Professional Documents

Culture Documents

FF Rev4

FF Rev4

Uploaded by

juniorferrari06Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FF Rev4

FF Rev4

Uploaded by

juniorferrari06Copyright:

Available Formats

1 2 3 4 5 6 7 8

1

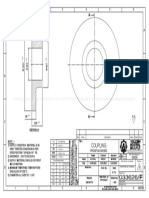

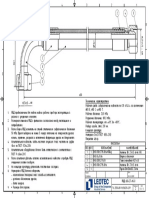

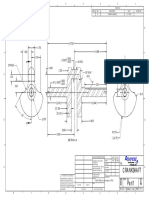

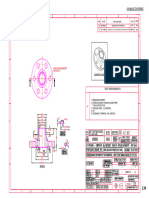

3089242 THIS DRAWING AND THE

REV. REVISION DESCRIPTION ECO DATE REVISED CHECKED

1 INFORMATION IT CONTAINS ARE

A THE PROPERTY OF DEERE-HITACHI 4 UPDATED NOTES.REVISED 21949 12/17/2015 J.SAVINA M.GLOWACKI A

PAGE DRAWING NO. CONSTRUCTION MACHINERY AND

MAY BE USED BY OTHERS ONLY PLATING SPECS IN NOTE 3.

DIMENSIONAL TOLERANCES AS AUTHORIZED.

FOR WELDING (TES 102-142)

L< 63 \ 1.6

63 <_ L < 125 \ 2.0

125 <_ L < 250 \ 2.5

250 <_ L < 500 \ 3.1 5

500 <_ L < 1000 \ 4.0

1000 <_ L < 2000 \ 5.0

2000 <_ L < 4000 \ 6.3

4000 <_ L < 8000 \ 8.0 10 (354 AREA OF INDUCTION HARDEN) 59

8000 <_ L < 16000 \ 10.0

6.3 6.3

DIMENSIONAL TOLERANCES

FOR MACHINING: MIDDLE (TES 102-144)

B 4

L <_

< L <_

4

16

\ 0.1

\ 0.2 6.3 6.3 6.3 3.2 B

16 < L <_ 63 \ 0.3 3.2

C2

63 < L <_ 250 \ 0.5

250 < L <_ 1000 \ 0.8

RAW MATERIAL

1000 < L <_ 4000 \ 1.2 5

AFTER PLATING

AFTER PLATING

65 -0.204

65 -0.204

0.2

-0.1

-0.1

8

70

64.5

C 15 DRILL C

R0.8 OR LESS 17 DRILL (THRU)

BOTH ENDS MAYBE

SAWCUT 20 20 (THRU)

127 122 30

382 28 1 (13)

(5) 423

428

REFER TO NOTE 1.

D D

LESS THAN

INDUCTION HARDEN AT 480

0.2

HARDNESS DEPTH

4 HS 65 ~80 2MM OR GREATER ( HV450)

NOTES:1. REFER TO NOTE 2

ALLOWABLE VALUE OF DISTORTION MUST BE LESS THAN 0.2 mm AFTER INDUCTION HARDENING.2. 4

THE LOT NUMBER TO BE STAMPED ON THE HEAD OF THE PIN.3.

4 ELECTROPLATE FINISHED PIN PER JIS H8610/8625 (MFZnll-C) (Cr6+)-Free REFER TO DWG.NO.9985429 ABOUT

MINIMUM PLATING THICKNESS TO BE 0.005 mm, MAXIMUM PLATING THICKNESS TO BE 0.020 mm SPECIFICATION OF MATERIAL

E ALTERNATIVE PLATING SPEC: JDM F23 C OR ASTM B633 Fe/Zn 5 TYPE V (WITH COLORLESS PASSIVATE) E

B H TQF700 D70 428 10.8

WORK SHOP NEXT HEAT MATERIAL SHAPE OF MATERIAL LENGTH WEIGHT

UNLESS OTHERWISE SPECIFIED STAT TREAT

SURFACE ROUGHNESS TO BE: METRIC SCALE PART CODE REFERENCE DRAWING NO.

1:2 065,0X0423,0 3087518

MODEL DRAWN DRAWN PART NAME

UNLESS OTHERWISE SPECIFIED 120D130G ZX130-6 SOUNODAI 09/21/99

SURFACE ROUGHNESS OF CHECKED APPROVED

METRIC THREADS TO BE PER

CLASS 2 OF JIS -

HASEGAWA

CHECKED SUZUKI

PIN

ELECTRONIC SIGNATURE DRAWING NO. PAGE REV.

