Professional Documents

Culture Documents

L.T. Joint Sealant: Main Application

L.T. Joint Sealant: Main Application

Uploaded by

Lee Kok RoyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L.T. Joint Sealant: Main Application

L.T. Joint Sealant: Main Application

Uploaded by

Lee Kok RoyCopyright:

Available Formats

SHC 105-01

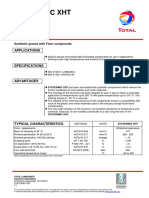

L.T. JOINT SEALANT

MAIN APPLICATION

◇ Elastomer based vapor barrier sealant in the joints

of insulation to prevent the vapor migration into

the cold insulation system

◇ Flexible elastomeric sealant

◇ Preventing damage to the insulation against

thermal cycling

SHC 105-01

SHC 105-01 is a one component butyl based joint sealant for cold and cryogenic insulation.

COLOR WATER VAPOR PERMEANCE (ASTM E 96)

White 0.02 perms @2.62㎜ DFT

APPLICATION TOOL WET FLAMMABILITY (ASTM D3278)

Trowel, Putty Knife Flash Point : ≥44℃

AVERAGE WEIGHT / LITER (ASTM D1475) REMARKS

1.50 ±0.05 kg/Liter

Store and apply between 4℃ and 38℃.

AVERAGE NON-VOLATILE (ASTM D2369) Contains no asbestos, lead, mercury or mercury compounds.

84% ±3.9 by volume Do not apply over greasy, oily, damp or frosty surface.

90% ±4.2 by weight Always test plastic material for compatibility when using

a solvent base product.

COVERAGE RANGE (SHTM 13)

(Subject to type of surface and nature of material being sealed)

3.6 kg/㎡

Wet Film Thickness: 2.3 ㎜

Dry Film Thickness: 2.0 ㎜

DRYING TIME (25℃ 50%RH) (ASTM D 1640)

Set To Touch: 2~4 hours

Essentially non-drying

SERVICE TEMPERATURE LIMITS (SHTM 08)

(Temperature at coated surface)

-196℃ ~ 93℃

SHTM : SAM HWA TEST METHOD

Sam Hwa Chemicals Co., Ltd.

71-17, Cheonjeong 2-gil, Mokcheon-eup, Dongnam-gu, Cheonan-si, Chungnam, Korea T: +82-2-517-6847 E: sales@shckorea.com / www.shckorea.com

The warranted shelf life is one year from date of shipment. 210503

SHC 105-01

L.T. JOINT SEALANT

Preparation for application

- Do not thin product.

- Apply only to clean, dry, oil-free surfaces.

- Keep the container of product firmly closed in times of not in use to prevent evaporation of solvent and surface skinning.

Application Method

- Apply SHC 105-01 at a thickness of 2.3mm in wet, which is equivalent to 3.6kg/m2.

- Apply the insulation to be stuck firmly to another leaving no room to keep air in the sealant.

- Remove sealant protruded out of jointed area clearly with trowel or putt- knife.

- This application provides dry film thickness of 2.0mm.

- As rough or porous surfaces require more products, higher built thickness is recommended.

- It takes two to four hours to have dried surface but it’s basically impossible to have 100 % dried one by reason

of product properties. Additional application should be done after complete drying out of the first surface

as drying time varies according to the application temperature.

Tools

- Use clean trowel, putt-knife.

- Be mindful to have uniform thickness using the tools.

Clean up

- As dried product is too difficult to remove, clean them before drying.

- After dried, use mineral spirits or chlorinated solvent, once cured, employ strong solvent like xylene to clean the equipment.

SHTM : SAM HWA TEST METHOD

Sam Hwa Chemicals Co., Ltd.

71-17, Cheonjeong 2-gil, Mokcheon-eup, Dongnam-gu, Cheonan-si, Chungnam, Korea T: +82-2-517-6847 E: sales@shckorea.com / www.shckorea.com

The warranted shelf life is one year from date of shipment. 210503

You might also like

- Metal Sealant: Main ApplicationDocument2 pagesMetal Sealant: Main ApplicationHung Mai VanNo ratings yet

- Poly Cell Adhesive: Main ApplicationDocument2 pagesPoly Cell Adhesive: Main ApplicationHung Mai VanNo ratings yet

- C Mastic: Main ApplicationDocument1 pageC Mastic: Main ApplicationHung Mai Van100% (2)

- SHC 700-121W/122W: Buseal Wrap 12Document2 pagesSHC 700-121W/122W: Buseal Wrap 12Lee Kok RoyNo ratings yet

- Buseal Wrap 12: Main PurposeDocument2 pagesBuseal Wrap 12: Main PurposeLee Kok RoyNo ratings yet

- Poly Cell Adhesive: Main ApplicationDocument1 pagePoly Cell Adhesive: Main ApplicationHung Mai VanNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- En - Silcoset 152 TDS - 2Document1 pageEn - Silcoset 152 TDS - 2Андрей МошкинNo ratings yet

