Professional Documents

Culture Documents

05 - 220kv GIS Service Continuity Property

05 - 220kv GIS Service Continuity Property

Uploaded by

amany moemenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 - 220kv GIS Service Continuity Property

05 - 220kv GIS Service Continuity Property

Uploaded by

amany moemenCopyright:

Available Formats

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

Single phase GIS

Maintenance, Repair and Extension (MRE)

Solutions assessment in

Double Busbar arrangement

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 1/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

Contents

1 Introduction ................................................................................................................................. 3

2 Definitions and guidelines .......................................................................................................... 3

2.1 Acronyms ........................................................................................................................................... 3

2.2 Guidelines .......................................................................................................................................... 3

2.3 Substation Operation Modes.............................................................................................................. 4

2.4 Safety rules ........................................................................................................................................ 5

2.4.1 Introduction....................................................................................................................... 5

2.4.2 Safety principles ................................................................................................................ 5

2.4.3 Intervention permissions and constraints ...................................................................... 5

3 MRE solutions Summary (Double busbar arrangement) ....................................................... 7

3.1 Global Chart....................................................................................................................................... 7

4 CB Removal – Basic arrangement ............................................................................................. 8

4.1 Summary ............................................................................................................................................ 8

4.2 Steps of dismantling .......................................................................................................................... 8

5 CB Removal – Standard Arrangement ..................................................................................... 9

5.1 Summary ............................................................................................................................................ 9

5.2 Steps of dismantling .......................................................................................................................... 9

6 CB Removal – MID Arrangement ........................................................................................... 10

6.1 Summary .......................................................................................................................................... 10

6.2 Steps of dismantling ........................................................................................................................ 10

7 Busbar DS Removal – Standard Arrangement ...................................................................... 11

7.1 Summary .......................................................................................................................................... 11

7.2 Steps of dismantling ........................................................................................................................ 12

8 Busbar DS Removal – Buffer Arrangement ........................................................................... 13

8.1 Summary .......................................................................................................................................... 13

8.2 Steps of dismantling ........................................................................................................................ 14

9 Busbar DS Removal – MID Arrangement .............................................................................. 15

9.1 Summary .......................................................................................................................................... 15

9.2 Steps of dismantling ........................................................................................................................ 16

10 Availability matrix .................................................................................................................... 17

10.1 Legend ............................................................................................................................................. 17

10.2 Circuit-Breaker removal availability matrix .................................................................................... 17

10.3 Busbar disconnector removal availability matrix ............................................................................ 17

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 2/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

1 Introduction

In electrical networks, substations are the main nodes where a single event may impact several feeders, if

not the entire substation.

The degree of continuous operation (quite higher for large power plants or aluminum smelters than for

standard substations in a meshed system), safety requirements and repair reliability are altogether fully

driving the decisions to be made when considering the design and planning of any new GIS.

Such safety contingencies, due to the pressurized insulating gas contained in GIS enclosures, require specific

design, especially when Maintenance, Repair and Extension (MRE) processes are considered.

Since completely different, the “immediate”, “under repair” and “during HV test” availabilities require

independent analyses. Customer shall first determine what he is able to tolerate or not during MRE process.

This document is limited to Maintenance, Repair and Extension (MRE) capability in single phase GIS which

may trigger unavailability of several bays, sometimes even of the entire substation.

2 Definitions and guidelines

2.1 Acronyms

Bay: As per IEC standards, a bay corresponds to a 3-phase assembly consisting of one circuit-breaker, its

associated disconnectors, instrument transformers, interconnecting bus up to and including the line

disconnector (if applicable), and the section of main bus (if applicable).

MRE: Maintenance - Repair - Extension

MRE x: In terms of MRE capability, “x” stands for the number of bays which are de-energized during the

repair process associated with the most detrimental failure.

2.2 Guidelines

- Safety is first requirement: No work inside a compartment, one gas-barrier of which remains

pressurized. Exceptions (even with mechanical stress limiter) shall be avoided.

- Reliability is a must: Any major work, such as but not limited to internal parts replacing, shall be

checked by a high-voltage withstand test. Quite often, prerequisites of such a test deeply impact

substation operation.

