Professional Documents

Culture Documents

PXX 57

PXX 57

Uploaded by

The GunnersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PXX 57

PXX 57

Uploaded by

The GunnersCopyright:

Available Formats

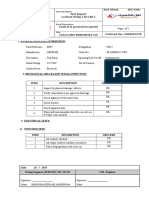

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: Tialoc- Truong Giang 190819-1 Seri number: 190780002E

Equipment: Busbar, flexible labour and accessories

connect from Trans 630kVA to MSB 2000A\

Customer: TIALOC MALAYSIA SDN BHD Date of test: 16/08/2019

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 2200 x 1800 x1000mm √

1.1.2 Painting: RAL7032 √

1.1.3 Thickness: Steel sheet 2.0mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables coulor √

2. Electrical operation test √

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase squence √

2.5 Verification of instruments √

3. Dielectric test

3.1 Test voltage 2500 V application time 5 s

Phases checked 1000 VDC 2500 VAC

Before HV test After HV test Leakage current (mA)

L1 - L2L3NE √

L2 - L1L3NE √

L3 - L1L2NE √

N-E √

3.2 Contact Resistance Test

No Phase 1 Phase 2 Phase 3 Phase N

main circuit resistance ( μΩ ) √

connected contact resistance ( μΩ √

3.3 Check voltage

No L1 - L2 L2 - L3 L1 -L3 L1 -N L2 - N L3 - N

Input (V) √

Output (V) √

3.3 Test voltage 500 V minimum resistence verifiable for control circuit (M Ω) √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

4.1 Water proof protection IPx2 √

4.2 Soild proof protection IP3x √

4.3 Form 4b √

6.Final check

5.1 Label descriptions √

5.2 Enclosed documentation √

Test responsible Approved

Tong Phuoc Nhan Nguyen Dinh Cam

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 95mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2E25A

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1214 1198 0.23 √

L2 - L1+L3+E+N 1649 1654 0.34 √

L3 - L1+L2+E+N 2145 1957 0.55 √

N - L1+L2+L3+E 1267 1176 0.27 √

E - L1+L2+L3+N 1312 1285 0.33 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 50mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2H19A

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1712 1701 0.32 √

L2 - L1+L3+E+N 1148 1162 0.46 √

L3 - L1+L2+E+N 1284 1198 0.31 √

N - L1+L2+L3+E 1375 1223 0.25 √

E - L1+L2+L3+N 1212 1256 0.42 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 50mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2H19B

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1369 1324 0.38 √

L2 - L1+L3+E+N 2156 2110 0.4 √

L3 - L1+L2+E+N 1193 1154 0.58 √

N - L1+L2+L3+E 1101 1127 0.33 √

E - L1+L2+L3+N 1428 1367 0.29 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 95mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2E19A

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 2178 2109 0.42 √

L2 - L1+L3+E+N 1352 1332 0.44 √

L3 - L1+L2+E+N 1221 1201 0.61 √

N - L1+L2+L3+E 1486 1427 0.39 √

E - L1+L2+L3+N 1575 1531 0.32 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 70mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2F22A

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1272 1236 0.56 √

L2 - L1+L3+E+N 1530 1494 0.33 √

L3 - L1+L2+E+N 1223 1197 0.37 √

N - L1+L2+L3+E 1149 1123 0.41 √

E - L1+L2+L3+N 1256 1201 0.52 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 70mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2F22B

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1835 1778 0.37 √

L2 - L1+L3+E+N 1563 1435 0.41 √

L3 - L1+L2+E+N 1199 1205 0.56 √

N - L1+L2+L3+E 1472 1451 0.48 √

E - L1+L2+L3+N 1321 1348 0.26 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 95mm2/

- CXV 4x2x1CX95mm(RYBN) + CV2x1Cx

50mm( PE)

