Professional Documents

Culture Documents

Tambour Cabinet Plan

Tambour Cabinet Plan

Uploaded by

vidawo1012Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tambour Cabinet Plan

Tambour Cabinet Plan

Uploaded by

vidawo1012Copyright:

Available Formats

Tambour

Console

Cabinet

1 Woodworker’s Journal

256.038-045 P2 Tambour Console Cabinet.indd 38 5/22/19 3:30 PM

By Rob Johnstone

Great details like waterfall

corners, handmade tambour

doors and tapered legs are an

inspiration to get into the shop!

A

s I was growing up, the furniture in our home

was Mid-Century Modern style. Of course,

then it was just furniture ... period. So that

may be one reason that I am drawn to the style. Not

everything Mid-Century Modern strikes my fancy,

but this console certainly does.

When you first look at the piece, it is easy to miss

many of the fine details. And that is one of the truly

pleasurable things about this console — the more

you look, the more you like. The wood grain of the solid

walnut flows around the carcass. The tambour doors provide

Waterfall Corner Joinery

excellent access to the interior and are a stunning collection of

vertical lines when closed. The angled and tapered legs (also

Waterfall joints are a subtle Next, if you are using a solid

of solid walnut) have the mass to balance the carcass and but lovely design feature that wood panel, aligning the stock

draw your eyes up from the floor. The interior of the console has gained popularity lately. as you glue up the large panel

is made from naturally finished maple plywood, making the can be a challenge. Splines or

Featured on kitchen islands in

most of the light that bounces into the recesses of the cabinet.

And, while certainly not last, the finish on the hand-selected cable TV home improvement biscuits can make that task eas-

walnut lumber brings out the rich color of this truly American shows, this particular type of ier, but be careful not to locate

wood. There are many more lovely details, but I will leave them where future machining

mitered corner has become

them for you to discover. Even so, I would like to give a nod to

Jacob Garrison and others on the Journal's staff for the work nearly ubiquitous. That's really will expose them to view. Take

they did in designing this project. what we are talking about: time to "compose” the panel,

mitered corners, conceived in arranging the boards for the

You Can Build This!

such a way as to allow the grain most pleasing blend of grain.

The techniques required to build this console are not overly

difficult and are within the skill level of most woodworkers. of your panel to "flow” around Additionally, you will need a

The biggest challenge is surfacing the wide walnut panels. the corner. way to accurately cut the miters

This task can be achieved using a variety of solutions, but it

So, what are the details to in your panel. This is critical.

should be considered before you start.

Go ahead and get your solid lumber and bring it into your keep in mind when you are con- (Here we constructed a crosscut

shop for a week or so to get it acclimated to its surroundings. sidering a waterfall joint? Let's sled for the table saw to make

Purchase about 30% more 5/4 roughsawn walnut than you

start with the most obvious: the that happen.) Finally, you'll need

think you will need to allow for regular waste and an “oops”

here or there. To accommodate the waterfall miter joinery, panel from which you’ll cut your a way to accurately align the

you will need boards of sufficient length: just a bit under 8' of corners has to be long enough to miter joints while wrangling

length as long as there are no serious flaws in the stock. Sur-

have continuous grain — in our a really large project. Again,

face the lumber to just a bit thicker than 1", say a scant 1/16"

over, so you can flatten the glued-up panel later and retain example here, the “waterfall” splines or biscuits are lifesavers

the 1" thickness. Joint the edges of the lumber to flatten and flows between the sides and the here. Having a friend around

square them 90° to the faces of the stock.

top. Our bottom panel does not during the glue-up is also a

Now you need to compose the panel (put the boards

together so the grain pattern is most pleasing) and do a bit of have continuous grain. good idea.

Woodworker’s Journal 2

256.038-045 P2 Tambour Console Cabinet.indd 39 5/22/19 2:20 PM

This project’s waterfall joinery

requires a very long panel.

