Professional Documents

Culture Documents

Lateral Stability Telehandler

Lateral Stability Telehandler

Uploaded by

Reginald D'SouzaCopyright:

Available Formats

You might also like

- Shaft Misalignment and Vibration - A ModelDocument13 pagesShaft Misalignment and Vibration - A ModelPeak NeoNo ratings yet

- Herbal Hair OilDocument26 pagesHerbal Hair Oilrajesh1924100% (2)

- Applsci 13 10990Document15 pagesApplsci 13 10990Aries SebayangNo ratings yet

- 0279 Icnsc177Document6 pages0279 Icnsc177josa12No ratings yet

- Effect of The Tire Lateral Force Saturation On Stability Control of 4WDEV SteeringDocument5 pagesEffect of The Tire Lateral Force Saturation On Stability Control of 4WDEV SteeringBerkay ÇelikNo ratings yet

- Qian (2017) - Modeling and Analysis of Outrigger Reaction Forces of Hydraulic Mobile CraneDocument7 pagesQian (2017) - Modeling and Analysis of Outrigger Reaction Forces of Hydraulic Mobile CraneGogyNo ratings yet

- 07 21-039 OkDocument9 pages07 21-039 OkTạp chí onlineNo ratings yet

- Deflection Calculation and Dynamic Detection of Non-Uniform Beam Via Multi-Point Strain Measurement For Freight TrainsDocument18 pagesDeflection Calculation and Dynamic Detection of Non-Uniform Beam Via Multi-Point Strain Measurement For Freight TrainsAmrutha Valli GurramNo ratings yet

- New 1 s2.0 S0141029622006344 MainDocument16 pagesNew 1 s2.0 S0141029622006344 MainK. NALLASIVAMNo ratings yet

- Engineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengDocument10 pagesEngineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengShivNo ratings yet

- An Analysis of Rollover Stability MeasurementDocument6 pagesAn Analysis of Rollover Stability MeasurementLuis VelascoNo ratings yet

- 1 s2.0 S095741581930114X MainDocument18 pages1 s2.0 S095741581930114X MainBaligh TrabelsiNo ratings yet

- The Dynamic Stability of Railway Vehicle Wheelsets and Bogies Having Profiled WheelsDocument23 pagesThe Dynamic Stability of Railway Vehicle Wheelsets and Bogies Having Profiled WheelsFedericoBertoNo ratings yet

- A Vertical Near-Fault Scenario Earthquakes-Based Generic Simulation Framework For Elastoplastic Seismic Analysis of Light Rail Vehicle-Viaduct SystemDocument26 pagesA Vertical Near-Fault Scenario Earthquakes-Based Generic Simulation Framework For Elastoplastic Seismic Analysis of Light Rail Vehicle-Viaduct SystemjustinhehanuaNo ratings yet

- WCE2010 pp1913-1916Document4 pagesWCE2010 pp1913-1916Katherine FoxNo ratings yet

- Handle Bar Vibration MmotorcycleDocument12 pagesHandle Bar Vibration MmotorcycleabhijitNo ratings yet

- Mergos 2012Document20 pagesMergos 2012Marco Gaetani d'AragonaNo ratings yet

- 1.9 Forces Acting On A Rail Vehicle System: 1. Constraint Forces Between W/RDocument35 pages1.9 Forces Acting On A Rail Vehicle System: 1. Constraint Forces Between W/RAbel TeclayNo ratings yet

- Mode The High-Speed Navigation of Road: VehiclesDocument5 pagesMode The High-Speed Navigation of Road: Vehiclesali_raza117No ratings yet

- Tire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresDocument8 pagesTire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresbijejournalNo ratings yet

- Nonlinear Analysis of Reinforced Concrete Frames: (Received 25 April 1980)Document5 pagesNonlinear Analysis of Reinforced Concrete Frames: (Received 25 April 1980)juan carlos molano toroNo ratings yet

- General Procedure To Perform Pushover AnalysisDocument16 pagesGeneral Procedure To Perform Pushover AnalysisalbikNo ratings yet

- Effect of Change of Cross Section and Frequency Analysis of Anti-Roll Bar Using FEADocument8 pagesEffect of Change of Cross Section and Frequency Analysis of Anti-Roll Bar Using FEAGogyNo ratings yet

- C 9 - Long ColumnsDocument29 pagesC 9 - Long ColumnsRekanNo ratings yet

- Experimental and Theoretical Study On Softening and Pinching Effects of Bridge ColumnDocument7 pagesExperimental and Theoretical Study On Softening and Pinching Effects of Bridge Columnhayder_mehdiNo ratings yet

- 1997 Dámbrisi and FilippouDocument20 pages1997 Dámbrisi and FilippoufsimaNo ratings yet

- Design and Analysis Trends of Helicopter Rotor SystemsDocument40 pagesDesign and Analysis Trends of Helicopter Rotor SystemsHasan ÖzgenNo ratings yet

- Dumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFDocument10 pagesDumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFFabiano OliveiraNo ratings yet

- Kobe University Repository: KernelDocument27 pagesKobe University Repository: KernelTrầmLãngNo ratings yet

- Modeling and Simulation of Hydraulic Actuated Multibody Systems by Bond Graphs (Procedia Engineering, Vol. 69) (2014)Document7 pagesModeling and Simulation of Hydraulic Actuated Multibody Systems by Bond Graphs (Procedia Engineering, Vol. 69) (2014)Karim SalesNo ratings yet

- 3 Symposium On Lift and Escalator TechnologiesDocument9 pages3 Symposium On Lift and Escalator TechnologiesfreddyjoertyNo ratings yet

- Fatigue Life Evaluvation of An Automobile Front AxleDocument7 pagesFatigue Life Evaluvation of An Automobile Front AxleKivanc SengozNo ratings yet

- Yaw Rate and Sideslip Control Using PID Controller For Double Lane ChangingDocument5 pagesYaw Rate and Sideslip Control Using PID Controller For Double Lane ChangingAnugrah SasindranNo ratings yet

- Dumitriu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1018 012001Document10 pagesDumitriu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1018 012001DanteNo ratings yet

- Vehicle Dynamics Under Longitudinal ForcesDocument10 pagesVehicle Dynamics Under Longitudinal ForcesNeerajNo ratings yet

- Mechanical Analysis of Crossbeam in A Gantry Machine Tool and Its Deformation CompensationDocument6 pagesMechanical Analysis of Crossbeam in A Gantry Machine Tool and Its Deformation CompensationTrâm Anh NguyenNo ratings yet

- Leborgne 2014Document14 pagesLeborgne 2014saeed betyarNo ratings yet

- Jaisohn Kim Ferris 2024 Adopting The Performance Margin in Horizontal Curve DesignDocument14 pagesJaisohn Kim Ferris 2024 Adopting The Performance Margin in Horizontal Curve DesignroadbugNo ratings yet