- Disconnectors cannot withstand the HV test voltage on one terminal while the other one is energized

by the network. Such test requires either de-energizing the entire substation, or having two series

disconnecting gaps between the tested section and the operating section.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 3/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

- Each busbar section (enclosure and conductor) shall incorporate a dismantling facility (i.e. telescopic

enclosure, bellow, etc.) to provide the required maintainability. The add-on of compartments and/or

disconnecting devices requires the add-on of dismantling facilities.

- Repair process shall remain simple: Replacing a busbar disconnector by a by-passing enclosure shall

not be a standard repair process. Such process, not only quite more complex and longer, requires several

HV tests.

2.3 Substation Operation Modes

The following diagrams illustrate the phases which generally occur during the substation’s lifecycle:

Maintenance: After a given number of operations, normal maintenance is generally recommended by

the manufacturer.

Repair: After a fault occurrence, the substation must be reconfigured as soon as possible before repairs,

in order to minimize the loss of lines.

HV Testing: After heavy maintenance, repairs or extensions, a HV test is required. Availability during testing will

be different in terms of MRE=x levels, depending on the design and specifications of the GIS

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 4/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

2.4 Safety rules

2.4.1 Introduction

These safety rules, which are common sense principles, have been developed in coordination with the

different departments of ALSTOM, including Alstom experts and the intervention teams. The respect

of these principles in GIS design and in substation engineering allows the site staff to work with

confidence, for safe and quick interventions.

The principles presented here are specific to ALSTOM products but should apply globally as a

reference guide to basic security and model evaluation.

2.4.2 Safety principles

The following principles must be strictly observed because they describe the basic principles applied

to gas compartment arrangements and gas barrier and insulating element arrangements.

The combination of gas-compartment arrangements, gas-barrier and insulating elements,

architecture and other possible features lead to different levels of maintenance, repair and

extension capabilities.

The principles are forward thinking and must be applied at the SLD stage to anticipate safety concerns

and to take into account the necessary outages during repairs:

2.4.3 Intervention permissions and constraints

No work must be undertaken inside a compartment of which one gas-barrier remains pressurized.

Exceptions are possible, but only on a case-by-case basis. (See figures 4, 5)

No work can be directly undertaken on a pressurized gas-barrier while an additional mechanical load is

applied or can possibly be applied. (See figure 3)

The partitions or support insulators directly in proximity to an internal flashover in the involved

compartment shall be replaced or require at least a thorough check and cleaning of gas decomposition

products.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 5/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

Legend :

Direct Contact :

• Stress applied directly to the pressurized partition à risk is very high.

• Risk of mechanical shock on the pressurized partition à risk is very high.

Mechanical Barrier with Partition :

• Stress is not applied directly to the pressurized partition à no risk.

• No risk of mechanical shock on the pressurized partition à no risk.

Mechanical Barrier with Support Insulator (Horizontal arrangement) :

• Stress is not applied directly to the pressurized partition à no risk.

• No risk of mechanical shock on the pressurized partition à no risk.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 6/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

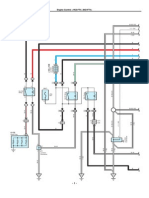

3 MRE solutions Summary (Double busbar arrangement)

3.1 Global Chart

The following chart gives, as an example, a summary of the different service continuity possibilities for

the busbar disconnector removal in a double busbar scheme, depending on the type of GIS design selected

for a specific substation.

Legend :

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 7/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

4 CB Removal – Basic arrangement

This first example involves a CB where partitions (1) and (2) of the CB are not removed with the CB,

more specifically the partition on the busbar side (1).

4.1 Summary

4.2 Steps of dismantling

Feeder with CB Degassing and HV testing

failure removal of the

Circuit breaker

In this case, the circuit-breaker can be removed without affecting the neighbor bays. Circuit-Breaker

partition cannot be removed, only cleaning is possible. If the partition has to be removed, both busbar are

out of service. Avoiding this lead to next ‘standard’ arrangement

Only during HV test, an outage of the busbar BB1 and BB2 is requested.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 8/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

5 CB Removal – Standard Arrangement

In this arrangement, the partitions (1) and (2) of the CB can be removed with the CB. In order to carry

out the operation in line with the safety rules, one support insulator (3) is required in the common point.

When the CB is removed, the conductors in the common point do not create any stress on the pressurized

partitions (4) and (5) of the busbar disconnectors.

5.1 Summary

5.2 Steps of dismantling

Feeder with CB Degassing and HV testing

failure removal of the

Circuit breaker

In this case, the circuit-breaker can be removed without affecting the neighbor bays. Circuit-Breaker

partition is removed with the circuit-breaker, both busbars remaining in service.