Mark the miter locations as

well as where the biscuits will

be inserted to help plan your

panel’s layout.

noodling regarding how you will glue and clamp the panel to- the next page, you’ll find the details to create the template. It

gether. We used biscuits to help keep the boards’ edges nicely allows you to plow the tracks that the tambour doors will slide

aligned during the gluing and clamping phase. I also chose in as they open and close. I used a 5/16" straight bit chucked

Titebond® III for this task, as it has a longer open time. Every in my router and a properly sized rub collar to guide the tool.

little thing can be helpful. One note about the biscuits used to Because the interior will not be seen, I screwed the template

align the long boards: plan ahead and keep their locations out in place to be certain it would not move as I routed.

of the area where the mitered corner joints will occur. At this And here is an important point. Try as you might, when you

time, I also glued up the stock to make the bottom panel of create the template, it is unlikely to be exactly symmetrical.

the console. Because of that inaccuracy, if you were to trace the shape of

Once the glue has cured and you’ve removed the glue the template onto a large piece of paper, then flip the template

squeeze-out, it is time to cut the miters. The crosscut sled over and trace its shape again, you would see that the lines

we built for this task had a couple of special features. Pur- would not match perfectly. To avoid plowing mismatched

pose-built cleats and a toggle clamp held the panels securely. I tracks into the top and bottom panels, mark the opposite faces

first cut the panels to their exact size and then tilted the blade of the template “top” and “bottom.” When you plow the track

over to form the miters on the smaller pieces. Between those in the top, you should see the word “top,” and you should see

two cuts, I surfaced the panels to their 1" thickness. the word “bottom” when routing the bottom. Doing that will

There is a video online that documents nearly every step of keep the tracks perfectly aligned despite template irregularity.

building this console. View it by clicking on More on the Web For the last bit of routing, plow the dadoes that will later

at woodworkersjournal.com. accept the vertical dividers. These are stopped dadoes sized

to match the plywood thickness. See the Drawings for details.

Ready to Rout With that done, you have just a couple more tasks before you

With the four large walnut carcass

components cut to size and mitered,

form a 1/4" x 3/8" rabbet on their in-

terior back edges. When that’s done,

it is time to rout their inside faces. But

before you can do that machining,

you need to construct a template to

guide the router. In the Drawings on

To accurately miter cut

panels this large, the author

employed a crosscut sled

with cleats and a hold-down

clamp to secure the stock as

it was being cut.

3 Woodworker’s Journal

256.038-045 P2 Tambour Console Cabinet.indd 40 5/22/19 2:20 PM

1

15

7 9 8

8 12

9

10 8

9

6 11 10

5

13 13

14 2

4 4

3

Exploded View 4

Track Filler Piece

MATERIAL LIST (Top View) 4

TxWxL

1 Top (1) 1" x 18" x 44" Stile

14 (End View)

2 Sides (2) 1" x 18" x 20"

3 Bottom (1) 1" x 18" x 44" 30°

4 Leg Blanks (4) 3" x 31⁄ 4" x 17" Note: This small piece fills in

1

/8" 13 1"

the wood removed when routing

5 Tambour Handles (2) 7/8" x 21⁄ 8" x 181 ⁄ 2" the vertical divider dadoes.

21/2"

6 Tambour Sticks (40) 3/4" x 13 ⁄ 16" x 181 ⁄ 2"

7 Canvas Tambour Backing (2) Duck Canvas Fabric Groove Routing Template

(Top View) Each square = 1/2"

8 Vertical Dividers (3) 3/4" x 141 ⁄ 4" x 181⁄ 2"

Note: Make the

9 Vertical Divider Trim (3) 1/4" x 3/4" x 18" template from 1/4"

10 Shelves (2) 3/4" x 141 ⁄ 4" x 1613⁄ 16" plywood or hardboard.

Screw it to the

11 Shelf Trim (2) 1/4" x 3/4" x 1613⁄ 16" console pieces to

12 Inner Case Back (1) 1/4" x 18" x 351 ⁄ 4" keep it secure while

routing.

13 Stiles (2) 1" x 21 ⁄ 2" x 18"

14 Track Filler Pieces (4) 1/4" x 3/4" x 3/4"

15 Back Panel (1) 1/4" x 181⁄ 2" x 421 ⁄ 2"

Tambour Console Hard-to-Find Hardware

TransTint® Orange Dye (1) #22307 ....................................... $21.99 ea.