- Study On Safety Level of RC Beam Bridges Under Earthquake: Articles You May Be Interested inDocument9 pagesStudy On Safety Level of RC Beam Bridges Under Earthquake: Articles You May Be Interested inVidisha ChothaniNo ratings yet

- TruptiDocument7 pagesTruptidebanshushekharNo ratings yet

- Yao (2015) - Buckling Failure Analysis of All-Terrain Crane Telescopic Boom SectionDocument13 pagesYao (2015) - Buckling Failure Analysis of All-Terrain Crane Telescopic Boom SectionGogyNo ratings yet

- Effect of Lateral Stiffness of Secondary Suspensions On Heavy-Haul Locomotives Stability During Braking Based On Simulation and ExperimentDocument11 pagesEffect of Lateral Stiffness of Secondary Suspensions On Heavy-Haul Locomotives Stability During Braking Based On Simulation and ExperimentBiruk YifruNo ratings yet

- Combined Bounce, Pitch, and Roll Dynamics of Vehicles Negotiating Single Speed Bump EventsDocument8 pagesCombined Bounce, Pitch, and Roll Dynamics of Vehicles Negotiating Single Speed Bump EventsZibusiso NcubeNo ratings yet

- Front Wheel Angle Control of Steering by Wire System Based On Fuzzy Adaptive PID AlgorithmDocument7 pagesFront Wheel Angle Control of Steering by Wire System Based On Fuzzy Adaptive PID AlgorithmdashNo ratings yet

- 1114 Ijceup 05Document12 pages1114 Ijceup 05ircivilNo ratings yet

- A Novel Control Approach For A Thrust Vector System With An Electromechanical ActuatorDocument9 pagesA Novel Control Approach For A Thrust Vector System With An Electromechanical ActuatorVũ Kiên CNo ratings yet

- Na Et Al 2014 A Novel Method For Bending Stiffness Evaluation of Bus BodyDocument10 pagesNa Et Al 2014 A Novel Method For Bending Stiffness Evaluation of Bus BodyHồ Thanh TùngNo ratings yet

- Dynamic Modeling and Characterization of The Core-XY Cartesian Motion SystemDocument6 pagesDynamic Modeling and Characterization of The Core-XY Cartesian Motion Systemdumler v2No ratings yet

- Guide To Single Point Moorings OldDocument14 pagesGuide To Single Point Moorings OldsarifinNo ratings yet

- Dynamic Analysis of Bridge Under Vehicle Load Using MATLAB and Evaluation of AASHTO Impact FormulaDocument6 pagesDynamic Analysis of Bridge Under Vehicle Load Using MATLAB and Evaluation of AASHTO Impact FormulaeddieNo ratings yet

- Stability and Control of Two-Wheel Drive Tractors and Machinery On Sloping GroundDocument20 pagesStability and Control of Two-Wheel Drive Tractors and Machinery On Sloping GroundSergey ZlenkoNo ratings yet

- A Study On The Dynamic Analysis Modelling For High-Speed Roller BearingsDocument10 pagesA Study On The Dynamic Analysis Modelling For High-Speed Roller BearingsRCUNo ratings yet

- Sample Seismic Analysis ReportDocument14 pagesSample Seismic Analysis ReportricardobonillaNo ratings yet

- An Improved Hysteresis Model For Circular Reinforced Concrete Columns Under Cyclic Torsional LoadingDocument12 pagesAn Improved Hysteresis Model For Circular Reinforced Concrete Columns Under Cyclic Torsional LoadingKevin Prudencio ParraNo ratings yet

- Safety Assessment For Flange Climb Derailment of Train Running at Low Speeds On Sharp CurvesDocument7 pagesSafety Assessment For Flange Climb Derailment of Train Running at Low Speeds On Sharp CurvesnwatpdgrtmiepuwuiwNo ratings yet

- Experimental and Theoretical Dynamic System Identification of Damaged RC BeamsDocument11 pagesExperimental and Theoretical Dynamic System Identification of Damaged RC BeamsKy Visoth SambathNo ratings yet

- Implication of The Seismic Code On The Seismic Design of Bridges in AlgeriaDocument8 pagesImplication of The Seismic Code On The Seismic Design of Bridges in Algeriagorgika papandNo ratings yet

- Archive of SID: Comparison of Static and Dynamic Pushover Analysis in Assessment of The Target DisplacementDocument14 pagesArchive of SID: Comparison of Static and Dynamic Pushover Analysis in Assessment of The Target DisplacementAdel CivilNo ratings yet

- A Study On Hysteresis Modeling of Reinforced Concrete ColumnsDocument12 pagesA Study On Hysteresis Modeling of Reinforced Concrete ColumnsangelomarinilliNo ratings yet

- Seismic Capacity Evaluation of Post-Tensioned Concrete Slab-Column Frame Buildings by Pushover AnalysisDocument15 pagesSeismic Capacity Evaluation of Post-Tensioned Concrete Slab-Column Frame Buildings by Pushover AnalysisJavsarNo ratings yet

- Layered Control of Forklift Lateral Stability Based On Takagi-Sugenofuzzy Neural NetworkDocument15 pagesLayered Control of Forklift Lateral Stability Based On Takagi-Sugenofuzzy Neural NetworkReginald D'SouzaNo ratings yet

- En 16203 (2014) (E)Document3 pagesEn 16203 (2014) (E)Reginald D'SouzaNo ratings yet

- Analytical Method For Assessing StabilitDocument11 pagesAnalytical Method For Assessing StabilitReginald D'SouzaNo ratings yet

- Virtual Testing of Counterbalance Forklift TrucksDocument16 pagesVirtual Testing of Counterbalance Forklift TrucksReginald D'SouzaNo ratings yet

- Welcoming The VighnahartaDocument2 pagesWelcoming The VighnahartaDeepa HNo ratings yet

- Unit 4 Travel and Holidays: Pre IeltsDocument21 pagesUnit 4 Travel and Holidays: Pre IeltsQuoc Tan HuynhNo ratings yet

- Rodan and Fields Product GuideDocument17 pagesRodan and Fields Product GuideSusy MariaNo ratings yet

- What Is Physics Through The Eyes of ScientistsDocument39 pagesWhat Is Physics Through The Eyes of ScientistsAHMET TOPRAKNo ratings yet

- Cengg11 Midterm 2021Document2 pagesCengg11 Midterm 2021Angelo VilleroNo ratings yet

- wk06 IVDocument34 pageswk06 IVyingdong liuNo ratings yet

- ATs 5,6,7,8 in AHO2 2ndsem MidDocument7 pagesATs 5,6,7,8 in AHO2 2ndsem MidVanessa NicolNo ratings yet

- Final-Past Exam QuestionsDocument8 pagesFinal-Past Exam QuestionsKhánh Linh Nguyễn NgọcNo ratings yet

