Professional Documents

Culture Documents

SABIC Cycolac MG47F

SABIC Cycolac MG47F

Uploaded by

Chu ChuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SABIC Cycolac MG47F

SABIC Cycolac MG47F

Uploaded by

Chu ChuCopyright:

Available Formats

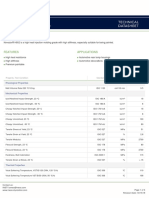

CYCOLAC™ RESIN MG47F

REGION ASIA

DESCRIPTION

Multi-purpose, injection molding ABS providing a favorable balance of engineering properties. FDA compliant.

TYPICAL PROPERTY VALUES Revision 20170706

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

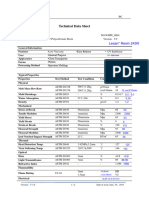

MECHANICAL

Tensile Stress, yld, Type I, 5 mm/min 44 MPa ASTM D 638

Tensile Stress, brk, Type I, 5 mm/min 33 MPa ASTM D 638

Tensile Strain, yld, Type I, 5 mm/min 2 % ASTM D 638

Tensile Strain, brk, Type I, 5 mm/min 24 % ASTM D 638

Tensile Modulus, 5 mm/min 2270 MPa ASTM D 638

Flexural Stress, yld, 1.3 mm/min, 50 mm span 70 MPa ASTM D 790

Flexural Modulus, 1.3 mm/min, 50 mm span 2300 MPa ASTM D 790

Hardness, Rockwell R 112 - ASTM D 785

Tensile Stress, yield, 50 mm/min 47 MPa ISO 527

Tensile Stress, break, 50 mm/min 35 MPa ISO 527

Tensile Strain, yield, 50 mm/min 2.6 % ISO 527

Tensile Strain, break, 50 mm/min 25 % ISO 527

Tensile Modulus, 1 mm/min 2370 MPa ISO 527

Flexural Stress, yield, 2 mm/min 70 MPa ISO 178

Flexural Modulus, 2 mm/min 2200 MPa ISO 178

IMPACT

Izod Impact, notched, 23°C 320 J/m ASTM D 256

Instrumented Impact Total Energy, 23°C 30 J ASTM D 3763

Izod Impact, notched 80*10*4 +23°C 22 kJ/m² ISO 180/1A

Izod Impact, notched 80*10*4 -30°C 8 kJ/m² ISO 180/1A

Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm 26 kJ/m² ISO 179/1eA

Charpy -30°C, V-notch Edgew 80*10*4 sp=62mm 9 kJ/m² ISO 179/1eA

THERMAL

Vicat Softening Temp, Rate B/50 99 °C ASTM D 1525

HDT, 0.45 MPa, 3.2 mm, unannealed 94 °C ASTM D 648

HDT, 1.82 MPa, 3.2mm, unannealed 80 °C ASTM D 648

CTE, -40°C to 40°C, flow 8.82E-05 1/°C ASTM E 831

© 2017 Copyright by SABIC. All rights reserved

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

CTE, -40°C to 40°C, xflow 8.82E-05 1/°C ASTM E 831

Vicat Softening Temp, Rate B/50 98 °C ISO 306

Vicat Softening Temp, Rate B/120 100 °C ISO 306

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 81 °C ISO 75/Af

Relative Temp Index, Elec 60 °C UL 746B

Relative Temp Index, Mech w/impact 60 °C UL 746B

Relative Temp Index, Mech w/o impact 60 °C UL 746B

PHYSICAL

Specific Gravity 1.04 - ASTM D 792

Mold Shrinkage, flow, 3.2 mm (5) 0.5 – 0.8 % SABIC method

Melt Flow Rate, 230°C/3.8 kgf 5.6 g/10 min ASTM D 1238

Melt Viscosity, 240°C, 1000 sec-1 2250 Poise ASTM D 3825

Density 1.04 g/cm³ ISO 1183

Melt Flow Rate, 220°C/10.0 kg 18 g/10 min ISO 1133

ELECTRICAL

Arc Resistance, Tungsten {PLC} 6 PLC Code ASTM D 495

Hot Wire Ignition {PLC) 3 PLC Code UL 746A

High Voltage Arc Track Rate {PLC} 3 PLC Code UL 746A

High Ampere Arc Ign, surface {PLC} 0 PLC Code UL 746A

Comparative Tracking Index (UL) {PLC} 0 PLC Code UL 746A

FLAME CHARACTERISTICS

UL Recognized, 94HB Flame Class Rating (3) 1.5 mm UL 94

INJECTION MOLDING

Drying Temperature 80 – 95 °C

Drying Time 2–4 hrs

Drying Time (Cumulative) 8 hrs

Maximum Moisture Content 0.1 %

Melt Temperature 220 – 260 °C

Nozzle Temperature 220 – 260 °C

Front - Zone 3 Temperature 215 – 240 °C

Middle - Zone 2 Temperature 205 – 225 °C

Rear - Zone 1 Temperature 190 – 210 °C

Mold Temperature 50 – 70 °C

Back Pressure 0.3 – 0.7 MPa

Screw Speed 30 – 60 rpm

Shot to Cylinder Size 50 – 70 %

Vent Depth 0.038 – 0.051 mm

© 2017 Copyright by SABIC. All rights reserved

DISCLAIMER

The information contained herein may include typical properties of our products or their typical performances when used in certain

typical applications. Actual properties of our products, in particular when used in conjunction with any third party material(s) or for any