-CXV 4x2x1CX95mm(RYBN) + CV1Cx

95mm( PE)TS1J2J26A Date of test: 18/09/2023

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1439 1364 0.29 √

L2 - L1+L3+E+N 1207 1132 0.53 √

L3 - L1+L2+E+N 1372 1325 0.59 √

N - L1+L2+L3+E 1661 1629 0.37 √

E - L1+L2+L3+N 1274 1225 0.3 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: 0808/2023/HDKT-TGE-VK

Customer: Viet Kha energy technology limited Equipment: JUNCTION BOX COUPLIN

company CONECTION FOR CABLE 70mm2-5 Input/ 5 Date of test: 18/09/2023

output/TS1J2J25A

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 600 x 500 x 300mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 1.5 mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase sequence √

2.5 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+E+N 1824 1828 0.61 √

L2 - L1+L3+E+N 2003 1958 0.49 √

L3 - L1+L2+E+N 1875 1802 0.37 √

N - L1+L2+L3+E 1204 1287 0.21 √

E - L1+L2+L3+N 1438 1432 0.36 √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx1 √

5.2 Soild proof protection IP3x √

5.3 Form 1 √

6.Final check

6.1 Label descriptions √

6.2 Enclosed documentation √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

You might also like

- Barb - A - Watt QRP Power - SWR MeterDocument18 pagesBarb - A - Watt QRP Power - SWR Meterfox7878No ratings yet

- Ðóêîâîäñòâî ÏÎ Òåõ. Îáñëóæèâàíèþ Kerberos - eDocument14 pagesÐóêîâîäñòâî ÏÎ Òåõ. Îáñëóæèâàíèþ Kerberos - eJustino Cassul MirandaNo ratings yet

- Condensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHDocument41 pagesCondensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHMilton UrrozNo ratings yet

- Test Report LV 080324 r1Document3 pagesTest Report LV 080324 r1The GunnersNo ratings yet

- Installation Ground Terminal Block - UTI 2,5-PE/L/L - 3076029Document7 pagesInstallation Ground Terminal Block - UTI 2,5-PE/L/L - 3076029EngChengLengNo ratings yet

- Feed-Through Terminal Block - UK 5 - 3004016: Key Commercial DataDocument25 pagesFeed-Through Terminal Block - UK 5 - 3004016: Key Commercial DataA. Muhsin PamungkasNo ratings yet

- Knife Disconnect Terminal Block - UK 5-MTK-P/P - 3004032: Key Commercial DataDocument16 pagesKnife Disconnect Terminal Block - UK 5-MTK-P/P - 3004032: Key Commercial DatapoweranalystNo ratings yet

- Component Terminal Block - PT 2,5-DIO/L-R - 3210224: Key Commercial DataDocument4 pagesComponent Terminal Block - PT 2,5-DIO/L-R - 3210224: Key Commercial DataminurajraNo ratings yet

- Test Disconnect Terminal Block - URTKSP - 0311126Document20 pagesTest Disconnect Terminal Block - URTKSP - 0311126Praneeth Madhushan BandaraNo ratings yet

- Feed-Through Terminal Block - UK 2,5 N RD - 0719074: Key Commercial DataDocument22 pagesFeed-Through Terminal Block - UK 2,5 N RD - 0719074: Key Commercial Datasherub wangdiNo ratings yet

- Borna PT 16N DatasheetDocument20 pagesBorna PT 16N DatasheetFelipe Sobrino RebotoNo ratings yet

- B 81707 BDCDocument29 pagesB 81707 BDCfirdNo ratings yet

- Feed-Through Terminal Block - UK 2,5 B - 3001035: Key Commercial DataDocument21 pagesFeed-Through Terminal Block - UK 2,5 B - 3001035: Key Commercial DatacauvongkhongmauNo ratings yet

- Motor Terminal - PT 2,5-PE/3L - 3210542: Key Commercial DataDocument28 pagesMotor Terminal - PT 2,5-PE/3L - 3210542: Key Commercial DatamohamedNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- Udk 4 - 2775016Document20 pagesUdk 4 - 2775016A. Muhsin PamungkasNo ratings yet

