Professional Documents

Culture Documents

Ip TPS Series

Ip TPS Series

Uploaded by

Sayyeda Sumaiyah0 ratings0% found this document useful (0 votes)

45 views577 pageshll

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthll

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

45 views577 pagesIp TPS Series

Ip TPS Series

Uploaded by

Sayyeda Sumaiyahhll

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 577

TP. Ss "Textbook"

Technical Pharmacy Series

Strictly Based On PCI Syllabus

INDUSTRIAL

PHARMACY - I

a

F

IFTH SEM. B. PHARM

> Yogesh N. Gholse

Re kn » Dr. Rahul H. Kasliwal

vbdpublications.com OR amazonin » Dr. Dinesh R. Chaple

SYLLABUS

UNIT -I

Preformulation Studies: Introduction to preformulation, goals

and objectives, study of physicochemical characteristics of drug

substances.

(a) Physical properties: Physical form (crystal and

amorphous), particle size, shape, flow properties, solubility

profile (pKa, pH, partition coefficient), polymorphism

(b) Chemical Properties: Hydrolysis, oxidation, reduction,

racemisation, polymerization BCS classification of drugs and

its significance. Application of preformulation considerations in

the development of solid, liquid oral and parenteral dosage

forms and its impact on stability of dosage forms.

UNIT - I

Tablets:

(a) Introduction, ideal characteristics of tablets, classification of

tablets. Excipients, Formulation of tablets, granulation methods,

compression and processing problems.

Equipments and tablet tooling.

(b) Tablet coating: Types of coating, coating materials,

formulation of coating composition, methods of coating,

equipment employed and defects in coating.

(c) Quality control tests: In process and finished product tests

Liquid orals : Formulation and manufacturing consideration of

syrups and elixirs suspensions and emulsions; Filling and

packaging; evaluation of liquid orals official in pharmacopoeia.

UNIT - II

Capsules:

(a) Hard gelatin capsules : Introduction, Production of hard

gelatin capsule shells. size of capsules, Filling, finishing and

special techniques of formulation of hard gelatin capsules,

manufacturing defects. In process and final product quality

control tests for capsules.

INDUSTRIAL PHARMACY.I(B.Pharm. V SEM.)

(b) Soft gelatin capsules: Nature of shell and capsule content,

size of capsules,importance of base adsorption and minim/gram

factors, production, in process and final product quality control

tests. Packing, storage and stability testing of soft gelatin

capsules and their applications.

Pellets: Introduction, formulation requirements, pelletization

process, equipments for manufacture of pellets

UNIT - IV

Parenteral Products:

(a) Definition, types, advantages and limitations. Preformulation

factors and essential requirements, vehicles, additives,

importance of isotonicity.

(b) Production procedure, production facilities and controls,

aseptic processing

(c) Formulation of injections, sterile powders, large volume

parenterals and lyophilized products.

(d) Containers and closures selection, filling and sealing of

ampoules, vials and infusion fluids. Quality control tests of

parenteral products.

Ophthalmic Preparations : Introduction, formulation conside-

rations, formulation of eye drops, eye ointments and eye

lotions; methods of preparation; labeling, containers; evaluation

of ophthalmic preparations

: Formulation and preparation of the following

cosmetic preparations: lipsticks, shampoos, cold cream and

vanishing cream, tooth pastes, hair dyes and sunscreens.

Pharmaceutical Aerosols: Definition, propellants, containers,

valves, types of aerosol systems; formulation and manufacture

of aerosols; Evaluation of aerosols; Quality control and stability

studies.

Packaging Materials Science: Materials used for packaging of

pharmaceutical products, factors influencing choice of

containers, legal and official requirements for containers,

stability aspects of packaging materials, quality control tests.

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

CONTENTS OF PARTI

UNIT -I

11

Introduction

1.2 Goals and objectives 2

1.3 Study of physicochemical characteristics of

drug substances 3

1.4 Physical properties 4

1.5 Chemical properties 19

1.6 BCS classification of drugs and its significance 23

1.7 Application of preformulation considerations in the

development of solid dosage forms and its impact

on stability 33

1.8 Application of preformulation considerations in the

development of liquid oral dosage forms and its

impact on stability 36

1.9 Application of preformulation considerations in the

development of parenteral dosage forms and its

impact on stability 38

1.10 Points to remember 43

1.11 Exercise

UNIT - II

Tablets :