Only during HV test, an outage of the busbars BB1 and BB2 is requested.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 9/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

6 CB Removal – MID Arrangement

A maintenance isolating device (MID) is integrated in series with the busbar disconnector. The MID is

located in the common point and is not in the same compartment as the busbar DS. This MID provides an

additional isolation facility to be used when the pressure cannot be maintained in the busbar DS. In order to

provide full flexibility, one MID is associated with each busbar DS and an earthing switch is fitted between

each busbar DS and its corresponding MID. The MID is opened only when the corresponding busbar DS is

opened.

6.1 Summary

6.2 Steps of dismantling

Degassing and

Feeder with CB HV testing

removal of the

failure

Circuit breaker

The MID allows the removal of the CB in a safe manner: when the MID is opened, there is no direct

connection between the common point conductors and the corresponding busbar DS. With this arrangement,

there is no direct connection to any pressurized partitions. Another key feature of this arrangement is to provide

the facility for HV testing while keeping one busbar energized

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 10/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

7 Busbar DS Removal – Standard Arrangement

The following case shows a typical GIS arrangement as used on most of modern GIS. The busbar

DS and the busbar element are part of the same compartment.

To provide the maximum safety during MRE operations, a support insulator (1) is provided in the common

point. This insulator is used to minimize the stress applied on the adjacent busbar partition (2) and it enables

one busbar to remain in service during the operation.

7.1 Summary

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 11/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

7.2 Steps of dismantling

Bay with busbar

DS failure

Degassing and

removal of the

busbar DS

HV testing

With this arrangement, it can be seen that at minimum, 4 feeders need to be out of service (3 adjacent

feeders plus the one where the busbar DS is removed).

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 12/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

8 Busbar DS Removal – Buffer Arrangement

In the previous standard GIS arrangement, many feeders need to be switched off during MRE

operations. In this solution, we overcome this problem by adding "buffer zones" between feeders. This case

illustrates an optimum arrangement adopted on recent ALSTOM GISs.

An additional partition (1) and an additional support insulator (2) are added in the busbar element.

Depending on the GIS design, an additional dismantling element may also be required to allow dismantling

of the busbar DS. It is not shown on the following diagrams.

As with the previous case, the common point is fitted with the additional support insulator (3).

8.1 Summary

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 13/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

8.2 Steps of dismantling

Bay with busbar

DS failure

Degassing and

removal of the

busbar DS

HV testing

With this arrangement, MRE1 availability is achieved.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 14/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

9 Busbar DS Removal – MID Arrangement

The following case uses Maintenance Isolating Devices - MID (1) and (2) in the common point. One

partition (3) is also added in the busbar DS. This allows the removal of all partitions of the disconnector in

case of flashover. As observed in Case 1d (CB removal), this arrangement brings many benefits, as we will

show.

The opening of the corresponding MID suppresses any direct connection between removed components and

the pressurized partition. This also creates an additional gap which is useful during the HV test.

The GIS can be quickly re-configured using this solution and the feeder with the faulty busbar DS can be

re-energized, until an outage is available to replace the faulty equipment. This is achieved by isolating the

faulty disconnector, opening the corresponding maintenance isolating device, and switching all feeders to

busbar 2. This temporary configuration can be useful for the customer until the repair procedure is

implemented or in case of a strategic feeder. During this time (which can last for some weeks, depending on

availability of spare parts), MRE0 level is achieved. This sequence is illustrated in the following chart:

9.1 Summary

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 15/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

9.2 Steps of dismantling

Bay with busbar

DS failure

Degassing and

removal of the

busbar DS

HV testing

The key advantage is to be immediately ready to perform the HV test of the busbar DS after its replacement: all

MIDs are opened on the corresponding section of the busbar. Test voltage can be applied on busbar 1 while

maintaining busbar 2 in service. The replaced busbar DS can be tested in closed and opened positions.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 16/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

GRID - GAS INSULATED SUBSTATIONS

Aix‐les‐Bains

1, rue Paul Doumer ‐ BP 601 ‐ 73106 AIX‐LES‐BAINS CEDEX (France)

Phone: 33 (0) 4 79 88 79 80 ‐ Fax: 33 (0) 4 79 88 79 39 – www.grid.alstom.com

ALSTOM GRID SAS

SAS au capital de 74.478.096 € Siège social : Immeuble Galilée – 51 esplanade du Général de Gaulle – 92907 LA DEFENSE CEDEX

389 191 800 RCS Nanterre

10 Availability matrix

10.1 Legend

Remain in service.

