Professional Documents

Culture Documents

Shaft Classification and Excecise Problem

Shaft Classification and Excecise Problem

Uploaded by

AyushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft Classification and Excecise Problem

Shaft Classification and Excecise Problem

Uploaded by

AyushCopyright:

Available Formats

Shaft:

A shaft is a rotating or stationary member, usually of circular cross-section, having

mounted upon it such elements as gears, pulleys, flywheels, cranks, sprockets and other power-

transmitting elements. The shafts are relatively long and may be subjected to bending, tension,

compression or torsional loads, acting singly or in combination with one another. When they

are combined, one may expect to find both static and fatigue strengths to be important design

consideration, since a single shaft may be subjected to static stresses, completely reversed

stresses and repeated stresses, all acting at the same time.

a) Transmission shaft – It is used to transmit power between the power source and the

machines absorbing power. It is generally subjected to torque, bending moment and

axial load in combination e.g. line shaft, counter shaft, head shaft and all factory shafts.

b) Machine shaft – It is integral part of a machine. It is used to transfer motion and power

within the machine e.g. crank shaft, gear shaft.

c) Axle – It is a stationary or rotating shaft. It does not carry any torsional load. It is

subjected to bending moment due to transverse load only. It is used to support rotating

parts e.g. axles of automobiles.

d) Spindle – It is a short rotating shafts used to impart motion either to cutting tool or work

piece e.g. lathe spindle, drill press spindle.

Materials: Commonly adopted materials are mild steel. In addition, different types of alloy

steels are also used for shafts, depending on situation and types of application.

Deflection restraints: δ = L/1200, where δ and L are maximum transverse deflection of the

shaft and length of shaft between bearing supports respectively.

Twist restraint: Maximum twist is 2.5-3.5 degree per meter of shaft length for line shaft. It is

with 0.25 degree per meter of machine shaft.

Problem:

A solid horizontal steel shaft is to run in self-aligning bearings A and B, 2500mm apart.

The shaft is driven from the right of right-hand bearing with an electric motor. The power is

supplied to a machine from the shaft through a 500-mm diameter pulley, mounted on the shaft

with a rectangular key at 1200mm from the left-hand bearing. The belt tensions are 1800N and

840N and they are parallel to each other and at 64O to the horizontal. The weight of the pulley

is 500N. Determine the diameter of the shaft.

Use the following data:

Material = FeE 200; Factor of safety = 2.5;

Combined shock and fatigue factor for bending = 1.6;

Combined shock and fatigue factor for torsion = 1.2;

Allowable tensile stress for key material = 120MPa

You might also like

- CSWIP 3.1 - Welding Inspector WIS5 (2017)Document699 pagesCSWIP 3.1 - Welding Inspector WIS5 (2017)reezman96% (70)

- 69052Document53 pages69052amdevaNo ratings yet

- DME Unit 2 Design of Machine Elements - Shaft IntroDocument10 pagesDME Unit 2 Design of Machine Elements - Shaft IntrorenoldelsenNo ratings yet

- Shaft Design and Its ApplicationDocument19 pagesShaft Design and Its ApplicationAli MahmoudNo ratings yet

- Maintain and Repair Mechanical Drives and Transmission AssembliesDocument141 pagesMaintain and Repair Mechanical Drives and Transmission AssembliesMelku Abebe100% (1)

- Addis Ababa Science & Technology University Department of Electromechanical EngineeringDocument28 pagesAddis Ababa Science & Technology University Department of Electromechanical EngineeringMitiku AbebeNo ratings yet

- Machine Elements Design MEC212 - LEC 9Document23 pagesMachine Elements Design MEC212 - LEC 9maxmark02uNo ratings yet

- Introduction To ShaftsDocument10 pagesIntroduction To Shaftsसुमित शर्माNo ratings yet

- Transmission of Motion and PowerDocument15 pagesTransmission of Motion and PowerAbhijit DeyNo ratings yet

- BMe)Document23 pagesBMe)Furqan KhanNo ratings yet

- Chapter One: Shaft and Shaft ComponentDocument20 pagesChapter One: Shaft and Shaft ComponentAndlnatu TDNo ratings yet

- ShaftdesignlecDocument10 pagesShaftdesignlecTalha AbbasiNo ratings yet

- Kinematics of Machine ToolsDocument28 pagesKinematics of Machine ToolsRohit Kaushik100% (6)

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDocument93 pagesMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNo ratings yet

- Shaft 2013Document23 pagesShaft 2013Rinardi SoetjiptoNo ratings yet

- Scriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Document2 pagesScriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Vivek MishraNo ratings yet

- Elements of Power Transmission - 220308 - 154853Document14 pagesElements of Power Transmission - 220308 - 154853Dhruvi PadmaniNo ratings yet