- kh7 CVPDocument50 pageskh7 CVPأبوأحمد الحكيمNo ratings yet

- First Long Test in SPS 7Document3 pagesFirst Long Test in SPS 7Dennmark IgutNo ratings yet

- MC Ad Lab2023Document111 pagesMC Ad Lab202321131a0445No ratings yet

- 12 Lecture 4-Seismic Waves AFTER MidDocument80 pages12 Lecture 4-Seismic Waves AFTER MidusamaNo ratings yet

- The Properties of Determinants:: 11 22 II NNDocument15 pagesThe Properties of Determinants:: 11 22 II NNVivek SinghNo ratings yet

- INFLATIONDocument24 pagesINFLATIONLovely Bordaje dela FuenteNo ratings yet

- Describe Image TemplatesDocument2 pagesDescribe Image TemplatesGanesh prasad AdhikariNo ratings yet

- Indian Railways Carbon EmissionsDocument9 pagesIndian Railways Carbon EmissionsTechTrip IndiaNo ratings yet

- Reservation List As of June 27Document104 pagesReservation List As of June 27Francis DedumoNo ratings yet

- Thesis On Wind Power PlantDocument6 pagesThesis On Wind Power PlantPaperWritingServicesBestEvansville100% (2)

- Chicken Pastel Recipe: IngredientsDocument5 pagesChicken Pastel Recipe: IngredientsMariam SalongaNo ratings yet

- Mech PDFDocument9 pagesMech PDFgurusamyNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- 01 Masonry Grout Filler - Group 180821Document2 pages01 Masonry Grout Filler - Group 180821Maha MuflehNo ratings yet

- Industrialised Building SystemDocument20 pagesIndustrialised Building SystemreenaNo ratings yet

- Final Report of LPG Gas StoveDocument69 pagesFinal Report of LPG Gas StoveUdit SharmaNo ratings yet

- NITIN Rdbms AssignmentDocument131 pagesNITIN Rdbms Assignmentnitinsingaur.bizNo ratings yet

- 16 RMM Spring Edition 2020 Solutions CompressedDocument83 pages16 RMM Spring Edition 2020 Solutions CompressedKhokon GayenNo ratings yet

- Floating Aerators Covering Aquafen: Technical Specifications Installation, Maintenance, Starting Up, and WarrantiesDocument6 pagesFloating Aerators Covering Aquafen: Technical Specifications Installation, Maintenance, Starting Up, and WarrantiesMehedi HasanNo ratings yet

- NBIMS-US V3 2.4.4.7 OmniClass Table 31 PhasesDocument8 pagesNBIMS-US V3 2.4.4.7 OmniClass Table 31 Phasesmahmoud mokhtarNo ratings yet

- Fault Level CalculationDocument1 pageFault Level Calculationpb21No ratings yet

Lateral Stability Telehandler

Lateral Stability Telehandler

Uploaded by

Reginald D'SouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lateral Stability Telehandler

Lateral Stability Telehandler

Uploaded by

Reginald D'SouzaCopyright:

Available Formats

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

Lateral Stability Analysis of Telehandlers Based on Multibody

Dynamics

HAOLIANG GUO,1, * XIHUI MU,2 FENGPO DU,2 KAI LV1

1

Department of Ammunition Engineering

Ordnance Engineering College

Shijiazhuang

China (Beijing)

2

Research Institute of Ordnance Technology

Shijiazhuang

China (Beijing)

*

haocui876@163.com

Abstract: At the beginning, this article analyzed the lateral stability of telehandlers, and reached the following

results: the critical overturning angle, the critical sliding angle, and the conditions of sliding happen before

overturning. Then, the ADAM virtual prototype of telehandlers was built based on the multibody dynamics

model, and the dynamic simulation of the lateral stability of telehandlers was carried out, and then we got the

rule of that the right tire reacting force change with the critical overturning angle with frame leveling or not.

Base on the ‘UA’ model of tire, we studied the influence of vertical stiffness and lateral stiffness on the lateral

stability of telehandlers. The result of virtual simulation method was compared with that of the theoretical

calculation and platform experiment. It can be seen that the result of the virtual simulation method is closer to

the actual situation, and can shorten the development process and reduce the cost, which can guide the structure

design of telehandlers more scientifically. This article can also provide reference for the design of the lateral

stability of the rear axle articulated vehicles.

Key-Words: Telehandlers, Lateral Stability, ADAMS, Overturning Angle, Multibody Dynamics

1 Introduction as well as connected with each other. Platform

Telehandlers is mainly used in the fields of military experiment is a traditional method to verify the

and civilian logistics, architectural engineering, lateral stability of telehandlers, commonly used in

agriculture, etc. Vehicle integrates the functions of the performance simulation of virtual prototype.

cranes, forklifts, and loaders, becomes the important Theoretical calculation method is often used in the

logistics and engineering equipment. A variety of vehicle structure design, especially in the barycenter

works can be implemented, such as obstacle- position design, whose analysis result has some

surmounting operations, pulling in and out differences with the actual situation. Virtual

operations, loading and unloading operations simulation method is often used in the performance

without operation platform, as well as the integrated simulation of virtual prototype, which largely

high raising operations with large span. overcomes errors of the theoretical calculation to the

Telehandlers stability can maintain the normal actual, but also replaces the process of "physical

performance under all possible conditions without prototype design verification" in traditional design,

sliding and overturning. Sliding angle and which has large resource consumption. This method

overturning angle are usually used to evaluate the can avoid the phenomenon of rebuilding prototype

stability, and should be preferentially considered in due to parametric design unreasonable in platform

the structure layout and design of telehandlers[1]. A experiment [3, 4].

wealth of statistical data show that majority forklifts This paper studied the vehicle leveling system

rollover accidents happened are caused by the and the influence of tire vertical stiffness, lateral

lateral instability[2]. Therefore, the lateral stability stiffness on lateral stability of telehandlers by using

of telehandlers study is extremely necessary. ADAMS, and compared its result with those of

Currently, there are three methods to evaluate the theoretical calculation and platform experiment.

lateral stability of telehandlers: theoretical 2 The lateral stability analysis of

calculation, virtual simulation and platform telehandlers

experiment. They are distinguished from each other, For safety reasons, sliding and overturning are the

E-ISSN: 2224-3429 1 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

sign of instability, and overturning is a bigger angle between the barycenter line and vehicle

danger. So, it must be ensured that there is no longitudinal line when the barycenter line go

sliding and overturning happen, at least that the through the point P. So, it relates to the barycenter

sliding could happen before overturning, which is position of telehandlers, not the mass, and the

the precondition to stability analysis and critical overturning angle increases with the ratio of

calculation[1, 5]. Telehandlers with a rigid horizontal and vertical component of barycenter

suspension weighs G, its static force diagram on the position.

slope with α angle is as shown in the figure 1. The maximum static friction is given by:

The barycenter is marked as F, the support force Z Z1 Z2 1Y1 2Y2 (6)

from slope to two wheels is Y1 and Y2, and the static Where μ1 and μ2 are coefficients of static friction

friction is Z1 and Z2 as wheels sliding down. No- of the two wheels (that is adhesion coefficient),

load lateral overturning moment and stability normally, μ1=μ2=μ.

moment can be got at P, which is an intersection Critical sliding state, make that:

point of slope and the tire bottom. [6, 7]. Z mg sin s Y1 Y2 mg cos s (7)

The Critical sliding angle is given by:

s arctan (8)

It follows that, when the coefficients of static

friction of the two wheels is equal, the critical

sliding angle is proportion to the coefficient of static

friction.

