Professional Documents

Culture Documents

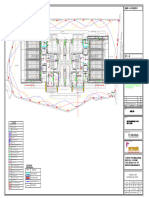

9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)

9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)

Uploaded by

jmdavies.isCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)

9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)

Uploaded by

jmdavies.isCopyright:

Available Formats

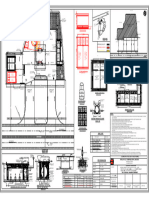

Group 4 Class D400 min.

gully top

Q A B V to BS EN124, set to cross fall and 225mm thick class B

profile of pavement 0 - 6mm below engineer brickwork to

channel level and bedded on BS 3921 bonded on

Q B V 10mm thick mortar designation(i). mortar designation (i).

A

600 max

600 min

Minimum Depth 600mm

750

Direction of flow

600 max

S

300mm min below M

675x675min Key to precast concrete manhole chamber details

lowest pipe invert

VARIES Cover and frame shall be ductile iron to BS 7903, BS EN 124 and Highways Agency document HA 104/ 02 Class D400, minimum frame depth shall be

A

S M 100mm (unless in block paved areas where the minimum depth shall be 150mm) in residential cul-de-sac, 150mm deep elsewhere, bedded on

900 min

Varies designation (i) mortar to BS EN 998 parts 1 and 2. Approved Packing material may be used if required. Manhole covers and frames shall be of

900

L non-rocking design which does not rely on the use of cushion inserts. Manhole covers shall be the non-ventilating type and shall have closed key.

B Type 2 cover frame seating rings with central access hole. 450 dia.

U A A U C Heavy duty reinforced concrete reducing slab, bedded with mortar, proprietary bitumen or resin mastic sealant. On manholes less than 1.5m

900 Min

D diameter, the reducing slab shall not be used and P.C. rings shall continue up to the cover slab.

U 150mm

diameter outlet Precast concrete gully pot to BS

K D 150mm thick GEN3 unreinforced concrete surround concrete mix shall also be designed with reference to to BRE Special Digest 1' Concrete in

300 E pipe. 5911: Part 230 or PVC-u gully pot to

A J T

A Aggressive ground and with reference to the ground investigation report (refer to specification clause (5.2.9.) of Sewers for Adoption 6th Edition.)

SECTION. BS EN 1401-1 with 150mm diameter

F D trapped outlet and rodding eye with

500 min 225 min U E Pre-cast concrete shaft, chamber sections and cover slab to BS 5911-3 and BS EN1917 on mortar bedding, with approved proprietary 10mm

G stopper and chain, bedded and

E uncompressed thickness bitumen or resin mastic sealant. Lifting eyes in concrete rings shall be pointed in with mortar designation (i).

surrounded in 150mm thick ST4

H unreinforced concrete to BS8500.

1:10 F The bottom of the chamber shall be set 75mm into the base slab.

low

to

1:30

of f

F G Construction Joint.

tion

G GEN3 unreinforced concrete mix shall also be designed with refernce to BRE Special Digest 1' Concrete in Aggressive ground andwith reference to Outlet position to Mortar descriptions (i) fillet.

H

ec

J the ground investigation report benching shall be finished with a minimum of 20mm thickness of grano concrete bought up to a dense smooth be as indicated on

L

Dir

face, neatly shaped and finished to all branch connections. Benching slope to be between 1 in 10 and 1 in 30. drainage layout.

R

Section A-A Plan L

100 min

M

H J Self cleansing toe holes to be provided in benching of sewers with a diameter of 450mm or greater.

min

225

NOTE: All insitu concrete

shall be sulphate

resisting unless

M Plan K Invert within chamber to be formed using channel pipes.

agreed otherwise. NOTE: All insitu concrete shall be L All pipes entering or leaving manholes shall have a joint as close as possible to the face of the manhole to allow a satisfactory joint.

sulphate resisting unless agreed NOTES. Grating omitted for

otherwise M Rocker pipe

clarity.

Section A-A N Ladder shall be either stainless steel grade 316S31 and comply with the dimensional requirements of BS 4211 class A, or GRP manufactured and 1. Mortar designation (i) shall

comprise 1 cement: 3 sand.

PLAN.

