Professional Documents

Culture Documents

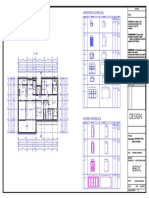

9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)

9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)

Uploaded by

jmdavies.isCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)

9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)

Uploaded by

jmdavies.isCopyright:

Available Formats

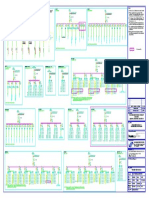

SURFACE LEVEL

Trench back fill (see note

1).

75mm Screed

Finish GEN 1 unreinforced concrete

FFL

surround where flexibly jointed

pipes are used, movement

joints shall be formed at Impermeable membrane wrapped around trench

Notes & Specification

Frame intervals not exceeding 5m and

comprise 20mm thick Type B filter material to clause 505 of the current

1. Processed granular bedding and side fill materials shall include aggregates to BS EN 12620 + A1 and

compressible filler board placed Highways Agency Specification for Highway

lightweight aggregates to BS EN 13055-1 and shall be graded as defined in the following tables:

at a pipe joint. Works.

Table 1

225mmØ perforated distributor pipe - invert level

varies; refer to plan

Pipe Nominal Maximum Maximum CF Material

Size (mm) Partical Size Value

(mm)

Bed and haunch

Notes & Specification

Typical section through filter drain

100 10 0.15 10mm nominal single size 1. Trench excavation shall be back filled as follows: a) Outside road pavements or areas where surface

frame in 1:3 settlement cannot be accepted, back filling shall be carried out using suitable fills. Suitable fills shall be

mortar capable of accepting compaction plant subject to the Engineer's approval and shall exclude boulders,

lumps of concrete, bricks, timber and vegetable matter. b) In areas below road pavements (or where 50x150mm hydraulically pressed

Structural Slab over 100 to 15 0.15 Materials within 450mm of the finished road

10 or 14mm nominal single size surface settlement cannot be accepted) (i) Where soffit of pipe is less than 0.5m below formation, back precast concrete edging type E F

150 or 14 to 5mm graded. surface must not be frost susceptible to BS EN 1340 Fig. 11

fill with GEN 0 unreinforced concrete. (ii) Where soffit of pipe is between 0.5m and 1.0m below

formation, back fill with Type 1 sub-base.

over 150 to 300 20 0.15 10, 14 or 20mm nominal single

size or 14 to 5mm graded or 2. Cover to pipes shall be: 2000mm or less in areas subject to heavy construction plant. 1000mm or

20mm to 5mm graded. less in areas subject to normal construction traffic. 1200mm or less to finished level of new main road

pavements. 600mm or less in landscape areas, foot ways, gardens or fields Otherwise use other

Cover and Frame over 300 to 550 20 0.15 14 or 20mm nominal single size specified surround and back fill details.

(NTS)

or 14 to 5mm graded or 20mm

to 5mm graded. 3. Pipes, unless otherwise stated, shall be: (i) Clay pipes with min FN of 40 to BS EN 295 and BS65 (ii)

Concrete pipes to BS 5911 and BS EN 1916 or, (iii) Flexible pipes shall be unplasticised UPVC to BS EN

Class D400 cover and frame

14, 20 or 40mm nominal single 13598. Concrete pipes shall not be used for foul sewers unless otherwise stated.

over 550 40 0.15

size or 14 to 5mm graded or

75mm Screed Finish 20mm to 5mm graded or 40 to 4. Construction, subsequent testing, operation and maintenance shall be carried out in accordance

with BS EN 752. Sewers to be adopted by water companies shall be installed in accordance with the Kerb foundation and

R.C Slab to structural 5mm graded. backing concrete ST4

current edition of 'Sewers for Adoption' produced by the Water Services Association. Sewers to be

FFL engineers details unreinforced concrete

Thickness as per slab detail

adopted by highway authorities shall be installed in accordance with the authority's specification. Notes

SSL 2. The sulphate content of bedding and side fill materials shall not be greater than 0.3% as

sulphur trioxide. The above specification has been produced based on the Water Industry 5. Back filling shall only be undertaken when the concrete bedding and surround has obtained 1. Kerb backing normally brought up to 50mm below top of kerb, but where final surface of

specification publication sufficient strength to accommodate back filling operations. adjacent foot way is flagged, kerb backing shall finish 75mm below top of kerb.