1/4" Nickel Pin Supports (1) #22773 ..................................... $4.99 pk.

Rockler Tambour Router Bit Set (1) #61896 ................... $99.99 ea.

Slipstick® Round Self-Stick Felt Pads (1) #57071 .......... $4.99 pk.

Rockler High-Carbon Steel Forstner Bit (1) #56974 .... $27.99 ea.

T-Slot Bolts-5/16" - 18 Thread 1" Long (4) #33965 .......... $1.49 ea.

Hex Drive Threaded Inserts (1) #31880 .............................. $6.99 pk.

To purchase these and other products online,

visit www.woodworkersjournal.com/hardware or

call 800-610-0883 (code WJ1577).

Woodworker’s Journal 4

256.038-045 P2 Tambour Console Cabinet.indd 41 5/28/19 10:55 AM

Plowing the track that the

tambour doors will slide in

requires a template to guide

the cut. Screw the template in

place for routing.

can glue the carcass together. The first is to

form the angled leg mortises in each corner

of the bottom. I did that by building a jig to

hold the bottom at the 7° angle on top of

my drill press table. As you can see in the

photos below, I made use of a 27 ⁄ 8"-diameter

Forstner bit to excavate the round mortises.

I tested the setup using some scrap plywood

before I drilled into the walnut bottom (bet-

ter safe than sorry). Later, the legs will be

turned to fit tightly into the angled recesses.

Before you leave the drill press, take the

time to bore a hole through the bottom at

the center of each leg mortise. You can use

the same jig as you drill these 3/8"-diameter

holes. Later, you will use these holes when

you mount the legs with threaded inserts.

Don’t be alarmed when the 3/8" holes inter-

sect with the dadoes; they’re supposed to do

so. In fact, now would be a good time to chop

out the four tiny mortises to fit the ends of

the T-nuts that will be installed later.

Cut three dadoes into the top and bottom panels to house the vertical dividers. Where the dadoes Glued-on Clamping Cauls

interrupt the tambour track, small fillers will be added to allow the doors to slide smoothly. Gluing and clamping together a large

mitered cabinet like this is no small chal-

lenge. I took two steps to make it easier. First, I sliced

three biscuit mortises per corner, to once again aid in

keeping the joints perfectly aligned. Second, I made

clamping cauls from scrap plywood. I glued those cauls

in place on the outside corners of the sides, bottom and

top, using a single squiggly line of liquid hide glue. I

A drill press jig will help bore the leg mortises at the proper

7° angle. Turn the top diameter of the legs to fit these mortises

tightly — it will add strength to the joints.

5 Woodworker’s Journal

256.038-045 P2 Tambour Console Cabinet.indd 42 5/22/19 2:20 PM

just rubbed the cauls back and forth until they

“grabbed,” employed a couple of Rockler Bandy

Clamps to hold them securely and then let them

cure for an hour or so.

I can almost hear you saying, “Why in the world

would you glue those ugly chunks of plywood to

the cabinet?” Don’t worry, they are just tempo-

rary: after the console is assembled, you will take

a chisel and break the cauls away. A little sanding

and scrubbing with some water (a big advantage

of hide glue’s reversibility!) and you will never

know the cauls were there — except that the miter

joints will be as tight as can be. Managing the glue-up of a large carcass like this one requires careful preparation.

It is always a good idea to do a dry assembly to Here, the author dry assembles the console to test fit the corner joints and to practice the

check out your joinery. That also gives you a test clamping order and procedure.

