Professional Documents

Culture Documents

Useful Equations and Information

Useful Equations and Information

Uploaded by

aj7scribdCopyright:

Available Formats

You might also like

- Flexures - Elements of Elastic MechanismsDocument445 pagesFlexures - Elements of Elastic Mechanismsaj7scribdNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- Understanding Optical Time Domain Reflectometry Poster PDFDocument1 pageUnderstanding Optical Time Domain Reflectometry Poster PDFyouvsyou100% (1)

- Tirupati Telecom Primary Account Holder Name: Your A/C StatusDocument12 pagesTirupati Telecom Primary Account Holder Name: Your A/C StatusMy PhotosNo ratings yet

- Modern Power Electronics and AC Drives by Bimal KDocument738 pagesModern Power Electronics and AC Drives by Bimal Kapi-3715281100% (4)

- ENVADocument42 pagesENVAkarim18aug09No ratings yet

- SBDN - Rnav Egobu 1a - Envap 1a Rwy 12 - Sid - 20221229Document1 pageSBDN - Rnav Egobu 1a - Envap 1a Rwy 12 - Sid - 20221229TI PIRESNo ratings yet

- LS AD 2 LSZH 24-9-7-1 en 2012-10-18Document2 pagesLS AD 2 LSZH 24-9-7-1 en 2012-10-18Reiss SchultzNo ratings yet

- Liebherr TechnicalDocument239 pagesLiebherr TechnicalDavid Chou100% (1)

- Schottky Barrier Diodes: External DimensionsDocument2 pagesSchottky Barrier Diodes: External Dimensionsamir baroughNo ratings yet

- SBCF Ils-T-Rwy-16 Iac 20210715Document1 pageSBCF Ils-T-Rwy-16 Iac 20210715Luiz SantosNo ratings yet

- BFCN-4800Document2 pagesBFCN-4800onallpelinNo ratings yet

- Ils Z Ou/Or Loc Z Rwy 17R (IAC) : SBP 433 3400' GNDDocument1 pageIls Z Ou/Or Loc Z Rwy 17R (IAC) : SBP 433 3400' GNDGuilherme Kazuo Ogawa100% (1)

- Egss Ils22 PathDocument1 pageEgss Ils22 PathpiwowarczykptNo ratings yet

- (2-14) Instr Apch ChartDocument16 pages(2-14) Instr Apch ChartLGK PUBGNo ratings yet

- ADF S72-1759: Sensor Systems IncDocument1 pageADF S72-1759: Sensor Systems IncMilena Rocío LamonegaNo ratings yet

- Clacton: FraneDocument1 pageClacton: FraneArman TabanovNo ratings yet

- VFR LY AD 2 LYSP 2-4-1 enDocument1 pageVFR LY AD 2 LYSP 2-4-1 enVojislav DabicNo ratings yet

- Product: Torsional Vibration Meter - Type 2523Document4 pagesProduct: Torsional Vibration Meter - Type 2523jhon vargas100% (1)

- SBFL Ils-Y-Rwy-14 Iac 20211202Document1 pageSBFL Ils-Y-Rwy-14 Iac 20211202gameplayPSNo ratings yet

- Vomm Ils Rwy 07Document1 pageVomm Ils Rwy 07Twotawan ThepilotNo ratings yet

- Segmented Photodiodes (SPOT Series) : Position Sensing Detector (PSD)Document6 pagesSegmented Photodiodes (SPOT Series) : Position Sensing Detector (PSD)erickNo ratings yet

- SBRJ - Pumso 3d Rwy 20l - Sid - 20210520Document1 pageSBRJ - Pumso 3d Rwy 20l - Sid - 20210520Henry CalNo ratings yet

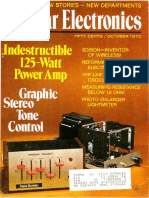

- Poptronics 1970 10Document120 pagesPoptronics 1970 10marcelo vintageNo ratings yet

- Ad2 Lgza Star 4Document1 pageAd2 Lgza Star 4lolopiloteNo ratings yet

- WFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtDocument2 pagesWFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtApichai ZankerNo ratings yet

- SBFL Ils-Y-Rwy-14 Iac 20221201Document1 pageSBFL Ils-Y-Rwy-14 Iac 20221201Leonardo Guimarães LacintraNo ratings yet

- (IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WDocument1 page(IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WFábio KastelamaryNo ratings yet

- MH - Ad-2.mhlm ArcDocument1 pageMH - Ad-2.mhlm ArcansiberytNo ratings yet

- RKJY JeppesenDocument11 pagesRKJY Jeppesenelio.aviatorNo ratings yet

- Rovaniemi, Finland: Approach Chart - Icao Instrument Rovaniemi Aerodrome Ilszorloczrwy21Document2 pagesRovaniemi, Finland: Approach Chart - Icao Instrument Rovaniemi Aerodrome Ilszorloczrwy21CaptAdamNo ratings yet

- Thessaloniki / Makedonia Standard Departure Chart Instrument (Sid) - IcaoDocument2 pagesThessaloniki / Makedonia Standard Departure Chart Instrument (Sid) - IcaosamNo ratings yet