2.1

2.2

2.3 Ideal characteristics of tablets 51

2.4 Classification of tablets 52

2.5 Excipients 55

2.6 Formulation of tablets 62

Introduction

Definition

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

2.7. Granulation methods

2.8 Compressions

2.9 Processing problems

2.10 Equipments and tablet tooling

2.11 Tablet coating

2.12 Types of coating

2.13 Coating materials

2.14 Formulation of coating composition

2.15 Methods of coating

2.16 Equipment employed

2.17 Quality control tests

2.17.1 In process and finished product tests

2.17.2 IPQC and FPQC test for pharmaceutical

tablets according to pharmacopoeias are

listed below

Liquid orals :

2.18 Introduction

2.18.1 Formulation and manufacturing consideration

of syrups

2.19 Formulation and manufacturing consideration

of elixirs

2.20 Formulation and manufacturing consideration

of suspensions

2.21 Formulation and manufacturing consideration

of emulsions

2.22 Filling and packaging

2.23. Evaluation of liquid orals official in pharmacopoeia

2.24 Points to remember

2.25 Exercise

INDUSTRIAL PHARMACY-|(B.Pharm. V SEM.)

UNIT - III

Capsule :

3.1 Introduction

3.2 Definition

3.3 Hard gelatin capsules

3.3.1 Production of hard gelatin capsule shells

3.3.2 Size of capsules

3.3.3 Filling and finishing

3.3.4 Special techniques of formulation of hard

gelatin capsules

3.3.5 Manufacturing defects

3.3.6 In-process and final product quality control

tests for capsules

3.4 Soft gelatin capsules

3.4.1 Nature of shell

3.4.2 Capsule content

3.4.3 Size of capsules

3.4.4 Importance of base adsorption and minim

/gram factors

3.4.5 Production

3.4.6 In-process and final product quality control tests

3.4.7 Packing and storage

3.4.8 stability testing of soft gelatin capsules

3.4.9 Applications

Pellets :

3.5 Introduction

3.6 Formulation requirements

3.7 Pelletization process

3.8 Equipments for manufacture of pellets

3.9 Points to remember

3.10 Exercise

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

CONTENTS OF PART II

UNIT - IV

Parenteral products :

4.1 Introduction

4.2 Definition, types, advantages and limitations

of parenteral product

4.3. Preformulation factors

4.4 Essential requirements, vehicles and additives

4.5 Importance of isotonicity

4.6 Production procedure, production facilities,

controls and aseptic processing

4.7 Formulation of injections

4.8 Formulation of sterile powders

4.9 Formulation of large volume parenterals

4.10 Formulation of lyophilized products

4.11 Containers and closures selection, filling

and sealing of ampoules

4.12 Containers and closures selection, filling and

sealing of vials

4.13 Containers and closures selection, filling

and sealing of infusion fluids

4.14 Quality control tests of parenteral products,

ophthalmic preparations

Ophthalmic Preparations :

4.15 Introduction

4.16 Definition, properties, characteristics, types of

ophthalmic dosage forms

4.17 Formulation considerations

4.18 Eye drops

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

4.19 Eye lotions

4.20 Eye ointments

4.21 Evaluation of ophthalmic preparations

4.22 Points to remember

4.23 Exercise

UNIT-V

Cosmetics :

5.1 Introduction

5.2 Formulation and preparation of the lipsticks

5.3 Formulation and preparation of the shampoos

5.4 Formulation and preparation of the cold cream

5.5 Formulation and preparation of the vanishing cream

5.6 Formulation and preparation of the tooth pastes

5.7 Formulation and preparation of the hair dyes

5.8 Formulation and preparation of the sunscreens

Pharmaceutical aerosols :

5.9 Introduction

5.10 Propellants

5.11 Containers

5.12 Valves

5.13 Actuators

5.14 Types of aerosol systems

5.15 Formulation of aerosols

5.16 Manufacture of aerosols

5.17 Evaluation of aerosols

5.18 Quality control

5.19 Stability studies

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

Packaging material science :

5.20

5.21

5.22

5.23

5.24

5.25

5.26

5.27

Introduction

Materials used for packaging of pharmaceutical products

Factors influencing choice of containers

Legal and official requirements for containers

Stability aspects of packaging materials

Quality contro! tests

Points to remember

Exercise

VIVA-VOCE

Glossary

Index

INDUSTRIAL PHARMACY-| (B.Pharm. V SEM.)

TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) 1

UNIT -I

PREFORMULATION STUDIES

SYLLABUS

Preformulation Studies : Introduction to preformulation, goals

and objectives, study of physicochemical characteristics of drug

substances.

(a) Physical properties : Physical form (crystal and amorphous),

particle size, shape, flow properties, solubility profile (pKa, pH,

partition coefficient), polymorphism.

(b) Chemical Properties : Hydrolysis, oxidation, reduction,

racemisation, polymerization BCS classification of drugs and

its significant.

Application of preformulation considerations in the development

of solid, liquid oral and parenteral dosage forms and its impact

on stability of dosage forms.

1.1 INTRODUCTION:

. Preformulation is a first learning phase of the dosage form

development. It is considered as a first step in the rational

development of dosage forms of a drug substance since 1950

and early 1960.

«The fundamental, physical and chemical properties of the

drug molecule and other properties of the drug are necessary

to determine before development of any kind of dosage form.

e It involves the application of biopharmaceutical principles of

the physicochemical property of the drug with the goal of

designing effective drug delivery system.

1.2

(i)

(ii)

(iii)

(iv)

TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.)

The pharmacokinetic and pharmacodynamic properties of the

drug is characterized and established during this develop-

mental stage.

Definition :

It is a development stage during which the physicochemical

properties of the drug substance alone and when combined

with excipients is characterized and established.

It may be described as the process of optimizing a drug

through determination of those physical and chemical properties

considered important in the formulation of a stable, effective

and safe dosage form.

Preformulation influences :

Selection of the drug candidate itself.

Selection of formulation components.

API and drug product manufacturing processes.

Determination of the most appropriate container closure

system.

Development of analytical methods.

Assignment of API retest periods.

The synthetic route of the API.

Toxicological strategy.

GOALS AND OBJECTIVES :

Goals :

Following are the goals of performulation studies :

To establish the physico-chemical parameters of new drug

substance.

To establish the kinetic rate profile.

To establish the compatibility with the common excipient.

To choose the correct form of a drug substance.

‘TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) 3

vy)

(vi)

1.3

qd)

Q)

@)

To generate a thorough understanding of the materials stability

under the conditions that will lead to development of an

optimal drug delivery system.

To provide a scientific data to support the dosage form design

and evaluation of the product efficiency and stability.

Objectives :

Following are the objectives of performalation studies :

To generate information useful to the formulator in developing

stable and bioavailable dosage forms that can be mass produced.

To develop the elegant dosage forms (stable, effective and safe).

To understand the physical description of a drug substance

before dosage form development.

To generates useful information to the formulator to design

an optimum drug delivery system.

STUDY OF PHYSICOCHEMICAL

CHARACTERISTICS OF DRUG SUBSTANCES :

———— aera

Various physical and chemical properties consider for

preformulation study of drug substances such as :

Physical Properties :

Organoleptic properties.

Bulk characteristics :

(a) Solid state characteristics.

(b) Flow properties.

(c) Densities.

(d) Compressibility.

(e) Crystalline.

(f) Polymorphism.

(g) Hygroscopicity.

Solubility analysis :

(a) Ionization constant (Pka).

TPS

(4)

1.4

ay

(a)

TRS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.)

(b) Partition co-efficient.

(c) Solubilization

(d) Thermal effect.

(e) Common ion effect (Ksp).

(f) Dissolution.

Stability analysis :

(a) Solution-state stability

(b) Solid-state stability

(c) Drug-excipients compatibility

Chemical Properties :

(1) Hydrolysis

(2) Oxidation

(3) Photolysis

(4) Recemization

(5) Polymerization

(6) Isomerization

PHYSICAL PROPERTIES :

In the dosage form development, the acceptable stability of

the drug substance and drug product is one of the basic

requirements for clinical studies, regulatory approval, and

marketing. The stability of a drug product is related not only

to the intrinsic chemical stability of the drug molecule, but

also to the physical forms and various physical properties of

drug. Physical properties mainly affect dosage form dis-

integration, dissolution, solubility, permeability, absorption

and finally bioavailability of drug.

Physical form (crystal and amorphous) :

Amorphous drugs :

Amorphous drugs have randomly arranged atoms or molecules

same as ina liquid.

PS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) 6

(b)

Amorphous forms are prepared by rapid precipitation,

lyophilization, or rapid cooling of liquid melts.

They are highly soluble and have higher dissolution rate as

they have higher thermodynamic energy.

It is converted in to more stable form on storage.

