Professional Documents

Culture Documents

ETP 100 KLD Green Way India Raipur 04.07.2023

ETP 100 KLD Green Way India Raipur 04.07.2023

Uploaded by

Ravpreet SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETP 100 KLD Green Way India Raipur 04.07.2023

ETP 100 KLD Green Way India Raipur 04.07.2023

Uploaded by

Ravpreet SinghCopyright:

Available Formats

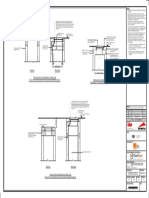

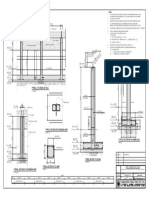

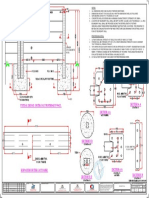

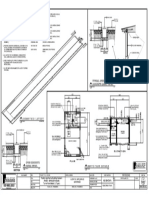

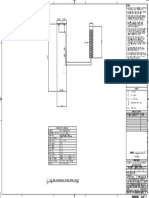

NOTES:-

1. ALL DIMENSIONS ARE IN MM.

2. DIMENSIONS ARE NOT TO BE SCALED. ONLY WRITTEN DIMENSIONS

ARE TO BE FOLLOWED.

3. WALL FACES AND BASE FLOOR OF THE TANKS SHOULD BE TREATED

WITH WATERPROOFING CHEMICALS TO AVOID SEEPAGE.

2100 2250 4. DRAINAGE POINT MUST BE PROVIDED FOR REACTION TANK, CHEMICAL

TANK AND TREATED TANK TO PROVIDE CLEANING FACILITY. LEVEL OF

2000 DRAINAGE POINT SHALL BE TAKEN 100 MM ABOVE FROM THE FINISHED

FACE OF BASE SLAB OF THE TANKS.

G.L. G.L. G.L. 5. INLET LEVEL OF BAR SCREEN CHAMBER WILL BE IN ACCORDANCE

INLET INLET EFFLUENT LINE COMING FROM PLANT.

6. INLET LEVEL OF OIL & GREASE TANK SHOULD BE 50 MM DOWN FROM

ELEVATION THE INLET LEVEL OF BAR SCREEN CHAMBER.

7. INLET LEVEL OF COLLECTION TANK 50 MM DOWN FROM THE INLET

LEVEL OIL & GREASE TANK.

8. INLET LEVEL OF CHEMICAL TANK SHOULD BE 50 MM DOWN FROM

2500 2500 INLET LEVEL OF REACTION TANK.

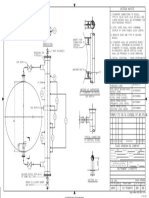

S.N. NOMANCLATURE NAME OF COMPONENTS S.N. DESCRIPTION OF TANKS: SIZE ( IN MTR.) CAPACITY 4000 3000 9. INLET LEVEL OF TUBE SETTLER TANK SHOULD BE 50 MM DOWN FROM

W H L (KL) INLET LEVEL OF CHEMICAL TANK.