3. No. 4-08-01 (issue 4) February 1994. 6. This detail shall not be used where the drainage is to be adopted by Water companies. 2. Gap between kerbs shall be 1 to 2mm.

4. Compaction factor (CF) shall be determined in accordance with the water industry publication 7. Workmanship shall be in accordance with BS 8000 - 14: 198. 3. Precast concrete edgings shall be cut to accommodate tight radii.

250mm 1000mm 250mm For Concrete and reinforcement spec No 4-08-02 (issue 1) February 1994 - appendix B.

see structural engineers detail. 4. Kerb face to be shuttered and mechanically vibrated to ensure proper compaction.

Limitations of Use

Galvanised mild steel or plastic Specification for bedding and sidefill materials for flexible Carrier drain - class z bedding, surround 1. For edging foot ways only

encapsulated step irons at 250mm or

300mm to BS EN 13101:2002 Cast Iron Inspection Chamber to be cast

into manhole base slab. Inspection

pipes (class s & b bedding) and backfill

chamber to be Pam Saint-Gobain Ensign Footway edging type EF

ED012 or Timesaver TD14. All pipe

fitting, bends, flanges and end caps to be

tested as per manufacturers installation

instructions prior to casting concrete.

Cast Iron Drainage to be cast

into benching.

Construction joint

75mm Concrete Rainwater pipe or foul stack Cladding Wade vari-level gully grating to

Kicker continuation by M&E engineer and architect's specification

services contractor.

250mm

Double socket connector

75mm

Pipe with bolted access door by or adaptor as necessary.

MEP engineer and services FFL

contractor.

Cut pipe off 10mm below slab SFL

50mm Thick blinding 250x250x75mm Deep recess level and fit temporary

around rainwater pipe or foul protective cap during

stack to be infilled with concrete sub-structure works Wade cast iron extension

by flooring / screeding contractor. piece(s) as required (refer to TD06 Timesaver 45º bend

Depth to invert level of pipe table for available heights) for cast iron pipes

15x10mm Deep polysulphide joint

varies (This depth is to be

Class D400 cover and frame sealant to pipe.

75mm Screed Finish accommodated in the length of Rodding access plug

R.C Slab to structural double spigot pipe)

engineers details Hepworth square gully ref. SG2/2 With back

FFL

Thickness as per slab detail

inlet, ih2c hinged grating and frame and square Hydrophilic strip

SSL Perimeter structure raising piece as required to suit ground level

600mm

100mm uPVC / HDPE / Clay / Cast 150mm Thick insitu concrete Wade G304 'P' Trapped

iron double spigot pipe length to around cover. Edges formed to gully body or equal Timesaver TD01 coupling

250mm 1200mm 250mm suit required invert level at heel Rocker Pipe line in with paving. for cast iron pipes or

rest bend. hepsure QAC1362 adaptor

for clay pipes

For Concrete and reinforcement spec 100mm Coupling or adaptor if Rocker Pipe

see structural engineers detail.

Galvanised mild steel or required (Hepworth clay / uPVC or Timesaver TD01 coupling

plastic encapsulated step clay / HDPE or Ensign ED001 Cast

irons at 250mm or iron / Cast iron).

300mm to BS EN Cast Iron Inspection Chamber to be cast 150mm min. GEN3 concrete

13101:2002 into manhole base slab. Inspection surround to gully.

chamber to be Pam Saint-Gobain Ensign

Hepworth 90° rest bend ref. SBR1 Hepworth 100mm dia. coupling

Cast Iron Drainage to be cast ED012 or Timesaver TD14. All pipe fitting,

or equivalent for clay or ensign 88° ref.sc1/1 or equ. for clay or

into benching. bends, flanges and end caps to be tested

bend with heel rest ref. ED007 or ensign ductile iron coupling ref

as per manufacturers installation

equivalent for cast iron. ed.001 or equ. For cast iron.

instructions prior to casting concrete.