- VEBN-ILS(Z)-RWY-27Document1 pageVEBN-ILS(Z)-RWY-27anurag1911.96No ratings yet

- SBFL Vor-Y-Rwy-32 Iac 20231102Document1 pageSBFL Vor-Y-Rwy-32 Iac 20231102Frederico SagasNo ratings yet

- D8R II Plano Electrico PDFDocument2 pagesD8R II Plano Electrico PDFDarío Ache EmeNo ratings yet

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNo ratings yet

- Rev02 GS20 Datasheet ENDocument2 pagesRev02 GS20 Datasheet ENDu RoyNo ratings yet

- A Nálisis Del M Odo y E Fecto de La F AllaDocument43 pagesA Nálisis Del M Odo y E Fecto de La F AllaAlfredoNo ratings yet

- Sbdo - NDB A Rwy 06 24 - Iac - 20170525Document1 pageSbdo - NDB A Rwy 06 24 - Iac - 20170525Matheus BrandtNo ratings yet

- 11 1 Ils DmeDocument1 page11 1 Ils DmehkiatchaNo ratings yet

- Sbco Vor-Y-Rwy-13 Iac 20220127Document1 pageSbco Vor-Y-Rwy-13 Iac 20220127Pedro MonteiroNo ratings yet

- Unindo CB500 - RFQ001Document43 pagesUnindo CB500 - RFQ001Kalimkarawang321 Kalimkarawang321No ratings yet

- 5200 Multi-Axis Load Cell (Us & Metric) : Standard Configuration Features & BenefitsDocument2 pages5200 Multi-Axis Load Cell (Us & Metric) : Standard Configuration Features & BenefitsLalo MejiaNo ratings yet

- Witn (SBG) - Maimun SalehDocument4 pagesWitn (SBG) - Maimun SalehRafly AndrianzaNo ratings yet

- Laser InatraDocument1 pageLaser InatraKleberBuñayNo ratings yet

- Sbae Ndb-Rwy-35 Iac 20210812Document1 pageSbae Ndb-Rwy-35 Iac 20210812Cassiano CapellassiNo ratings yet

- Wipb (LLJ) - SilampariDocument4 pagesWipb (LLJ) - SilampariRafly AndrianzaNo ratings yet

- Ef Ad 2 Efhk 04L RNPDocument2 pagesEf Ad 2 Efhk 04L RNPHarhaliiniNo ratings yet

- Ef Ad 2 Efhk 04R RNPDocument2 pagesEf Ad 2 Efhk 04R RNPHarhaliiniNo ratings yet

- Chart LsgsDocument24 pagesChart Lsgsleron.gundlurNo ratings yet

- (IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqDocument1 page(IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqBoalboalboa NemiandosNo ratings yet

- Ad Elev - 15 FT Amsl: Rotterdam Airport Aerodrome ChartDocument15 pagesAd Elev - 15 FT Amsl: Rotterdam Airport Aerodrome ChartBen HermannNo ratings yet

- LSZH Dep1 Transit Deges ZueDocument1 pageLSZH Dep1 Transit Deges Zuesamykarim2009No ratings yet

- (IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WDocument1 page(IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WGuilherme Kazuo OgawaNo ratings yet

- Acarigua, Venezuela Svac/Agv RNAV (GNSS) Rwy 29Document1 pageAcarigua, Venezuela Svac/Agv RNAV (GNSS) Rwy 29said artigasNo ratings yet

- SBFL Vor-Z-Rwy-14 Iac 20171012 PDFDocument1 pageSBFL Vor-Z-Rwy-14 Iac 20171012 PDFRômullo Furtado BeltrameNo ratings yet

- EG AD 2 EGSS 7-5 en 2013-05-02Document1 pageEG AD 2 EGSS 7-5 en 2013-05-02chrisdantusevoNo ratings yet

- Ltci ChartsDocument10 pagesLtci ChartsOnurhan ErgüderNo ratings yet

- SKBO ILS Rwy 13RDocument1 pageSKBO ILS Rwy 13RBobNo ratings yet

- SBSP Rnp-Y-Rwy-17r Iac 20231130Document1 pageSBSP Rnp-Y-Rwy-17r Iac 20231130carine mirandaNo ratings yet

- SBXF TMA FlorianópolisDocument1 pageSBXF TMA Florianópolisazx72No ratings yet

- Lztt/Tat Poprad, Slovakia: Abrag 2D (Abra2D) Orlan 1D (Orla1D) Marka 2D (Mark2D) Udrel 2D (Udre2D) Rnav Arrivals (RWY 27)Document23 pagesLztt/Tat Poprad, Slovakia: Abrag 2D (Abra2D) Orlan 1D (Orla1D) Marka 2D (Mark2D) Udrel 2D (Udre2D) Rnav Arrivals (RWY 27)Tweed3ANo ratings yet

- 05 Optical CoatingsDocument44 pages05 Optical Coatingsaj7scribdNo ratings yet

- Designing With Toroids Max RiedlDocument1 pageDesigning With Toroids Max Riedlaj7scribdNo ratings yet

