Professional Documents

Culture Documents

Astm A743 Cf3m

Astm A743 Cf3m

Uploaded by

akdrnlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A743 Cf3m

Astm A743 Cf3m

Uploaded by

akdrnlCopyright:

Available Formats

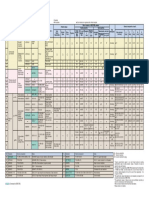

Material ‐ ASTM A743 CF3M

Standard Specification for Castings, Iron‐Chromium‐Nickel, Corrosion Resistant, for

General Application

Group ‐ Ferrous Stainless Steel Alloys

Sub Group ‐ ASTM A743 / A743M Casting, Iron‐Chromium‐Nickel, corrosion Resistant Casting, for General

Applicaton

Application ‐ Intended for Valves, Pumps, General Engineering, Automobile and Other Industries

Grade Belongs to the Industry ‐ Casting

Chemical Composition Heat Treatment

Carbon C% 0.030 max.

Silicon Si % 1.500 max.

Manganese Mn % 1.500 max.

Phosphorus P% 0.040 max. Solution Annealing

Sulphur S% 0.040 max.

Chromium Cr % 17.000 ‐ 21.000

Nickel Ni % 9.000 ‐ 13.000

Molybdenum Mo % 2.000 ‐ 3.000

Iron Fe % Balance Mechanical Properties

‐ ‐ ‐ Tensile Strength in Mpa 485 min.

‐ ‐ ‐ Yield Strength in Mpa 205 min.

‐ ‐ ‐ Elongation in % 30 min.

‐ ‐ ‐ Reduction of Area in % ‐

‐ ‐ ‐ Hardness in BHN ‐

‐ ‐ ‐ Impact in Joule ‐

Cross Reference Table

Material Standard Country Grade Belong to the Industry

316L AISI USA Bar, Wire, Strip, Plate, Sheet and Forging

1.4404 DIN Germany Cold Rolled, Strips, Slit Coils and Sheets

1.4404 EN European Union Rod, Bars, Wire and Forging

316 S 11 BS British Bright Bars, Hot Rolled and Cold Rolled Coil

SUS 316L JIS Japan Hot Rolled Equal Leg Angles

03CH17N14M3 GOST Russia Pipes, Fittings, Bar, Sheet and Forging

ASTM A 351 CF3M ASTM USA Casting

Further any inquiry to discuss with Gravity Cast Pvt. Ltd. – Gravity Group of Companies team member Call

on +918469160029, or email marketing@gravitycastindia.com

All information in our data sheets and website is indicative only and is not intended to be a substitute for the full specification from which it is extracted. It is intended to

provide typical values to allow comparison between metal alloy option rather than a definitive statement of mechanical performance or suitability for a particular

application as these will vary with temperature, product type and product application. It is presented apart from contractual obligations and does not constitute any

guarantee of properties or of processing or application possibilities in individual cases. Our warranties and liabilities are stated exclusively in our terms of business.

ONE STOP SOLUTION FOR METAL PARTS

You might also like

- Gateway B2+ Test Unit 1 ADocument6 pagesGateway B2+ Test Unit 1 Aana maria csalinas56% (9)

- DISA Parts and Services Catalogue 2019Document141 pagesDISA Parts and Services Catalogue 2019Yanto Daryanto100% (2)

- API Valve Trim ChartDocument2 pagesAPI Valve Trim Chartkhaireddin100% (1)

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Astm A351 Cf8Document1 pageAstm A351 Cf8akdrnlNo ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

- Astm B 163 N06690Document1 pageAstm B 163 N06690Cassio Lopes BrazNo ratings yet

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocument1 pageMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05No ratings yet

- Din 1.0619Document1 pageDin 1.0619aniketNo ratings yet

- Uns S44800Document1 pageUns S44800Mohammad TaherNo ratings yet

- Aisi 1045Document1 pageAisi 1045Achmad MiftahNo ratings yet

- DIN G S 17 CrMo 5-5Document1 pageDIN G S 17 CrMo 5-5kaushal sagarNo ratings yet

- Sae 1022Document1 pageSae 1022talebimahdi924No ratings yet

- Astm A216 WCBDocument1 pageAstm A216 WCBAkshay ValaNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- Asme Sa-29 1018Document1 pageAsme Sa-29 1018Nelson RangelNo ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Aisi 4330Document1 pageAisi 4330ahmedNo ratings yet

- Jis C 3602 BDDocument1 pageJis C 3602 BDvedveersinghNo ratings yet

- Jis H 5302 Adc12Document1 pageJis H 5302 Adc12Hazem MahmoudNo ratings yet

- Technical Specifications - ASTM A27 Grade 70-40Document1 pageTechnical Specifications - ASTM A27 Grade 70-40S.Mohsin AliNo ratings yet

- Ref TC - ANSI - AA B390Document1 pageRef TC - ANSI - AA B390Abhilash BaranwalNo ratings yet

- Astm B 491 6063Document1 pageAstm B 491 6063جبر البرحNo ratings yet

- BS 970 En8dDocument1 pageBS 970 En8djobseekerarulkumarNo ratings yet

- ASTM A 510 1040Document1 pageASTM A 510 1040ashishshukla.kecNo ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- NoRestriction - AFNOR NF 1.0213Document1 pageNoRestriction - AFNOR NF 1.0213Parag VirojaNo ratings yet

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaNo ratings yet

- ASTM A 494 CU5MCuCDocument1 pageASTM A 494 CU5MCuCdss1234No ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Ficha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)Document1 pageFicha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)freddy benavidesNo ratings yet

