve the restraint forces and avoid

Fig. 6.3 Separation Between Areas Forming an Irregular Shape

cracking. These connection details need to be adequately

designed and detailed on the structural drawings. Special

care is required during construction to ensure that move-

ment joints pelform as designed. Fig. 6.4 shows some exam-

ples of movement details that have been used successfiilly.

You might also like

- Brick Cladding To Steel Framed Buildings - CommentryDocument59 pagesBrick Cladding To Steel Framed Buildings - Commentryalaa4altaie100% (1)

- Design of MSE Walls at Pile Supported AbutmentsDocument15 pagesDesign of MSE Walls at Pile Supported AbutmentsLjubomir JocicNo ratings yet

- Base Plate and Anchor Rod Design 2nd PDFDocument8 pagesBase Plate and Anchor Rod Design 2nd PDFAmol JdvNo ratings yet

- Guide To Fixings For GRC CladdingDocument55 pagesGuide To Fixings For GRC CladdingThompson Lai100% (4)

- ACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresDocument16 pagesACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresnoijpNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Jsa For ScaffoldingDocument3 pagesJsa For Scaffoldingsoubhagya100% (4)

- Steel ConstructionsDocument23 pagesSteel ConstructionsdanmertzNo ratings yet

- Joints in Concrete BuildingsDocument8 pagesJoints in Concrete BuildingsHossam Al-Dein Mostafa Helmy100% (1)

- Deflection Considerations in Two-Way Reinforced CoDocument13 pagesDeflection Considerations in Two-Way Reinforced CoHamid HassanzadaNo ratings yet

- Portal Frame Footings and Slab - 4ed - bk180Document12 pagesPortal Frame Footings and Slab - 4ed - bk180NivarNo ratings yet

- Location of WallsDocument14 pagesLocation of WallsEr Sourav DasNo ratings yet

- Traduccion AciDocument6 pagesTraduccion AcifelipeNo ratings yet

- Variations in Position of Columns and SlabsDocument13 pagesVariations in Position of Columns and SlabsuserinterestedNo ratings yet

- C StructuralComponents CateDocument3 pagesC StructuralComponents Cateimde2No ratings yet

- Camber Considerations: Lawrence A. Kloiber, PE, and Susan B. Burmeister, PEDocument5 pagesCamber Considerations: Lawrence A. Kloiber, PE, and Susan B. Burmeister, PEalberto rosadoNo ratings yet

- 3 Other Design RequirementDocument2 pages3 Other Design RequirementRajan_2010No ratings yet

- Some Aspects of The Design of Face Loaded Slender Precast Concrete Wall Panels - SESOC Journal Vol29 No2 Sep 2016Document2 pagesSome Aspects of The Design of Face Loaded Slender Precast Concrete Wall Panels - SESOC Journal Vol29 No2 Sep 2016junhe898No ratings yet

- Flat Slab (Efficient Construction)Document4 pagesFlat Slab (Efficient Construction)tanhh5678No ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!esgsNo ratings yet

- Composite and Steel Construction CompendiumDocument3 pagesComposite and Steel Construction CompendiumΤε ΧνηNo ratings yet

- 1.2.5 Initial Estimation of Member Dimensions: N N N N N N N NDocument7 pages1.2.5 Initial Estimation of Member Dimensions: N N N N N N N NSuman.SNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 26Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 26behnam fallahNo ratings yet

- ASSESSMENT REPORT NDocument9 pagesASSESSMENT REPORT NMudassur HussainNo ratings yet

- KEYSTONE-GSRW Retaining WallsDocument24 pagesKEYSTONE-GSRW Retaining WallsIsti HaryantoNo ratings yet

- Measures To Mitigate Cracks in Reinforced Concrete StructuresDocument8 pagesMeasures To Mitigate Cracks in Reinforced Concrete StructuresLee TaiNo ratings yet

- Measures To Mitigate Cracks in Reinforced Concrete StructuresDocument4 pagesMeasures To Mitigate Cracks in Reinforced Concrete StructuresNiraj ShindeNo ratings yet

- 2001 08 VaryaniDocument2 pages2001 08 Varyaniraj_anu130% (1)

- Code of Practice For Structural Use of Concrete - HK - 1987Document68 pagesCode of Practice For Structural Use of Concrete - HK - 1987nebojsadj6411100% (1)

- 01. HTU Structural Design CommentsDocument4 pages01. HTU Structural Design CommentsElias DefalgnNo ratings yet

- Hollow Core SpecificationsDocument19 pagesHollow Core SpecificationsShivanan SinghNo ratings yet

- Constructability of Embedded Steel Plates in CIP ConcreteDocument7 pagesConstructability of Embedded Steel Plates in CIP ConcreteimranNo ratings yet

- DN 32 Connection ArchiDocument40 pagesDN 32 Connection ArchiAjit SinghNo ratings yet

- Ibc DeflectionDocument3 pagesIbc Deflectiongraziella njeimNo ratings yet

- Concrete Chapter 6Document144 pagesConcrete Chapter 6bryexplorerNo ratings yet

- C StructuralDesign NGDocument3 pagesC StructuralDesign NGHafiz SaeedNo ratings yet

- MortarlessDM AS3700 Part1 Section 1 140601Document8 pagesMortarlessDM AS3700 Part1 Section 1 140601jonnypremNo ratings yet

- Tolleranze PCIDocument20 pagesTolleranze PCIkurtainNo ratings yet

- Solutions: Practical SDocument5 pagesSolutions: Practical SArjun Chitradurga RamachandraRaoNo ratings yet

- Design of Unstiffened Extended Single Plate Shear ConnectionsDocument14 pagesDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasNo ratings yet

