Professional Documents

Culture Documents

08072016000000record Est 317-1-Engl-Rev 0

08072016000000record Est 317-1-Engl-Rev 0

Uploaded by

Ayodele MastaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08072016000000record Est 317-1-Engl-Rev 0

08072016000000record Est 317-1-Engl-Rev 0

Uploaded by

Ayodele MastaCopyright:

Available Formats

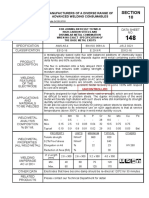

Record EST 317-1

Flux for cladding

EN 760 :(E) SA FB 2 Cr Ni Mo

DESCRIPTION

• Highly basic agglomerated flux for Electroslag strip cladding of alloy 317L in one layer with

Soudotape 21.13.3L

• Excellent weldability and good wetting

• Easy slag removal even at high temperatures

GENERAL CHARACTERISTICS

• Current DC+

• Basicity index 5.5 ( according to Bonizewski; calculated in mole % )

• Grain size 0.25 - 1 mm ( 18 x 60 N° ASTM )

• Apparent density 1.0

• Consumption 0.75( kg fused flux / kg strip )

• Redrying 1 to 2 hours at 350 +/- 50°C

• Applicable strip dimensions :

Strip widths (mm) 30 60 90

Typical deposition rates 12 24 36

(kg/h)

TYPICAL WELD METAL ANALYSIS OF STRIP/FLUX COMBINATION (WEIGHT %)

• Base metal 2 ¼Cr 1Mo

• Strip dimensions 60 x 0.5 mm

• Cladding parameters 1350 A - 24 V - 25 cm/min

Alloy Layer Strip C Mn Si Cr Ni Mo N Thickn. FN

Soudotape (mm)

317L - 21.13.3L 0.010 1.60 0.23 21.2 14.8 2.80 0.020 - -

317L 1 21.13.3L 0.015 1.20 0.30 18.5 13.8 3.20 0.030 4 7

PACKING

25 kg (pail): SAP Stock number: 46082

All information provided is based upon careful investigation and intensive research. CJ 02/2015 Rev. 0

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Matlab Music SynthesisDocument11 pagesMatlab Music SynthesisDarwin Lajato Tipdas0% (1)

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- Flux Cored - Welding Wire - E71T-1Document1 pageFlux Cored - Welding Wire - E71T-1Hafiz HidayaturrakhmanNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- (g02!01!049) Toj XX ZZM NSN Unv (Nokia)Document2 pages(g02!01!049) Toj XX ZZM NSN Unv (Nokia)Chusé Antón Burillo ArbejNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- Las Tek FillerDocument2 pagesLas Tek Fillerseeralan balakrishnanNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- 1snk516010r0000 CPDocument1 page1snk516010r0000 CPArturoNo ratings yet

- ETABS 19.1.0-Design Details3Document2 pagesETABS 19.1.0-Design Details3Alejandro Tovar MolinaNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Description Appearance: 1 Watt Metal Case Zener DiodesDocument3 pagesDescription Appearance: 1 Watt Metal Case Zener DiodesStuxnetNo ratings yet

- tOP SLABDocument68 pagestOP SLABSagar GowdaNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- Trench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 PackingDocument10 pagesTrench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 Packingkrimo biomédicalNo ratings yet

- LPCB Fire Resistant CableDocument2 pagesLPCB Fire Resistant CableArjunNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- SokenDocument2 pagesSokenRamires dos SantosNo ratings yet

- SDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 BeaconDocument1 pageSDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 Beaconchandrahai hrangkhawlNo ratings yet

- 5 - K. Horova, J. Tomsu, F. Wald - To Base Plates of Hollow Sections ColumnsDocument36 pages5 - K. Horova, J. Tomsu, F. Wald - To Base Plates of Hollow Sections ColumnsAnonymous bqV7MbFSuNo ratings yet