- Astm A29 4130Document1 pageAstm A29 4130comprasacsa1208No ratings yet

- ASTM B148 Nickle Aluminum Bronze UNS C95500Document1 pageASTM B148 Nickle Aluminum Bronze UNS C95500Aneesh AwasthiNo ratings yet

- ASTM A128 Grade B-3 PDFDocument1 pageASTM A128 Grade B-3 PDFEko PrasetyoNo ratings yet

- Sae J403 Uns G10050Document1 pageSae J403 Uns G10050Shrikar KuradeNo ratings yet

- Welding ConsumableDocument82 pagesWelding ConsumableAzmin BorkhanNo ratings yet

- Astm b176 Uns c86500Document1 pageAstm b176 Uns c86500Kashif MohiuddinNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Din en 1706 Ac - 71100Document1 pageDin en 1706 Ac - 71100Anudeep NittalaNo ratings yet

- Astm A 108 Grade 1215Document1 pageAstm A 108 Grade 1215sagj0330No ratings yet

- C 4721Document2 pagesC 4721Eileen TylerNo ratings yet

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Document10 pagesStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- Aluminum 7005-T6, 7005-T63, and 7005-T6351Document3 pagesAluminum 7005-T6, 7005-T63, and 7005-T6351Dule JovanovicNo ratings yet

- BS 970 070 M46Document2 pagesBS 970 070 M46Dinesh GaikwadNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Materials BookDocument37 pagesMaterials BooktanNo ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- Din 1Document1 pageDin 1ttpatelNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument2 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionALEX MURPHYNo ratings yet

- ss310sDocument2 pagesss310sFathia AlkelaeNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- UNSDocument42 pagesUNSPaolo Osorio WongNo ratings yet

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocument2 pagesCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Chapter 12Document61 pagesChapter 12AmalNo ratings yet

- Type 9, 12, 16, 20, 24 & 36 Brake Chamber (SD-02-1302)Document4 pagesType 9, 12, 16, 20, 24 & 36 Brake Chamber (SD-02-1302)Angel Dlsg100% (1)

- Bird Beak Adaptations LabDocument7 pagesBird Beak Adaptations LabjjNo ratings yet

- VMP 530vhmDocument2 pagesVMP 530vhmelienai10% (1)

- Canteen Block - Report DailuxDocument106 pagesCanteen Block - Report Dailuxkailash kumar soniNo ratings yet

- I. Personal Data Name: Age: Address: Contact No.: Name of ParentsDocument5 pagesI. Personal Data Name: Age: Address: Contact No.: Name of ParentsJohn MendozaNo ratings yet

- Hydro OneDocument28 pagesHydro Onefruitnuts67% (3)

- Software Engineering PresentationDocument3 pagesSoftware Engineering PresentationMohammad AlRifaiNo ratings yet

- DISASTER RISK ASSESSMENT Overview of Basic Principles and Methodology GeorgeDocument45 pagesDISASTER RISK ASSESSMENT Overview of Basic Principles and Methodology Georgedr georgeNo ratings yet

- FC Sem 3 Science in Every Day LifeDocument12 pagesFC Sem 3 Science in Every Day LifeHamza GhadiallyNo ratings yet

- Introduction To Business Policy and Strategic ManagementDocument3 pagesIntroduction To Business Policy and Strategic ManagementSaket BehlNo ratings yet

- 5 MSHMS Course DescriptionsDocument1 page5 MSHMS Course DescriptionsJay BagayasNo ratings yet

- Adverbs PlaceDocument2 pagesAdverbs PlaceLuizNo ratings yet

- Closed Loop Fed DC DriveDocument103 pagesClosed Loop Fed DC DriveDhivagar NamakkalNo ratings yet

- Syllabus in Pec 106Document6 pagesSyllabus in Pec 106Clarisse MacalintalNo ratings yet

- Post Tensioning System July 2018Document12 pagesPost Tensioning System July 2018pandianNo ratings yet

- Failure Codes Fendt 900 Vario 09 2007Document20 pagesFailure Codes Fendt 900 Vario 09 2007Maureen100% (66)

- Introduction To The Catering IndustryDocument33 pagesIntroduction To The Catering IndustrySandeep SinghNo ratings yet

- Technical Information: ProcedureDocument5 pagesTechnical Information: ProcedureOunna PechNo ratings yet

- Tornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartDocument1 pageTornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartGabriel Cabezas NaranjoNo ratings yet

- China's Foreign Exchange Market AnalysisDocument27 pagesChina's Foreign Exchange Market AnalysisMilanNo ratings yet

- QMLN 01 Schrödinger EquationDocument10 pagesQMLN 01 Schrödinger EquationAnum Hosen ShawonNo ratings yet

- UntitledDocument1,251 pagesUntitledMaria Jose Santos silvaNo ratings yet

- Alpha ThalassemiaDocument4 pagesAlpha ThalassemiaNorman DamaaNo ratings yet

- HSM 541 Week 7 Course ProjectDocument5 pagesHSM 541 Week 7 Course ProjecttheresajonesasNo ratings yet

- Non-Local Consciousness and The Anthropo PDFDocument4 pagesNon-Local Consciousness and The Anthropo PDFtoffaloniNo ratings yet

- C3g - 2 People v. NardoDocument2 pagesC3g - 2 People v. NardoAaron AristonNo ratings yet

- Ionic EquilibriaDocument2 pagesIonic EquilibriaAnonymous ZVYEN6rBNNo ratings yet