SHAFT DIAMETERS tested in accordance with "British Ladder Manufactures Association "Code of Practice for GRP Ladders" BLMA No1 and comply with the

For every two additional ROCKER PIPES dimensional requirements of BS 4211. The clear distance from the wall to the rung shall be 230mm and the maximum distance from the cover to

Dia of largest Int. Dia of incoming pipes, the diameter of LIMITATIONS OF USE.

Pipe diameter Effective the first rung shall be 675mm.

pipe in MH (mm) MH (mm) the manhole shall be increase by (mm) Length (mm)

1200 150mm. P Ladder fixing brackets (3no. min) at 2.0m centers, or as required. All fixing bolts to be stainless steel and secured with proprietary epoxy grout. 1. For normal vehicular loads.

Less than 375

150 to 600 600 ROCKER PIPES

SHAFT DIAMETERS

375 to 450 1500 For every two additional pipe diameter Effective Q Class M1, M2 to BS EN 998-2 or Epoxy mortar haunching for manhole cover and frame

Dia of largest Int. Dia of incoming pipes, the diameter of (mm) length (mm)

pipe in MH (mm) MH (mm) the manhole shall be increase by 150 to 600 600 R Chambers with outgoing pipes greater than 600mm diameter shall be fitted with removable stainless steel safety chains (grade 316S31) or

1200 150mm. polypropylene rope. Ropes or chains shall be secured with M12 stainless steel eyebolts, fixed with epoxy grout.

Less than 375

over 600 1000

1500 S Heavy Duty reinforced concrete cover slab to BS 5911 with 750x600 access (BS752)

375 to 700

over 750 1250

750 to 900 1800 T Direction of Flow

Precast concrete catchpit U Type D Class1 stainless steel Grade 316S13 or polypropylene encapsulated MS to BS EN 13101 and WIS 4-33-01 (280mm min width at 250mm

depth to soffit up to 3.0m Precast concrete manhole centers max). Max. distance from cover level to first step 675mm.

(depth to soffit up to 3m) V Type 1 cover frame a seating ring with eccentric access hole (BS752) bedded on mortar.

Footway edging type EF

SURFACE LEVEL

U A Trench back fill (see note

1).

max.

675

Brickwork

One brick corbel to

GEN 1 unreinforced concrete

relieving arch suit cover. surround where flexibly jointed

over pipe to full pipes are used, movement

thickness of joints shall be formed at

brickwork. Notes & Specification Impermeable membrane wrapped around trench

intervals not exceeding 5m and

L L M

M comprise 20mm thick Type B filter material to clause 505 of the current

1. Processed granular bedding and side fill materials shall include aggregates to BS EN 12620 + A1 and

compressible filler board placed Highways Agency Specification for Highway

lightweight aggregates to BS EN 13055-1 and shall be graded as defined in the following tables:

at a pipe joint. Works.

Table 1

225mmØ perforated distributor pipe - invert level

150 225 varies; refer to plan

Pipe Nominal Maximum Maximum CF Material

200

150.0000

D

Size (mm) Partical Size Value

(mm)

Pipe Joint with Channel to

be located inside face of

Notes & Specification

Typical section through filter drain

chamber bedded on

mortar

SECTION B-B 100 10 0.15 10mm nominal single size 1. Trench excavation shall be back filled as follows: a) Outside road pavements or areas where surface

settlement cannot be accepted, back filling shall be carried out using suitable fills. Suitable fills shall be

SECTION A-A capable of accepting compaction plant subject to the Engineer's approval and shall exclude boulders,

50x150mm hydraulically pressed

225mm Class B Engineering

brick. English bond with joints

A over 100 to 15 0.15 10 or 14mm nominal single size

lumps of concrete, bricks, timber and vegetable matter. b) In areas below road pavements (or where Materials within 450mm of the finished road precast concrete edging type E F

surface settlement cannot be accepted) (i) Where soffit of pipe is less than 0.5m below formation, back surface must not be frost susceptible

filled with well compacted 150 or 14 to 5mm graded. to BS EN 1340 Fig. 11

mortar 4mm to 6mm thick, 1240

fill with GEN 0 unreinforced concrete. (ii) Where soffit of pipe is between 0.5m and 1.0m below

completly filled and flushed formation, back fill with Type 1 sub-base.