- Fat Report MV - 080324Document5 pagesFat Report MV - 080324The GunnersNo ratings yet

- Feed-Through Terminal Block - UK 2,5 N BK - 0719100: Key Commercial DataDocument22 pagesFeed-Through Terminal Block - UK 2,5 N BK - 0719100: Key Commercial Datasherub wangdiNo ratings yet

- Double-Level Terminal Block - UTTB 4 - 3044814: Key Commercial DataDocument5 pagesDouble-Level Terminal Block - UTTB 4 - 3044814: Key Commercial DataMauricio AguilarNo ratings yet

- Feed-Through Terminal Block - TB 2,5 EI - 3246010: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - TB 2,5 EI - 3246010: Key Commercial DataAssad ShafiqueNo ratings yet

- Knife Disconnect Terminal Block - UT 2.5 MT - 3046362: Key Commercial DataDocument24 pagesKnife Disconnect Terminal Block - UT 2.5 MT - 3046362: Key Commercial DataPrabhu DevNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial DataDocument27 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial Datanet natNo ratings yet

- Test Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataDocument20 pagesTest Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataMatko ŽajaNo ratings yet

- S.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsDocument5 pagesS.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsnagarajanNo ratings yet

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument25 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataJemeraldNo ratings yet

- Distribution Block - PTFIX 16X1,5-NS15A YE - 3002960: Key Commercial DataDocument10 pagesDistribution Block - PTFIX 16X1,5-NS15A YE - 3002960: Key Commercial DatasantiagoNo ratings yet

- Feed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataDocument27 pagesFeed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataChung NguyenNo ratings yet

- Double Level TB 3210567Document31 pagesDouble Level TB 3210567adamnorazlanNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- DET4TCR2 Product SpecificationDocument3 pagesDET4TCR2 Product SpecificationAmer KhanNo ratings yet

- Mhob 04-Pw Protection (Translay) RelayDocument1 pageMhob 04-Pw Protection (Translay) RelayTHILAKKUMARNo ratings yet

- Asefa - MV Test Procedure (SWG)Document6 pagesAsefa - MV Test Procedure (SWG)Magicneering PredictNo ratings yet

- Feed-Through Terminal Block - PT 2,5 - 3209510: Key Commercial DataDocument34 pagesFeed-Through Terminal Block - PT 2,5 - 3209510: Key Commercial Dataomar zaquinaulaNo ratings yet

- Single 4 Point TB 3211797Document31 pagesSingle 4 Point TB 3211797adamnorazlanNo ratings yet

- Feed-Through Terminal Block - UT 16 BK - 3044197: Key Commercial DataDocument15 pagesFeed-Through Terminal Block - UT 16 BK - 3044197: Key Commercial DataJediKnight012No ratings yet

- Electrical Testing and DocumentationDocument3 pagesElectrical Testing and DocumentationMohamad AshNo ratings yet

- Feed-Through Terminal Block - UT 4 - 3044102: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UT 4 - 3044102: Key Commercial DataAlicia AltamiranoNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial DataDocument26 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial Datasyahril boonieNo ratings yet

- HV Power Cable TestDocument9 pagesHV Power Cable TestMohammad Nasar100% (1)

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataHendra WiratamaNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Megger Det4tc2 Earth Tester DatasheetDocument3 pagesMegger Det4tc2 Earth Tester DatasheetEMD NSPCLNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Terminal Blocks DatasheetDocument4 pagesTerminal Blocks DatasheetdriveladderNo ratings yet

- Disconnect Terminal Block - TB 6-T EI - 3075838: Key Commercial DataDocument17 pagesDisconnect Terminal Block - TB 6-T EI - 3075838: Key Commercial DataEdciel EbuenNo ratings yet