- Zap Comix #2 Sample Page 2 atDocument1 pageZap Comix #2 Sample Page 2 ataj7scribdNo ratings yet

- TIG200ACDCP (Ahp) Manual 2016.05Document14 pagesTIG200ACDCP (Ahp) Manual 2016.05aj7scribdNo ratings yet

- Frequency Stabilization of Internal-Mirror Helium-Neon LasersDocument3 pagesFrequency Stabilization of Internal-Mirror Helium-Neon Lasersaj7scribdNo ratings yet

- Birchby W.N. - White Light Interference Fringes With A Thick Glass Plate in One Path (1924)Document6 pagesBirchby W.N. - White Light Interference Fringes With A Thick Glass Plate in One Path (1924)aj7scribdNo ratings yet

- ECEN 4616/5616: Class Website With Past Lectures, Various Files, and AssignmentsDocument41 pagesECEN 4616/5616: Class Website With Past Lectures, Various Files, and Assignmentsaj7scribdNo ratings yet

- A Simple, High Power Nitrogen LaserDocument7 pagesA Simple, High Power Nitrogen Laseraj7scribdNo ratings yet

- Management of Anal Irritation: Oxford University HospitalsDocument4 pagesManagement of Anal Irritation: Oxford University Hospitalsaj7scribdNo ratings yet

- Design of Saturable Reactors 31295000058858Document112 pagesDesign of Saturable Reactors 31295000058858aj7scribd100% (1)

- Electronic Design Ebook - Back To Basics - Impedance MatchingDocument24 pagesElectronic Design Ebook - Back To Basics - Impedance Matchingaj7scribdNo ratings yet

- Handbook Noise MeasurementDocument397 pagesHandbook Noise Measurementaj7scribdNo ratings yet

- Assessment of Voice Coil Peak Displacement XMAX 02Document15 pagesAssessment of Voice Coil Peak Displacement XMAX 02aj7scribdNo ratings yet

- Analysis and Simulation of Hybrid Electric Vehicles For Sedan VehicleDocument5 pagesAnalysis and Simulation of Hybrid Electric Vehicles For Sedan VehicleSureshNo ratings yet

- AnimejsDocument27 pagesAnimejsJesus RodriguezNo ratings yet

- MBA II BRM Trimester End ExamDocument3 pagesMBA II BRM Trimester End ExamRadha Mahat0% (1)

- CVE 3rd PTDocument4 pagesCVE 3rd PTAlexa AustriaNo ratings yet

- 2014 Elec HD FS CKTruck 100713 ChevroletDocument247 pages2014 Elec HD FS CKTruck 100713 ChevroletREINALDO GONZALEZNo ratings yet

- Yamaha Nmax Smart Key SystemDocument1 pageYamaha Nmax Smart Key Systemmotley crewzNo ratings yet

- Chem 1-8Document43 pagesChem 1-8Cabacungan, John VinceNo ratings yet

- Kingair 350i Wiring - 21 Air ConditionedDocument68 pagesKingair 350i Wiring - 21 Air ConditionedLaboratorio01 AvionicsNo ratings yet

- VSD Training Nu Blu Data SheetDocument2 pagesVSD Training Nu Blu Data Sheetابرار عمرNo ratings yet

- Mitsubishi Triton BrochureDocument24 pagesMitsubishi Triton BrochureShahbazAhmadNo ratings yet

- Limbo PowerpointDocument10 pagesLimbo Powerpointapi-693306390No ratings yet

- Self-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalDocument7 pagesSelf-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- First Conditional ChainDocument3 pagesFirst Conditional ChainSonia DivileNo ratings yet

- G6 - Year End Exam (2018) - Southern Provincial Department of EducationDocument8 pagesG6 - Year End Exam (2018) - Southern Provincial Department of EducationXiao ShadowlordNo ratings yet

- Sungrow-SG3 0RT-SG4 0RTDocument2 pagesSungrow-SG3 0RT-SG4 0RTchris dascalopoulosNo ratings yet

- 865-RUGC Manuscript-2653-1-10-20200306Document4 pages865-RUGC Manuscript-2653-1-10-20200306Bal Deep SharmaNo ratings yet

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- Microprocessor Book PDFDocument4 pagesMicroprocessor Book PDFJagan Eashwar0% (4)

- 6.003 Homework #13 Solutions: ProblemsDocument9 pages6.003 Homework #13 Solutions: Problemsvaishnavi khilariNo ratings yet

- Project Product DescriptionDocument5 pagesProject Product Descriptionpruebaproiba12No ratings yet

- 624-DEFLECTOR PLATE CHANGING of CSR#3Document4 pages624-DEFLECTOR PLATE CHANGING of CSR#3Buddy HartNo ratings yet

- Fuel EnergizerDocument29 pagesFuel EnergizeratulsemiloNo ratings yet

- E 10durometerDocument14 pagesE 10durometerDika DrogbaNo ratings yet

- Grade 9 Social Studies Textbook CbseDocument3 pagesGrade 9 Social Studies Textbook CbseKurtNo ratings yet