Internal dimensions of manhole pointed. over 150 to 300 20 0.15 10, 14 or 20mm nominal single

nominally 1240 x 685mm but size or 14 to 5mm graded or 2. Cover to pipes shall be: 2000mm or less in areas subject to heavy construction plant. 1000mm or

manhole width increased for

L M 20mm to 5mm graded. less in areas subject to normal construction traffic. 1200mm or less to finished level of new main road

pipes larger than 225mm 600m long

diameter to give 225mm pavements. 600mm or less in landscape areas, foot ways, gardens or fields Otherwise use other

benching each side and brick M over 300 to 550 20 0.15 14 or 20mm nominal single size specified surround and back fill details.

work corbelled to suit cover. or 14 to 5mm graded or 20mm

675.000

to 5mm graded. 3. Pipes, unless otherwise stated, shall be: (i) Clay pipes with min FN of 40 to BS EN 295 and BS65 (ii)

Concrete pipes to BS 5911 and BS EN 1916 or, (iii) Flexible pipes shall be unplasticised UPVC to BS EN

B B over 550 40 0.15 14, 20 or 40mm nominal single 13598. Concrete pipes shall not be used for foul sewers unless otherwise stated.

size or 14 to 5mm graded or

Pipe joint to be positioned 20mm to 5mm graded or 40 to 4. Construction, subsequent testing, operation and maintenance shall be carried out in accordance

within 100mm from face of with BS EN 752. Sewers to be adopted by water companies shall be installed in accordance with the Kerb foundation and

5mm graded. backing concrete ST4

manhole current edition of 'Sewers for Adoption' produced by the Water Services Association. Sewers to be

unreinforced concrete

A adopted by highway authorities shall be installed in accordance with the authority's specification. Notes

2. The sulphate content of bedding and side fill materials shall not be greater than 0.3% as

sulphur trioxide. The above specification has been produced based on the Water Industry 5. Back filling shall only be undertaken when the concrete bedding and surround has obtained 1. Kerb backing normally brought up to 50mm below top of kerb, but where final surface of

PLAN specification publication sufficient strength to accommodate back filling operations. adjacent foot way is flagged, kerb backing shall finish 75mm below top of kerb.

3. No. 4-08-01 (issue 4) February 1994. 6. This detail shall not be used where the drainage is to be adopted by Water companies. 2. Gap between kerbs shall be 1 to 2mm.

Brickwork Manhole 4. Compaction factor (CF) shall be determined in accordance with the water industry publication 7. Workmanship shall be in accordance with BS 8000 - 14: 198. 3. Precast concrete edgings shall be cut to accommodate tight radii.

No 4-08-02 (issue 1) February 1994 - appendix B.

4. Kerb face to be shuttered and mechanically vibrated to ensure proper compaction.

Limitations of Use

Specification for bedding and sidefill materials for flexible Carrier drain - class z bedding, surround 1. For edging foot ways only

pipes (class s & b bedding) and backfill Footway edging type EF

Rev P3 Drawing status updated to TENDER By SWF Checked TH 17.06.2019

Rev P2 Channel gully detail added to drawing By GL Checked 17.06.2019

Drawn By: SWF Client Castleoak Group

Northampton

4 Ironstone Way, Brixworth,

Northampton NN6 9UD

T: 01604 781811

· Infrastructure Design · Geotechnical & Environmental Chkd By: GL

Project Lower Mill Care Home

Manchester Scale @ A1: 1:10 Kingston Road

3rd Floor, 82 King Street, E: mail@jppuk.net · Structural Engineering · Surveying Ewell

Manchester. M2 4WQ

T:0161 6822927 W: jppuk.net Date: April 2019 Title Private Construction Details

Milton Keynes Sheet 2 of 2

Suite 25 Linford Forum, Rockingham Drive, · Planning Services · Professional Advice Status: TENDER

Linford Wood, Milton Keynes. MK14 6LY

T: 01908 889433

Project No.: 9946Z Drawing No: 0657-SP-SL-DE-C-G77-451 Rev: P3

JPP QA Document T07 R1

You might also like

- Bill of QuantitiesDocument20 pagesBill of QuantitiesArnold Tunduli86% (7)

- Water Tank DesignDocument28 pagesWater Tank DesignDurval Párraga100% (3)