- Knife Disconnect Terminal Block - UT 2,5-MT - 3046362: Key Commercial DataDocument6 pagesKnife Disconnect Terminal Block - UT 2,5-MT - 3046362: Key Commercial DataDarwin LibrandaNo ratings yet

- FXBW 220 160 204 Test ReportDocument8 pagesFXBW 220 160 204 Test ReportbinodeNo ratings yet

- TDS 400kVA 20kV 400V 50Hz Dyn5 - 5 IndoorDocument2 pagesTDS 400kVA 20kV 400V 50Hz Dyn5 - 5 IndoorAfrizal AntariksaNo ratings yet

- Lor Ri 16-Rp 94f-2 6rp2Document2 pagesLor Ri 16-Rp 94f-2 6rp2Humayun AhsanNo ratings yet

- Feed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataDocument26 pagesFeed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataIdos AkmalNo ratings yet

- Mvtp11-Ct Supervision RelayDocument2 pagesMvtp11-Ct Supervision RelayTHILAKKUMARNo ratings yet

- NEMA Contactor and Starter Specifications: Technical DataDocument18 pagesNEMA Contactor and Starter Specifications: Technical DataNelsonNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- Installcheck Cca 240euraDocument2 pagesInstallcheck Cca 240eurazeljkoNo ratings yet

- Feed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataBinhvvNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- TB Diode 3211430Document27 pagesTB Diode 3211430adamnorazlanNo ratings yet

- 3UG45111AP20 Datasheet enDocument4 pages3UG45111AP20 Datasheet enMohammed FarahatNo ratings yet

- Lighting Wiring Diagrams 2010 NEWDocument36 pagesLighting Wiring Diagrams 2010 NEWAbdallah GhannamNo ratings yet

- Mvaj205 - Trip RelayDocument2 pagesMvaj205 - Trip Relayratheeshkumard100% (1)

- Bảo hành-57Document1 pageBảo hành-57The GunnersNo ratings yet

- Test Report LV 080324 r1Document3 pagesTest Report LV 080324 r1The GunnersNo ratings yet

- Đính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)Document9 pagesĐính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)The GunnersNo ratings yet

- DrawingDocument1 pageDrawingThe GunnersNo ratings yet

- Drawing of TMS1 Tge 15012024Document5 pagesDrawing of TMS1 Tge 15012024The GunnersNo ratings yet

- Fat Report MV - 080324Document5 pagesFat Report MV - 080324The GunnersNo ratings yet

- Mechanical Operation Test Drawing - r2Document2 pagesMechanical Operation Test Drawing - r2The GunnersNo ratings yet

- Drawing of TMS1 Tge 15012024Document5 pagesDrawing of TMS1 Tge 15012024The GunnersNo ratings yet

- TGE TYPE TEST VCB TV1 24kV 10.05.23Document4 pagesTGE TYPE TEST VCB TV1 24kV 10.05.23The GunnersNo ratings yet

- TGE TYPE TEST ES TES1 24kV 10.05.23Document2 pagesTGE TYPE TEST ES TES1 24kV 10.05.23The GunnersNo ratings yet

- 1.2 TMS1 Type Test - Secondary-04.07.23Document25 pages1.2 TMS1 Type Test - Secondary-04.07.23The GunnersNo ratings yet

- Uec Busway Guide Web N MAY-159Document221 pagesUec Busway Guide Web N MAY-159Hisham AL-OmariNo ratings yet

- 6SL3220-2YD42-0UB0 Datasheet enDocument3 pages6SL3220-2YD42-0UB0 Datasheet enLong HoàngNo ratings yet

- DC PWM Motor Speed Controller: Circuit DiagramDocument2 pagesDC PWM Motor Speed Controller: Circuit DiagramarminNo ratings yet

- Rhino 196000-0601Document5 pagesRhino 196000-0601admin tigasaudaraNo ratings yet