- Internal Combustion Engines - R. K. RajputDocument352 pagesInternal Combustion Engines - R. K. RajputmeetbalakumarNo ratings yet

- UPS KAISE 600-800va - Hoja de DatosDocument2 pagesUPS KAISE 600-800va - Hoja de DatosGermanYPNo ratings yet

- 5S Implementation Manual Part 2Document63 pages5S Implementation Manual Part 2jgprasadNo ratings yet

- Update On School Readiness and Covid-19Document2 pagesUpdate On School Readiness and Covid-19RianaNo ratings yet

Useful Equations and Information

Useful Equations and Information

Uploaded by

aj7scribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Useful Equations and Information

Useful Equations and Information

Uploaded by

aj7scribdCopyright:

Available Formats

WAVELENGTH TRANSMISSION RANGE AND REFRACTIVE INDEX POLARIZATION FABRICATION TOLERANCES

Malus’s Law:

USEFUL EQUATIONS AND INFORMATION

USEFUL EQUATIONS AND INFORMATION

Surface Tolerances Precision Laser Grade Mfg Limit

Optical Material Transmission Range | Wavelength (nm)/Index of Refraction 1 2

I= c e0 E0 cos2v = I0 cos2v Surface quality (scratch/dig) 40-20 10-5 5-2

2

BK7 532 800 1064 1550 Surface roughness (Å, RA) 20 5 2.5

h =1.51947 h =1.51078 h =1.50663 h =1.50065

Faraday Rotation:

Spherical irregularity (waves, P-V @ 633 nm) 0.5 0.2 0.01

b = VBd,

UV grade 193 248 266 1064 Spherical radius (fringes) 5 3 0.5

Fused Silica h =1.56077 h =1.50855 h =1.49968 h =1.44963 b = angle of rotation

Flat irregularity (waves, P-V @ 633 nm) 0.5 0.1 0.04

Optical Activity:

193 213 248 3000

CaF2 h =1.50153 h =1.4854 h =1.46803 h =1.41785 d-rotary is when hl > hr

Dimensional Tolerances Commercial Precision Mfg Limit

l-rotary is when hr > hl

0.1 0.4 0.7 1.0 3.0 6.0 10 Diameter (mm) +0.000/-0.250 +0.000/-0.025 +0.000/-0.005

()

pd

b= (hl4hr) 1

l0 0 Length & Width (mm) ±0.050 +0.000/-0.025 +0.000/-0.010

0

Thickness (mm) ±0.250 ±0.050 ±0.005

()

1

1

0 Centration (edge thickness difference, mm) 0.050 0.010 0.005

FOCAL LENGTH FORMULAS FOR SINGLET LENSES 1

0 Wedge <10 ± 5 arc min ≤1 arc sec ≤0.5 arc sec

()

1 Clear aperture (%) 85 90 100

Focal Length Back Focal Distance Front Focal Distance 41

The general tolerance specifications above provide a guideline regarding manufacturing capabilities for optics ranging in size from 3-100mm.

Type Orientation ƒ BFD FFD 0

()

The manufacturing limits are not absolute; tighter tolerances may be possible. Part specific tolerances may vary depending on component size,

2 0 1 shape, and/or material. l/100 surfaces are achievable. Call us for more details.

R1 = R1

[(h41)#( R1 4 R1 = t hR(h41) ] [ tc (h41)

] [ tc (h41)

]

c -1

1

General ƒ# 1 4 ƒ# 1 = 0

R2 = R2 1 R 2 1 2 hR1 hR2 0

R

COATINGS

tc (h41)

R1 = R

[ ] Magnetron

()

Plano-Convex ƒ# 1 4 ƒ 1

R2 = r E-beam IAD APS IBS Sputtering

h41 hR 0

41 Stoke’s

4R tc (h41)

Plano-Concave

R1 = 4R

[

ƒ# 1 = ] ƒ 0 Vector Laser Damage Threshold* >20J/cm2 >40J/cm2 >40J/cm2 >20J/cm2 >40J/cm2

()

R2 = r

()

h41 hR

1 S0

tc (h41) S1 Scatter and

[

2(h41) tc (h41)2

] [ ]

tc (h41) 0

R1 = R

[ ] <0.2 <0.15 <0.15 <1 PPM <50 PPM

-1

Bi-Convex 4 ƒ# 1 4 ƒ# 1 4 0 S2 Absorption (%)

R2 = 4R R hR2 hR hR 41

S3

tc (h41)

Bi-Concave

R1 = 4R

R2 = R

4 [

2(h41)

R

4

tc (h41)2

hR2

] -1

[

ƒ# 1 =

tc (h41)

] ƒ# 1 =[ hR

] Surface Roughness (Å rms) 5 7 7 <1 <9

hR LASER SELECTION GUIDE

Wet/Dry Shift (range) (%) <0.8 <0.3 0.00 0.00 0.00

πωo2

Rayleigh length zR = These values may be slightly higher or lower depending on deposition conditions and other process related parameters. Overall plasma processes

have lower absorptions than conventional e-beam technologies. *Laser-Inducer Damage Threshold (LIDT) depends on Test Wavelength, Pulse Width,

l repetition rate and inspection method. This data is from 1064 nm, 10 ns, 20 Hz.