Example : Novobiocin : It is inactive when administered in

crystalline form, but when they are administered in the

amorphous form, absorption from the gastrointestinal tract

proceeds rapidly with good therapeutic response.

Advantage : Amorphous forms have higher solubility as well

as dissolution rates as compared to crystalline forms.

Disadvantage : As it converts in to more stable forms the

thermodynamic instability can occur during bulk processing

or within dosage forms.

Crystalline drugs :

Crystals are characterized by repetitious spacing of constituent

atoms or molecules in a three dimensional array.

A crystal structure is a unique arrangement of atoms in a

crystal.

A crystalline particle is characterized by definite external and

internal structures.

Example : Penicillin : the crystalline forms of penicillin as

potassium or sodium salt is considerably more stable and

result in excellent therapeutic response than amorphous forms.

It can be classifies as Internal structures (cubic, tetragonal,

hexagonal, rhombic, etc.), Solid habits (platy, needle, tabular,

prismatic, bladed, etc.), Changing the internal structures alter

the crystal habits, Changing the chemical form (e.g. salt

formation) alter both the internal structure and crystal habit.

Crystal habit describes the external shape of a crystal.

a)

Q)

GB)

(4)

‘PPS INDUSTRIAL PHARMACY- | (B.Pharm. v SEM)

Different polymorphs are obtained by crystallization from

different solvents and by solidification after melting.

Solvate :

It is a crystalline compound in which crystallizing Organic

solvent get incorporated within the crystal lattice.

It is undesirable to use solvates for drugs and pharmaceuticals,

as the presence of organic solvent residues may be toxic;

regulations for all the organic solvents in products for human

use establish specific limits to how much daily exposure to

residual solvent in the formulated preparation is allowed.

The solubility and dissolution rate of a drug can significantly

differ for different solvates, and in particular hydrates.

Hydrate :

It is a crystalline compound in which water get incorporated

within the crystal lattice.

On the basis of numbers of water molecules incorporated,

hydrate are of following types :

Hemihydrate : It is a crystalline compound in which half

molecule of water get incorporated within the crystal lattice.

Monohydrate : It is a crystalline compound in which one

molecule of water get incorporated within the crystal lattice.

Dihydrate : It is a crystalline compound in which two

molecule of water get incorporated within the crystal lattice.

Anhydrous : It is a crystalline compound which Not containing

any molecule of water get incorporated within the crystal

lattice.

Hydrates may have a faster or slower dissolution rate than the

Corresponding anhydrous form, though more frequently, the

former are slower than the latter, perhaps because there are

fewer sites of the drug molecule available for interaction with

water during dissolution,

Q)

TPS INDUSTRIAL PHARMACY. | (B.Pharm. V SEM.) 7

SS em

Example : Theophylline Anhydrate, which dissolves faster

than its hydrate form.

In other cases, the hydrate form exhibits a more rapid dissolution

rate than its anhydrous form

Example : Erythromycin Dihydrate was found to exhibit a

significantly faster dissolution rate than that of monohydrate

and anhydrous forms.

Particle size and shape :

Before the preformulation, each new drug should be tested

with the smallest particle size as is practical facilitate prepa-

ration of homogeneous samples and maximize the drug’s

surface area for interactions.

Certain physical and chemical properties of drug substances

are affected by the particle size distribution, including flow

characteristics, sedimentation rates, drug dissolution rate,

bioavailability, content uniformity, taste, texture color, and

stability.

The effect is not only on the physical properties of solid

drugs but also, in some instances, on their biopharmaceutical

behavior.

Example : The bioavailability of griseofulvin and phenacetin

is directly related to the particle size distributions of these drug.

In case of tablets, size and shape influence the flow and the

mixing efficiency of powders and granules.

Size can also be a factor in stability, fine materials are

relatively more open to attack from atmospheric oxygen, the

humidity and interacting excipients than are coarse materials.

When large differences in size exist between the active com-

ponents and excipients, mutual sieving (de-mixing) effects

can occur making thorough mixing difficult or if attained

difficult to maintain during the subsequent processing steps.

8 ‘TRS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.)

Sr. No. Technique Particle size (am)

(1) _ | Microscopic method 1-100

(2) _| Sieve analysis method >5

(3) Sedimentation method >I

| (4 __| Elutriation method 1-50

(5) Centrifugal method <50

(6) Permeability method >I

(7) Light scattering method 0.5 - 50

Table 1; Common techniques for measuring fine particles of various sizes

(3) Flow properties

During the preformulation of the drug substance, its

flowability characteristic should be studied, especially when

the anticipated dose of the drug is large.