- Benja PlanDocument1 pageBenja Planmasumba patrickNo ratings yet

- Construction Details - Seating Element: Section Aa' Section BB'Document1 pageConstruction Details - Seating Element: Section Aa' Section BB'Vaishnavi MhatreNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Drawing 4.Document1 pageDrawing 4.tiyaniNo ratings yet

- Mefort Marondera ModelDocument1 pageMefort Marondera Modelbryan mutariNo ratings yet

- NTR Final 3259 Plot-1Document1 pageNTR Final 3259 Plot-1seoresercherNo ratings yet

- Member Schedule Legend: Safe AustraliaDocument1 pageMember Schedule Legend: Safe Australiarao_vinay8296No ratings yet

- Ar Ged 04Document1 pageAr Ged 04Bahaa MohamedNo ratings yet

- Dc-R2b-U22000 AlkyplusDocument1 pageDc-R2b-U22000 AlkyplusSergio Cesar Estrada CortazaNo ratings yet

- AAAABDocument1 pageAAAABAbuzar KhanNo ratings yet

- Project Information Company InformationDocument2 pagesProject Information Company InformationHasrudin UsmanNo ratings yet

- Plano Actual 1° Etapa Vista Hermosa 03-12-2022Document1 pagePlano Actual 1° Etapa Vista Hermosa 03-12-2022Juan Daniel GonzalesNo ratings yet

- Plano Replanteo San Mateo 2Document1 pagePlano Replanteo San Mateo 2Yerzi Arturo Arroyo AstudilloNo ratings yet

- PPVCDocument1 pagePPVClow Yi JunNo ratings yet

- SSWP - Notch Area Working Sequence For Perimeter FormDocument2 pagesSSWP - Notch Area Working Sequence For Perimeter Formpolaris projectNo ratings yet

- A102 - Proposed Setting Out PlanDocument1 pageA102 - Proposed Setting Out PlanØwięs MØhãmmedNo ratings yet

- Blasting Quantities Long SectionDocument1 pageBlasting Quantities Long Sectiontapiwanaishe maunduNo ratings yet

- Oil InterceptorDocument3 pagesOil InterceptorOkudetum RaphealNo ratings yet

- Barking To Tower Gateway: CS3: Newham General HospitalDocument1 pageBarking To Tower Gateway: CS3: Newham General Hospitaldarhio87No ratings yet

- NM E W S: ImplantaçãoDocument1 pageNM E W S: ImplantaçãoGustavo Henrique EstevesNo ratings yet

- Draft Structural Drawings-Lucky Mwanga 5BD House - BackupDocument7 pagesDraft Structural Drawings-Lucky Mwanga 5BD House - BackupFrex AumandoNo ratings yet

- WA203 - Decor Floor Plan Rev.BDocument1 pageWA203 - Decor Floor Plan Rev.BSTS-SPARK GAMINGNo ratings yet

- Water Supply Base Map of Bellary City: Allipura Impounding Reservoir - 12633 MLDocument1 pageWater Supply Base Map of Bellary City: Allipura Impounding Reservoir - 12633 MLShivangiTannaNo ratings yet

- LC 144B Electrical GadDocument3 pagesLC 144B Electrical Gadeswarsaisvuc0No ratings yet

- Pipe Culvert Reconstruction 1 ROW 1200 EncasingDocument1 pagePipe Culvert Reconstruction 1 ROW 1200 EncasingShivam SharmaNo ratings yet

- RevisionsDocument1 pageRevisionsVisakha DasNo ratings yet

- BW Tok JiringDocument4 pagesBW Tok JiringHakimi ZulkifliNo ratings yet

- PL001Document1 pagePL001johnkarl.bentingNo ratings yet

- Detail of Diversion Work Sections2Document1 pageDetail of Diversion Work Sections2RODEL YUNTINGNo ratings yet

- Marlow Series 580: In-Line Mounted Centrifugal PumpDocument32 pagesMarlow Series 580: In-Line Mounted Centrifugal PumpCarlosama MarioNo ratings yet

- Office Building Architectural DrawingsDocument3 pagesOffice Building Architectural DrawingsBrian MaunduNo ratings yet