State of out of service. In certain case, a number of bays can be indicated.

10.2 Circuit-Breaker removal availability matrix

Standard MID

State of Basic arrangement

arrangement arrangement

Involved bay

Adjacent feeder bay

Busbar BB1

Busbar BB2

During HV test

For BB1

For BB2

10.3 Busbar disconnector removal availability matrix

Standard Buffer MID

State of

arrangement arrangement arrangement

Involved bay MRE 0 **

Adjacent feeder bay MRE 4 * MRE 1 MRE 1 **

Busbar BB1

Busbar BB2

During HV test

For BB1

For BB2

* MRE 5 if Disconnector partition needs to be removed.

** MRE 0 until repair, and MRE 1 during repair and HV tests.

This document is the exclusive property of ALSTOM Grid. It is submitted on a confidential basis and may not be passed to third parties, used or reproduced except

in exact accordance with prior express permission.

Drawn up

MODIF A by :

Page 17/17

DATE 10/09/10 Appr. by : Ch. LAURENT FD000_070_1E

You might also like

- Cat C-13 Valve LashDocument6 pagesCat C-13 Valve LashEwgeny100% (5)

- VLine - Fencing Right of Way (SAST-1)Document22 pagesVLine - Fencing Right of Way (SAST-1)4493464No ratings yet

- Manual Crane CalculationDocument98 pagesManual Crane CalculationLarry Bea67% (15)

- Screen OneDocument2 pagesScreen OneMtyghm Tymmt100% (1)

- Concise Guide to OTN optical transport networksFrom EverandConcise Guide to OTN optical transport networksRating: 4 out of 5 stars4/5 (2)

- Coduri Eroare Volvo-RenaultDocument12 pagesCoduri Eroare Volvo-RenaultGeorge Alexandru Vâță0% (1)

- TC303 ManualDocument4 pagesTC303 ManualYordano Dwi YunanNo ratings yet

- 20.312 D02 Rev 01 Design BriefDocument17 pages20.312 D02 Rev 01 Design BriefSarah PerezNo ratings yet

- Aeronautical Propagation Model Guide V2Document14 pagesAeronautical Propagation Model Guide V2oldjanusNo ratings yet

- UMTS 900 Engineering-Rules Deployment-Guidelines V3.2Document117 pagesUMTS 900 Engineering-Rules Deployment-Guidelines V3.2Khalid SaidiNo ratings yet

- Technical Notice SLS.38 Rev.1 - IGPS Rollover TT-3026XDocument1 pageTechnical Notice SLS.38 Rev.1 - IGPS Rollover TT-3026XWyn PriceNo ratings yet

- Refer Report - ICES-HSEF-11-Daily CHCK List of Camera and X-Ray GeneratorDocument15 pagesRefer Report - ICES-HSEF-11-Daily CHCK List of Camera and X-Ray GeneratorSharique NezamiNo ratings yet

- LNG-simulator ManualDocument364 pagesLNG-simulator ManualKostya MukhinNo ratings yet

- Tech Note FBB E325727 FleetOne SW Release 124Document5 pagesTech Note FBB E325727 FleetOne SW Release 124al nakheel electronicsNo ratings yet

- Sailor RT4822Document31 pagesSailor RT4822Сергей Бородин0% (1)

- Sailor 900 VsatDocument356 pagesSailor 900 VsatAlhayun AlqayumNo ratings yet

- GSM T SDocument81 pagesGSM T StheraphimNo ratings yet

- Stratos Scada White Paper ValusekDocument15 pagesStratos Scada White Paper Valusekapi-205999899No ratings yet

- Engineering SupportDocument8 pagesEngineering SupportJivendra KumarNo ratings yet

- Mil STD 1760dDocument187 pagesMil STD 1760daoyildizNo ratings yet

- Technical Description Sigma Air Manager: GSM Modem Retrofit KitDocument20 pagesTechnical Description Sigma Air Manager: GSM Modem Retrofit KitEvandro Jva compressoresNo ratings yet

- MX521A Installation-ManualDocument36 pagesMX521A Installation-ManualJavier Fundora PaezNo ratings yet