- Selectrode: 7018 Moisture Resistant Low HydrogenDocument3 pagesSelectrode: 7018 Moisture Resistant Low HydrogenbalamuruganNo ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- TR-XLPE Power CableDocument2 pagesTR-XLPE Power CableRodni EmslieNo ratings yet

- Input Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)Document7 pagesInput Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)sloane01No ratings yet

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosNo ratings yet

- Cor A Rosta304lDocument2 pagesCor A Rosta304lbhichaiNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- Simplified Calculation of U-Value and Total Thermal Resistance of A Structural ElementDocument1 pageSimplified Calculation of U-Value and Total Thermal Resistance of A Structural ElementKantishNo ratings yet

- Ferrites and Accesories - E 25-13-7 (EF25) PDFDocument10 pagesFerrites and Accesories - E 25-13-7 (EF25) PDFcarlosD2884No ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Light/Extra Light Pipe To Australian Standards: Specification GalvanizingDocument1 pageLight/Extra Light Pipe To Australian Standards: Specification GalvanizingMohamed amine El mtalakNo ratings yet

- T300 Technical Data Sheet 1 PDFDocument2 pagesT300 Technical Data Sheet 1 PDFmaraNo ratings yet

- Duplex Basket Strainer EnglishDocument3 pagesDuplex Basket Strainer EnglishEko PrastyoNo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesAdel DechirNo ratings yet

- ACS712 Low Current Sensor Board v14Document5 pagesACS712 Low Current Sensor Board v14geniunetNo ratings yet

- Katalog Armored 2016Document40 pagesKatalog Armored 2016RizalNo ratings yet

- Bidirectional Orifice Without Bevel - Thickness: 0.25 To 0.5 Mm. Unidirectional Orifice With Bevel 0.5 To 1.25 MMDocument2 pagesBidirectional Orifice Without Bevel - Thickness: 0.25 To 0.5 Mm. Unidirectional Orifice With Bevel 0.5 To 1.25 MMMarcel BaliñoNo ratings yet

- Product Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'C7 TGNo ratings yet

- Magnetic Float Level Switch - KleevDocument2 pagesMagnetic Float Level Switch - KleevRAMZI ALJILANYNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFGustavoNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFgk9No ratings yet

- TS-1PRX1.5MM, 2PRX1.5MM - Blue (New)Document2 pagesTS-1PRX1.5MM, 2PRX1.5MM - Blue (New)mohd darusNo ratings yet

- Mill Quad FeedDocument12 pagesMill Quad FeedMartin huntNo ratings yet

- Calculation Sheet 03Document2 pagesCalculation Sheet 03kkgcNo ratings yet

- Torque-Air Brake FittingsDocument2 pagesTorque-Air Brake Fittingsyoga_jpbmbmNo ratings yet

- HED317Document130 pagesHED317Ayodele MastaNo ratings yet

- 2020F CHM102 E1 DensityDocument19 pages2020F CHM102 E1 DensityAyodele MastaNo ratings yet

- Aaqprctp 06 Meteorologicalmeasure 200105 FinalDocument15 pagesAaqprctp 06 Meteorologicalmeasure 200105 FinalAyodele MastaNo ratings yet

- Stone Base Buimo Nig LTD PDFDocument1 pageStone Base Buimo Nig LTD PDFAyodele MastaNo ratings yet

- 4301CIVHDocument3 pages4301CIVHAyodele MastaNo ratings yet

- SSSSS PDFDocument1 pageSSSSS PDFAyodele MastaNo ratings yet

- Faith - ResultsDocument1 pageFaith - ResultsAyodele MastaNo ratings yet

- Unesco - Eolss Sample Chapters: Groundwater HydrogeologyDocument7 pagesUnesco - Eolss Sample Chapters: Groundwater HydrogeologyAyodele MastaNo ratings yet

- Tochi ResultDocument1 pageTochi ResultAyodele MastaNo ratings yet

- Firearms in America 1600 - 1899Document310 pagesFirearms in America 1600 - 1899Mike100% (3)

- B-Housing and Living - 1Document2 pagesB-Housing and Living - 1Štěpánka OndrůškováNo ratings yet