Now go ahead and build the legs. They are made from

glued-up walnut blanks measuring 3" x 31 ⁄ 4" x 17". Their shape

is a straight taper that starts at 27 ⁄ 8" at the wide end and reduc-

es to a 1" diameter at the narrow end. I mounted mine on the

lathe by drilling a hole for a threaded insert at the wide end

and then using a mandrel in the drive head of the lathe. (The

threaded inserts and bolts are optional, but I found them to be

a good idea.) A standard live center will work at the narrow

end. Start with a spindle roughing gouge, get the shape close,

then switch to a square-end scraper. If you are comfortable

with it, finish the task with a skew chisel. Sand the legs

smooth all the way up to 600-grit paper. With that, the shaping

is done, but before you set them aside, take a few minutes

A thin bead of liquid hide glue attaches the temporary clamping cauls to and seal the end grain of the wide end of the legs with hide

the carcass components. These cauls will then be easy to break loose

glue. Later, you’ll use the same glue to secure the legs in their

without damaging the wood: simply scrub away the dried glue.

mortises. This step will make the leg joints much stronger.

run to determine how complicated the glue-up process will be.

The clamping cauls make this gluing and clamping process so

much easier to do. If the glue joints fit well, go

ahead and apply glue and clamp the carcass to-

gether, and measure the diagonals to verify it is

square. Allow the glue to cure for several hours,

overnight if possible. After the glue cures, use

a wide chisel and a mallet to pop the cauls off of

the walnut. Do this by laying the flat back of the

chisel on the walnut, and use the bevel of the

chisel as a wedge to pop and pry the cauls free.

Then sand and wash the hide glue residue away.

A combination of glued-on cauls and

alignment biscuits turn this challenging

assembly job into a very manageable task.

Woodworker’s Journal 6

256.038-045 P2 Tambour Console Cabinet.indd 43 5/22/19 2:20 PM

Tambour is Terrific door. You join them by gluing them to a canvas backing. I

If you have never made a tambour panel before, it can seem a used liquid hide glue to glue the canvas to the tambour, but

bit tricky and even overly complicated. But in truth, it is really the tambour sticks need to be tightly held together as that

pretty easy, especially when you use Rockler’s tambour cut- process happens. So build a frame on a plywood substrate as

ting router bits. Following the directions on the tambour bit shown in the photo below. Keep one of the three frame pieces

packaging, cut your stock to its width and thickness. I chose removable so that you can screw it in place and apply pressure

to leave the pieces long, rather than cut them to length before — compressing the tambour pieces together (with the addi-

I machined them. I think it saved time. Each piece needs to be tional tambour “door handle” piece in place). With the sticks

machined twice. Make sure you shape enough stock to have a in their jig, use blue masking tape to create a boundary for the

few extra pieces, then cut the pieces to length. hide glue when it is applied.

Tambour Rabbet

The next step is to cut a small rabbet into the front-facing Cut your canvas oversized Detail 1

/4"

ends of each piece of tambour. These rabbets will allow the and spread the liquid hide (Side View)

pieces to fit and slide in the top and bottom tracks. I made glue onto both the canvas and 1

/4"

a little jig to hold each piece and used a dado stack to form the tambour assembly with

the rabbet on the table saw. See the Drawing at right for the a small roller. Put a heavier

tambour details. coat of glue on the canvas and

With the machining done, you’ll need to hold the tambour a light coat on the assembly.

6

together as you assemble the separate sticks into a sliding Then carefully lay the canvas,

Tambour Assembly

1

/2" 3

/4" 1

/2" (End View)

3

/8"

5 6 6

Rockler’s tambour router bit set makes the two-step routing process

easy and manageable. Be sure to use featherboards to keep the

tambour stock well-controlled while shaping the edges.

With the tambour sticks tightly

held in a frame, apply liquid

hide glue to both the tambour

assembly and the canvas

backing. A small foam roller

will allow you to control the

amount of glue applied.

7 Woodworker’s Journal

256.038-045 P2 Tambour Console Cabinet.indd 44 5/22/19 2:21 PM

Add Orange to Your Walnut

Walnut lumber that has been

kiln-dried sometimes ends up

glue to glue, on top of the tambour panel and vigorously rub looking gray and wan. Our

it smooth with your hand. The heat from the friction you

finishing expert, Michael

create will help the bond form. After the glue has cured, use

a razor knife to trim the canvas at the perimeter you formed Dresdner, recommends using

with the masking tape. It works really slick. Remove the panel an orange dye on bland-looking

from the jig and test the fit in the console carcass. Repeat the

walnut to pop the colors that

process for the second panel.