Flow properties are affected by changes in particle size,

density, shape, electrostatic charges, and adsorbed moisture.

The flow properties of powders are critical for an efficient

tableting operation. A good flow of the powder or granulation

to be compressed is necessary to assure efficient mixing and

acceptable weight uniformity for the compressed tablets.

Flow properties of powder can be determine by the parameters

like angle of repose, Hausner’s ratio, Carr’s index and com-

pressibility of any powdered sample.

. Changes in particles size and shape are generally very important

an increase in crystal size or a more uniform shape will lead

to a small angle of repose and a smaller Carr’s index.

(a) Angle of repose :

© The angle of repose can be defined as the constant three

dimensional angle measured relatively to the horizontal base,

assumed by a cone-like pile of material formed when the

powder is passed through a funnel-like container.

Ho

TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) 9

(b)

The maximum angle which is formed between the surface of

pile of powder and horizontal surface is called the angle of

repose.

Angle of repose has been used in the several branches of

science to characterize the flow properties of solids.

Angle of repose is a characteristic related to inter particulate

friction or resistance to movement between particles.

For most pharmaceutical powders, the angle-of repose values

range from 25 to 45°, with lower values indicating better

flow characteristics.

It can be calculated by formula :

Tan 0=h/r

Where,

h = height of heap of pile,

r= radius of base of pile

This method is very simple but has some disadvantages. The

powder experiences segregation, consolidation or aeration,

which influence the cone formation.

Compressibility index :

In recent years the compressibility index has become the

simple, fast and popular methods of predicting powder flow

characteristics. This index measures the tendency of a

powder to consolidate.

The compressibility index has been proposed as an indirect

measure of bulk density, size and shape, surface area, moisture

content and cohesiveness of materials influence the observed

compressibility index.

The compressibility index has an inverse relation with

flowability, i.e. the more compressible is the material the less

flowable it will be.

10 ‘TRS INDUSTRIAL PHARMACY. | (B.Pharm. V SEM)

. The compressibility index calculated using measured value

for bulk density and tapped density as follows :

Tapped density — Bulk density

Compressibility index = —“PP&E CCDS ~ Suk Censity 49

Tapped density

Angle of Carr’s Ha

usner’:

ae Flow ngie o | Compressibility eee

No. repose E ratio

index

(1) | Excellent <25 5-15 1.00-1.11

(2) [Good 25-30 12-16 112-118

(3) | Fair 30-40 18-21 1.19- 1.25

(4) | Poor >40 23 - 35 1.35 - 1.45

(5) | Very poor 56 - 65 33-38 1.46 - 1.59

(6) |Extremely poor} >66 >40 >1.60

Table 2 : Relationship between Flow, Angle of repose, Carr’s index and

Hausner’s Ratio.

(c) Hausner’s ratio :

¢ The Hausner ratio is defined as the ratio between the tapped

density and the bulk density.

* This ratio is a useful measure of cohesion reflecting particle

friction.

* It become the simple, fast, and popular methods of predicting

powder flow characteristics,

* Hausner’s ratio may be calculated using measured value for

bulk density and tapped density as follows :

Tapped density

"Bulk density

(4) Solubility profile (pKa, pH and Partition coefficient) :

° A drug must possess some aqueous solubility for therapeutic

efficacy.

Hausner’s ratio =

‘TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) a

TRS INDUSTRIAL PHARMACY-1(B.Pharm.VSEM) 17

a)

In order for a drug to enter the systemic circulation to exert a

therapeutic effect, it must first be in solution.

We need to perform solubility analysis of a new drug to

provide a basis for later formulation work and can affect drug

performance.

Drugs with an aqueous solubility less than 1 % (10 mg/ml)

will suffer from bioabsorption problems.

Relatively insoluble compounds often exhibit incomplete

absorption.