So, the condition to ensure sliding happen before

overturning is that: s t , which means that the

ratio of horizontal and vertical component of

barycenter position is bigger than the coefficient of

static friction:

b d 2e

(9)

2h

Fig. 1 Force diagram of telehandlers when laterally

driving on the slope

3 Multibody dynamics model of

No-load lateral overturning moment is given by: telehandlers

Tw mgh sin (1) The dynamic system of telehandlers is made up of

Where m is the no-load mass of the vehicle, α is several parts, it has many kinematic characteristics,

the gradient, h is the perpendicular distance from such as inertia, elasticity, damping, etc. Because

barycenter to slope with none-load. telehandlers can be influenced by the steering wheel

No-load lateral stability moment is given by: rotation, aerodynamic (such as lateral wind) and

bd

uneven road, its kinestate can be changed easily,

Tz mg ( e) cos (2) which may cause overturning happen. Because the

2

influence factors are dynamic, it is difficult to guide

Where b is the wheelbase, d is the wheel width; e

the vehicle barycenter position inspection and

is the offset distance from barycenter to the

structure parameter adjustment according to usual

longitudinal symmetry plane.

static criteria of lateral stability. Therefore, to

The stability coefficient is defined as: (normally,

establish a dynamic model and test the stability of

the value should be greater than 1.5)

telehandlers by ADAMS kinematics simulation is

Tw

n (3) necessary [6, 8].

Tz Telehandlers has the four-wheel drive system and

State of critical overturning: make n be 1, get three-section telescopic boom structure, and three

that: steering ways, such as two-wheel steering, four-

b d 2e wheel steering and crab steering. Front axle and rear

tan (4)

2h axle are connected by rigid suspension. The frame

So, we can get that: hinges with front axle and rear axle through the

t arctan b d 2e 2h (5) cylindrical joint, and can swing with some degree

opposite to the both sides of axle. The front axle

Where αt is the critical overturning angle. installs the leveling cylinder, which makes the front

It follows that the critical overturning angle is the

E-ISSN: 2224-3429 2 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

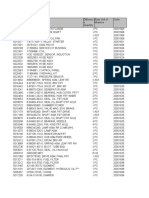

axle could be locked and makes the frame can level Tab 1. Related simulation parameters of

within 10 degree more or less. Therefore, telehandlers

telehandlers can handle the uneven placed materials, Parameters Signs Values Units

or drive on the slope full-loaded. Overall Length L 6590 mm

Based on the frame structure and the multibody Overall Width W 2340 mm

dynamics theory, we established the vehicle Overall Height H 2390 mm

multibody dynamics model. The mass of the vehicle Maximum Loads G 2500 kg

can be divided into three parts, the mass of frame Total Mass M 7990 kg

and front axle marked as M1, rear axle mass marked Front Axle Mass M1 2560 kg

as M2, the combined mass of telescopic boom and Rear Axle Mass M2 3707 kg

fork marked as M3, as shown in figure 2. Simplify Telescopic Boom and

the part between the telescopic boom and the frame M3 1723 kg

Fork

to a piecewise linear spring with viscous damping. Load Center Distance h1 600 mm

Spring is located between the two hinge point Maximum Speed V 45 km/h

marked as F and F' of the hydraulic cylinder, spring Minimum Turning

stiffness is set as Kb, and damping is set as Cb. R 7200 mm

Radius

Simplify the tires to a three-dimensional piecewise Minimum Ground

linear springs with viscous damping. h2 400 mm

Clearance

Take the right front wheel for example, vertical Vertical Stiffness Kf1 1000 N/mm

spring is located between the point A0 and the wheel Vertical Damping

center point A, and it’s vertical stiffness is set as Kf1, Cf1 3.1

Coefficient

vertical damping is set as Cf1. Lengthways spring is Lengthways Stiffness Kf2 40000 N

connected with point A0 at one end, and the other Lateral Stiffness Kf3 30000 N/rad

end is suspended along the lengthways direction, Lateral Damping

and it’s lengthways stiffness is set as Kf2, Cf3 2.3

Coefficient

lengthways damping is set as Cf2. Driving force PA Static Friction UMA

and running resistance FA act on point A' along the 1.1

Coefficient X

lengthways direction, which on the suspended end Rolling Resistance

of lengthways spring. Lateral spring is connected f 4.0

Coefficient

with the point A0 at one end, and on the other end of Tire Radius RT 650 mm

lateral spring is suspended along the lateral Tire Width WT 350 mm

direction, and it’s lateral stiffness is set as Kf3,

lateral damping is set as Cf3. Lateral force SA (lateral

adhesion force or sliding friction force) laterally act 4 Dynamics simulation for lateral

on point A", which on the suspended end of lateral stability

spring. 4.1 The multi-body dynamics simulation model

Similarly, the other three wheels are simplified in design

the same way with the right front wheel. So, the Based on the above multibody dynamics model of

dynamic system has complete six degrees of telehandlers, the ADAMS virtual prototype model

freedom [9-11]. with rigid suspension system is established,

avoiding the complex mathematical formula

derivation process. Import the UG model with the

X_T format into ADAMS to simulate. Before

simulation, the environment of simulation is set, and

then the required constraints is added after summing

several parts of model, not only because that can

make it easier to add constraints, but also can reduce

the calculation amount during simulation and

improve the accuracy of the simulation results[12].

Whether the frame of telehandlers level or not

can directly affect the barycenter position, and also

Fig. 2 Multibody dynamics model of telehandlers directly affect its lateral stability. Therefore,

Related simulation parameters of telehandlers as different conditions must be studied respectively.

following: The UA tire model used in the virtual prototype

simulation model belongs to physical model, which

E-ISSN: 2224-3429 3 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

takes the unstable condition into account, and the

effective frequency could be set to 8 Hz. It has good

accuracy considering limited parameters. To prevent

sliding happen before overturning, the coefficient of

static friction should be set as 0.9.

As shown in figure 3, the ADAMS virtual

prototype model of telehandlers with leveling

system move on a 2D slope at no-load, and its

telescopic boom was drawn back.