F WELDING QUALITY

TES 102-097 1 4 F

DEERE-HITACHI PDF

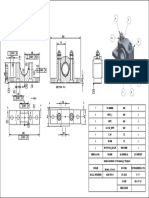

NOTE

FRAME_A3

PIECE

NO. DRAWING NO. Q-TY

1

PART NAME

2

MATERIAL SHAPE OF MATERIAL LENGTH

3

WEIGHT CONSTRUCTION MACHINERY

6 I-DEAS

3089242

7 8

1 STAMP

80

0

4 5

You might also like

- Post 3 45540 22 Pocket Pistol Dwgs PDFDocument9 pagesPost 3 45540 22 Pocket Pistol Dwgs PDF41das1100% (1)

- Decision Tables ExercisesDocument3 pagesDecision Tables ExercisesmubasherNo ratings yet

- FF850342 BZ Rev1Document1 pageFF850342 BZ Rev1juniorferrari06No ratings yet

- HLURB 2007 Stat Re LTSDocument2 pagesHLURB 2007 Stat Re LTSSheilaNo ratings yet

- 4 Way Power Div DrawingDocument1 page4 Way Power Div DrawingvenkyrkvNo ratings yet

- 2023-218 615 Kennedy RD - Raft FoundationDocument2 pages2023-218 615 Kennedy RD - Raft FoundationKiran JoshiNo ratings yet

- SM34165DTDocument1 pageSM34165DTancrsama_09No ratings yet

- DRW - 14 156484651Document1 pageDRW - 14 156484651k koradiaNo ratings yet

- Drawn Tolerances Unless SpecifiedDocument1 pageDrawn Tolerances Unless SpecifiedMuhammad NawirNo ratings yet

- Idnev 10.11.2020Document1 pageIdnev 10.11.2020ddgtNo ratings yet

- Metode Momen Distribusi (Cross) Contoh Soal: Panjang BatangDocument6 pagesMetode Momen Distribusi (Cross) Contoh Soal: Panjang BatangsupardipardiNo ratings yet

- Pps 13229Document1 pagePps 13229kawsar.bpNo ratings yet

- Sample Bar Chart, Manpower&Equipt. SchedDocument5 pagesSample Bar Chart, Manpower&Equipt. SchedThe EfferelNo ratings yet

- A C E D B H G K J I: BY CHK C.P. - New Release Rev Zone Revision Description DateDocument1 pageA C E D B H G K J I: BY CHK C.P. - New Release Rev Zone Revision Description Dateroy RamirezNo ratings yet

- Mazak Smart Series Live Tooling For Quick Turn Smart 200M 250M ManualDocument2 pagesMazak Smart Series Live Tooling For Quick Turn Smart 200M 250M ManualrazielakaNo ratings yet

- HOUSING2Document1 pageHOUSING2Danil AdityaNo ratings yet

- Shell, ResultadosDocument9 pagesShell, Resultadosandre.torresNo ratings yet

- Sheave With Ball Bearings: SeriesDocument1 pageSheave With Ball Bearings: SeriescoutoNo ratings yet

- 2.SLDDRWDocument1 page2.SLDDRWEricson. TatlongmariaNo ratings yet

- 1.SLDDRWDocument1 page1.SLDDRWEricson. TatlongmariaNo ratings yet

- Section A-A: PLUNGER, LGA, 7X7, G3Document1 pageSection A-A: PLUNGER, LGA, 7X7, G3Ericson. TatlongmariaNo ratings yet

- As Ulir M12: All Sharp Edges C0.3-0.5Document1 pageAs Ulir M12: All Sharp Edges C0.3-0.5Arief FibonacciNo ratings yet

- Material Requisition / Purchase SpecificationDocument16 pagesMaterial Requisition / Purchase SpecificationPalani KarthiNo ratings yet

- For Of: InstallationDocument26 pagesFor Of: Installationlokesh.kukadiyaNo ratings yet

- A DP 120160 DrawingsDocument1 pageA DP 120160 DrawingsShiladitya Aditya BasuNo ratings yet

- SlabDocument1 pageSlabAwadhi SuleimanNo ratings yet

- Impeler PDFDocument1 pageImpeler PDFArief FibonacciNo ratings yet

- Boxer PDFDocument5 pagesBoxer PDFmhNo ratings yet

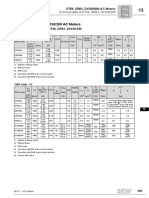

- 13 DT56, DR63, DV250/280 AC MotorsDocument36 pages13 DT56, DR63, DV250/280 AC MotorsSaim PAKERNo ratings yet

- IEC 60947-1-2007 Termal RiseDocument4 pagesIEC 60947-1-2007 Termal RisePhạmVănLuânNo ratings yet