1

BASIC EQUATIONS INTERNAL REFLECTION DIFFRACTION-LIMITED BEAM Sum Frequency l sum =

& CRITICAL ANGLE DIAMETER DIVERGENCE Generation 1 1

= E beam 190nm - 10µm

l1 l2

]2ab 44ac

2 Ion Assisted 250nm - 2200nm

4b 8 vc = sin-1(h2 / h1), for h2< h1 p p d 0 D0 Difference 1

x= M2 = w0V0 = l difference =

l l 2 2ƒ Frequency Advanced Plasma Source 250nm - 2200nm

Generation 1 1

4

]sin v 4(h /h )

(h2 / h1)2 cosv14i 2 2

1 l1 l2 Ion Beam Sputtering 250nm - 2200nm

OD = log10 ( ) rp =

1 2 1

Achievable focal spot diameter, d0

T Brightness or P

]

2 2 2

(h / h ) cosv =i sin v 4(h /h ) M2 4 lƒ

Magnetron Sputtering 250nm - 2200nm

2 1 1 1 2 1

d0 = Radiance B=

Snell’s Law: pD0 of Laser Beam πωo2 πv 2 0.1 0.2 1.0 3.0 10 20

h1sinv1 = h2sinv2

]

2 2

cosv 4i sin v 4(h / h )

1 1 2 1

r =

s AVAILABLE LASER WAVELENGTHS (nm)

Fresnel reflection at 0°:

]

2 2

cosv =i sin v 4(h / h ) 10,000

MAXIMUM POWER (mW)

1 1 2 1 ETALONS

R= (h24h1 2

h2=h1

) tp = ts = 0

1000

I 1

T = trans = 100

ƒ Number: I inc

]sin v

cosv1 sin2v14h2 4R

ƒ/# =

ƒ

=

1 d = fs4fp = 2

h2

tan-1 [ 2

], 1=

(14R) 2

sin2 (d/2)

10

D 2(NA) where h =

1 l2

h1 FSR = 1

2d 325 375 405 442 454 457 465 473 476 483 488 496 502 515 520 532 543 561 568 594 633 635 640 647 650 660 670 676 685 780 830 1310 1550

Mirror Focal Length:

DPSS

Radius of Curvature h2 FSR

ƒ=

2 vB = tan-1 h

1

( ) FWHM =

F

DIODE

GAS

www.cvimellesgriot.com www.cvimellesgriot.com

TechGuide_Cover_working.indd 2 2/23/2012 1:58:00 PM

WAVELENGTH TRANSMISSION RANGE AND REFRACTIVE INDEX POLARIZATION FABRICATION TOLERANCES

Malus’s Law:

USEFUL EQUATIONS AND INFORMATION

USEFUL EQUATIONS AND INFORMATION

Surface Tolerances Precision Laser Grade Mfg Limit

Optical Material Transmission Range | Wavelength (nm)/Index of Refraction 1 2

I= c e0 E0 cos2v = I0 cos2v Surface quality (scratch/dig) 40-20 10-5 5-2

2

BK7 532 800 1064 1550 Surface roughness (Å, RA) 20 5 2.5

h =1.51947 h =1.51078 h =1.50663 h =1.50065

Faraday Rotation:

Spherical irregularity (waves, P-V @ 633 nm) 0.5 0.2 0.01

b = VBd,

UV grade 193 248 266 1064 Spherical radius (fringes) 5 3 0.5

Fused Silica h =1.56077 h =1.50855 h =1.49968 h =1.44963 b = angle of rotation

Flat irregularity (waves, P-V @ 633 nm) 0.5 0.1 0.04

Optical Activity:

193 213 248 3000

CaF2 h =1.50153 h =1.4854 h =1.46803 h =1.41785 d-rotary is when hl > hr

Dimensional Tolerances Commercial Precision Mfg Limit

l-rotary is when hr > hl

0.1 0.4 0.7 1.0 3.0 6.0 10 Diameter (mm) +0.000/-0.250 +0.000/-0.025 +0.000/-0.005

()

pd

b= (hl4hr) 1

l0 0 Length & Width (mm) ±0.050 +0.000/-0.025 +0.000/-0.010

0

Thickness (mm) ±0.250 ±0.050 ±0.005

()

1

1

0 Centration (edge thickness difference, mm) 0.050 0.010 0.005

FOCAL LENGTH FORMULAS FOR SINGLET LENSES 1

0 Wedge <10 ± 5 arc min ≤1 arc sec ≤0.5 arc sec

()

1 Clear aperture (%) 85 90 100

Focal Length Back Focal Distance Front Focal Distance 41

The general tolerance specifications above provide a guideline regarding manufacturing capabilities for optics ranging in size from 3-100mm.