Fig. 5 Curve of the reacting force of the right rear

tire changed with the slope angle

By comparing Figure 4 and Figure 5, it is found

that with the leveling system, the critical

overturning angle of right rear tire slightly larger

than the right front tire, which is caused by the

Fig. 3 The ADAMS virtual prototype model of center of gravity of the vehicle close to the rear

telehandlers with leveling system move on a slope tires. So, when lateral instability of telehandlers

occurred, it tended to occur at the right front tire

4.2 The effect of leveling system on the first. Because the rear axle of telehandler

lateral stability of telehandlers articulated, only the front axle has leveling oil

In the lateral stability dynamics simulation, the cylinder, that frame leveling system has little effect

slope angle can be modified by STEP function. And on the reacting force of the right front tire, but has

the reacting forces of the right front tire and the greater impact on the critical overturning angle of

right rear tire change with the slope angle was the right rear tire.

studied. The simulation results as seen in figure 4

and figure 5, the reacting force decreases with the 4.3 The effect of vertical stiffness of tires on

increase of slope angle. When the reacting force

lateral stability of telehandlers

approximate to zero, telehandlers becomes instable,

Vertical stiffness of the tire determines its vertical

and its critical overturning angle of right front tire

deformation, related to the tire load and pressure,

can be obtained to be 35 degree if with leveling

which increases with the increase of tire pressure,

system, and 30.9 degree if without leveling system.

and then growth slows down, which appears

The critical overturning angle of right rear tire can

logarithmical increase. In order to make the results

be obtained to be 38.5 degree if with leveling

more comparable, study the state without leveling

system, and 34.9 degree if without leveling system.

system only.

In UA tire model, the vertical stiffness values

were set to be 600, 800, 1000, 1200, 1400

respectively, other parameters could be found in

Table 1. We got curves of the reacting force of the

right front tire and right rear tire, changing with the

slope angle at different vertical stiffness, shown in

Figure 6, 7.

Fig. 4 Curve of the reacting force of the right front

tire changed with the slope angle

E-ISSN: 2224-3429 4 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

lateral stiffness, shown in Figure 8, 9.

Fig. 6 Curves of the reacting force of the right front

tire

Fig. 8 Curves of the reacting force of the right front

tire

Fig. 7 Curves of the reacting force of the right rear

tire

Fig. 9 Curves of the reacting force of the right rear

Figure 6&7 shows that the reacting force of the tire

right front tire or the right rear tire are very nearly at

different vertical stiffness. So, we can draw a As shown in Figures 8&9, the curves almost

conclusion that the vertical stiffness of the tire has completely overlap, so we can see that the tire

little effect on tire reacting force, and little effect on lateral stiffness has no effect on lateral stability,

the critical overturning angles of telehandler. The owing to the lateral stiffness of the tire determines

critical overturning angle at the right front tire is its lateral deformation only.

about 31 °, and that at the right rear tire is about

38 °. Therefore, the tire vertical stiffness has little 5 Statics calculation for lateral

effect on lateral stability of telehandler.

stability of telehandlers

Because the rear axle of telehandlers is articulated

4.4 The effect of lateral stiffness of tires on with the frame, the supporting plane turns to ABE

lateral stability of telehandlers plane from ABCD plane. Its front fulcrum A and B

Lateral stiffness of the tire determines its lateral are the ground points of left and right wheels,

deformation. We still only study the state of the respectively, and the rear fulcrum E is the hinge

frame without leveling system. In UA tire model, center of rear axle and frame, as shown in figure 10.

the lateral stiffness values were set to be 20000, The point J is the projection of the barycenter on the

25000, 30000, 35000, and 40000 respectively, other ABE plane. Line JK parallel to line AB, and meet in

parameters could be found in Table 1. We got curves point K with line BE. When telehandlers laterally

of the reacting force of the right front tire and right overturn, its overturning axis is line BE or AE[13].

rear tire, changing with the slope angle at different

E-ISSN: 2224-3429 5 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

Fig. 10 The overturning angle of telehandlers

analysis Fig. 11 Platform experiment for lateral stability of

telehandlers

By the formula (5), when e = 0, the overturning The critical overturning angle was been gotten at

angle of telehandlers is at arctan( JK / FJ ) . the Testing Center. The critical overturning angle of

5.1 Frame without leveling telehandlers with frame without leveling is 30.1

Using traditional method to analyze the stability of degree. The critical overturning angle of

telehandlers, the position of the barycenter must be telehandlers with frame leveling is 34.6 degree. The

known at first. Normally, the position of the angles gotten by three methods of theoretical

barycenter could be measured on prototype using calculation, virtual simulation and platform

platform experiment method, and then prototype’s experiment were compared, as shown in table 2.

stability can be checked[3]. In this paper, we build Tab 2.Lateral overturning angles by statics and

the global coordinate system for ADAMS virtual dynamics method with leveling or not

prototype model as shown in figure 10. We can get Overturning Angles Without Leveling Leveling

the barycenter position exactly in ADAMS by the Dynamic Simulation 30.9° 35.0°

command of Aggregate Mass, and the barycenter Statics Calculation 28.2° 32.8°

coordinates is (XF, YF, ZF)=(1604, 0.28, 1178), Platform Experiment 30.1° 34.6°

BO=930mm, and the coordinates of point E is (XE,

YE, ZE)=(3300, 0, 590), then:

FJ Z F X F Z E / X E 891.22 (10) As seen in the table 2, whether the frame have

leveling or not, can easily affect the position of the

JK 1 X F / X E BO YF 478.24 (11)

barycenter, the critical overturning angle of

at arctan( JK / FJ ) 28.2 (12) telehandlers with frame leveling is bigger than that

5.2 Frame leveling without leveling. It can obviously improve the

After the frame leveling on the slope, the barycenter lateral stability that telehandlers is leveled when

position is changed, that can improve the lateral driving or operating on the slope.

reliability of telehandlers. The coordinates of point The dynamic simulation result is closer to the

E is (XE, YE, ZE) = (3300, 0, 590), the barycenter platform experiment result compared to the statics

coordinates is (XF, YF, ZF) = (1604, 90, 1168), and calculation result. The main reason is that the tire is

BO=930mm, then: seen as a totally rigid part in statics calculation, and

FJ Z F X F Z E / X E 881.22 (13) the overturning point is the intersection point of

JK 1 X F / X E BO YF 567.96 (14) slope and the bottom of the left tire. However, in the

dynamical simulation, the vertical stiffness and

at arctan( JK / FJ ) 32.8 (15)

damping coefficient of the tire is being considered,

6 Platform experiment for lateral so that the result of dynamical simulation seems to

stability of telehandlers be closer to the actual situation. Therefore, the

Through early structural design and virtual dynamics simulation can guide the structure design

simulation, we produced the prototype. And then, of telehandlers more scientifically compared with

we finished the lateral stability experiment using the statics calculation.