Rocker Pipe

Typical Internal Floor Gully Detail

Rocker Pipe

(100mm DIA. Outlet And No Back Inlet)

Construction joint Typical Building Perimeter Rainwater Pipe Detail

250mm

75mm

75mm Concrete

Kicker

Concrete Interior Manhole 50mm Thick blinding

Cold Slab Construction

Typical 1200mm x 1000mm Cast In-situ Manhole Detail

(1.5 To 3m (max) To Crown Of Pipe)

Rev P3 Drawing status updated to TENDER By SWF Checked TH 10.07.2019

Rev P2 Cast insitu interior manhole detail added By GL Checked 17.06.2019

Drawn By: SWF Client Castleoak Group

Northampton

4 Ironstone Way, Brixworth,

Northampton NN6 9UD

T: 01604 781811

· Infrastructure Design · Geotechnical & Environmental Chkd By: GL

Project Lower Mill Care Home

Manchester Scale @ A1: 1:10 Kingston Road

3rd Floor, 82 King Street, E: mail@jppuk.net · Structural Engineering · Surveying Ewell

Manchester. M2 4WQ

T:0161 6822927 W: jppuk.net Date: April 2019 Title Private Construction Details

Milton Keynes Sheet 1 of 2

Suite 25 Linford Forum, Rockingham Drive, · Planning Services · Professional Advice Status: TENDER

Linford Wood, Milton Keynes. MK14 6LY

T: 01908 889433

Project No.: 9946Z Drawing No: 0657-SP-SL-DE-C-G77-450 Rev: P3

JPP QA Document T07 R1

You might also like

- Week 3.2 EAPP Evaluating and Citing SourcesDocument33 pagesWeek 3.2 EAPP Evaluating and Citing SourcesTin Aguilera100% (1)

- Waiter System (Was1:) Workshop 5 (25) Three-Tier ApplicationDocument6 pagesWaiter System (Was1:) Workshop 5 (25) Three-Tier Applicationhayathmail9375No ratings yet

- A1 - Detalii de Armare Radier R1Document1 pageA1 - Detalii de Armare Radier R1Andrei Kovacs100% (1)

- ROLE OF Information TECHNOLOGY IN SUPPLY CHAIN MANAGEMENT-2Document37 pagesROLE OF Information TECHNOLOGY IN SUPPLY CHAIN MANAGEMENT-2ved254910198% (120)

- Staircase DetailDocument1 pageStaircase Detailأعرف أعرفNo ratings yet

- Title:: 100mm Dia Cast Iron Inlet / Outlet Pipes Half Round ChannelDocument1 pageTitle:: 100mm Dia Cast Iron Inlet / Outlet Pipes Half Round Channeljohnopira3No ratings yet

- Lot 129 To Lot 132Document4 pagesLot 129 To Lot 132kewcottagesNo ratings yet

- General Detail-General Detail FullDocument1 pageGeneral Detail-General Detail FullHaque BossAnwarNo ratings yet

- Notes: Electrical KeyDocument1 pageNotes: Electrical KeyanzaniNo ratings yet

- Installation Guide: Subject To Wind LoadingsDocument2 pagesInstallation Guide: Subject To Wind LoadingsGabi DanutNo ratings yet

- George 3BHKDocument1 pageGeorge 3BHKTWIJUKYE HUZAIFANo ratings yet

- Lot 125 To Lot 128Document4 pagesLot 125 To Lot 128kewcottagesNo ratings yet

- 3 - Architectural Drawings - Part 2Document9 pages3 - Architectural Drawings - Part 2princessharengarciaNo ratings yet

- Ar Ged 04Document1 pageAr Ged 04Bahaa MohamedNo ratings yet

- Applicable Overhead Sign Supports, Wind Velocity & Ice Zones ForDocument1 pageApplicable Overhead Sign Supports, Wind Velocity & Ice Zones ForAnonymous ZO1piE3VNo ratings yet

- Notes:: Drop 50 MM Drop 50 MM Drop 50 MMDocument1 pageNotes:: Drop 50 MM Drop 50 MM Drop 50 MMassis alihNo ratings yet

- Concrete Storage Tanks Rev 1 Structurals 171102-1Document9 pagesConcrete Storage Tanks Rev 1 Structurals 171102-1Chancedaniels EmunaNo ratings yet

- A-199 - Subcellar 1 Floor PlanDocument1 pageA-199 - Subcellar 1 Floor PlanRobert 20No ratings yet

- SSWP - Notch Area Working Sequence For Perimeter FormDocument2 pagesSSWP - Notch Area Working Sequence For Perimeter Formpolaris projectNo ratings yet