- EML2322L Design For Manufacturing Examples PDFDocument13 pagesEML2322L Design For Manufacturing Examples PDFNitinNo ratings yet

- Poly 2180 PDFDocument2 pagesPoly 2180 PDFArpad BartiNo ratings yet

- Ok NG: Check Sheet Finish Good SSIDocument2 pagesOk NG: Check Sheet Finish Good SSIkutangkupaNo ratings yet

- Cover Housing: All Sharp Edges C0.3-0.5Document1 pageCover Housing: All Sharp Edges C0.3-0.5Arief FibonacciNo ratings yet

- Thyristor Bridge, SCR, Bridge: Disc DiodeDocument4 pagesThyristor Bridge, SCR, Bridge: Disc DiodeFran PerezNo ratings yet

- 1 Solid CrankDocument2 pages1 Solid CrankFaiq ZulfiarNo ratings yet

- Air BoxDocument1 pageAir BoxThái TrangNo ratings yet

- Despiece IDB 1250Document2 pagesDespiece IDB 1250MarcosNo ratings yet

- Laporan MingguanDocument36 pagesLaporan MingguanMiranda Primadini100% (1)

- BBS 07 Garden Beams 58.45 CheckedDocument14 pagesBBS 07 Garden Beams 58.45 Checkedgautam kumar PODDARNo ratings yet

- Degree of Leverage: Iocl 1.14193 1.847533 6.27214 12.5746 15.7416 INDUSTRY 6.666026 - 0.64564 - 0.06532 - 5.06864 - 0.15429Document18 pagesDegree of Leverage: Iocl 1.14193 1.847533 6.27214 12.5746 15.7416 INDUSTRY 6.666026 - 0.64564 - 0.06532 - 5.06864 - 0.15429rashi agarwalNo ratings yet

- Met S20 041 2400 1Document1 pageMet S20 041 2400 1Ranganathan RameshNo ratings yet

- 3W HousingDocument1 page3W HousingSuraj VishwakarmaNo ratings yet

- Skyrift24v1 ModelDocument1 pageSkyrift24v1 ModelPatrick Wendell CaballeroNo ratings yet

- Freno Histeresis 610-55 610 CutsheetDocument3 pagesFreno Histeresis 610-55 610 Cutsheetproydes proydesNo ratings yet

- Ti - OLFs - Vol - XVII 63Document1 pageTi - OLFs - Vol - XVII 63bknrdrfzh4No ratings yet

- Anchors Shall Be Hot Stamped To Show Rail Size and Date of Manufacturing (Date Code) - Dimensions in Inches (Millimeters)Document1 pageAnchors Shall Be Hot Stamped To Show Rail Size and Date of Manufacturing (Date Code) - Dimensions in Inches (Millimeters)didbeauNo ratings yet

- 01-LS-04.748-036-10001 Rev 0Document1 page01-LS-04.748-036-10001 Rev 0Dinesh YkatilNo ratings yet

- Standalone Financial Results For December 31, 2016 (Result)Document3 pagesStandalone Financial Results For December 31, 2016 (Result)Shyam SunderNo ratings yet

- Relé DowKey 401-2X08 - KDocument3 pagesRelé DowKey 401-2X08 - Kmiguel.pelicano@gmail.comNo ratings yet

- UntitledDocument12 pagesUntitledAdar OsNo ratings yet

- PlummerblockDocument1 pagePlummerblockBeesam Ramesh KumarNo ratings yet

- 13871R Lap RapDocument6 pages13871R Lap RapNguyen Dinh Quoc KhanhNo ratings yet

- CHKD Title Part Name DSGNDDocument11 pagesCHKD Title Part Name DSGNDNguyen Dinh Quoc KhanhNo ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous ONsqg3No ratings yet

- DIgSILENT RED - PROTECCIONESDocument1 pageDIgSILENT RED - PROTECCIONESSteven CanalesNo ratings yet

- Example 3: Analyze The Frame Completely. E 200gpa, I 0.0006M Member Area, M 1 0.05 2 0.03 3 0.02 4 0.03 5 0.05 6 0.02 7 0.02Document13 pagesExample 3: Analyze The Frame Completely. E 200gpa, I 0.0006M Member Area, M 1 0.05 2 0.03 3 0.02 4 0.03 5 0.05 6 0.02 7 0.02Kimberly Binay-anNo ratings yet