may have been muted by the

Adding the Interior Components drying process. The dye is easy

Take some time now to cut the vertical dividers and their

to use: mix it with water, flood

shelves. I drilled 1/4" holes for shelf pins in just the left-hand

compartment, but you can make the shelves in both compart- it onto the wood and then wipe

ments adjustable if you prefer. I applied a hardwood strip to it off. In the case of our console,

their front edges, as well as on the vertical dividers. I stopped

the outcome was stunning.

those strips to create two small notches at either end of the di-

viders (see the Drawings) so these strips would hide the end

of the routed dadoes. Create the plywood back panel for the wool, allowing the wax to dry between coats and buffing it

internal compartment, and set all those pieces aside for now. with a soft clean cloth. In my opinion, this delivers a perfect

Next, make the walnut stiles that are located on both sides Mid-Century Modern finish and truly enhances the piece.

of the carcass, where they are set back in the opening about After the finish was applied, I assembled the components,

1/4" to hide the curve in the tambour track. They need to starting by attaching the legs with hide glue and T-bolts. Then

fit tightly and are attached with pocket-hole screws. The I added the interior components, slid the tambour doors into

carcass’s back panel is 1/4" Masonite — very typical of this their tracks, installed the track spacers and finally tacked the

construction style. Go ahead and cut a piece to fit. back panel in place.

There are four tiny track filler pieces that you need to make While I am taking credit for this project, it was truly a group

now, as well. They fill in small gaps in the tambour track that effort. The good news for you is that we figured out all the

were incidentally formed when the dadoes for the vertical details and you can build it and properly get all the credit.

dividers were cut. See the Drawing for details.

Rob Johnstone is publisher of Woodworker's Journal

Finishing and Final Assembly

Well, you’ve been waiting for it ... it

is time to sand! I sanded all the hard-

wood pieces of the console up through

600-grit, because I wanted a specific

finish that is slightly out of the norm.

For me, the beauty of the walnut was

paramount. So, my plan was as follows:

sand ultra-smooth, apply an orange dye

(suspended in water) to the walnut, use

#0000 steel wool to polish down the grain

that the water-based dye raised, apply a

thinned coat of Zinsser® SealCoat™ to

seal the wood cells, and then apply three

coats of clear BRIWAX® using more #0000 steel

www.woodworkersjournal.com

MORE ON THE WEB

As beautiful in 2019 as it would have been

in 1950, this tambour door walnut console To watch a video of the author building the Tambour

is a piece of furniture to use and enjoy. VIDEO Console Cabinet, please visit woodworkersjournal.com

and click on "More on the Web" under the Magazine tab.

Woodworker’s Journal 8

256.038-045 P2 Tambour Console Cabinet.indd 45 5/22/19 2:21 PM

You might also like

- Internal Cutters: Manual E535Document23 pagesInternal Cutters: Manual E535Wagner AmaralNo ratings yet

- Shaker FurnitureDocument25 pagesShaker Furniturevictor100% (1)

- Woodworking Woodcraft Project Book PDFDocument10 pagesWoodworking Woodcraft Project Book PDFmaxi_131200100% (1)

- The Essential "All Purpose" Workbench: Challenging ProjectDocument34 pagesThe Essential "All Purpose" Workbench: Challenging ProjectB. IonutNo ratings yet

- PagodarackDocument7 pagesPagodarackDoctor FunkNo ratings yet

- Wooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsFrom EverandWooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsRating: 5 out of 5 stars5/5 (1)

- FLTM BP 101-01 Rubber Ozone ResistanceDocument10 pagesFLTM BP 101-01 Rubber Ozone ResistanceFrancesco VignaliNo ratings yet

- Your Guide To Shaker Furniture: 3 Classic ProjectsDocument25 pagesYour Guide To Shaker Furniture: 3 Classic Projectsjpl.guedes6842100% (1)

- Building A Chain of Underground ChasmsDocument17 pagesBuilding A Chain of Underground ChasmsUser7222No ratings yet

- SN08016 - Heirloom Tool CabinetDocument19 pagesSN08016 - Heirloom Tool Cabinetxploited.caNo ratings yet