platform method in China National Construction

Machinery Quality Supervision Testing Center. As 6 Conclusion

seen in Figure 11. By studying the lateral reliability of telehandlers, it

can be found that to ensure sliding happen before

overturning must make sure that the ratio of

E-ISSN: 2224-3429 6 Volume 11, 2016

WSEAS TRANSACTIONS on APPLIED and THEORETICAL MECHANICS Haoliang Guo, Xihui Mu, Fengpo Du, Kai Lv

horizontal and vertical component of barycenter Professional Society for Research Work:

position is bigger than the coefficient of static Lozenec, Bulgaria. p. 147-152.

friction. And it is found that the effect of frame [5] Gong, Q., Research on Design and Analyse of

leveling on the lateral stability of telehandlers is Tracked Vehicles Key Technologies. 2008,

significant; during ramp movement security can be YangZhou University: Yang Zhou, China.

improved if with frame leveling. For rear axle [6] Lemerle, P., O. Hoeppner, and J. Rebelle,

articulated vehicle, when front axle is fixed or with Dynamic stability of forklift trucks in cornering

frame leveling system the critical overturning angle situations: parametrical analysis using a driving

occur in the right front tire. By using UA tire model simulator. Vehicle System Dynamics. Vol.49,

simulation, it is shown that the tire vertical stiffness No.10, 2011, pp. 1673-1693.

has little effect on the lateral stability, and lateral [7] Jo, J.S., et al., Vehicle stability control system

stiffness almost no effect on lateral stability. for enhancing steerabilty, lateral stability, and

It can be seen from the example in this article roll stability. International Journal Of

that the virtual simulation method could drive Automotive Technology. Vol.9, No.5, 2008, pp.

product development by using simulation 571-576.

technology, which can avoid complex mathematical [8] Yin, G., et al., A Study on mu-Synthesis

formula derivation process, and can make it come Control for Four-Wheel Steering System to

true to simulating lateral stability with high Enhance Vehicle Lateral Stability. Journal of

precision simulation in design phase, and its result is Dynamic Systems, Measurement and Control.

more close to actual situation comparing with the Vol.133, No.1, 2011, pp. 011002 (6 pages).

theoretical calculation method, that can improve the [9] Yang, X., N. Kang, and X. Li, Nonlinear

lateral reliability analysis and forecasting abilities. dynamics and lateral stability of tractor semi-

Comparing with prototype testing it can greatly trailer vehicle. Journal of Mechanical

optimize the development cycle, shorten the process Engineering. Vol.48, No.8, 2012, pp. 79-89.

and reduce costs. [10] Sutru, N., G. Boiangiu, and S. Popescu,

Contributions to theoretical and experimental

6 Acknowledgement study of the dynamic stability of the forklift

The authors would like to acknowledge the financial trucks. Journal of EcoAgriTourism. Vol.8,

support from the National Natural Science No.2, 2012, pp. 150-156.

Foundation of China (Grant No. 51205101, [11] Ren, A., Z. Wu, and J. Bao, Study on Lateral

58670106, 61471385). The authors are grateful to Stability of Vehicle-Trailer System Based on

the anonymous reviewers for valuable comments Multi-Body Dynamic Simulation. Advanced

and suggestions, which helped to improve this Materials Research. Vol.765-767, 2013, pp.

study. 345-50.

[12] Xia, G., et al., ADAMS-based Simulation

References: Study on Lateral Stability of Counterbalanced

[1] Wan, H., Stability Analysis and Calculation of Forklift Trucks. Applied Mechanics and

Engineering Machinery. Construction Materials. Vol.464, 2014, pp. 105-9.

Machinery, No.8, 1998, pp. 12-16. [13] Huang, G., Research on Stability of

[2] Quan, B. and H. Xiong, Instability Analysis of Counterbalanced Forklift. Forklift Technology,

Counterbalanced Forklift and Visualization of No.1, 1999, pp. 7-14.

Accident Reconstruction Technology. Port

Operation, No.4, 2013, pp. 4-6.

[3] Su, X., et al., ADAMS-based Static Stability

Analysis and Simulation on Forklifts. Chinese

Journal of Construction Machinery. Vol.10,

No.1, 2012, pp. 77-80.

[4] Popescu, S., N. Sutru, and G. Boiangiu,

Theortical and experimental research on of the

longitudinal dynamic stability of the forklift

trucks, in Proceedings of the Third

International Research People and Actual

Tasks on Multidisciplinary Sciences

Conference. 2011, Bulgarian National

Multidisciplinary Scientific Network of the

E-ISSN: 2224-3429 7 Volume 11, 2016

You might also like

- Shaft Misalignment and Vibration - A ModelDocument13 pagesShaft Misalignment and Vibration - A ModelPeak NeoNo ratings yet

- Herbal Hair OilDocument26 pagesHerbal Hair Oilrajesh1924100% (2)

- Applsci 13 10990Document15 pagesApplsci 13 10990Aries SebayangNo ratings yet

- 0279 Icnsc177Document6 pages0279 Icnsc177josa12No ratings yet

- Effect of The Tire Lateral Force Saturation On Stability Control of 4WDEV SteeringDocument5 pagesEffect of The Tire Lateral Force Saturation On Stability Control of 4WDEV SteeringBerkay ÇelikNo ratings yet

- Qian (2017) - Modeling and Analysis of Outrigger Reaction Forces of Hydraulic Mobile CraneDocument7 pagesQian (2017) - Modeling and Analysis of Outrigger Reaction Forces of Hydraulic Mobile CraneGogyNo ratings yet

- 07 21-039 OkDocument9 pages07 21-039 OkTạp chí onlineNo ratings yet

- Deflection Calculation and Dynamic Detection of Non-Uniform Beam Via Multi-Point Strain Measurement For Freight TrainsDocument18 pagesDeflection Calculation and Dynamic Detection of Non-Uniform Beam Via Multi-Point Strain Measurement For Freight TrainsAmrutha Valli GurramNo ratings yet

- New 1 s2.0 S0141029622006344 MainDocument16 pagesNew 1 s2.0 S0141029622006344 MainK. NALLASIVAMNo ratings yet

- Engineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengDocument10 pagesEngineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengShivNo ratings yet

- An Analysis of Rollover Stability MeasurementDocument6 pagesAn Analysis of Rollover Stability MeasurementLuis VelascoNo ratings yet

- 1 s2.0 S095741581930114X MainDocument18 pages1 s2.0 S095741581930114X MainBaligh TrabelsiNo ratings yet

- The Dynamic Stability of Railway Vehicle Wheelsets and Bogies Having Profiled WheelsDocument23 pagesThe Dynamic Stability of Railway Vehicle Wheelsets and Bogies Having Profiled WheelsFedericoBertoNo ratings yet

- A Vertical Near-Fault Scenario Earthquakes-Based Generic Simulation Framework For Elastoplastic Seismic Analysis of Light Rail Vehicle-Viaduct SystemDocument26 pagesA Vertical Near-Fault Scenario Earthquakes-Based Generic Simulation Framework For Elastoplastic Seismic Analysis of Light Rail Vehicle-Viaduct SystemjustinhehanuaNo ratings yet