- Name: Joudat Bilal Reg Number: BME 173083 Section:02 Machine Design and CAD-1 DATE: December 30, 2019Document5 pagesName: Joudat Bilal Reg Number: BME 173083 Section:02 Machine Design and CAD-1 DATE: December 30, 2019Bill 007No ratings yet

- Shaft DesignDocument73 pagesShaft Designmeenakumari05No ratings yet

- UNIT - 1.1 Shafts, Keys, Coupling and BearingDocument75 pagesUNIT - 1.1 Shafts, Keys, Coupling and BearingJeetender Mishra100% (1)

- Module 2 Design of ShaftsDocument3 pagesModule 2 Design of Shaftsjhoannachristinelou.perezNo ratings yet

- ShaftsDocument33 pagesShafts20BME011 HARSHIT GUPTANo ratings yet

- Transmission of Motion and PowerDocument62 pagesTransmission of Motion and PowerVishith ReddyNo ratings yet

- Shaft CalcDocument6 pagesShaft CalcAkshay JadhavNo ratings yet

- Coupling - WikipediaDocument40 pagesCoupling - WikipediaManojkumarNo ratings yet

- Shaft DesignDocument16 pagesShaft DesignOgunsina AdebayoNo ratings yet

- Machine Design PresentaionDocument24 pagesMachine Design PresentaionAwais RaoNo ratings yet

- Zadaća 11Document1 pageZadaća 11AdmiirNo ratings yet

- Machine Design 4Document3 pagesMachine Design 4birhanutaye427No ratings yet

- Report About Summer Training 1Document23 pagesReport About Summer Training 1man330055No ratings yet

- ACFrOgCBbUzWbifi3HUd2hlv2jClqW1h-MLkfgt7 ek4q4UNn-Lf6zxYt7xUcFMyudSogv6iFTQj76J0WFOChJEeD9Ls5XnmhkehuXoNULGMspr3hsaJCXlYtUi4dYD oMG3j3t1tYtdWZD7Jc2oDocument33 pagesACFrOgCBbUzWbifi3HUd2hlv2jClqW1h-MLkfgt7 ek4q4UNn-Lf6zxYt7xUcFMyudSogv6iFTQj76J0WFOChJEeD9Ls5XnmhkehuXoNULGMspr3hsaJCXlYtUi4dYD oMG3j3t1tYtdWZD7Jc2oShriparno deyNo ratings yet

- Chapter 2 Notes - BME - May - 2023Document49 pagesChapter 2 Notes - BME - May - 2023gamingendless003No ratings yet

- Design Aspects and Parametric Study of 3-Roll Heavy-Duty Plate-Bending MachinesDocument14 pagesDesign Aspects and Parametric Study of 3-Roll Heavy-Duty Plate-Bending Machinesjuan carlos molano toroNo ratings yet

- Desig of Shaft, Keys and CouplingsDocument24 pagesDesig of Shaft, Keys and CouplingsDnyaneshwar AkhareNo ratings yet

- Mbeya University of Science and TechnologyDocument37 pagesMbeya University of Science and TechnologySadikiel100% (1)

- Multiwheel Nut Removal N TightnerDocument11 pagesMultiwheel Nut Removal N TightnerAnonymous D5g37JjpGB88% (8)

- Shaft Design1Document23 pagesShaft Design120pwmct0739No ratings yet

- Welcome IN Sem Ii: by Prof. N. S. SurnerDocument95 pagesWelcome IN Sem Ii: by Prof. N. S. SurnerBalamuruganNo ratings yet

- Chapter OneDocument28 pagesChapter OneAbyot yassabNo ratings yet

- Parts of A DC GeneratorDocument7 pagesParts of A DC GeneratorRolen GeocadinNo ratings yet

- DynamometersDocument19 pagesDynamometersBhukya Reethvik RathodNo ratings yet

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- Term PaperDocument23 pagesTerm PaperAman Goyal (B19ME004)No ratings yet

- Lab 1Document8 pagesLab 1Mansoob BukhariNo ratings yet

- 2.1. Theory of Hoisting Equipment Classification Is Based On Various Characteristics Such As Movement and PurposeDocument54 pages2.1. Theory of Hoisting Equipment Classification Is Based On Various Characteristics Such As Movement and Purposeahmed jemalNo ratings yet

- LatheDocument6 pagesLatheBINAYAK DATTA ROYNo ratings yet

- ME374 Module 2Document57 pagesME374 Module 2Christian Breth BurgosNo ratings yet

- GearsDocument3 pagesGearspritamjyotideka909No ratings yet

- Dme Unit V (17.11.22)Document16 pagesDme Unit V (17.11.22)sathiaNo ratings yet

- Qualitative of Machine Component DesignDocument22 pagesQualitative of Machine Component DesignRicky YeohNo ratings yet

- ReportDocument25 pagesReport9897856218No ratings yet

- Crank Shaft Operated Multi Blade HacksawDocument15 pagesCrank Shaft Operated Multi Blade HacksawTanvi Khurana100% (2)