- Diplex 09-21 K 793532Document2 pagesDiplex 09-21 K 793532yacasiestaNo ratings yet

- Specification: 0 13.05.2020 First Issue SC VB SJGDocument8 pagesSpecification: 0 13.05.2020 First Issue SC VB SJGvishal bhamreNo ratings yet

- GSM Modem Md720Document6 pagesGSM Modem Md720catalinccNo ratings yet

- Case Study Increase Safety Reduce Unplanned Shutdowns of Sand Separators FDM Micro Motion en Us 98862Document2 pagesCase Study Increase Safety Reduce Unplanned Shutdowns of Sand Separators FDM Micro Motion en Us 98862Nestor Camilo Beltran AvilaNo ratings yet

- General Guide Lines For Design of Electrical Distribution Network of Private SchemesDocument8 pagesGeneral Guide Lines For Design of Electrical Distribution Network of Private SchemesMohamad GhosenNo ratings yet

- Iala Guideline 1098 Application of AIS AtoN On Buoys Doc 427 EngDocument27 pagesIala Guideline 1098 Application of AIS AtoN On Buoys Doc 427 EngIliuţă Marius-CătălinNo ratings yet

- GL DCDSDocument28 pagesGL DCDSNour BenNo ratings yet

- Transmode TG Series ADocument6 pagesTransmode TG Series Asotrix84No ratings yet

- Operating Instructions: N - R 472C en 05.12Document42 pagesOperating Instructions: N - R 472C en 05.12Long HuynhNo ratings yet

- Manual AUMA MOVDocument60 pagesManual AUMA MOVBonzo DigolodogNo ratings yet

- Fleet Vehicle GSM/GPRS/GPS Tracker FL-2000G User's ManualDocument13 pagesFleet Vehicle GSM/GPRS/GPS Tracker FL-2000G User's ManualOlesya BorodykhinaNo ratings yet

- MKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemDocument16 pagesMKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemĐiệnBiênNhâm100% (1)

- 7 - 5250 - 01880 - 01E NachrüstsatzDocument11 pages7 - 5250 - 01880 - 01E NachrüstsatzEvandro Jva compressoresNo ratings yet

- WP Modular Safety ConceptsDocument23 pagesWP Modular Safety ConceptsAdam Mazurek100% (1)

- GIS ReportDocument34 pagesGIS Reportibra_sh80% (5)

- MAN YLD01C Chain Hoists eDocument44 pagesMAN YLD01C Chain Hoists eJohannesJacobsNo ratings yet

- C2SAT Catalogue V1.71 PDFDocument35 pagesC2SAT Catalogue V1.71 PDFOrionTroconisNo ratings yet

- SM Cat 320d2 FullDocument1,334 pagesSM Cat 320d2 FullHengki Hen100% (1)

- Users Manual Tron Air 740888Document32 pagesUsers Manual Tron Air 740888NEILNo ratings yet

- Centumvp1 PDFDocument86 pagesCentumvp1 PDFkishoreprithikaNo ratings yet

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtNo ratings yet

- GYRO Compass PDFDocument82 pagesGYRO Compass PDFBf Ipanema60% (5)

- EPD PT Plus Duct SystemDocument14 pagesEPD PT Plus Duct SystemJose GouveiaNo ratings yet

- Compact Substation SolutionsDocument6 pagesCompact Substation SolutionsVICTORMARCENo ratings yet

- 0054-6051 - Wind Farm Roads Requirements - V9Document31 pages0054-6051 - Wind Farm Roads Requirements - V9Cung Manh TuanNo ratings yet

- Mixed Technology HV Switchgear and SubstationsDocument8 pagesMixed Technology HV Switchgear and Substationswas00266No ratings yet

- Circuit BreakerDocument2 pagesCircuit Breakerzawmoe aungNo ratings yet

- Saes T 903Document29 pagesSaes T 903Eagle SpiritNo ratings yet

- C3003 With Crawler Control Unit CCU186Document38 pagesC3003 With Crawler Control Unit CCU186Felix U Onojeta67% (3)

- Certus SAILOR 4300 ManualDocument96 pagesCertus SAILOR 4300 ManualSandymaung AstriumNo ratings yet

- Kathrein 2002Document179 pagesKathrein 2002Hendi SeptiawanNo ratings yet

- KRF 102 350 - 6 800+900Document2 pagesKRF 102 350 - 6 800+900niall_f100% (1)