The approximate solubilities of pharmacopeial and national

formulary substances are indicated by the descriptive terms in

accompanying table.

or Solubility Part of solvent require

No. to soluble part of solute

(1) | Very soluble Less than ]

(2) |Freely soluble From | to 10

(3) |Soluble From 10 to 30

(4) | Sparingly soluble From 32 to 100

(5) | Slightly soluble From 100 to 1000

(6) | Very slightly soluble | From 1000 to 10000

(7) {Insoluble From 10000 to Over

Table 3 : Solubility parameters

Common solvents used for solubility determination are :

Water, Polyethylene Glycols, Propylene Glycol, Glycerin,

Sorbitol, Ethyl Alcohol, Methanol, Benzyl Alcohol, Isopropyl

Alcohol, Tweens, Polysorbates, Castor Oil, Peanut Oil, Sesame

Oil, Buffer at various pHs

Factors affecting the solubility of a drug are :

Temperature,

2

(2)

@)

(4)

(5)

(6)

(a)

TPS INDUSTRIAL PHARMACY- 1(B.Pharm. V SEM.)

Chemical and physical properties of both the solute and the

solvent,

Pressure,

Acidity or basicity of the solution,

State of subdivision of the solute and solvent,

Physical agitation applied to the solution durin

g the dissolving

process etc.

Methods of solubility analysis include :

(1) Solubility determination.

(2) pKa determination.

(3) Partition coefficient.

(4) Dissolution behavior.

(5) Common ion effect.

(6) Membrane permeability.

Methods to improve drug solubility are :

(1) Chemical modification of the drug into salt or ester forms,

(2) Use of a different solubilizing agent,

(3) Use of co-solvents,

(4) Micronization,

(5) Solid dispersion,

(6) Adjustment of the pH of the solvent in which the drug is

to be dissolved etc.

Intrinsic solubility (Co) :

When the purity of the drug sample can be assured the

solubility obtained in acid for a weak acid or alkali for a

weak base can be assured to be the intrinsic solubility (Co)

i.e. the fundamental solubility when completely unionized.

An increase in solubility in acid compared to aqueous solubility

suggests a weak base and an increase in alkali, a weak acid.

An increase in acidic and alkaline solubility suggests either

impotence or zwitter ion behaviour.

TPS

‘TPS INDUSTRIAL PHARMACY. | (B.Pharm. V SEM.) 13

Q)

Q)

(b)

In this case there will be two pKa’s, one acidic and one basic.

The intrinsic solubility should be measured at two temperature :

4 to 5°Cto ensure good physical stability and to extend short

term storage and chemical stability until more definite data is

available.

37° Cto support biopharmaceutical evaluation. The solubility

of weakly acidic and weakly basic drug as function of pH can

be predicted with help of equation.

S =So {1 + (K1/[H+])} For weak acids.

S = So {1 + ({H+]/K2)} For weak base.

Where, S = solubility at given pH.

So = intrinsic solubility of neutral form.

K1 = dissociation constant for the weak acid.

K2 = dissociation constant for weak base.

pH and Ionization Constant (pKa) :

Determination of dissociation constant for a drug capable of

ionization with in a pH range of 1 to 10 is important since

solubility, consequently absorption, can be changed by changing

in pH.

Many drugs are either weakly acidic or basic compounds and

in solution, depending on the pH value, exist as ionized or

un-ionized species.

Knowledge of their individual ionization or dissociation

characteristics is important, because their absorption is governed

to a large extent by their degrees of ionization as they are

presented to the membrane barriers.

The degree of a drug's ionization depends both on the pH of

the solution in which it is presented to the biologic membrane

and on the pKa, or dissociation constant of the drug (whether

an acid or base).

vex}

14

qd)

Q)

G3)

TPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM)

The unionized species are more lipid soluble and hence more

readily absorbed.

The gastrointestinal absorption of weakly acidic or basic

drugs is thus related to the fraction of the drug in solution that

is unionized.

The conditions that suppress ionization favor absorption.

The factors that are important in the absorption of weakly

acidic and basic compounds are :

The pH at the site of absorption,

The ionization constant and

The lipid solubility of the unionized species.

These factors together constitute the widely accepted pH

partition theory.

The relative concentrations of un-ionized and ionized forms

of a weakly acidic or basic drug in a solution at a given pH

can be readily calculated using the Henderson-Hasselbalch

equations.

For Bases, pH = pKa + log [Wnionized form]

[lonized form]

For Acids, pH = pKa + log _Llonized form] _

Unionized form]

Weakly acidic compounds (pKa < 4.3) were absorbed relatively

rapidly. Those with pKa values ranging between 2.0 and 4.3

were absorbed more slowly; and strong acids (pKa > 2.4)

were hardly absorbed.