- WCE2010 pp1913-1916Document4 pagesWCE2010 pp1913-1916Katherine FoxNo ratings yet

- Handle Bar Vibration MmotorcycleDocument12 pagesHandle Bar Vibration MmotorcycleabhijitNo ratings yet

- Mergos 2012Document20 pagesMergos 2012Marco Gaetani d'AragonaNo ratings yet

- 1.9 Forces Acting On A Rail Vehicle System: 1. Constraint Forces Between W/RDocument35 pages1.9 Forces Acting On A Rail Vehicle System: 1. Constraint Forces Between W/RAbel TeclayNo ratings yet

- Mode The High-Speed Navigation of Road: VehiclesDocument5 pagesMode The High-Speed Navigation of Road: Vehiclesali_raza117No ratings yet

- Tire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresDocument8 pagesTire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresbijejournalNo ratings yet

- Nonlinear Analysis of Reinforced Concrete Frames: (Received 25 April 1980)Document5 pagesNonlinear Analysis of Reinforced Concrete Frames: (Received 25 April 1980)juan carlos molano toroNo ratings yet

- General Procedure To Perform Pushover AnalysisDocument16 pagesGeneral Procedure To Perform Pushover AnalysisalbikNo ratings yet

- Effect of Change of Cross Section and Frequency Analysis of Anti-Roll Bar Using FEADocument8 pagesEffect of Change of Cross Section and Frequency Analysis of Anti-Roll Bar Using FEAGogyNo ratings yet

- C 9 - Long ColumnsDocument29 pagesC 9 - Long ColumnsRekanNo ratings yet

- Experimental and Theoretical Study On Softening and Pinching Effects of Bridge ColumnDocument7 pagesExperimental and Theoretical Study On Softening and Pinching Effects of Bridge Columnhayder_mehdiNo ratings yet

- 1997 Dámbrisi and FilippouDocument20 pages1997 Dámbrisi and FilippoufsimaNo ratings yet

- Design and Analysis Trends of Helicopter Rotor SystemsDocument40 pagesDesign and Analysis Trends of Helicopter Rotor SystemsHasan ÖzgenNo ratings yet

- Dumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFDocument10 pagesDumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFFabiano OliveiraNo ratings yet

- Kobe University Repository: KernelDocument27 pagesKobe University Repository: KernelTrầmLãngNo ratings yet

- Modeling and Simulation of Hydraulic Actuated Multibody Systems by Bond Graphs (Procedia Engineering, Vol. 69) (2014)Document7 pagesModeling and Simulation of Hydraulic Actuated Multibody Systems by Bond Graphs (Procedia Engineering, Vol. 69) (2014)Karim SalesNo ratings yet

- 3 Symposium On Lift and Escalator TechnologiesDocument9 pages3 Symposium On Lift and Escalator TechnologiesfreddyjoertyNo ratings yet

- Fatigue Life Evaluvation of An Automobile Front AxleDocument7 pagesFatigue Life Evaluvation of An Automobile Front AxleKivanc SengozNo ratings yet

- Yaw Rate and Sideslip Control Using PID Controller For Double Lane ChangingDocument5 pagesYaw Rate and Sideslip Control Using PID Controller For Double Lane ChangingAnugrah SasindranNo ratings yet

- Dumitriu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1018 012001Document10 pagesDumitriu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1018 012001DanteNo ratings yet

- Vehicle Dynamics Under Longitudinal ForcesDocument10 pagesVehicle Dynamics Under Longitudinal ForcesNeerajNo ratings yet

- Mechanical Analysis of Crossbeam in A Gantry Machine Tool and Its Deformation CompensationDocument6 pagesMechanical Analysis of Crossbeam in A Gantry Machine Tool and Its Deformation CompensationTrâm Anh NguyenNo ratings yet

- Leborgne 2014Document14 pagesLeborgne 2014saeed betyarNo ratings yet

- Jaisohn Kim Ferris 2024 Adopting The Performance Margin in Horizontal Curve DesignDocument14 pagesJaisohn Kim Ferris 2024 Adopting The Performance Margin in Horizontal Curve DesignroadbugNo ratings yet

- Study On Safety Level of RC Beam Bridges Under Earthquake: Articles You May Be Interested inDocument9 pagesStudy On Safety Level of RC Beam Bridges Under Earthquake: Articles You May Be Interested inVidisha ChothaniNo ratings yet

- TruptiDocument7 pagesTruptidebanshushekharNo ratings yet

- Yao (2015) - Buckling Failure Analysis of All-Terrain Crane Telescopic Boom SectionDocument13 pagesYao (2015) - Buckling Failure Analysis of All-Terrain Crane Telescopic Boom SectionGogyNo ratings yet

- Effect of Lateral Stiffness of Secondary Suspensions On Heavy-Haul Locomotives Stability During Braking Based On Simulation and ExperimentDocument11 pagesEffect of Lateral Stiffness of Secondary Suspensions On Heavy-Haul Locomotives Stability During Braking Based On Simulation and ExperimentBiruk YifruNo ratings yet

- Combined Bounce, Pitch, and Roll Dynamics of Vehicles Negotiating Single Speed Bump EventsDocument8 pagesCombined Bounce, Pitch, and Roll Dynamics of Vehicles Negotiating Single Speed Bump EventsZibusiso NcubeNo ratings yet

- Front Wheel Angle Control of Steering by Wire System Based On Fuzzy Adaptive PID AlgorithmDocument7 pagesFront Wheel Angle Control of Steering by Wire System Based On Fuzzy Adaptive PID AlgorithmdashNo ratings yet

- 1114 Ijceup 05Document12 pages1114 Ijceup 05ircivilNo ratings yet

- A Novel Control Approach For A Thrust Vector System With An Electromechanical ActuatorDocument9 pagesA Novel Control Approach For A Thrust Vector System With An Electromechanical ActuatorVũ Kiên CNo ratings yet

- Na Et Al 2014 A Novel Method For Bending Stiffness Evaluation of Bus BodyDocument10 pagesNa Et Al 2014 A Novel Method For Bending Stiffness Evaluation of Bus BodyHồ Thanh TùngNo ratings yet

- Dynamic Modeling and Characterization of The Core-XY Cartesian Motion SystemDocument6 pagesDynamic Modeling and Characterization of The Core-XY Cartesian Motion Systemdumler v2No ratings yet

- Guide To Single Point Moorings OldDocument14 pagesGuide To Single Point Moorings OldsarifinNo ratings yet

- Dynamic Analysis of Bridge Under Vehicle Load Using MATLAB and Evaluation of AASHTO Impact FormulaDocument6 pagesDynamic Analysis of Bridge Under Vehicle Load Using MATLAB and Evaluation of AASHTO Impact FormulaeddieNo ratings yet