1. ELP EFFLUENT LIFT PUMP

10. INLET LEVEL OF FILTER FEED TANK SHOULD BE 50 MM DOWN FROM

1. BAR SCREEN CHAMBER

2. FFP FILTER FEED PUMP 1.0 1.0 2.0 2.0 INLET LEVEL OF TUBE SETTLER TANK.

2. OIL & GREASE TANK 11. OVER FLOW PIPES FOR GRAVITY FLOW IN EACH TANKS WILL BE OF 100

3. MGF MULTI GRADE FILTER MM DIA.

3. COLLECTION TANK 5.0 2.5 4.0 50.0

4. ACF ACTIVATED CARBON FILTER 12. SEPARATION WALL OF TUBE SETTLER TANK WILL BE 200 MM THICK &

4. REACTION TANK 2.0 2.25 2.25 10.0 AT A DISTANCE OF 200 MM FROM CHEMICAL TANK OUTLET WALL.

5. DP DOSING PUMP

5. CHEMICAL TANK 2.0 2.20 2.30 10.0 RCC SLAB 13. PP/PVC FOOT STEPS TO BE USED AS LADDER IN COLLECTION TANK.

6. TUBE SETTLER TANK 2.0 1.7 3.0 10.0 SAND FILLING SECTION B-B

7. FILTER FEED TANK 2.4 2.1 2.0 10.0 MOORUM FILLING VARING DEPTH CLIENT DETAIL

8. TREATED TANK 2.0 2.5 2.0 10.0

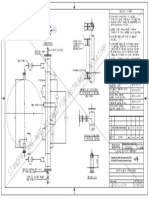

9. SLUDGE DRYING BED 2.0 1.0 1.0 2.0 SECTION A-A INLET

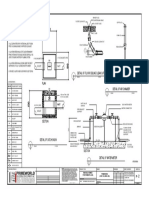

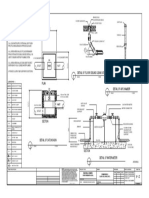

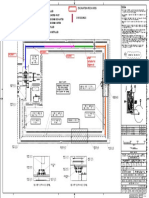

G.L. PROJECT TITLE

B

ETP 100 KLD

1000

550 DESIGNED BY:

SANDESH

1150

550

750

VENDOR:

4 5 4 5 6 GREEN WAY INDIA, RAIPUR

9 9

6 A A

C

SECTION C-C

1 1 DP1DP2

DRAIN

DP3

DRAIN

E.L.P. POINT BLOWERS POINT

7 7

F.F.P

F.F.P

2 2

MGF ACF

MGF ACF

C

3 3

8 8

POINT

DRAIN

B

UNDERGROUND FLOOR PLAN

ABOVE THE GROUND FLOOR PLAN

You might also like

- Grab Handholds: Sectional Plan Top PlanDocument1 pageGrab Handholds: Sectional Plan Top PlanAbdelmoneimNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- QP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementDocument1 pageQP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementnawajhaNo ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- B-H110978004V00 Fa Miscellaneous DetailsDocument1 pageB-H110978004V00 Fa Miscellaneous DetailsAnonymous X3PnFL6No ratings yet

- Warf Wall (Cutting Section)Document1 pageWarf Wall (Cutting Section)soumodip SahaNo ratings yet

- Eds 07 3102 50 Plinth Design For Freestanding 6 8 Way LV Pillars 1Document2 pagesEds 07 3102 50 Plinth Design For Freestanding 6 8 Way LV Pillars 1Umerfarooq TawriNo ratings yet

- Tpl-Yiapl-Ph1&2-An-27 R0Document1 pageTpl-Yiapl-Ph1&2-An-27 R0Ramesh BabuNo ratings yet

- BR 30 StrengtheningDocument1 pageBR 30 Strengtheningdesign MridcNo ratings yet

- Legend:: Service EntranceDocument1 pageLegend:: Service EntranceRODEAN HOPE LACSINo ratings yet

- Pl-Herbert Yu-P-1 PDFDocument1 pagePl-Herbert Yu-P-1 PDFSoy DesignoNo ratings yet

- Kenneth1 - 1Document6 pagesKenneth1 - 1Timothy TuviNo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesRODEAN HOPE LACSINo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesHana YeppeodaNo ratings yet

- Dpw-1 Retaining Wall 1028' RFTDocument1 pageDpw-1 Retaining Wall 1028' RFTM JAVEDNo ratings yet

- CCA-CPFa EMBANKMENT WALK WAY STAIRCASEDocument1 pageCCA-CPFa EMBANKMENT WALK WAY STAIRCASEElizabeth KansiimeNo ratings yet

- Structural Drawings Extension LondonDocument1 pageStructural Drawings Extension LondonVlad CiupituNo ratings yet

- DRNG No - 4 Footing BeamDocument1 pageDRNG No - 4 Footing BeamAjay KunduNo ratings yet

- Etp 29.05.2023Document1 pageEtp 29.05.2023Ravpreet SinghNo ratings yet

- Etp 40 KLD 29.05.2023Document1 pageEtp 40 KLD 29.05.2023Ravpreet SinghNo ratings yet

- Electrical Drawing 3359602 Electrical DrawingDocument3 pagesElectrical Drawing 3359602 Electrical Drawingyasrig2No ratings yet

- Column ND Footing DetailsDocument1 pageColumn ND Footing Details025Karthik ReddyNo ratings yet