- A1.24a Reflected Ceiling Plan West Level 4 Rev.4Document1 pageA1.24a Reflected Ceiling Plan West Level 4 Rev.4Miguel CasianoNo ratings yet

- WA203 - Decor Floor Plan Rev.BDocument1 pageWA203 - Decor Floor Plan Rev.BSTS-SPARK GAMINGNo ratings yet

- Annexure 6Document1 pageAnnexure 6enock ngorimaNo ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- Asct Borehole Geophysics Tool Summary TableDocument1 pageAsct Borehole Geophysics Tool Summary TableAugusto PetryNo ratings yet

- Detailed Plan of St-01: Esteban Y. Tan & AssociatesDocument1 pageDetailed Plan of St-01: Esteban Y. Tan & AssociatesRnln Sagales AmataNo ratings yet

- DSA DSA DSA: Guardrail - Partial ElevationDocument1 pageDSA DSA DSA: Guardrail - Partial ElevationPerr CortezNo ratings yet

- Mark Up For Load and & Non Load Bearing WallDocument1 pageMark Up For Load and & Non Load Bearing WallSaiful IslamNo ratings yet

- Amphi TheatreDocument1 pageAmphi TheatreanzaniNo ratings yet

- Attic Access - TguDocument5 pagesAttic Access - TgujhamiralexNo ratings yet

- Lap Portion Detail: For Official Use OnlyDocument1 pageLap Portion Detail: For Official Use OnlySubhekshya ShresthaNo ratings yet

- Level 3 MEP ServicesDocument2 pagesLevel 3 MEP ServicesLeyla MoranNo ratings yet

- FafnirDocument3 pagesFafnirGustavo NielNo ratings yet

- Benja PlanDocument1 pageBenja Planmasumba patrickNo ratings yet

- UNDP - SZ - Environment - Doors-Windows Schedule PDFDocument1 pageUNDP - SZ - Environment - Doors-Windows Schedule PDFA MNo ratings yet

- 120 CorroTile Flyer WEB RE0914 PDFDocument1 page120 CorroTile Flyer WEB RE0914 PDFHKM IngenierosNo ratings yet

- Drawing 2.Document1 pageDrawing 2.tiyaniNo ratings yet

- 31293F PDFDocument1 page31293F PDFHany NassimNo ratings yet

- Window SchedulesDocument1 pageWindow SchedulesdenisNo ratings yet

- Anexo Iii - Lay Out de EmergenciasDocument1 pageAnexo Iii - Lay Out de EmergenciasStephanie Ruiz IslasNo ratings yet

- Existing Main Distribution Board: Mdb-ExsDocument1 pageExisting Main Distribution Board: Mdb-Exsb.u.pushpakumaraNo ratings yet

- Sta CC 14034 23 L02 120Document1 pageSta CC 14034 23 L02 120wcdrg59chcNo ratings yet

- 9035 Erction DWG (Demirsan)Document1 page9035 Erction DWG (Demirsan)ghulamNo ratings yet

- Vectorworks Educational Version: Sense and SensibilityDocument1 pageVectorworks Educational Version: Sense and Sensibilityapi-510574946No ratings yet

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocument1 pageBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNo ratings yet

- ELEVATIONS (1:100) SECTION A-A (1:50) : NotesDocument2 pagesELEVATIONS (1:100) SECTION A-A (1:50) : NotesLubangakene BrianNo ratings yet

- Mega City Floor LevelsDocument3 pagesMega City Floor Levelsbillajohn.66No ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Mlolongo Project Architectural PDFDocument1 pageMlolongo Project Architectural PDFNewtonNo ratings yet

- Mlolongo Project ArchitecturalDocument1 pageMlolongo Project ArchitecturalNewtonNo ratings yet

- Drawing 1.Document1 pageDrawing 1.tiyaniNo ratings yet

- Attachment 1 (RFI 271 Rev 00)Document1 pageAttachment 1 (RFI 271 Rev 00)Ramume188No ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- Refer Attached Comment Sheet For "Notes" and For Other Comments. Vendor To Do The Needful AccordinglyDocument1 pageRefer Attached Comment Sheet For "Notes" and For Other Comments. Vendor To Do The Needful Accordinglytitir bagchiNo ratings yet

- Hse Dema's Invoice02-09-2413-02-43Document1 pageHse Dema's Invoice02-09-2413-02-43stayinmyhome0828No ratings yet