- AISC Trusses 03Document7 pagesAISC Trusses 03sugi zhuangNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Reinforcement Congestion in CIP Concrete CI - 12 22Document11 pagesReinforcement Congestion in CIP Concrete CI - 12 22JAZPAKNo ratings yet

- Erection ManualDocument20 pagesErection ManualJose Arthur AbellaNo ratings yet

- Needham Connections PDFDocument11 pagesNeedham Connections PDFjeddijNo ratings yet

- Pile Cap DesignDocument12 pagesPile Cap DesignBhaskar Jyoti Das100% (2)

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Time-dependent Behaviour and Design of Composite Steel-concrete StructuresFrom EverandTime-dependent Behaviour and Design of Composite Steel-concrete StructuresNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- 2006 Fire Resitant Gypsum ManualDocument28 pages2006 Fire Resitant Gypsum Manuallangley.zhu.cnNo ratings yet

- Infinity BrochureDocument30 pagesInfinity Brochurelangley.zhu.cnNo ratings yet

- Epicore MSR Design ManualDocument68 pagesEpicore MSR Design Manuallangley.zhu.cnNo ratings yet

- MilitaryHandbook AluminumStructuresCompositeStructuresStructuralPlasticsandFiber ReinforcedCompositesDocument35 pagesMilitaryHandbook AluminumStructuresCompositeStructuresStructuralPlasticsandFiber ReinforcedCompositeslangley.zhu.cnNo ratings yet

- Rendering Fat Screw PressDocument2 pagesRendering Fat Screw Presssofiane mokhtariNo ratings yet

- Von Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622Document2 pagesVon Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622edielNo ratings yet

- Uma 120 MBHDocument24 pagesUma 120 MBHSergio Cataño GaleanoNo ratings yet

- Pakistan Steel Marketing DepartmentDocument5 pagesPakistan Steel Marketing DepartmentHamid NaveedNo ratings yet

- Safety Harness ChecklistDocument2 pagesSafety Harness ChecklistTilak RajNo ratings yet

- P 726 ED tcm135 566229 PDFDocument11 pagesP 726 ED tcm135 566229 PDFВасилий ЗотовNo ratings yet

- Air Refrigeration SystemDocument29 pagesAir Refrigeration SystemSumit KumarNo ratings yet

- Catalog For Clamps For Clamp Hub ConnectionsDocument17 pagesCatalog For Clamps For Clamp Hub ConnectionsDavid OrtegaNo ratings yet

- Maneurop® Reciprocating Compressors: MT/MTZDocument34 pagesManeurop® Reciprocating Compressors: MT/MTZLevi Lr'sNo ratings yet

- Bosch Cordless Screwdriver GSR 120 PDFDocument60 pagesBosch Cordless Screwdriver GSR 120 PDFNsrdn AlloyNo ratings yet

- Thermo King Parts Manual CF-II M53 (uPA+) - P PDFDocument93 pagesThermo King Parts Manual CF-II M53 (uPA+) - P PDFSerhiiNo ratings yet

- Design Drawings PV Pump Sizing ReportsDocument117 pagesDesign Drawings PV Pump Sizing ReportsafeworkNo ratings yet

- CEC 409 EXAMi 2022Document5 pagesCEC 409 EXAMi 2022Abdullahi MuhammadNo ratings yet

- 2430-3-DIN-Piggable Piping Systems Part 3 Trial Pigging (Prior To Commissioning)Document2 pages2430-3-DIN-Piggable Piping Systems Part 3 Trial Pigging (Prior To Commissioning)dgkmurtiNo ratings yet

- Engin EngDocument5 pagesEngin EngAbhimanyu SinghNo ratings yet

- 2web OppeningDocument3 pages2web OppeningHozaifaNo ratings yet

- Curriculum Vitae: (Piping Engineer)Document3 pagesCurriculum Vitae: (Piping Engineer)oil hguNo ratings yet

- MATH Timber Design and Construction MethDocument4 pagesMATH Timber Design and Construction MethJeth Verdejo RiveroNo ratings yet

- 8a Homework Unit 1 Imię I NazwiskoDocument2 pages8a Homework Unit 1 Imię I NazwiskoAgnieszka Wieteczka WietechaNo ratings yet

- Ti Spec FedStd H28 1969Document2 pagesTi Spec FedStd H28 1969Nick TsikasNo ratings yet

- Surebind 3 Service ManualDocument106 pagesSurebind 3 Service ManualFatema NasreenNo ratings yet

- Beam Clamp - Universal - Tiger LiftingDocument2 pagesBeam Clamp - Universal - Tiger LiftingYADAGIRI REDDYNo ratings yet

- 8564 - KNT-WNT-0172-X-P - XL - Rev 5 - STR - 15-Oct-2021 - Rev 0 - 202110193052Document15 pages8564 - KNT-WNT-0172-X-P - XL - Rev 5 - STR - 15-Oct-2021 - Rev 0 - 202110193052NanankNo ratings yet

- XXXXXX Hydac Blasenspeicher GBDocument8 pagesXXXXXX Hydac Blasenspeicher GBManuel AvendanoNo ratings yet

- Teh 375a PDFDocument27 pagesTeh 375a PDFomarNo ratings yet

- Catalog Pasx 710Document65 pagesCatalog Pasx 710Drew Reaz100% (1)

- 1969 6 EngDocument15 pages1969 6 EngTateNo ratings yet

- Pressue CompensatorDocument2 pagesPressue CompensatorMahmud MaherNo ratings yet

- FS-C5350DN ECOSYS-P6030cdn: Parts ListDocument38 pagesFS-C5350DN ECOSYS-P6030cdn: Parts ListangevilessNo ratings yet