- 07section AADocument1 page07section AAShane BiliNo ratings yet

- Collector DrawingsDocument2 pagesCollector DrawingsMohammad ShayanNo ratings yet

- WDD First Floor Plaster-ELEVATIONS-Layout1Document1 pageWDD First Floor Plaster-ELEVATIONS-Layout1Aaron lisboaNo ratings yet

- WDD First Floor Plaster-Layout1Document1 pageWDD First Floor Plaster-Layout1Aaron lisboaNo ratings yet

- Second & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLDocument1 pageSecond & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLSarvang PandyaNo ratings yet

- Dome Slab Detail R1Document1 pageDome Slab Detail R1dipesh sharmaNo ratings yet

- Saudi Arabian Oil Company: Co2 Fire Suppression System Piping LayoutDocument1 pageSaudi Arabian Oil Company: Co2 Fire Suppression System Piping Layoutsaleem shahidNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- Legend Notes and Specifications: Plumbing Layout PlanDocument1 pageLegend Notes and Specifications: Plumbing Layout PlanRod NajarroNo ratings yet

- 1002016-0100-DRG-CC-0003 Typical Details Pipe Marker DetailDocument1 page1002016-0100-DRG-CC-0003 Typical Details Pipe Marker Detailhexiaogang167No ratings yet

- DHP As Built Fire Protection FP 01 - 16 Dec 2022Document1 pageDHP As Built Fire Protection FP 01 - 16 Dec 2022Angelo EndozoNo ratings yet

- 1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)Document1 page1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)rohanZorbaNo ratings yet

- MHJ Rooftop Vanity 19.12.23Document14 pagesMHJ Rooftop Vanity 19.12.23Michael MogakaNo ratings yet

- Anthony Wanjiku Revised StructuralDocument1 pageAnthony Wanjiku Revised Structuralpatrickmore09No ratings yet

- Gate ElevationDocument1 pageGate Elevationno oneNo ratings yet

- R03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Document1 pageR03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Eleazar SacloloNo ratings yet

- (Indicative Only - Package Provided by Others) : NotesDocument1 page(Indicative Only - Package Provided by Others) : NotesIskandar HasibuanNo ratings yet

- Typical Detail of Pre-Cast Boundary Wall Section A-A Section A-ADocument1 pageTypical Detail of Pre-Cast Boundary Wall Section A-A Section A-AManupriya KapleshNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- Footing Schedule Column Schedule: WF-O1 C1Document1 pageFooting Schedule Column Schedule: WF-O1 C1Bj GutierrezNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Storm Water ManagementDocument1 pageStorm Water ManagementmmceplNo ratings yet

- HPC 2x1000Document1 pageHPC 2x1000Shivam SharmaNo ratings yet

- JERSD J 0071 Instrument StandpipesDocument1 pageJERSD J 0071 Instrument StandpipescesarvalenciaperdomoNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Design: Construction NotesDocument1 pageDesign: Construction NotesLhea May Paz SarguetNo ratings yet

- 32 Oakleigh Way - Drainage - Assessment-X9Document1 page32 Oakleigh Way - Drainage - Assessment-X9Juan Carlos Gaxiola ReinholdNo ratings yet

- U32 - HCIS Cat. IIDocument1 pageU32 - HCIS Cat. IImohan sirNo ratings yet

- CHB Perimeter Wall 1ADocument1 pageCHB Perimeter Wall 1Aleanne DespaNo ratings yet

- Septic Tank DetailsDocument1 pageSeptic Tank DetailsdeanNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesWaqarNo ratings yet

- Annex 7 - Structural - Stamped Structural DrawingsDocument15 pagesAnnex 7 - Structural - Stamped Structural Drawingsjema; belihuNo ratings yet

- T1 - Storm Water Drain With Manhole ShaftDocument4 pagesT1 - Storm Water Drain With Manhole ShaftMirNo ratings yet

- D 1855 PDFDocument1 pageD 1855 PDFManikandan VNo ratings yet

- Box Bed Final 2Document1 pageBox Bed Final 2Vishakha MaratheNo ratings yet

- Automatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50Document1 pageAutomatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50nawajhaNo ratings yet

- PH.D Admission July-Dec 2022 - 06!05!22-2Document8 pagesPH.D Admission July-Dec 2022 - 06!05!22-2Ravpreet SinghNo ratings yet