non-typical applications, may differ from typical properties.

It is the customer's responsibility to inspect and test our product(s) in order to satisfy itself as to the suitability of the product(s) for its

and its customers particular purposes. The customer is responsible for the appropriate, safe and legal use, processing and handling of

all product(s) purchased from us.

Nothing herein is intended to be nor shall it constitute a warranty whatsoever, in particular, warranty of merchantability or fitness for a

particular purpose.

SABIC as referred to herein means any legal entity belonging to the group of companies headed by Saudi Arabia Basic Industries

Corporation.

© 2017 Copyright by SABIC. All rights reserved

You might also like

- Letters To A Young Lawyer by DershowitzDocument225 pagesLetters To A Young Lawyer by DershowitzKent Barcenas100% (2)

- Obituary: Record of Yale Graduates 1918-1919Document493 pagesObituary: Record of Yale Graduates 1918-1919Jason McDonaldNo ratings yet

- Age of FractureDocument361 pagesAge of FractureGeo ScripcariuNo ratings yet

- Portfolio Part 2: Practical Case Study InstructionsDocument4 pagesPortfolio Part 2: Practical Case Study InstructionsNour KhairallahNo ratings yet

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- Sins Against The CommandmentsDocument5 pagesSins Against The CommandmentsBella75% (8)

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- Sabic PC 10 Mfi pc1003rDocument3 pagesSabic PC 10 Mfi pc1003rChu ChuNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- A GD VDBDocument3 pagesA GD VDBthehoang12310No ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocument2 pagesULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- CYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetLidiane RibeiroNo ratings yet

- LEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetSapphire PolycarbonatesNo ratings yet

- LEXAN™ Copolymer - EXL9330 - Americas - Technical - Data - SheetDocument4 pagesLEXAN™ Copolymer - EXL9330 - Americas - Technical - Data - SheetBrent TairaNo ratings yet

- LEXAN™ Copolymer - EXL9330 - Asia - Technical - Data - SheetDocument4 pagesLEXAN™ Copolymer - EXL9330 - Asia - Technical - Data - Sheetkls.thorodinsonNo ratings yet

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 pagesCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- Lexan FR Resin 505rDocument3 pagesLexan FR Resin 505rShabi HadashNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- TDS - Lexan 141R (141R-701)Document2 pagesTDS - Lexan 141R (141R-701)It WittayaNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- LEXAN™ Resin - 121R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 121R - Europe - Technical - Data - Sheetanggun dewiNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- LNP™ ELCRES™ - SR8338 - Global - Technical - Data - SheetDocument3 pagesLNP™ ELCRES™ - SR8338 - Global - Technical - Data - SheeterayNo ratings yet

- LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetDocument1 pageLNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetWang MbaoNo ratings yet

- Santoprene 201 64 - MDS - ENDocument3 pagesSantoprene 201 64 - MDS - ENLITCoupie RAKVANNo ratings yet

- ABS Cycolac MG47Document3 pagesABS Cycolac MG47countzeroaslNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Document3 pagesSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Mama410438 Lexan Healthcare Resin hp2Document5 pagesMama410438 Lexan Healthcare Resin hp2joey arturoNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- SABIC® PPcompound - G3230A - Americas - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - G3230A - Americas - Technical - Data - SheetAarón González MedinaNo ratings yet