For bases, those with pKa values smaller than 8.5 were

absorbed relatively rapidly; those with a pK a between 9 and

12 were absorbed more slowly; and completely ionized

quaternary ammonium compounds were not absorbed.

qa)

2)

GB)

(4)

qd)

Q)

@)

(4)

‘FPS INDUSTRIAL PHARMACY- | (B.Pharm. V SEM.) 15

NB Pharm VSEM)

The pKa value is the PH at which acidic or basic groups

attached to molecules exist as 50% ionized and 50%

nonionized in aqueous solution.

The pKa value provides valuable data on the interaction of an

ionizable drug with charged biological membranes and

Teceptor sites and information on where the drug may be

absorbed in the digestive tract.

Knowing the pKa also enables the scientist to know how

much to alter the pH to drive a compound to its fully ionized

or nonionized form for analytical and other purposes, such as

formulation, solubility and stability.

If the drug dissolves too early, it may reprecipitate in a form

that is poorly absorbed. Determination of the dissociation

content for a drug capable of ionization within a pH rang of

1 to 10 is important since solubility and consequently absorption,

cab be altered by orders of magnitude with changing pH.

Determination of pKa :

Potentiometric titration.

Spectrophotometric determination.

Dissolution rate method.

Liquid-Liquid partition method.

Significances :

Provided that the intrinsic solubility and pKa are known, the

solubility at any pH can be predicted.

Henderson equations can facilitate the selection of suitable

salt forming compounds and predict salt’s solubility.

Determination of the ratio of the ionized to the unionized

form of a drug molecule.

This is useful to predict which form will predominate at

different Physiologic pH.

va AY

16

(5)

(c)

TRS INDUSTRIAL PHARMACY. | (B.Pharm. V SEM)

The pKa will determine the species of molecules, which is

likely to be present at the site of action and how quickly or

completely would the species cross a large number of transport

barriers in the body, regardless of the route of administration,

Partition coefficient :

It is also known as distribution coefficient and is essentially

independent of concentration of dilute solutions of a given

solute species.

The oil/water partition coefficient is a measure of a molecule’s

lipophilic characters that is, its preference for the hydrophilic

or lipophilic phase.

Ifa solute is added to a mixture of two immiscible liquids, it

will distribute between the two phases and reach equilibrium

at a constant temperature.

The distribution of the solute (un-aggregated and un-dissociated)

between the two immiscible layers can be described as

follows : it is the ratio of the unionized drug distributed

between the organic (upper phase) and aqueous (lower)

phases at equilibrium.

The lipophilicity of an organic compound is usually described

in terms of a partition coefficient; log P, which can be

defined as the ratio of the concentration of the unionized

compound, at equilibrium, between organic and aqueous

phases :

Log P= [Unionized compound] Org.

(Unionized compound] Ags.

Log P = 0 means that the compound is equally soluble in

water and in the partitioning solvent.

If the compound has a log P = 5, then the compound is

100,000 times more soluble in the partitioning solvent.

Deny

‘TPS INDUSTRIAL PHARMACY. | (B.Pharm. V SEM.) aL

FES INDUSTRIAL PHARMACY-I(B.Pharm.VSEM) 17.

qa)

Q)

@)

(4)

6)

(6)

a)

Q)

(3)

(4)

6)

(6)

)

A log P = — 2 means that the compound is 100 times more

soluble in water, i.e., it is quite hydrophilic.

Drugs having values of P much greater than | are classified

as lipophilic, whereas those with partition coefficients much

less than 1 are indicative of a hydrophilic drug.

Although it appears that the partition coefficient may be the

best predictor of absorption rate, the effect of dissolution rate.

Various organic solvents such as chloroform, ether, amyl

acetate, isopropylmyristate, carbon tetrachloride, and n -

Octanol can be used in the determination of the partition

coefficient, with the latter gaining increasing acceptance.

Determination of partition coefficient :

Shake-flask method

Chromatographic method.

Countercurrent and filter probe method.

Tomlinson’s filter probe method.

Micro electrometric titration method.

Automated instrument is now available.

Applications of partition coefficient :

Recovery of antibiotics from fermentation broth.

Extraction of drug from biological fluid for therapeutic

monitoring.

Absorption of drug from dosage forms. (Ointments, Supp-

ositories, Transdermal patches).

Study of distribution of flavoring oil between oil and water in

emulsion.

It does provide a means of characterizing the lipophilic /

hydrophilic nature of the drug.

It is a contributing factor for the rate and extent of drug

absorption.

