Professional Documents

Culture Documents

Motor de Combustión InternaEnglish

Motor de Combustión InternaEnglish

Uploaded by

apazayanquigustavo1234Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor de Combustión InternaEnglish

Motor de Combustión InternaEnglish

Uploaded by

apazayanquigustavo1234Copyright:

Available Formats

Motor de combustión internaEnglish

Internal combustion engines (ICM) are the most common form of heat engines,

as they are used in vehicles, ships, ships, airplanes and trains. They are so

called because the fuel is ignited to do work inside the engine. The same

mixture of fuel and air is emitted as exhaust. This can be done using a piston

(called a reciprocating engine), or with a turbine.

La ley de los gases ideales

Internal combustion heat engines can be understood by reflecting on the ideal

gas law: Increasing the temperature of a gas increases the pressure that makes

the gas want to expand. An internal combustion engine has a chamber to which

fuel is added that is ignited to increase the temperature of the gas.

When heat is added to the system, the gas inside is forced to expand. In a

piston engine, this causes the piston to rise (see Fig. 2). By coupling the piston

to a crankshaft (or crankshaft), the engine is capable of converting a portion of

the energy provided to the system into useful work.

To compress the piston in an intermittent combustion engine, the engine expels

gas. A heat sink is then used to keep the system running at a constant

temperature. A gas turbine, which uses continuous combustion, simply

exhausts its gases continuously rather than in a cycle. Heat engines with gas

turbines work according to a similar principle: hot air is introduced into the

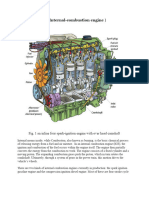

turbine chamber, making it rotate (fig. 1).

Pistones vs turbinas

Fig. 1. Diagram of a gas turbine engine.

An engine that uses a piston is called an intermittent combustion engine, while one

that uses a turbine is called a continuous combustion engine. The difference in

mechanics is obvious from the names, but the difference in usage is less obvious.

A piston engine is extremely sensitive, compared to a turbine, as well as more fuel

efficient at low powers. This makes them ideal for use in vehicles as they also get

going faster. On the contrary, a turbine has a higher power-to-weight ratio than a

piston engine, and its design is more reliable for high and continuous

performances. A turbine also performs better than a naturally aspirated piston

engine at high altitudes and at low temperatures. Their lightweight construction,

reliability and altitude capability make turbines the preferred engine for aircraft.

Turbines are also commonly used in power plants for electricity generation.

Ejemplos de MCI

Motor de cuatro tiempos

Fig. 2. 4-stroke internal combustion engine. 1: Fuel injection, 2: Ignition, 3:

Expansion (work is done), 4: Exhaust.

Although there are many types of internal combustion engines, the

four-stroke piston engine (Fig. 2) is one of the most common. It is

used in various automobiles (which specifically use gasoline as fuel)

such as cars, trucks and some motorcycles. A four-stroke engine

provides one power stroke for every two piston cycles. To the right is

an animation of a four-stroke engine and a more detailed explanation

of the process.

1. El combustible se inyecta en la cámara.

2. The fuel catches fire (this happens differently in a diesel engine

than in a gasoline engine).

3. This fire pushes the piston, which is the useful movement.

4. Residual chemicals, by volume (or mass), are primarily water

vapor and carbon dioxide. There may also be pollutants such as

carbon monoxide from incomplete combustion.

Motor de dos tiempos

Fig. 3. 2-stroke internal combustion engine.

As its name suggests, the system only requires two piston movements

to generate power. The main differentiating factor that allows the two-

stroke engine to operate with only two piston movements is that the

exhaust and intake of gases occur simultaneously, as seen in fig. 3. The

piston itself is used as a system valve, along with the crankshaft, to

direct the flow of gases. Additionally, due to its frequent contact with

moving components, fuel mixes with oil to add lubrication, allowing for

smoother racing. In general, the two-stroke engine contains two

processes:

1. The air-fuel mixture is added and the piston moves upward

(compression). The intake port opens due to the position of the piston

and the air-fuel mixture enters the holding chamber. A spark plug ignites

the compressed fuel and the power stroke begins.