- PDS of GPL-30HTDocument1 pagePDS of GPL-30HTSaw VernalNo ratings yet

- Marks CalculatorDocument6 pagesMarks CalculatorPickup ZacNo ratings yet

- Magazine CoverDocument4 pagesMagazine CoverYadix RayNo ratings yet

- Api 0005CTDocument308 pagesApi 0005CTjuniorferrari06No ratings yet

- Api 0011PGTDocument75 pagesApi 0011PGTjuniorferrari06No ratings yet

- BS 5500-1997Document521 pagesBS 5500-1997juniorferrari06No ratings yet

- Asme b16.11Document27 pagesAsme b16.11juniorferrari06No ratings yet

- HDES-D0165 General Tolerance in Dimension (Eng)Document1 pageHDES-D0165 General Tolerance in Dimension (Eng)juniorferrari06100% (1)

- HGS102 190 (1) EngDocument10 pagesHGS102 190 (1) Engjuniorferrari06No ratings yet

- 1.0 Scope: Format Change OnlyDocument1 page1.0 Scope: Format Change Onlyjuniorferrari06No ratings yet

- ENS0201Document1 pageENS0201juniorferrari06No ratings yet

- FF850342 BZ Rev1Document1 pageFF850342 BZ Rev1juniorferrari06No ratings yet

- Engineering Specification: Jerry WarrenDocument20 pagesEngineering Specification: Jerry Warrenjuniorferrari06No ratings yet

- CGR1 Text ModeDocument11 pagesCGR1 Text ModeRaj SuraseNo ratings yet

- Data SufficiencyDocument7 pagesData SufficiencySaurav BhasinNo ratings yet

- ArenaDocument54 pagesArenaNVNo ratings yet

- 7 Natural Law Readings and Activity PDFDocument5 pages7 Natural Law Readings and Activity PDFLorelene RomeroNo ratings yet

- Efm Cip UfDocument6 pagesEfm Cip UfDaneAoneNo ratings yet

- SM 4500 OdDocument8 pagesSM 4500 OdThainy BressanNo ratings yet

- Secrets of A Millionaire Magician DeluxeDocument480 pagesSecrets of A Millionaire Magician DeluxelautaroNo ratings yet

- Class 10 Science Revision NotesDocument76 pagesClass 10 Science Revision Notessharmarajankumar822No ratings yet

- Prinsip-Prinsip EkonomiDocument11 pagesPrinsip-Prinsip EkonomiRev AwNo ratings yet

- Unit 2 PythonDocument37 pagesUnit 2 PythonANSH SINGHNo ratings yet

- Understanding The Self Syllabus 2nd Sem 2021-22Document7 pagesUnderstanding The Self Syllabus 2nd Sem 2021-22Mary Crisza RentoriaNo ratings yet

- Ohes4411 - 4Document42 pagesOhes4411 - 4Emre ParlakNo ratings yet

- Aluminium FormworkDocument14 pagesAluminium FormworkebinVettuchirayil100% (6)

- Secret CodesDocument6 pagesSecret CodesUMANo ratings yet

- Merged Smallpdf - Com 2Document185 pagesMerged Smallpdf - Com 2molihoneyNo ratings yet

- Ipc 2581BDocument9 pagesIpc 2581BlaxenovNo ratings yet

- The Condensed Satanic BibleDocument123 pagesThe Condensed Satanic Biblestregonebr100% (1)

- Ignou Assignment Wala Ehi 1 Solved Assignment 2018-19Document7 pagesIgnou Assignment Wala Ehi 1 Solved Assignment 2018-19NEW THINK CLASSES100% (1)

- Slide Plate ApplicationsDocument2 pagesSlide Plate ApplicationsvietrossNo ratings yet

- Bongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Document2 pagesBongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Cire HerreraNo ratings yet

- 752034main Ozone Hole Poster PDFDocument1 page752034main Ozone Hole Poster PDFTenveer BhuttaNo ratings yet

- A Movie CriticDocument12 pagesA Movie CriticEnge Perez Hong100% (1)

- 8344 20466 1 PBDocument11 pages8344 20466 1 PBpetra taeNo ratings yet

- Tooling CatalogDocument20 pagesTooling CatalogAlisNo ratings yet

- CMRIDocument6 pagesCMRIatnu_chowdhuryNo ratings yet

- GVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFDocument28 pagesGVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFanjanaNo ratings yet

- Pemanfaatan Produk Perikanan Sebagai Nilai Tambah-DikonversiDocument12 pagesPemanfaatan Produk Perikanan Sebagai Nilai Tambah-DikonversiUlfi MarjanNo ratings yet

- Pulse Amplitude ModulationDocument19 pagesPulse Amplitude ModulationShubhangBaghelNo ratings yet

- 2022-23 - Grade IV - Math - Term I - Revision PS 1Document7 pages2022-23 - Grade IV - Math - Term I - Revision PS 1sankar raoNo ratings yet