Measure of Lipophilic character of molecules.

e-Ay

(i)

(ii)

‘TRS INDUSTRIAL PHARMACY: I (B.Pharm. V SEM,

Polymorphism :

Polymorphism is the ability of a compound to crystallize ag

more than one distinct crystalline species with different

internal lattices or crystal packing arrangement even they are

chemically identical depending on the variation in;

(a) Temperature

(b) Solvent

(c) Time

They have different physicochemical properties (melting point,

density, vapor pressure, X-ray, color, crystal shape, hardness,

solubility, dissolution rate and bioavailability).

Differences in the dissolution rates and solubilities of different

polymorphic forms of a given drug are very commonly

observed.

When the absorption of a drug is dissolution rate limited, a

more soluble and faster-dissolving from may be utilized to

improve the rate and extent of bioavailability.

During preformulation, it is important to identify the

polymorph that is stable at room temperature.

For Ex. Chloromphenicol exist in A, B and C forms, of

these B form is more stable and most preferable.

For Ex. Riboflavin has I, II and III forms and the III form

shows 20 times more water solubility than form I.

Polymorphisms are of two types :

Enantiotropic : Enantiotropic polymorphisms can be reversely

changed into another by varying temperature and pressure.

E.g. Sulphur, Carbon, Nitrogen and Oxygen.

Monotropic polymorphism : polymorph is unstable at all

temperature and pressure.

E.g. Glyceryl stearate.

pak

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Industrial Pharmacy II PDFDocument113 pagesIndustrial Pharmacy II PDFnileshmpharm69% (32)

- Evaluation of Disinfectants PD II YrDocument5 pagesEvaluation of Disinfectants PD II YrSayyeda SumaiyahNo ratings yet

- Sources of Contamination and PreventionDocument4 pagesSources of Contamination and PreventionSayyeda SumaiyahNo ratings yet

- Disinfectants PD IIDocument4 pagesDisinfectants PD IISayyeda SumaiyahNo ratings yet

- StainingDocument8 pagesStainingSayyeda SumaiyahNo ratings yet

- FungiDocument2 pagesFungiSayyeda SumaiyahNo ratings yet

- Prokaryotes EukaryotesDocument4 pagesProkaryotes EukaryotesSayyeda SumaiyahNo ratings yet

- Bactericidal TestDocument2 pagesBactericidal TestSayyeda SumaiyahNo ratings yet

- Selective Differential MediaDocument5 pagesSelective Differential MediaSayyeda SumaiyahNo ratings yet

- Viable & Total CountDocument7 pagesViable & Total CountSayyeda SumaiyahNo ratings yet

- Maintenance of Lab CulturesDocument2 pagesMaintenance of Lab CulturesSayyeda SumaiyahNo ratings yet

- Blockchain The India Strategy Part I 2Document5 pagesBlockchain The India Strategy Part I 2Sayyeda SumaiyahNo ratings yet

- Double Neural Bypass Poster InfoDocument3 pagesDouble Neural Bypass Poster InfoSayyeda SumaiyahNo ratings yet

- Electron MicrosDocument1 pageElectron MicrosSayyeda SumaiyahNo ratings yet

- Blockchain Technology-1Document24 pagesBlockchain Technology-1Sayyeda SumaiyahNo ratings yet

- MicrosDocument5 pagesMicrosSayyeda SumaiyahNo ratings yet

- Solubility of DrugsDocument33 pagesSolubility of DrugsSayyeda SumaiyahNo ratings yet

- Faiza 2nd Poster PresentationDocument1 pageFaiza 2nd Poster PresentationSayyeda SumaiyahNo ratings yet

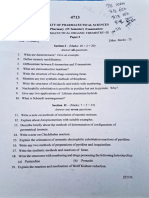

- Previous Year Q PapersDocument32 pagesPrevious Year Q PapersSayyeda SumaiyahNo ratings yet

- DNB Final 1Document1 pageDNB Final 1Sayyeda SumaiyahNo ratings yet

- Cog 2 TPS SeriesDocument315 pagesCog 2 TPS SeriesSayyeda SumaiyahNo ratings yet

- Human Brain (Mini Project) FNLDocument35 pagesHuman Brain (Mini Project) FNLSayyeda SumaiyahNo ratings yet

- CAR T Cell Immunotherapy For Human CancerDocument1 pageCAR T Cell Immunotherapy For Human CancerSayyeda SumaiyahNo ratings yet

- Col TPS SeriesDocument423 pagesCol TPS SeriesSayyeda SumaiyahNo ratings yet