- Stability and Control of Two-Wheel Drive Tractors and Machinery On Sloping GroundDocument20 pagesStability and Control of Two-Wheel Drive Tractors and Machinery On Sloping GroundSergey ZlenkoNo ratings yet

- A Study On The Dynamic Analysis Modelling For High-Speed Roller BearingsDocument10 pagesA Study On The Dynamic Analysis Modelling For High-Speed Roller BearingsRCUNo ratings yet

- Sample Seismic Analysis ReportDocument14 pagesSample Seismic Analysis ReportricardobonillaNo ratings yet

- An Improved Hysteresis Model For Circular Reinforced Concrete Columns Under Cyclic Torsional LoadingDocument12 pagesAn Improved Hysteresis Model For Circular Reinforced Concrete Columns Under Cyclic Torsional LoadingKevin Prudencio ParraNo ratings yet

- Safety Assessment For Flange Climb Derailment of Train Running at Low Speeds On Sharp CurvesDocument7 pagesSafety Assessment For Flange Climb Derailment of Train Running at Low Speeds On Sharp CurvesnwatpdgrtmiepuwuiwNo ratings yet

- Experimental and Theoretical Dynamic System Identification of Damaged RC BeamsDocument11 pagesExperimental and Theoretical Dynamic System Identification of Damaged RC BeamsKy Visoth SambathNo ratings yet

- Implication of The Seismic Code On The Seismic Design of Bridges in AlgeriaDocument8 pagesImplication of The Seismic Code On The Seismic Design of Bridges in Algeriagorgika papandNo ratings yet

- Archive of SID: Comparison of Static and Dynamic Pushover Analysis in Assessment of The Target DisplacementDocument14 pagesArchive of SID: Comparison of Static and Dynamic Pushover Analysis in Assessment of The Target DisplacementAdel CivilNo ratings yet

- A Study On Hysteresis Modeling of Reinforced Concrete ColumnsDocument12 pagesA Study On Hysteresis Modeling of Reinforced Concrete ColumnsangelomarinilliNo ratings yet

- Seismic Capacity Evaluation of Post-Tensioned Concrete Slab-Column Frame Buildings by Pushover AnalysisDocument15 pagesSeismic Capacity Evaluation of Post-Tensioned Concrete Slab-Column Frame Buildings by Pushover AnalysisJavsarNo ratings yet

- Layered Control of Forklift Lateral Stability Based On Takagi-Sugenofuzzy Neural NetworkDocument15 pagesLayered Control of Forklift Lateral Stability Based On Takagi-Sugenofuzzy Neural NetworkReginald D'SouzaNo ratings yet

- En 16203 (2014) (E)Document3 pagesEn 16203 (2014) (E)Reginald D'SouzaNo ratings yet

- Analytical Method For Assessing StabilitDocument11 pagesAnalytical Method For Assessing StabilitReginald D'SouzaNo ratings yet

- Virtual Testing of Counterbalance Forklift TrucksDocument16 pagesVirtual Testing of Counterbalance Forklift TrucksReginald D'SouzaNo ratings yet

- Welcoming The VighnahartaDocument2 pagesWelcoming The VighnahartaDeepa HNo ratings yet

- Unit 4 Travel and Holidays: Pre IeltsDocument21 pagesUnit 4 Travel and Holidays: Pre IeltsQuoc Tan HuynhNo ratings yet

- Rodan and Fields Product GuideDocument17 pagesRodan and Fields Product GuideSusy MariaNo ratings yet

- What Is Physics Through The Eyes of ScientistsDocument39 pagesWhat Is Physics Through The Eyes of ScientistsAHMET TOPRAKNo ratings yet

- Cengg11 Midterm 2021Document2 pagesCengg11 Midterm 2021Angelo VilleroNo ratings yet

- wk06 IVDocument34 pageswk06 IVyingdong liuNo ratings yet

- ATs 5,6,7,8 in AHO2 2ndsem MidDocument7 pagesATs 5,6,7,8 in AHO2 2ndsem MidVanessa NicolNo ratings yet

- Final-Past Exam QuestionsDocument8 pagesFinal-Past Exam QuestionsKhánh Linh Nguyễn NgọcNo ratings yet

- kh7 CVPDocument50 pageskh7 CVPأبوأحمد الحكيمNo ratings yet

- First Long Test in SPS 7Document3 pagesFirst Long Test in SPS 7Dennmark IgutNo ratings yet

- MC Ad Lab2023Document111 pagesMC Ad Lab202321131a0445No ratings yet

- 12 Lecture 4-Seismic Waves AFTER MidDocument80 pages12 Lecture 4-Seismic Waves AFTER MidusamaNo ratings yet

- The Properties of Determinants:: 11 22 II NNDocument15 pagesThe Properties of Determinants:: 11 22 II NNVivek SinghNo ratings yet

- INFLATIONDocument24 pagesINFLATIONLovely Bordaje dela FuenteNo ratings yet

- Describe Image TemplatesDocument2 pagesDescribe Image TemplatesGanesh prasad AdhikariNo ratings yet

- Indian Railways Carbon EmissionsDocument9 pagesIndian Railways Carbon EmissionsTechTrip IndiaNo ratings yet

- Reservation List As of June 27Document104 pagesReservation List As of June 27Francis DedumoNo ratings yet

- Thesis On Wind Power PlantDocument6 pagesThesis On Wind Power PlantPaperWritingServicesBestEvansville100% (2)

- Chicken Pastel Recipe: IngredientsDocument5 pagesChicken Pastel Recipe: IngredientsMariam SalongaNo ratings yet

- Mech PDFDocument9 pagesMech PDFgurusamyNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- 01 Masonry Grout Filler - Group 180821Document2 pages01 Masonry Grout Filler - Group 180821Maha MuflehNo ratings yet

- Industrialised Building SystemDocument20 pagesIndustrialised Building SystemreenaNo ratings yet

- Final Report of LPG Gas StoveDocument69 pagesFinal Report of LPG Gas StoveUdit SharmaNo ratings yet

- NITIN Rdbms AssignmentDocument131 pagesNITIN Rdbms Assignmentnitinsingaur.bizNo ratings yet

- 16 RMM Spring Edition 2020 Solutions CompressedDocument83 pages16 RMM Spring Edition 2020 Solutions CompressedKhokon GayenNo ratings yet

- Floating Aerators Covering Aquafen: Technical Specifications Installation, Maintenance, Starting Up, and WarrantiesDocument6 pagesFloating Aerators Covering Aquafen: Technical Specifications Installation, Maintenance, Starting Up, and WarrantiesMehedi HasanNo ratings yet

- NBIMS-US V3 2.4.4.7 OmniClass Table 31 PhasesDocument8 pagesNBIMS-US V3 2.4.4.7 OmniClass Table 31 Phasesmahmoud mokhtarNo ratings yet

- Fault Level CalculationDocument1 pageFault Level Calculationpb21No ratings yet