- Tcon/Power Block/Gamma: Multi DC/DC T-Con ConnectorDocument1 pageTcon/Power Block/Gamma: Multi DC/DC T-Con ConnectorPaulinho MenezesNo ratings yet

- Side Elevation Front Elevation Side Elevation Rear ElevationDocument1 pageSide Elevation Front Elevation Side Elevation Rear ElevationGary ChestersNo ratings yet

- Pati Village Model 1Document1 pagePati Village Model 1Anonymous zGMEFL72No ratings yet

- Elevation C Elevation A: Upper LevelDocument1 pageElevation C Elevation A: Upper LevelNixel SpielNo ratings yet

- PDF Formulario para BJT Jfet y Mosfet CompressDocument3 pagesPDF Formulario para BJT Jfet y Mosfet CompressErick Molina AlcarrazNo ratings yet

- TEC Series CatalogueDocument9 pagesTEC Series CatalogueAshutosh VishwakarmaNo ratings yet

- Second Floor Reflected Ceiling Plan: LegendDocument1 pageSecond Floor Reflected Ceiling Plan: Legendaceboy_17No ratings yet

- Nolimit Wahda Floor LayoutDocument1 pageNolimit Wahda Floor Layoutvasanth kumarNo ratings yet

- Eng SM Tan 020 - C3D - 01Document2 pagesEng SM Tan 020 - C3D - 01Валерий ШостакNo ratings yet

- Roha MIDC MapDocument1 pageRoha MIDC MapVikram RautNo ratings yet

- Ban Do KCN Tan HuongDocument1 pageBan Do KCN Tan HuongĐẶNG NGUYỄN TRƯỜNG GIANGNo ratings yet

- SBECCLAYOUTDocument1 pageSBECCLAYOUTjedzekiel05No ratings yet

- Kshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-ModelDocument1 pageKshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-Modelmanan.maheshwari298No ratings yet

- Sec Aa: Staircase Details: 16 Ø at 180 C/C Starter BarsDocument1 pageSec Aa: Staircase Details: 16 Ø at 180 C/C Starter Barsnimish.aquamarineNo ratings yet

- Gujranwala PasrurDocument1 pageGujranwala PasrurMuhammad Asif Qasim100% (3)

- R-03 - Civil DWG (631-2126) - Sectional DetailsDocument1 pageR-03 - Civil DWG (631-2126) - Sectional DetailsvigneshciviltnjNo ratings yet

- 1 PDFDocument1 page1 PDFzaki zakuNo ratings yet

- 141 CS 257 02008 02 - QDocument1 page141 CS 257 02008 02 - QIkramNo ratings yet

- Backup of DRW 24Document1 pageBackup of DRW 24thomas wesleyNo ratings yet

- Coastal Trading Company.-ModelDocument1 pageCoastal Trading Company.-ModelPRUTHWIRAJ DAS [पृथ्वीराज दास]No ratings yet

- Load Line Feeder Kls06 Pt. PLN (Persero) Rayon Semarang BaratDocument2 pagesLoad Line Feeder Kls06 Pt. PLN (Persero) Rayon Semarang Baratcandra heri saputraNo ratings yet

- Structural DrawingsDocument3 pagesStructural Drawingskwoshaba pidsonNo ratings yet

- CJ LocationDocument1 pageCJ LocationTerry CheukNo ratings yet

- Showroom Electrical Layout28524Document7 pagesShowroom Electrical Layout28524Suranga NGNo ratings yet

- Approved. 128.00srm.s.054.route - Map.and - Section.cableDocument20 pagesApproved. 128.00srm.s.054.route - Map.and - Section.cablefajar.manutd07No ratings yet

- Notes: Electrical KeyDocument1 pageNotes: Electrical KeyanzaniNo ratings yet

- Foundation SectionDocument1 pageFoundation SectionShreyansh JainNo ratings yet

- Cpq07-Civil-Issue For Construction-119Document1 pageCpq07-Civil-Issue For Construction-119Gerson FrançosoNo ratings yet

- RC Design FormulaDocument61 pagesRC Design FormulaKiran AcharyaNo ratings yet

- Structural Damage Zones Detection by Finite Elements: September 2018Document3 pagesStructural Damage Zones Detection by Finite Elements: September 2018Gigarostom AlgerNo ratings yet