- PBT Valox 420SEO 30%GLDocument3 pagesPBT Valox 420SEO 30%GLcountzeroaslNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

- Grade: St900 DM311: Polypropylene CompoundDocument1 pageGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyNo ratings yet

- CYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetShrikantNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Hyosung Topilene HJ646 PPDocument1 pageHyosung Topilene HJ646 PPChu ChuNo ratings yet

- SDS PP T03 LogoDocument5 pagesSDS PP T03 LogoChu ChuNo ratings yet

- H T NH A Lldpe 1002en TdsDocument1 pageH T NH A Lldpe 1002en TdsChu ChuNo ratings yet

- Lldpe HD21HS Qamar SPDC SpecsDocument2 pagesLldpe HD21HS Qamar SPDC SpecsChu ChuNo ratings yet

- Mike - Monthly PlannerDocument33 pagesMike - Monthly PlannerChu ChuNo ratings yet

- Sex Change and Sex ReassignmentDocument2 pagesSex Change and Sex Reassignmentapril75No ratings yet

- Corporate FinanceDocument22 pagesCorporate Financeramakrishnan prNo ratings yet

- App Iii Summer Midterm ExamDocument9 pagesApp Iii Summer Midterm ExamCharmaine PamintuanNo ratings yet

- Legal Client Intake FormDocument4 pagesLegal Client Intake Formk20220723No ratings yet

- Intellectual Warfare Professor Jacob H Carruthers Jedi Shemsu JehewtyDocument6 pagesIntellectual Warfare Professor Jacob H Carruthers Jedi Shemsu JehewtyAtyeb Ba Atum Re67% (6)

- GDMS Administration GuideDocument124 pagesGDMS Administration GuideMOhamedNo ratings yet

- Lesson 6Document7 pagesLesson 6Ira Charisse BurlaosNo ratings yet

- Forensic Analisys of Web Browser With Dual Layout Engine (Slides - Linda - ICDFI2012)Document20 pagesForensic Analisys of Web Browser With Dual Layout Engine (Slides - Linda - ICDFI2012)whiskmanNo ratings yet

- 323-1851-160 (6500 5400 8700 Interworking Solution) Issue7Document168 pages323-1851-160 (6500 5400 8700 Interworking Solution) Issue7José Pedro Batista Leite100% (1)

- ComponentbuilderDocument3 pagesComponentbuilderChrétien KenfackNo ratings yet

- Intel MB Dh67Document9 pagesIntel MB Dh67PinkyNo ratings yet

- E3h7 Financialreport enDocument7 pagesE3h7 Financialreport enperfilma2013No ratings yet

- Re: Google Inc., File No. 111 - 0163Document3 pagesRe: Google Inc., File No. 111 - 0163Grigory KovalchukNo ratings yet

- 1987 Constitution ReviewerDocument6 pages1987 Constitution ReviewerMiguel Milla100% (1)

- Quality IssueDocument2 pagesQuality IssueethandanfordNo ratings yet

- Passive Voice Tarea FerDocument3 pagesPassive Voice Tarea FerCheco RONo ratings yet

- Os Week 9Document6 pagesOs Week 9Movie explained in KannadaNo ratings yet

- Modern India History at A GlanceDocument32 pagesModern India History at A GlanceAnurag SinghNo ratings yet

- M B, TP, RDocument336 pagesM B, TP, RmegidNo ratings yet

- Project DemoDocument59 pagesProject DemoSHIREESHMA TNo ratings yet

- Title 1 - Chapter 1Document33 pagesTitle 1 - Chapter 1Rache GutierrezNo ratings yet

- DISTAT ENIM QVAE SYDERA TE EXCIPIANT Rodolfo SignoriniDocument2 pagesDISTAT ENIM QVAE SYDERA TE EXCIPIANT Rodolfo Signoriniberix100% (1)

- In The Court of Judge Banking Court LahoreDocument3 pagesIn The Court of Judge Banking Court Lahorehearthacker_302No ratings yet

- Copia de CANVA SUPPLIERS - PAYMENTS GUIDEDocument9 pagesCopia de CANVA SUPPLIERS - PAYMENTS GUIDECarlos Eduardo Gomez CouohNo ratings yet

- 487pg The Armenian Version of RevelationDocument487 pages487pg The Armenian Version of RevelationJohn KellyNo ratings yet