- A Current-Mode Analog Multiplier Based On Translinear PrincipleDocument3 pagesA Current-Mode Analog Multiplier Based On Translinear PrincipleSruthy sureshNo ratings yet

- Induction Motor Electric BrakingDocument12 pagesInduction Motor Electric Brakingmastanamma.Y100% (1)

- Electronic Workshop Project ReportDocument5 pagesElectronic Workshop Project ReportAbubakr AtiqueNo ratings yet

- Introduction WIRE HARNESS REPAIR INTRODUCTIONDocument2 pagesIntroduction WIRE HARNESS REPAIR INTRODUCTIONJaviersNo ratings yet

- Si3226/7 Si3208/9: D P Slic DC-DC CDocument38 pagesSi3226/7 Si3208/9: D P Slic DC-DC CDarwin SipayungNo ratings yet

- Boton Aborto 2080-9057Document4 pagesBoton Aborto 2080-9057Edinson Herrera VasquezNo ratings yet

- Infineon ApplicationNote ReferenceBoard REF XDPL8105 CDM10V ApplicationNotes v02 00 enDocument53 pagesInfineon ApplicationNote ReferenceBoard REF XDPL8105 CDM10V ApplicationNotes v02 00 enDuy HiếuNo ratings yet

- OpenECU-EVCC PinoutDocument4 pagesOpenECU-EVCC Pinoutsaranakom cheecharoenNo ratings yet

- Transistor Sot23 S8050 J3YDocument2 pagesTransistor Sot23 S8050 J3YCarlos Andres Viveros100% (1)

- PrecomMatricesRev17 (2003 10 15)Document22 pagesPrecomMatricesRev17 (2003 10 15)Mohammad MohseniNo ratings yet

- Title Specification For Distribution Transformer Pole Mounted Phase OilDocument33 pagesTitle Specification For Distribution Transformer Pole Mounted Phase OilTarkeshwar MallNo ratings yet

- 2010 D4DD MFI Control SystemDocument25 pages2010 D4DD MFI Control SystemHuy NguyễnNo ratings yet

- 50XM1000 Magnetic FlowmetersDocument58 pages50XM1000 Magnetic FlowmetersSEJIEDALNo ratings yet

- Battery BrochureDocument1 pageBattery BrochureDavid Estanislao COANo ratings yet

- Finder General Technical Information enDocument15 pagesFinder General Technical Information encuonglammanh98No ratings yet

- Lab Report 01 E2Document5 pagesLab Report 01 E2Ghayyas HassanNo ratings yet

- N2019-20 Power T and D L17Document30 pagesN2019-20 Power T and D L17guddu guptaNo ratings yet

- EEE 462 Switch Gear and ProtectionDocument18 pagesEEE 462 Switch Gear and ProtectionEmdadul Hoq RakibNo ratings yet

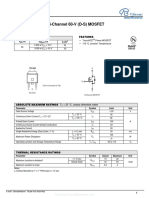

- N-Channel 6 0-V (D-S) MOSFET: Features Product SummaryDocument6 pagesN-Channel 6 0-V (D-S) MOSFET: Features Product SummaryRicardo MarquesNo ratings yet

- Low Bay Led - Msl8000lmllvmvoltgz1050k90cri - LithoniaDocument4 pagesLow Bay Led - Msl8000lmllvmvoltgz1050k90cri - LithoniaGustavo MarNo ratings yet

- Simulation of Three Phase Sine Wave Generation For Pulse Width Modulation (PWM)Document4 pagesSimulation of Three Phase Sine Wave Generation For Pulse Width Modulation (PWM)Yogi SaputraNo ratings yet

- Dynamo: DescriptionDocument6 pagesDynamo: Descriptionpawan dhingraNo ratings yet

- Lect 1 19EEE111 Introduction PartBDocument34 pagesLect 1 19EEE111 Introduction PartBDenifer DeepNo ratings yet