- Reinforced Concrete Design ExamplesDocument19 pagesReinforced Concrete Design ExamplesCraig SwensonNo ratings yet

- NSCP 2010Document758 pagesNSCP 2010Cherish Taguinod Aliguyon100% (2)

- Flexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementDocument23 pagesFlexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementCu ToànNo ratings yet

- Strain, Reinforced Concrete, ConfinementDocument125 pagesStrain, Reinforced Concrete, ConfinementArjun Mullu100% (1)

- Principles of Reinforced/Pre-Stressed Concrete Design Final ProjectDocument29 pagesPrinciples of Reinforced/Pre-Stressed Concrete Design Final ProjectRomulo TindoyNo ratings yet

- A Study On Rotational Behaviour of A New Industrialised Building System ConnectionDocument12 pagesA Study On Rotational Behaviour of A New Industrialised Building System ConnectionBiggsNo ratings yet

- DL 5022-1993Document134 pagesDL 5022-1993ecsuperal100% (1)

- Structural Concrete ElementsDocument3 pagesStructural Concrete ElementsR N PANDEYNo ratings yet

- Admixtures For Concrete PDFDocument26 pagesAdmixtures For Concrete PDFshahbaghi100% (4)

- Non-Linear Mechanics of Reinforced Concrete - (2 Two-Dimensional Analysis of Reinforced Concrete)Document112 pagesNon-Linear Mechanics of Reinforced Concrete - (2 Two-Dimensional Analysis of Reinforced Concrete)Alejandro SerratoNo ratings yet

- q01 g3 Ahmad AmalludinDocument5 pagesq01 g3 Ahmad AmalludinAmal AmranNo ratings yet

- Ali Kifah Kadumm PDFDocument11 pagesAli Kifah Kadumm PDFSatyam GondNo ratings yet

- Structural Design of Reinforced Concrete: Engr. Dean Carlson Alejandrino, MSCEDocument16 pagesStructural Design of Reinforced Concrete: Engr. Dean Carlson Alejandrino, MSCEAlbert SaludNo ratings yet

- Sikafume - Technical Data SheetDocument2 pagesSikafume - Technical Data SheetSigit PurwandiNo ratings yet

- Netsanet BezuDocument93 pagesNetsanet BezuabadittadesseNo ratings yet

- RCI-Chapter 1-GeneralDocument55 pagesRCI-Chapter 1-GeneralMahlet EshetuNo ratings yet

- Comparative Study of RC Multi-Storey Building Subjected To Elevated Temperature For Different StoreysDocument31 pagesComparative Study of RC Multi-Storey Building Subjected To Elevated Temperature For Different StoreyskarthiksampNo ratings yet

- L5 Composites Part 1and2 23sep15Document117 pagesL5 Composites Part 1and2 23sep15Tayyab AttariNo ratings yet

- SikaFiber Selection GuideDocument4 pagesSikaFiber Selection GuideMohamed ElfawalNo ratings yet

- 5927913concrete PPT 2 by Badal SirDocument20 pages5927913concrete PPT 2 by Badal Sirsakshm guptaNo ratings yet

- Behavior of Bamboo Wall Panel Under Bullet Impact LoadDocument6 pagesBehavior of Bamboo Wall Panel Under Bullet Impact LoadKamalJangra84No ratings yet

- Revamping Corrosion Damaged Reinforced Concrete Balconies - Life Cycle Assessment and Life Cycle Cost of Life Extending Repair MethodsDocument24 pagesRevamping Corrosion Damaged Reinforced Concrete Balconies - Life Cycle Assessment and Life Cycle Cost of Life Extending Repair MethodsSyed RafiuzzamanNo ratings yet

- STL261S Assignment 2 - 2022Document5 pagesSTL261S Assignment 2 - 2022SimphiweNo ratings yet

- A Review of Prestressed Concrete Pile With CirculaDocument10 pagesA Review of Prestressed Concrete Pile With CirculahasithrNo ratings yet

- Eray BaranDocument2 pagesEray BaranIzzetcan GunbeyNo ratings yet

- Pile Foundations Lecture Note 1 PDFDocument99 pagesPile Foundations Lecture Note 1 PDFMalbattaNo ratings yet