Type Orientation ƒ BFD FFD 0

()

The manufacturing limits are not absolute; tighter tolerances may be possible. Part specific tolerances may vary depending on component size,

0 1 shape, and/or material. l/100 surfaces are achievable. Call us for more details.

tc (h41)2

R1 = R1

[ 1

] [ tc (h41)

] [ tc (h41)

]

1 -1

1

General (h41)#( 4 = ƒ# 1 4 ƒ# 1 = 0

R2 = R2 R1 R2 hR1R2 hR1 hR2 0

R

COATINGS

tc (h41)

R1 = R

[ ] Magnetron

()

Plano-Convex ƒ# 1 4 ƒ 1

R2 = r E-beam IAD APS IBS Sputtering

h41 hR 0

41 Stoke’s

4R tc (h41)

Plano-Concave

R1 = 4R

[

ƒ# 1 = ] ƒ 0 Vector Laser Damage Threshold* >20J/cm2 >40J/cm2 >40J/cm2 >20J/cm2 >40J/cm2

()

R2 = r

()

h41 hR

1 S0

tc (h41) S1 Scatter and

[

2(h41) tc (h41)2

] [ ]

tc (h41) 0

R1 = R

[ ] <0.2 <0.15 <0.15 <1 PPM <50 PPM

-1

Bi-Convex 4 ƒ# 1 4 ƒ# 1 4 0 S2 Absorption (%)

R2 = 4R R hR2 hR hR 41

S3

tc (h41)

Bi-Concave

R1 = 4R

R2 = R

4 [

2(h41)

R

4

tc (h41)2

hR2

] -1

[

ƒ# 1 =

tc (h41)

] ƒ# 1 =[ hR

] Surface Roughness (Å rms) 5 7 7 <1 <9

hR LASER SELECTION GUIDE

Wet/Dry Shift (range) (%) <0.8 <0.3 0.00 0.00 0.00

πωo2

Rayleigh length zR = These values may be slightly higher or lower depending on deposition conditions and other process related parameters. Overall plasma processes

have lower absorptions than conventional e-beam technologies. *Laser-Inducer Damage Threshold (LIDT) depends on Test Wavelength, Pulse Width,

l repetition rate and inspection method. This data is from 1064 nm, 10 ns, 20 Hz.

1

BASIC EQUATIONS INTERNAL REFLECTION DIFFRACTION-LIMITED BEAM Sum Frequency l sum =

& CRITICAL ANGLE DIAMETER DIVERGENCE Generation 1 1

= E beam 190nm - 10µm

l1 l2

]2ab 44ac

2 Ion Assisted 250nm - 2200nm

4b 8 vc = sin-1(h2 / h1), for h2< h1 p p d 0 D0 Difference 1

x= M2 = w0V0 = l difference =

l l 2 2ƒ Frequency Advanced Plasma Source 250nm - 2200nm

Generation 1 1

4

OD = log10 (

1

T

) rp =

(h2 / h1

] 4(h /h

)2 cosv14i sin2v 1 2 1 )2

Achievable focal spot diameter, d0

Brightness or P

l1 l2 Ion Beam Sputtering 250nm - 2200nm

]

2 2 2

(h / h ) cosv =i sin v 4(h /h ) M2 4 lƒ

Magnetron Sputtering 250nm - 2200nm

2 1 1 1 2 1

d0 = Radiance B=

Snell’s Law: pD0 of Laser Beam πωo2 πv 2 0.1 0.2 1.0 3.0 10 20

h1sinv1 = h2sinv2

]

2 2

cosv 4i sin v 4(h / h )

1 1 2 1

r =

s AVAILABLE LASER WAVELENGTHS (nm)

Fresnel reflection at 0°:

]

2 2

cosv =i sin v 4(h / h ) 10,000

MAXIMUM POWER (mW)

1 1 2 1 ETALONS

R= (h24h1 2

h2=h1

) tp = ts = 0

1000

I 1

T = trans = 100

ƒ Number: I inc

]sin v

cosv1 sin2v14h2 4R

ƒ/# =

ƒ

=

1 d = fs4fp = 2

h2

tan-1 [ 2

], 1=

(14R) 2

sin2 (d/2)

10

D 2(NA) where h =

1 l2

h1 FSR = 1

2d 325 375 405 425 442 454 457 465 473 476 483 488 496 502 515 520 532 543 561 568 594 633 635 640 647 650 660 670 676 685 780 830

Mirror Focal Length:

DPSS

Radius of Curvature h2 FSR

ƒ=

2 vB = tan-1 h

1

( ) FWHM =

F

DIODE

GAS

www.cvimellesgriot.com www.cvimellesgriot.com

TechGuide_Cover_working.indd 2 3/14/2012 9:40:49 AM

Tech_Guide_Index_working.qxd 2/23/2012 11:48 AM Page 10

Technical Guide Index

Ask About Our Build-to-Print and Custom Capabilities

OEM

Acronyms, Abbreviations, and Units

Q ohm ESPI electronic speckle pattern NBS National Bureau of

msec microsecond interferometry Standards

mW microwatt FC fiber coupling ND neutral density

A ampere ft foot NEP noise-equivalent power

A analog fsec femtosecond NIST National Institute for

A/D analog to digital FSR free spectral range Science and Technology

ac alternating current FWHM full width at half nm nanometer

ACC Automatic Current maximum OD Optical Density

Control g gram OD outside diameter

ANSI American National GQ gigaohm OEM original equipment

Standards Institute HEBBAR™ high-efficiency broad- manufacturer

AO acousto-optic band antireflection pA picoampere

APC automatic power control HEL high-energy laser PC personal computer

AR antireflection HP horizontal points PCI Peripheral Component

BFL back focal length Hz Hertz Interconnect

BNC Berkeley Nucleonics IC integrated circuit PCMCIA Personal Computer

Corporation IEC International Memory Card

CA clear aperture Electrotechnical International

Technical Guide Index

CAN controller area network Commission Association. Often

CCD charge-coupled device IEEE Institute of Electrical and called PC cards

CDRH Center for Devices and Electronics Engineers pF picofarad

Radiological Health IMS integrated modular p-p peak-to-peak

CFC chlorofluorocarbons system PSD power spectral density

CIE International in. inch PZT piezo electric transducers

Commission on IR infrared QCW quasi continuous wave

Illumination ISO International Standards RH relative humidity

(Commission Organization rms root mean square

Internationale de IVM integrated vision module sec second

l'Éclairage) kg kilograms SPC statistical process control

CLT clear lightweight kV kilovolt T transmissibility

technology lb pound TE thermoelectric

CMOS Complementary Metal LCD liquid crystal display TEC thermoelectric cooler

Oxide Semiconductor LED light emitting diode TIR total internal reflection

CVD chemical vapor LSO laser safety officer TSA transverse spherical

deposition mA milliampere aberration

cw continuous wave mm millimeter TTL transistor-transistor logic

D digital MPE maximum piezoelectric USB universal serial bus

dB decibel extension UV ultraviolet

dc direct current msec millisecond UVGSFS UV-grade synthetic fused

DIP dual inline package MTF modulation transfer silica

DOF Depth of Field function V volt

DVO diffuse viewing only MTTF mean time to failure Vac volts, alternating current

EFL effective focal length N/A not applicable Vdc volts, direct current

EMI electromagnetic nA nanoampere W watt

interference NA numerical aperture YAG yttrium aluminum garnet

EO electro-optic NAS nonaspheric side ZIF zero insertion force

ESD electrostatic discharge

10 Technical Guide Index

www. cvimellesgriot . com

You might also like

- Flexures - Elements of Elastic MechanismsDocument445 pagesFlexures - Elements of Elastic Mechanismsaj7scribdNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- Understanding Optical Time Domain Reflectometry Poster PDFDocument1 pageUnderstanding Optical Time Domain Reflectometry Poster PDFyouvsyou100% (1)

- Tirupati Telecom Primary Account Holder Name: Your A/C StatusDocument12 pagesTirupati Telecom Primary Account Holder Name: Your A/C StatusMy PhotosNo ratings yet

- Modern Power Electronics and AC Drives by Bimal KDocument738 pagesModern Power Electronics and AC Drives by Bimal Kapi-3715281100% (4)

- ENVADocument42 pagesENVAkarim18aug09No ratings yet

- SBDN - Rnav Egobu 1a - Envap 1a Rwy 12 - Sid - 20221229Document1 pageSBDN - Rnav Egobu 1a - Envap 1a Rwy 12 - Sid - 20221229TI PIRESNo ratings yet

- LS AD 2 LSZH 24-9-7-1 en 2012-10-18Document2 pagesLS AD 2 LSZH 24-9-7-1 en 2012-10-18Reiss SchultzNo ratings yet

- Liebherr TechnicalDocument239 pagesLiebherr TechnicalDavid Chou100% (1)

- Schottky Barrier Diodes: External DimensionsDocument2 pagesSchottky Barrier Diodes: External Dimensionsamir baroughNo ratings yet

- SBCF Ils-T-Rwy-16 Iac 20210715Document1 pageSBCF Ils-T-Rwy-16 Iac 20210715Luiz SantosNo ratings yet

- BFCN-4800Document2 pagesBFCN-4800onallpelinNo ratings yet

- Ils Z Ou/Or Loc Z Rwy 17R (IAC) : SBP 433 3400' GNDDocument1 pageIls Z Ou/Or Loc Z Rwy 17R (IAC) : SBP 433 3400' GNDGuilherme Kazuo Ogawa100% (1)

- Egss Ils22 PathDocument1 pageEgss Ils22 PathpiwowarczykptNo ratings yet

- (2-14) Instr Apch ChartDocument16 pages(2-14) Instr Apch ChartLGK PUBGNo ratings yet

- ADF S72-1759: Sensor Systems IncDocument1 pageADF S72-1759: Sensor Systems IncMilena Rocío LamonegaNo ratings yet

- Clacton: FraneDocument1 pageClacton: FraneArman TabanovNo ratings yet

- VFR LY AD 2 LYSP 2-4-1 enDocument1 pageVFR LY AD 2 LYSP 2-4-1 enVojislav DabicNo ratings yet

- Product: Torsional Vibration Meter - Type 2523Document4 pagesProduct: Torsional Vibration Meter - Type 2523jhon vargas100% (1)