- Cheerful ChapterchapOneDocument8 pagesCheerful ChapterchapOnekq9yzcgkdtNo ratings yet

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDocument5 pagesSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNo ratings yet

- Gentleman's Workbench Stool Cabinet: Colin Sullivan Is InspiredDocument8 pagesGentleman's Workbench Stool Cabinet: Colin Sullivan Is InspiredVideo100% (1)

- 18th Century Six-Board ChestDocument6 pages18th Century Six-Board ChestSteven HeinsNo ratings yet

- WJ149 Steamer Trunk Dresser PDFDocument9 pagesWJ149 Steamer Trunk Dresser PDFroose1100% (2)

- A Donut Fort and Huts and HutsDocument4 pagesA Donut Fort and Huts and HutsFaustnikNo ratings yet

- A Classic CaseDocument6 pagesA Classic Casediegocearram100% (4)

- Let's Make A Crokinole Board!: by GeekswoodshopDocument14 pagesLet's Make A Crokinole Board!: by GeekswoodshopManuel TorresNo ratings yet

- December 2015 PWM Pages 39 42Document4 pagesDecember 2015 PWM Pages 39 42JuanRodriguez100% (2)

- Simple 8 X 8 ShedDocument41 pagesSimple 8 X 8 ShedJeremy SmathersNo ratings yet

- Hanging ShelvesDocument2 pagesHanging ShelvesdjfwalkerNo ratings yet

- The Basics Conga DrumDocument10 pagesThe Basics Conga DrumAidil Amin100% (1)

- Melting Display Shelves PlansDocument14 pagesMelting Display Shelves Plansmihai.stanNo ratings yet

- Jewelry BoxesDocument14 pagesJewelry BoxesDan Goodpasture100% (4)

- Low Cherry Bookcase: © 2013 August Home Publishing CoDocument12 pagesLow Cherry Bookcase: © 2013 August Home Publishing CoGeorge BoyleNo ratings yet

- Chip Carved Book RackDocument17 pagesChip Carved Book Rackjofoeus100% (1)

- Bow Top Conestoga Gypsy Vardo: InstructablesDocument28 pagesBow Top Conestoga Gypsy Vardo: InstructablesRod HyattNo ratings yet

- Coffee TableDocument9 pagesCoffee TableMostagfera100% (1)

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

- A Bridge Too Far: Building An Arnhem Battlefield by Kyran HenryDocument6 pagesA Bridge Too Far: Building An Arnhem Battlefield by Kyran HenryFixxxer76100% (2)

- How To Build A Wood Paddle BoardDocument8 pagesHow To Build A Wood Paddle BoardJavi JaviNo ratings yet

- Corner O Ce Desk: Step 1: PlansDocument28 pagesCorner O Ce Desk: Step 1: Plansarmando.alanisNo ratings yet

- TV TableDocument4 pagesTV TableSergioNo ratings yet

- BookcasePlans PDFDocument26 pagesBookcasePlans PDFFlogamag100% (1)

- Making A Plywood Kayak PDFDocument44 pagesMaking A Plywood Kayak PDFEber Davalos100% (1)

- ABlanket Chest With LegsDocument6 pagesABlanket Chest With LegsAnonymous QJ5j94luLmNo ratings yet

- (Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildDocument38 pages(Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildAbraham TedyNo ratings yet

- How To Build An Optimist: How Hard Can It Be, There's Only Five Bits ofDocument4 pagesHow To Build An Optimist: How Hard Can It Be, There's Only Five Bits ofhaujes0% (1)

- Build Better BookcasesDocument10 pagesBuild Better BookcaseslucaskrowNo ratings yet

- Bonus Download Scroll SawDocument15 pagesBonus Download Scroll SawAdrian Lopez89% (9)

- RoutertableDocument5 pagesRoutertablesenthil karthik100% (1)

- WJ041 G&G Inspired DeskDocument0 pagesWJ041 G&G Inspired Deskroose1100% (1)