2. The heated gas exerts high pressure on the piston, the piston moves

downward (expansion), and the residual heat is expelled.

Motor rotativo (Wankel)

Fig. 4. The rotary engine cycle. It takes in air/fuel, compresses it, ignites

providing useful work, and then exhausts the gas.

In this type of motor, there is a rotor (inner circle labeled "B" in Fig. 4) that is

contained in an oval-shaped casing. It performs the common steps of the four-

stroke cycle (intake, compression, ignition, exhaust), but these steps occur 3

times for each rotation of the rotor, creating three power strokes per rotation.

You might also like

- Jeppesen Powerplant Textbook4Document728 pagesJeppesen Powerplant Textbook4sat011291% (11)

- Format Report (Diesel Engines) - FinalDocument33 pagesFormat Report (Diesel Engines) - Finalapi-285539674No ratings yet

- 2 - Rotary VibrationsDocument6 pages2 - Rotary VibrationsJoako Torres100% (1)

- Wankel CC PaperDocument15 pagesWankel CC Paperravian439No ratings yet

- Engine Design ClassificationDocument76 pagesEngine Design ClassificationLuis NunesNo ratings yet

- Energy EducationDocument46 pagesEnergy EducationCharol AoayNo ratings yet

- Lecture 1 ICEDocument26 pagesLecture 1 ICEIslam MahmoudNo ratings yet

- Gas Turbines Definition Applications Working Components Types Design Advantages PDFDocument13 pagesGas Turbines Definition Applications Working Components Types Design Advantages PDFSaadi DzNo ratings yet

- Internal Combustion EnginesDocument32 pagesInternal Combustion Enginespramodkb_cusatNo ratings yet

- Internal Combustion EngineDocument16 pagesInternal Combustion EngineHamzeh Al-QaisiNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentSahil KalaNo ratings yet

- Me 56Document9 pagesMe 56RhizhailNo ratings yet

- Six Stroke Engine SeminarDocument37 pagesSix Stroke Engine SeminarShiv Raj KhojaNo ratings yet

- THERMO BS II NotesDocument8 pagesTHERMO BS II Notesm.waseemNo ratings yet

- Gas TurbineDocument1 pageGas TurbineGeneva Elfiel PanaliganNo ratings yet

- Me 56Document7 pagesMe 56RhizhailNo ratings yet

- Gas Turbine: Principle of OperationDocument20 pagesGas Turbine: Principle of Operationwaleed paliNo ratings yet

- Communication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Document6 pagesCommunication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Hemu723No ratings yet

- Principle of Operation:: Unit IiiDocument20 pagesPrinciple of Operation:: Unit Iiilakshmigsr6610No ratings yet

- Heat Engine: Name: Joezel A. Entienza Date:May 1, 2018 Lab 4Document11 pagesHeat Engine: Name: Joezel A. Entienza Date:May 1, 2018 Lab 4joshua jan allawanNo ratings yet

- Unit5 - Heat Engine-Notes1Document17 pagesUnit5 - Heat Engine-Notes1Krishna AgarwalNo ratings yet

- Hand Made CarDocument33 pagesHand Made CarSahil DhirNo ratings yet

- ENGINEDocument7 pagesENGINEayesha amjadNo ratings yet

- Siege Engine Electric Engine: NomenclatureDocument11 pagesSiege Engine Electric Engine: NomenclatureZülfüNo ratings yet

- BME M4-Ktunotes - inDocument25 pagesBME M4-Ktunotes - inbaijudas11No ratings yet

- Mce 211-Lecture Note-Internal Combustion EnginesDocument10 pagesMce 211-Lecture Note-Internal Combustion EnginesUmar Yahiya AhmedNo ratings yet