- MESC Power Cable CatalogueDocument76 pagesMESC Power Cable Catalogue1youssefsNo ratings yet

- Adr155c EngDocument31 pagesAdr155c EngqweasdererNo ratings yet

- Vignal Data Sheet Beacons Atlas Led 212020Document3 pagesVignal Data Sheet Beacons Atlas Led 212020Vuk FilipovicNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- DTC B0118/46 Short in Side Squib (LH) Circuit (To B+)Document3 pagesDTC B0118/46 Short in Side Squib (LH) Circuit (To B+)salusfrankNo ratings yet

- How To Reset The Polar AXN500 (And Change Display Contrast)Document5 pagesHow To Reset The Polar AXN500 (And Change Display Contrast)Juan LeytonNo ratings yet

- CX1100-00xx: Hardware DocumentationDocument78 pagesCX1100-00xx: Hardware DocumentationThiago FernandesNo ratings yet

- Unisonic Technologies Co., LTD: 50 Amps, 60 Volts N-Channel Power MosfetDocument8 pagesUnisonic Technologies Co., LTD: 50 Amps, 60 Volts N-Channel Power MosfetgenibraNo ratings yet

- 3.FLSmidth CrossBar Cooler v2Document8 pages3.FLSmidth CrossBar Cooler v2Sunil T V SuniNo ratings yet

- 3 A6d0e6333a Unit 1 ExamplesDocument8 pages3 A6d0e6333a Unit 1 ExamplesBadal NayakNo ratings yet

- Kalmar Straddle Carrier: Data SheetDocument8 pagesKalmar Straddle Carrier: Data SheetSafae khaloutiNo ratings yet

- EstimateDocument5 pagesEstimateJohn Michael Siao BolandresNo ratings yet

- Dynatech C130 Spares ListDocument39 pagesDynatech C130 Spares ListJose Miguel Atehortua ArenasNo ratings yet

- TJC 4 - enDocument4 pagesTJC 4 - endraganpostaNo ratings yet

- 903001-001 Parts Q500T Rev3Document166 pages903001-001 Parts Q500T Rev3week redNo ratings yet

- Comparch PDFDocument84 pagesComparch PDFSushil KumarNo ratings yet

- Tachogenerators: Shaft Ø7-14 MM With Lange With Own BearingsDocument4 pagesTachogenerators: Shaft Ø7-14 MM With Lange With Own BearingsHitesh PanigrahiNo ratings yet

- PIC16F628A ExperimentosDocument11 pagesPIC16F628A ExperimentosCesar Matos100% (2)

- Engine ControlDocument15 pagesEngine ControlMichael Porter100% (4)

- Hydraulics - Self LevelingDocument3 pagesHydraulics - Self LevelingArildo Chaves de AndradeNo ratings yet

- Electrical Circuits (EEE-141)Document21 pagesElectrical Circuits (EEE-141)Sudipto Sarker SuptoNo ratings yet

- AravindDocument6 pagesAravindyuvi7003No ratings yet

- PFAFF 1520 30 40 English 109pDocument106 pagesPFAFF 1520 30 40 English 109pLautaro Ferrada Q.No ratings yet

- Jaw CrusherDocument3 pagesJaw CrusherAlpaniSaraBiaNo ratings yet

- BLS-700 Level SwitchDocument4 pagesBLS-700 Level SwitchargaNo ratings yet

- 12K PDFDocument1,021 pages12K PDFFedi KleiNo ratings yet

- Constructionv Nov 2022Document10 pagesConstructionv Nov 2022Fely Joy RelatoresNo ratings yet

- BQ 24741Document30 pagesBQ 24741Aleksandar KeracNo ratings yet

- Elint Labz - Magnetic Door Sensor Plug ManualDocument10 pagesElint Labz - Magnetic Door Sensor Plug ManualKartikey SinghNo ratings yet

- Technical Specification For 750hp Drilling Rig PackageDocument25 pagesTechnical Specification For 750hp Drilling Rig PackageAli mohammad100% (1)

- PC Based Temperature Controller Using Digital Pid/Fuzzy Logic Controller ObjectiveDocument3 pagesPC Based Temperature Controller Using Digital Pid/Fuzzy Logic Controller ObjectiveRajasekaran S100% (1)