- Dioramas PDF FreeDocument19 pagesDioramas PDF FreeluizNo ratings yet

- Classic Oak Book Press W/Dovetails: Step 1: Prepare The WoodDocument14 pagesClassic Oak Book Press W/Dovetails: Step 1: Prepare The Woodeugenio algeciras100% (1)

- Build The Tango: by Hank BravoDocument57 pagesBuild The Tango: by Hank BravoMarceloRossel100% (1)

- An Everyday CabinetDocument8 pagesAn Everyday CabinetJonathan Hopkins100% (2)

- How To Build A DoorDocument12 pagesHow To Build A DoorOkidok OkickiNo ratings yet

- Turn in Order Rotating BookcaseDocument7 pagesTurn in Order Rotating BookcasexXAlbert10Xx100% (1)

- Cherry and Fir BookcaseDocument6 pagesCherry and Fir Bookcasecaballo_blanco_2100% (1)

- Build Workbranch 1Document14 pagesBuild Workbranch 1cu-bisNo ratings yet

- T Mmi: Tambour Cabinet DoorsDocument5 pagesT Mmi: Tambour Cabinet DoorsTrọng LêNo ratings yet

- Plansnow Frame PanelDocument3 pagesPlansnow Frame PanelTa JavoNo ratings yet

- Model Train Layouts PDFDocument7 pagesModel Train Layouts PDFwarhammer123210% (1)

- Scrap Adirondack ChairDocument9 pagesScrap Adirondack ChairVictor M GonzalezNo ratings yet

- FWW SecretaryDocument8 pagesFWW SecretaryCaio Bernardes Fonseca Weber AbramoNo ratings yet

- Mistral HullDocument5 pagesMistral HullmikeNo ratings yet

- EAA 1000 Worktable PlansDocument5 pagesEAA 1000 Worktable PlansFrankVarrecchioNo ratings yet

- Oval Boxes: How To Make Steambent ContainersDocument4 pagesOval Boxes: How To Make Steambent ContainersAnonymous QJ5j94luLmNo ratings yet

- 100 Weekend Projects Anyone Can Do: Easy, practical projects using basic tools and standard materialsFrom Everand100 Weekend Projects Anyone Can Do: Easy, practical projects using basic tools and standard materialsRating: 5 out of 5 stars5/5 (4)

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Build Your Own Inexpensive Dollhouse: With One Sheet of 4' by 8' Plywood and Home ToolsFrom EverandBuild Your Own Inexpensive Dollhouse: With One Sheet of 4' by 8' Plywood and Home ToolsRating: 4.5 out of 5 stars4.5/5 (3)

- W213 Main Battery ReplacementDocument3 pagesW213 Main Battery Replacementvidawo1012No ratings yet

- Oil Maintenance (A Markets) Panamera V6 E-Hybrid Panamera Diesel S Diesel As of 2017 ModelDocument1 pageOil Maintenance (A Markets) Panamera V6 E-Hybrid Panamera Diesel S Diesel As of 2017 Modelvidawo1012No ratings yet

- Wood Pallet Composter: PostbiDocument2 pagesWood Pallet Composter: Postbividawo1012No ratings yet

- Porsche - Panamera - Engine PerformanceDocument256 pagesPorsche - Panamera - Engine Performancevidawo1012No ratings yet

- 28 Inch Mattone Cupola - Oven - BrickWood OvensDocument19 pages28 Inch Mattone Cupola - Oven - BrickWood Ovensvidawo1012No ratings yet

- Cortile Barile - Step 1 of 3 - Oven - BrickWood OvensDocument16 pagesCortile Barile - Step 1 of 3 - Oven - BrickWood Ovensvidawo1012No ratings yet

- Porsche 2020 992 OWM V2Document314 pagesPorsche 2020 992 OWM V2vidawo1012No ratings yet

- TWS 992 Powertrain ENDocument28 pagesTWS 992 Powertrain ENvidawo1012No ratings yet

- Modern Farmhouse Bed FrameDocument10 pagesModern Farmhouse Bed Framevidawo1012No ratings yet

- US AutoSeal II 100 (EN) 2009 12Document54 pagesUS AutoSeal II 100 (EN) 2009 12tafhim rashidNo ratings yet