- Zwaluw Gasket Sealant Red enDocument2 pagesZwaluw Gasket Sealant Red enAngelo Carlo MalabananNo ratings yet

- TDS-Foster 95-44 EN PDFDocument2 pagesTDS-Foster 95-44 EN PDFEshaghNo ratings yet

- Low Modulus 1 Part Polyurethane SealantDocument2 pagesLow Modulus 1 Part Polyurethane SealantVietpapayaNo ratings yet

- PDS7010EDocument2 pagesPDS7010EElie KhawandNo ratings yet

- TDS 13051310 en Black-Seal Special SiliconeDocument2 pagesTDS 13051310 en Black-Seal Special SiliconerezaNo ratings yet

- Weicon Black-Seal Special Silicone TDS PDFDocument2 pagesWeicon Black-Seal Special Silicone TDS PDFSaiful IslamNo ratings yet

- Seaquantum Ultra: Technical Data Sheet Application GuideDocument6 pagesSeaquantum Ultra: Technical Data Sheet Application GuideSardar AmedNo ratings yet

- Massa AcrilicaDocument1 pageMassa AcrilicaAndre MoutelaNo ratings yet

- Glass Cloth No.10: Main PurposeDocument1 pageGlass Cloth No.10: Main PurposeHung Mai VanNo ratings yet

- 764 PD3Document1 page764 PD3khaledNo ratings yet

- Jet-Lube Silicone Compound DMDocument1 pageJet-Lube Silicone Compound DMDon HowardNo ratings yet

- Sealant-DataSheet-CHEMSEAL W70Document1 pageSealant-DataSheet-CHEMSEAL W70Sampath Kumar KandasamyNo ratings yet

- Elastiseal Sealant 95-88: PropertiesDocument2 pagesElastiseal Sealant 95-88: PropertiesMyluv MyluvNo ratings yet

- En - Silcoset 153 TDS - 1Document1 pageEn - Silcoset 153 TDS - 1Андрей МошкинNo ratings yet

- Terlux 2802 TRDocument2 pagesTerlux 2802 TRDouglas AndradeNo ratings yet

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Feviseal GP TDSDocument3 pagesFeviseal GP TDSChetan MahajanNo ratings yet

- ( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant SealantDocument10 pages( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant Sealantstretfordend92No ratings yet

- VT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantDocument2 pagesVT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantENGINEER MONIRUJJAMANNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- TDS Pattex BondsealfillDocument5 pagesTDS Pattex BondsealfilldknisNo ratings yet

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerNo ratings yet

- TDS - Total - Statermic XHT - HNN - 201412 - enDocument1 pageTDS - Total - Statermic XHT - HNN - 201412 - enNibaldo KamelNo ratings yet

- 3MPOLYDocument4 pages3MPOLYsmtknivesNo ratings yet

- Dow Corning 730Document3 pagesDow Corning 730Mahdi abanNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Technical Details of Bonding ChemicalsDocument18 pagesTechnical Details of Bonding ChemicalsSangeet KarnaNo ratings yet

- DF EspumaDocument1 pageDF EspumaAndre MoutelaNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Terostat Ms 939-EnDocument2 pagesTerostat Ms 939-EnZoli PoliNo ratings yet

- Terostat Ms 930-EnDocument4 pagesTerostat Ms 930-Enken philipsNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Airvent - Dae - DC - DF - 1 - S11.1 - en - 10&4Document5 pagesAirvent - Dae - DC - DF - 1 - S11.1 - en - 10&4honghieutrNo ratings yet

- Foster 32-17Document2 pagesFoster 32-17Mostafa AymanNo ratings yet

- PTFE-Grease K 7132Document1 pagePTFE-Grease K 7132statisticssalesNo ratings yet

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionDocument4 pagesOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeNo ratings yet

- PDS Stopaq Wrappingband CZH DS V2 enDocument2 pagesPDS Stopaq Wrappingband CZH DS V2 enAndyNo ratings yet

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDocument3 pagesOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNo ratings yet

- PTDS Sicomet 100 v2 190615Document2 pagesPTDS Sicomet 100 v2 190615nhnamNo ratings yet

- Selection Guide Overview: Product Moulded Part Ref. Type Operating Temperature Product Designation PackagingDocument2 pagesSelection Guide Overview: Product Moulded Part Ref. Type Operating Temperature Product Designation Packagingtito titoNo ratings yet

- Sikahyflex 140 Construction - Pds enDocument4 pagesSikahyflex 140 Construction - Pds enPutra AfriadeNo ratings yet

- Teroson MS 930Document4 pagesTeroson MS 930subhangisharma1112No ratings yet

- MegayachtDocument6 pagesMegayachtvolme20No ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- En - Silcoset 158 TDS - 1Document1 pageEn - Silcoset 158 TDS - 1Андрей МошкинNo ratings yet

- Thanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionDocument1 pageThanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionHelen ChoiNo ratings yet

- Altis Mv2: ApplicationsDocument1 pageAltis Mv2: ApplicationsM.TayyabNo ratings yet

- Fasson 0828 DatasheetDocument1 pageFasson 0828 DatasheetGregory Alan Francisco IINo ratings yet

- VT 200Document2 pagesVT 200yusri jaafarNo ratings yet

- Autodesk Fabrication 2019 Pattern CatalogDocument352 pagesAutodesk Fabrication 2019 Pattern CatalogLee Kok RoyNo ratings yet

- Flytech IpoDocument10 pagesFlytech IpoLee Kok RoyNo ratings yet

- Child Development FormDocument8 pagesChild Development FormLee Kok RoyNo ratings yet

- RW Ti Pds Prorox Ps 970 Astm IndiaDocument1 pageRW Ti Pds Prorox Ps 970 Astm IndiaLee Kok RoyNo ratings yet

- Data Sheet CF LY 221129Document1 pageData Sheet CF LY 221129Lee Kok RoyNo ratings yet

- MG Board Data SheetDocument2 pagesMG Board Data SheetLee Kok RoyNo ratings yet

- Alcom Payung 11C 230314Document1 pageAlcom Payung 11C 230314Lee Kok RoyNo ratings yet

- Neyriz Grey Cement Co.: Date: 02.05.30Document1 pageNeyriz Grey Cement Co.: Date: 02.05.30alishahsavarNo ratings yet

- My Cheat SheetDocument3 pagesMy Cheat SheetTenzin KyizomNo ratings yet

- TanksDocument21 pagesTanksswabrightNo ratings yet

- SUMMARY - UCS Mpemba - IsongoleDocument12 pagesSUMMARY - UCS Mpemba - Isongoledavid karasilaNo ratings yet

- Copper ComplexationDocument208 pagesCopper ComplexationEveltonNo ratings yet

- Perforating Technology: China National Logging CorpDocument39 pagesPerforating Technology: China National Logging Corpdarryl_gilbertNo ratings yet

- Chapter01 Pressure Basic PDFDocument20 pagesChapter01 Pressure Basic PDFDoni KurniawanNo ratings yet

- Rexroth Filter SelectionDocument28 pagesRexroth Filter SelectionEbrahim Abd El HadyNo ratings yet

- Wasteless Economic Method of Production of Phenol and AcetoneDocument14 pagesWasteless Economic Method of Production of Phenol and AcetoneSiswand BIn Mohd AliNo ratings yet

- Kralova2009 PDFDocument22 pagesKralova2009 PDFnaalain fatimahNo ratings yet

- FGD-Fluegas Desulphurication Plant O&M PDFDocument299 pagesFGD-Fluegas Desulphurication Plant O&M PDFMAGUNAMNo ratings yet

- CV Emil SatriaDocument1 pageCV Emil SatriaazmiazfarNo ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- India S Scientific HeritageDocument3 pagesIndia S Scientific Heritageganesh_iyergNo ratings yet

- Reinforcing Heat Shrinkable Cable Repair SleeveDocument2 pagesReinforcing Heat Shrinkable Cable Repair Sleevesales3167No ratings yet

- Me 2403 Syllabus - PpeDocument2 pagesMe 2403 Syllabus - PpebsamantonyNo ratings yet

- Wiley's Chemistry JEE Main Practice ProblemsDocument369 pagesWiley's Chemistry JEE Main Practice Problemspal8979625519No ratings yet

- Influence of Anchor Inclination On Pull-Out Resistance of ClaysDocument6 pagesInfluence of Anchor Inclination On Pull-Out Resistance of ClaysSen HuNo ratings yet

- Drilling FormulaDocument109 pagesDrilling FormulaHeba SaidNo ratings yet

- Improving Biogas ProductionDocument308 pagesImproving Biogas Productionedo fabregas50% (2)

- Prospective ChemistryDocument10 pagesProspective ChemistryAdolfNo ratings yet

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- Bubbling Baking Soda AuthorsDocument12 pagesBubbling Baking Soda AuthorsMacaraeg, Janea MaeNo ratings yet

- SOM Lecture 03Document25 pagesSOM Lecture 03tvkbhanuprakashNo ratings yet

- RomagnoleDocument36 pagesRomagnoleFernando Togo CocaNo ratings yet

- Vol-II Reinforced Cement Concrete WorkDocument70 pagesVol-II Reinforced Cement Concrete WorkAnudeep RamagiriNo ratings yet

- Importance and Types of Transformer Cooling SystemsDocument3 pagesImportance and Types of Transformer Cooling Systemspctinformation100% (1)

- MPS-PA Compact-Workstation Workbook SolutionsDocument2,220 pagesMPS-PA Compact-Workstation Workbook SolutionsLiz Barbosa100% (5)

- Diploma in CivlDocument38 pagesDiploma in CivlBipul Prince BarmanNo ratings yet