- Thermodynamics Lab ReportDocument49 pagesThermodynamics Lab Reportjawad60% (5)

- Relation of Gas Law in A Cars Engine: By: Khaled AldhaheriDocument9 pagesRelation of Gas Law in A Cars Engine: By: Khaled AldhaheriSara AlhamesNo ratings yet

- Ic EngineDocument23 pagesIc EngineGanesh kumar100% (1)

- PJM Auto NotesDocument18 pagesPJM Auto NotesAswin PrasannanNo ratings yet

- JET ENGINE FundamentalsDocument18 pagesJET ENGINE FundamentalsHareesha N GNo ratings yet

- Combustion Turbines: Five-Stroke EngineDocument3 pagesCombustion Turbines: Five-Stroke EngineWolfMensch1216No ratings yet

- Basic Engine Edition (Common To All Work Ranks) : Structure of TextbookDocument111 pagesBasic Engine Edition (Common To All Work Ranks) : Structure of Textbookismail_69No ratings yet

- Otto CyclePowePointDocument27 pagesOtto CyclePowePointVamsi KrishnaNo ratings yet

- ThesisDocument54 pagesThesisANIL KUMARNo ratings yet

- Gas Turbine For Power Generation: Dates Back To 1939Document6 pagesGas Turbine For Power Generation: Dates Back To 1939Wakwkaka JssjaaNo ratings yet

- Lect 2Document13 pagesLect 2khalid mustafaNo ratings yet

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalNo ratings yet

- Experiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineDocument6 pagesExperiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineHafeez AliNo ratings yet

- Figure 61 - Combustion ChamberDocument18 pagesFigure 61 - Combustion ChamberGovea HeduNo ratings yet

- ICE (Internal Combustion Engine)Document22 pagesICE (Internal Combustion Engine)johnlloydsantossssNo ratings yet

- How Does An Internal Combustion Engine Work?Document5 pagesHow Does An Internal Combustion Engine Work?AsraNo ratings yet

- Internal Combustion Engine: From Wikipedia, The Free Encyclopedia Jump ToDocument7 pagesInternal Combustion Engine: From Wikipedia, The Free Encyclopedia Jump ToAbdullah KhaledNo ratings yet

- Unit 1 Construction and Operation: External Combustion EngineDocument14 pagesUnit 1 Construction and Operation: External Combustion Enginekrishna samNo ratings yet

- Internal Combustion EngineDocument13 pagesInternal Combustion EngineNAITAJINo ratings yet

- 115 ContinuationDocument5 pages115 ContinuationAbraham OmomhenleNo ratings yet

- 1.1 I.C Engines: 1.1.1 Definition of EngineDocument54 pages1.1 I.C Engines: 1.1.1 Definition of EngineANIL KUMARNo ratings yet

- Asi Unit 3Document21 pagesAsi Unit 3Raja RamNo ratings yet

- AGR 318 Lec 3 - Engine Cons & CompDocument42 pagesAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataNo ratings yet

- What Is An EngineDocument15 pagesWhat Is An Engineravidra markapudiNo ratings yet

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyDocument61 pagesEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyMuhammad BilalNo ratings yet

- Pasgt Module Prelim To FinalDocument100 pagesPasgt Module Prelim To FinalKyle100% (1)

- TEICENGINESDocument25 pagesTEICENGINESsrinithims78No ratings yet

- 2-Four and Two Stroke EnginesDocument27 pages2-Four and Two Stroke EnginesAHMADNo ratings yet

- IC Engine (Introduction)Document48 pagesIC Engine (Introduction)Abdul RahmanNo ratings yet

- Aircraft Propulsion Systems: Dr. Anmar H. AliDocument18 pagesAircraft Propulsion Systems: Dr. Anmar H. AliAlmukhtar AlkinanyNo ratings yet