- Power TransmissionDocument39 pagesPower Transmissioneldhopaul19894886No ratings yet

- Unit 2-At6402 Automotive ChassisDocument20 pagesUnit 2-At6402 Automotive ChassisSathis KumarNo ratings yet

- Glossary of Motor Terms LMRDocument20 pagesGlossary of Motor Terms LMRKOBE LKONo ratings yet

- Bobillo PogiDocument2 pagesBobillo PogiArjade GormeNo ratings yet

- Power Transmission PDFDocument89 pagesPower Transmission PDFKumar Rajesh85% (54)

- UNIT 12, EnglishDocument3 pagesUNIT 12, EnglishBerina DelicNo ratings yet

- List of Material For SpringDocument8 pagesList of Material For SpringPatranNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Ssab Astm A537 C2Document2 pagesSsab Astm A537 C2vasotermiNo ratings yet

- A Novel Four-Arm Planar Spiral Antenna For GNSS ApplicationDocument8 pagesA Novel Four-Arm Planar Spiral Antenna For GNSS ApplicationRifaqat HussainNo ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- Sistema Eléctrico 4RCDocument2 pagesSistema Eléctrico 4RCAlejandro HcNo ratings yet

- Laboratory Manual For Refractive Index of Prism Using A SpectrometerDocument8 pagesLaboratory Manual For Refractive Index of Prism Using A SpectrometerShubhamNo ratings yet

- CE11P2E Set1Document17 pagesCE11P2E Set1Hmt1167 HoNo ratings yet

- Lecture 9 29 11 2022Document5 pagesLecture 9 29 11 2022owronrawan74No ratings yet

- Electrical Safety Analyzer: User ManualDocument28 pagesElectrical Safety Analyzer: User ManualJuan Diego Sierra TiradoNo ratings yet

- PresentationDocument36 pagesPresentationapi-3834081100% (1)

- Table of Specification 9.4Document2 pagesTable of Specification 9.4Promise SalvatieraNo ratings yet

- Smart Timer Manual ME 8930Document40 pagesSmart Timer Manual ME 8930Moises JustavinoNo ratings yet

- Optical Signal ProcessingDocument38 pagesOptical Signal Processingsujay pujariNo ratings yet

- Uc Davis Thesis FormatDocument7 pagesUc Davis Thesis Formatmonicaturnercolumbia100% (1)

- Dreiding Stereomodels: Technical BulletinDocument2 pagesDreiding Stereomodels: Technical BulletinAlberto JimenezNo ratings yet

- Dredge Discharge DensityDocument7 pagesDredge Discharge Densityrodel lauronNo ratings yet

- NeoCryl B-736 PdsDocument2 pagesNeoCryl B-736 PdsLeandro EsvizaNo ratings yet

- Design of A High Precision Falling Ball Viscometer: Matthieu Brizard, Mohamed Megharfi, Claude Verdier, Eric MahéDocument14 pagesDesign of A High Precision Falling Ball Viscometer: Matthieu Brizard, Mohamed Megharfi, Claude Verdier, Eric MahéKarina MesaNo ratings yet

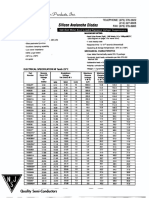

- 1N56 Series: Silicon Avalanche DiodesDocument2 pages1N56 Series: Silicon Avalanche DiodesabolfazlNo ratings yet

- WT045CDocument2 pagesWT045CDewa BayuNo ratings yet

- Food Science and Human WellnessDocument14 pagesFood Science and Human WellnessaleezaNo ratings yet

- Lec # 9 V-Belt DriveDocument46 pagesLec # 9 V-Belt DriveEl LordNo ratings yet

- Abstract Algebra by Rashid AliDocument274 pagesAbstract Algebra by Rashid Alisaba nazNo ratings yet

- Soil NoteDocument13 pagesSoil NoteBhuwan JoshiNo ratings yet

- Four Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetDocument1 pageFour Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetSha Sameer NizamiNo ratings yet

- Datasheet SMA 05 Ha7212 ENDocument18 pagesDatasheet SMA 05 Ha7212 ENNéstor LárezNo ratings yet

- Newton-Raphson Method To Solve Load Flow Equation in Power SystemDocument8 pagesNewton-Raphson Method To Solve Load Flow Equation in Power SystemNazmul IslamNo ratings yet

- Chemical Structures and Performance of Perovskite OxidesDocument38 pagesChemical Structures and Performance of Perovskite OxidesDobrescuMariusNo ratings yet

- Mechanics of Fluids Unit 3 Fluid DynamicDocument59 pagesMechanics of Fluids Unit 3 Fluid DynamicĐạt Vũ HữuNo ratings yet

- Steinmetz Circuit Influence On The Electric System Harmonic ResponseDocument8 pagesSteinmetz Circuit Influence On The Electric System Harmonic ResponseLuis Angel Garcia ReyesNo ratings yet