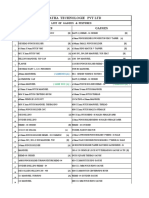

- List of Gauges & FixtureDocument8 pagesList of Gauges & FixturevenkatNo ratings yet

- ACT 7 Packer Technical ManualDocument15 pagesACT 7 Packer Technical ManualyasirismNo ratings yet

- HILTI - Cutting, Sawing and GrindingDocument14 pagesHILTI - Cutting, Sawing and GrindingSreekumar NairNo ratings yet

- 450 6152 30 Cummins M 11 InstructionsDocument4 pages450 6152 30 Cummins M 11 InstructionsJoseDavidSanchezYepes100% (1)

- Parkinson Gear Tester MetrologyDocument9 pagesParkinson Gear Tester MetrologyGabriel SoaresNo ratings yet

- TT Invertible PackerDocument12 pagesTT Invertible Packercasda73No ratings yet

- SR 2 4 Eco MechDocument168 pagesSR 2 4 Eco MechAniketos BubahimanaNo ratings yet

- The Rotary Draw Tube Bending GuideDocument13 pagesThe Rotary Draw Tube Bending GuideFernandoNass100% (3)

- CASVDocument17 pagesCASVvegaronNo ratings yet

- Modern American LATHE PRACTICEDocument438 pagesModern American LATHE PRACTICEJollygreen21100% (1)

- Ebook Learning Chinese Language and Culture Intermediate Chinese Textbook Volume 2 Weijia Huang Online PDF All ChapterDocument69 pagesEbook Learning Chinese Language and Culture Intermediate Chinese Textbook Volume 2 Weijia Huang Online PDF All Chapterjoseph.connell873100% (7)

- Standing Seam SSQ (Nueva)Document159 pagesStanding Seam SSQ (Nueva)Erick Quan LunaNo ratings yet

- Art Jewelry Corrugated Knot Chain Bracelet Howard SiegelDocument6 pagesArt Jewelry Corrugated Knot Chain Bracelet Howard SiegelAlexa Miha100% (3)

- HAINBUCH Segmented Mandrel MANDO T211 RD Installation ManualDocument72 pagesHAINBUCH Segmented Mandrel MANDO T211 RD Installation Manualsrinivas mNo ratings yet

- Design and Fabrication of Metal Spinning ComponentsDocument6 pagesDesign and Fabrication of Metal Spinning ComponentsAnonymous VRspXsmNo ratings yet

- Turner - 2nd - Year - (Volume II of II) TPDocument135 pagesTurner - 2nd - Year - (Volume II of II) TPravi9811075184No ratings yet

- Parkinson Gear Tester MetrologyDocument9 pagesParkinson Gear Tester MetrologyPriyank SharmaNo ratings yet

- DBC-4540A ENGLISH MANUAL (Updated)Document34 pagesDBC-4540A ENGLISH MANUAL (Updated)juan estebanNo ratings yet

- Boot Basket in EnglishDocument2 pagesBoot Basket in Englishyeruar 07No ratings yet

- Catalog 2016-2017Document498 pagesCatalog 2016-2017catcutzuNo ratings yet

- Como Hacen Cañones Er18980121Document24 pagesComo Hacen Cañones Er18980121flamenquitoNo ratings yet

- Gear Cutting Attachment For Small Lathes 209Document2 pagesGear Cutting Attachment For Small Lathes 209IyappanNo ratings yet

- Envisionlabs Wood ClocksDocument22 pagesEnvisionlabs Wood ClocksAlfonso100% (1)

- Metal Cutting and Production LAB Manual-New (ME452)Document58 pagesMetal Cutting and Production LAB Manual-New (ME452)Ravichandran GNo ratings yet

- Power Tools Vocabulary and FlashcardsDocument19 pagesPower Tools Vocabulary and Flashcardsapi-3815499890% (1)

- DI333 541 561 EngDocument21 pagesDI333 541 561 EngKrishna Mohan.p.rNo ratings yet

- Perforadora Cop-1432MEDocument52 pagesPerforadora Cop-1432MEsandropemaNo ratings yet