- ICE EngineDocument102 pagesICE EngineyanNo ratings yet

- Petrol Engine (Nehru Garden, JalandharDocument7 pagesPetrol Engine (Nehru Garden, Jalandharapi-3731257No ratings yet

- City and Guilds 9210 Level 6 Module - Unit 128 Applied ThermodynamicsDocument13 pagesCity and Guilds 9210 Level 6 Module - Unit 128 Applied ThermodynamicskhumisoNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineFrom EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineNo ratings yet

- Mechanical Engineering Department ME 47 (ME Final Year Project Study 1)Document20 pagesMechanical Engineering Department ME 47 (ME Final Year Project Study 1)Roy RagotNo ratings yet

- 03 Positive Displacement Compressors RotaryDocument5 pages03 Positive Displacement Compressors RotaryLe Anh DangNo ratings yet

- Three-Dimensional Simulation of A Novel Rotary-Piston Engine in The Motoring ModeDocument11 pagesThree-Dimensional Simulation of A Novel Rotary-Piston Engine in The Motoring ModeCHELIN_2305No ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Presentation On History of CarsDocument19 pagesPresentation On History of CarsDigvijay SinghNo ratings yet

- Thermodynamics Lab ReportDocument26 pagesThermodynamics Lab ReportAliNo ratings yet

- Ugly StikDocument23 pagesUgly StikThiago Da Silva Pinto100% (1)

- Toshiba 2012 - EnglishDocument182 pagesToshiba 2012 - Englishremwel_No ratings yet

- Ashok Leland Produce Varius VehiclesDocument37 pagesAshok Leland Produce Varius VehiclesRiddhesh PatelNo ratings yet

- Chapt1 - Classification & ParametersDocument94 pagesChapt1 - Classification & ParameterspeterNo ratings yet

- INCAST 2008-109: Design and Development of An Indigenous 55 HP Wankel EngineDocument5 pagesINCAST 2008-109: Design and Development of An Indigenous 55 HP Wankel EnginegauravamberkarNo ratings yet

- 4-2 Stroke DieselDocument36 pages4-2 Stroke DieselatulsemiloNo ratings yet

- The Tesla Disk TurbineDocument44 pagesThe Tesla Disk Turbinedharmaburning100% (6)

- Garside Norton Rotary Motorcycle EngineDocument18 pagesGarside Norton Rotary Motorcycle EngineToby Joseph ThomasNo ratings yet

- Low Pressure High Torque Quasi Turbine Rotary Air EngineDocument8 pagesLow Pressure High Torque Quasi Turbine Rotary Air Enginepravesh singhNo ratings yet

- Thermal Engineering IIDocument99 pagesThermal Engineering IIabinmace100% (1)

- ABE 131 Lecture (Chapter 2B)Document91 pagesABE 131 Lecture (Chapter 2B)leojhunpalisocNo ratings yet

- Compressors and Compressed Air SystemsDocument24 pagesCompressors and Compressed Air SystemsjimmyshaNo ratings yet

- SEMINAR REPORT On Rotary EngineDocument43 pagesSEMINAR REPORT On Rotary EngineDhaval Amrutiya100% (6)

- Trabajo Pa RichiDocument12 pagesTrabajo Pa RichiRafael GoñasNo ratings yet

- Dynamic Sealing Design For Wankel EnginesDocument5 pagesDynamic Sealing Design For Wankel EnginesFurqanNo ratings yet

- Petrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of EnginesDocument12 pagesPetrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of Enginesnishant010No ratings yet

- Introduction IC Engine and Reciprocating Machine CH - 1Document57 pagesIntroduction IC Engine and Reciprocating Machine CH - 1heonetubeNo ratings yet

- SM14 DetDocument12 pagesSM14 DetSanjay RajNo ratings yet

- Colomina, Domesticity at WarDocument29 pagesColomina, Domesticity at WarSusan SchuppliNo ratings yet

- Series II RX-8 FaceLiftDocument12 pagesSeries II RX-8 FaceLiftsavageflux7373No ratings yet