- C/C of Bearing: South East Central RailwayDocument1 pageC/C of Bearing: South East Central RailwayRavpreet SinghNo ratings yet

- Structure of Bridge. No. 3Document1 pageStructure of Bridge. No. 3Ravpreet SinghNo ratings yet

- Pile DesignDocument8 pagesPile DesignRavpreet SinghNo ratings yet

- Series PWC: Pure WaterDocument3 pagesSeries PWC: Pure WaterWattsNo ratings yet

- Contour Trenches NEWDocument33 pagesContour Trenches NEWrkjaiswal.nihNo ratings yet

- Castrol MHP 154 2020Document7 pagesCastrol MHP 154 2020fidan muradovaNo ratings yet

- Roadway Lighting: Technical Special ProvisionsDocument59 pagesRoadway Lighting: Technical Special ProvisionsJaka Sembung Golok100% (1)

- Membrane Filtration of Manure WastewaterDocument38 pagesMembrane Filtration of Manure Wastewaterpedro41No ratings yet

- MANUAL - Drainage Design ManualDocument89 pagesMANUAL - Drainage Design ManualAnnahuynhNo ratings yet

- Earthscience, PPTDocument12 pagesEarthscience, PPTAlaisa Claire Dela TorreNo ratings yet

- Dr. Iqbal BhuiyanDocument4 pagesDr. Iqbal BhuiyanMd. Juwel MondolNo ratings yet

- The Philippine Clean Water Act of 2004 TalagaDocument61 pagesThe Philippine Clean Water Act of 2004 Talagapaolojaspiras100% (1)

- Industrial Waste TreatmentDocument26 pagesIndustrial Waste TreatmentthannuhNo ratings yet

- 22 Principles of Plumbing From The Revised National Plumbing Code of The Philippines PDFDocument2 pages22 Principles of Plumbing From The Revised National Plumbing Code of The Philippines PDFMARK ANGELO CONSUL100% (1)

- Philippine Clean Water Act RA 9275Document2 pagesPhilippine Clean Water Act RA 9275Su Kings Abeto100% (2)

- Model: RO-PURE: Installation, Operation and Maintenance ManualDocument28 pagesModel: RO-PURE: Installation, Operation and Maintenance Manualnermeen ahmedNo ratings yet

- Acornvac BrochureDocument36 pagesAcornvac BrochureSenn OdrapmasdNo ratings yet

- Amphipod Key V 4Document120 pagesAmphipod Key V 4Ormphipod WongkamhaengNo ratings yet

- Midrex - Slurry TreatmentDocument2 pagesMidrex - Slurry TreatmentMorteza RafieiNo ratings yet

- Spc-02735-Env (Sewage Treatment Plant)Document13 pagesSpc-02735-Env (Sewage Treatment Plant)Anonymous NR3qZ30100% (2)

- MPPCBDocument46 pagesMPPCBspkpalkuNo ratings yet

- Hot Water Supply System MaterialsDocument4 pagesHot Water Supply System MaterialsVarunPatyalNo ratings yet

- E&G - Quaternary Science Journal: Quaternary Landscape Evolution in The Peribaltic RegionDocument104 pagesE&G - Quaternary Science Journal: Quaternary Landscape Evolution in The Peribaltic RegionGeozon Science MediaNo ratings yet

- Interference of ManDocument3 pagesInterference of ManChristian Paul RamosNo ratings yet

- Design of STPDocument53 pagesDesign of STPChanel100% (1)

- WQMM Previous PapersDocument13 pagesWQMM Previous PapersAbhishek MohapatraNo ratings yet

- 9english 2022Document10 pages9english 2022Ronak DubeyNo ratings yet

- Fish Farm ConstructionDocument4 pagesFish Farm ConstructionDivya PrabhaNo ratings yet

- Pab 10Document6 pagesPab 10MelvinDapitanonNo ratings yet

- GP3 - Eia Case Slide - 7BDocument15 pagesGP3 - Eia Case Slide - 7BHidayah AzizanNo ratings yet

- Chapter 3 Primary TreatmentDocument29 pagesChapter 3 Primary TreatmentSomaia Al-AkrasNo ratings yet

- Thesis Related To Water Quality IndexDocument5 pagesThesis Related To Water Quality Indexsdeaqoikd100% (2)