- East Coast Railway: IrpwmDocument1 pageEast Coast Railway: IrpwmRVNLPKG6B VBL-GTLM100% (1)

- Zibagwe OfficesDocument1 pageZibagwe OfficesdereramichaelNo ratings yet

- Shor BraceDocument1 pageShor BraceMuhammad ZuhayrNo ratings yet

- Vario GT 24: The Variable Girder Wall Formwork SystemDocument3 pagesVario GT 24: The Variable Girder Wall Formwork SystemLaw Chee SeongNo ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- Sense and Sensibility: Lighting Ground PlanDocument1 pageSense and Sensibility: Lighting Ground Planapi-509024597No ratings yet

- A.Nisansala Weeraperuma ResumeDocument1 pageA.Nisansala Weeraperuma Resumenisansaladilshani8No ratings yet

- Energy WebquestDocument2 pagesEnergy WebquestKlavel Pajollari100% (1)

- BS en 01902-2015Document14 pagesBS en 01902-2015samNo ratings yet

- Ac Circuit Lec-1 NotesDocument11 pagesAc Circuit Lec-1 NotesAhmad bhattiNo ratings yet

- Application Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostDocument19 pagesApplication Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostM Agus SudrajatNo ratings yet

- PG PHD Admission Jul 2023Document5 pagesPG PHD Admission Jul 2023apce.28No ratings yet

- Gutters, Downpipes and Overflow: CalculatorDocument5 pagesGutters, Downpipes and Overflow: CalculatorThaiNguyenNo ratings yet

- Growth of Radio in PakistanDocument10 pagesGrowth of Radio in PakistanAyesha ZahraNo ratings yet

- Washbook TrainingDocument54 pagesWashbook TrainingMark BwanakayaNo ratings yet

- Mach3 To Run JK02-M5 Breakout BoardDocument7 pagesMach3 To Run JK02-M5 Breakout BoardAmr MohamedNo ratings yet

- OUTLINE ASM1 Programming 2022Document31 pagesOUTLINE ASM1 Programming 2022hoangvuNo ratings yet

- Attendance Monitoring System For Christian College of Tanauan Using RfidDocument47 pagesAttendance Monitoring System For Christian College of Tanauan Using RfidChristian Alfred VillenaNo ratings yet

- ChE F242 Numerical Methods For Chemical Engineers Semester II 2023-2024Document6 pagesChE F242 Numerical Methods For Chemical Engineers Semester II 2023-2024AzureNo ratings yet

- Distribusi PCDocument18 pagesDistribusi PCnur rohmanNo ratings yet

- OR - Chapter 2Document52 pagesOR - Chapter 2SAIDA SHEEBANo ratings yet

- Attach-2 Triconex Technical Product Guide-CompressedDocument39 pagesAttach-2 Triconex Technical Product Guide-Compressedivan_sofyan_aNo ratings yet

- Unit 4Document77 pagesUnit 4baidnirvana8No ratings yet

- AD5933 CDocument7 pagesAD5933 CkakiksNo ratings yet

- Example 21: Gabriel Dawe S Rainbow Coloured Curves-Annotated Student WorkDocument12 pagesExample 21: Gabriel Dawe S Rainbow Coloured Curves-Annotated Student WorklailaNo ratings yet

- Lec 7 - Intro To CryptographyDocument38 pagesLec 7 - Intro To CryptographygNo ratings yet

- JKR Probe TestDocument3 pagesJKR Probe TestFatin Samsudin0% (1)

- User Manual With FAQs - Print Address On EnvelopeDocument9 pagesUser Manual With FAQs - Print Address On Envelopekhushi DuaNo ratings yet

- Linear Regression For Machine LearningDocument2 pagesLinear Regression For Machine LearningmanasNo ratings yet

- TechRefOverview enDocument10 pagesTechRefOverview enLuis RiveraNo ratings yet

- Robotics Safety-Teaching Module-PresentationDocument58 pagesRobotics Safety-Teaching Module-PresentationmohanmzcetNo ratings yet

- New Antibiotic Breakthrough by SlidesgoDocument47 pagesNew Antibiotic Breakthrough by SlidesgoMarianne GarciaNo ratings yet

- DC Series Motor LabDocument3 pagesDC Series Motor LabTen Kumar0% (1)