- Question Paper - BiologyDocument5 pagesQuestion Paper - BiologyAratrika ChakravartyNo ratings yet

- 3F4 Error Control Coding: Dr. I. J. WassellDocument70 pages3F4 Error Control Coding: Dr. I. J. WassellgpaswathyNo ratings yet

- Conduit Trunking Capacity Chart RM TechnicalDocument1 pageConduit Trunking Capacity Chart RM TechnicalPrabir BhowmikNo ratings yet

- Huawei FusionSolar Smart PV SolutionDocument32 pagesHuawei FusionSolar Smart PV SolutionJOGmzNo ratings yet

- Mento - Katalog Master Flo Choke Valves - 17.08.20 - LowDocument37 pagesMento - Katalog Master Flo Choke Valves - 17.08.20 - Lowsherif aymanNo ratings yet

- Putra, 003 - 3035 - I Wayan Adi Pranata - GalleyDocument7 pagesPutra, 003 - 3035 - I Wayan Adi Pranata - Galleyeunike jaequelineNo ratings yet

- 10 Traditional Chilean Desserts - Insanely Good PDFDocument1 page10 Traditional Chilean Desserts - Insanely Good PDFMarilynn SpringerNo ratings yet

- ITSDF B56-11-5-2014-Rev-12-2-14Document17 pagesITSDF B56-11-5-2014-Rev-12-2-14Fernando AguilarNo ratings yet

- Traffic Flow - WikipediaDocument146 pagesTraffic Flow - WikipediaAngeline AgunatNo ratings yet

- Automag Industries, Chennai: ISI StandardsDocument2 pagesAutomag Industries, Chennai: ISI Standardsnaga1501No ratings yet

- UNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestDocument21 pagesUNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestNayem Hossain HemuNo ratings yet

- IE 411 Lecture6 90ABDocument15 pagesIE 411 Lecture6 90ABZain Ul AbidinNo ratings yet

- Beyond Risk - Bacterial Biofilms and Their Regulating ApproachesDocument20 pagesBeyond Risk - Bacterial Biofilms and Their Regulating ApproachesVictor HugoNo ratings yet

- Biology Form 5 Notes Chapter 1Document39 pagesBiology Form 5 Notes Chapter 1Mayghen SelvanayagamNo ratings yet

- Introduction To Ipgcl & PPCLDocument31 pagesIntroduction To Ipgcl & PPCLSahil SethiNo ratings yet

- The Summer Internship at Limited: Hindustan AeronauticsDocument59 pagesThe Summer Internship at Limited: Hindustan AeronauticsAbhishek StarkNo ratings yet

- Task 2 Overview and Instructions 2021Document3 pagesTask 2 Overview and Instructions 2021alindafitrotNo ratings yet

- HESCO Sample PaperDocument3 pagesHESCO Sample PaperzakirNo ratings yet

- Structural Design Report 2017.12.25Document27 pagesStructural Design Report 2017.12.25Gihan ChathurangaNo ratings yet

- How To Start A Candle BusinessDocument49 pagesHow To Start A Candle BusinessJessica Rodrigo100% (1)

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 pagesAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- (M. J. Edwards) The ''Epistle To Rheginus'' ValenDocument17 pages(M. J. Edwards) The ''Epistle To Rheginus'' ValenGlebMatveevNo ratings yet

- FirePro Technical Prospectus PDFDocument28 pagesFirePro Technical Prospectus PDFRANJITHNo ratings yet

- Perform-3d-V5 0 0Document15 pagesPerform-3d-V5 0 0Darley MauricioNo ratings yet

- WCP Nietzsche OnNatureGodEthicsDocument4 pagesWCP Nietzsche OnNatureGodEthicsmasohaNo ratings yet

- XT0223S16128 Smart调试说明书 ENDocument81 pagesXT0223S16128 Smart调试说明书 ENBagwis100% (1)

- Beyond The Brain - Text 1Document5 pagesBeyond The Brain - Text 1ivona0mati0No ratings yet