- SBFL Ils-Y-Rwy-14 Iac 20211202Document1 pageSBFL Ils-Y-Rwy-14 Iac 20211202gameplayPSNo ratings yet

- Vomm Ils Rwy 07Document1 pageVomm Ils Rwy 07Twotawan ThepilotNo ratings yet

- Segmented Photodiodes (SPOT Series) : Position Sensing Detector (PSD)Document6 pagesSegmented Photodiodes (SPOT Series) : Position Sensing Detector (PSD)erickNo ratings yet

- SBRJ - Pumso 3d Rwy 20l - Sid - 20210520Document1 pageSBRJ - Pumso 3d Rwy 20l - Sid - 20210520Henry CalNo ratings yet

- Poptronics 1970 10Document120 pagesPoptronics 1970 10marcelo vintageNo ratings yet

- Ad2 Lgza Star 4Document1 pageAd2 Lgza Star 4lolopiloteNo ratings yet

- WFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtDocument2 pagesWFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtApichai ZankerNo ratings yet

- SBFL Ils-Y-Rwy-14 Iac 20221201Document1 pageSBFL Ils-Y-Rwy-14 Iac 20221201Leonardo Guimarães LacintraNo ratings yet

- (IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WDocument1 page(IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WFábio KastelamaryNo ratings yet

- MH - Ad-2.mhlm ArcDocument1 pageMH - Ad-2.mhlm ArcansiberytNo ratings yet

- RKJY JeppesenDocument11 pagesRKJY Jeppesenelio.aviatorNo ratings yet

- Rovaniemi, Finland: Approach Chart - Icao Instrument Rovaniemi Aerodrome Ilszorloczrwy21Document2 pagesRovaniemi, Finland: Approach Chart - Icao Instrument Rovaniemi Aerodrome Ilszorloczrwy21CaptAdamNo ratings yet

- Thessaloniki / Makedonia Standard Departure Chart Instrument (Sid) - IcaoDocument2 pagesThessaloniki / Makedonia Standard Departure Chart Instrument (Sid) - IcaosamNo ratings yet

- VEBN-ILS(Z)-RWY-27Document1 pageVEBN-ILS(Z)-RWY-27anurag1911.96No ratings yet

- SBFL Vor-Y-Rwy-32 Iac 20231102Document1 pageSBFL Vor-Y-Rwy-32 Iac 20231102Frederico SagasNo ratings yet

- D8R II Plano Electrico PDFDocument2 pagesD8R II Plano Electrico PDFDarío Ache EmeNo ratings yet

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNo ratings yet

- Rev02 GS20 Datasheet ENDocument2 pagesRev02 GS20 Datasheet ENDu RoyNo ratings yet

- A Nálisis Del M Odo y E Fecto de La F AllaDocument43 pagesA Nálisis Del M Odo y E Fecto de La F AllaAlfredoNo ratings yet

- Sbdo - NDB A Rwy 06 24 - Iac - 20170525Document1 pageSbdo - NDB A Rwy 06 24 - Iac - 20170525Matheus BrandtNo ratings yet

- 11 1 Ils DmeDocument1 page11 1 Ils DmehkiatchaNo ratings yet

- Sbco Vor-Y-Rwy-13 Iac 20220127Document1 pageSbco Vor-Y-Rwy-13 Iac 20220127Pedro MonteiroNo ratings yet

- Unindo CB500 - RFQ001Document43 pagesUnindo CB500 - RFQ001Kalimkarawang321 Kalimkarawang321No ratings yet

- 5200 Multi-Axis Load Cell (Us & Metric) : Standard Configuration Features & BenefitsDocument2 pages5200 Multi-Axis Load Cell (Us & Metric) : Standard Configuration Features & BenefitsLalo MejiaNo ratings yet

- Witn (SBG) - Maimun SalehDocument4 pagesWitn (SBG) - Maimun SalehRafly AndrianzaNo ratings yet

- Laser InatraDocument1 pageLaser InatraKleberBuñayNo ratings yet

- Sbae Ndb-Rwy-35 Iac 20210812Document1 pageSbae Ndb-Rwy-35 Iac 20210812Cassiano CapellassiNo ratings yet

- Wipb (LLJ) - SilampariDocument4 pagesWipb (LLJ) - SilampariRafly AndrianzaNo ratings yet

- Ef Ad 2 Efhk 04L RNPDocument2 pagesEf Ad 2 Efhk 04L RNPHarhaliiniNo ratings yet

- Ef Ad 2 Efhk 04R RNPDocument2 pagesEf Ad 2 Efhk 04R RNPHarhaliiniNo ratings yet

- Chart LsgsDocument24 pagesChart Lsgsleron.gundlurNo ratings yet

- (IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqDocument1 page(IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqBoalboalboa NemiandosNo ratings yet

- Ad Elev - 15 FT Amsl: Rotterdam Airport Aerodrome ChartDocument15 pagesAd Elev - 15 FT Amsl: Rotterdam Airport Aerodrome ChartBen HermannNo ratings yet

- LSZH Dep1 Transit Deges ZueDocument1 pageLSZH Dep1 Transit Deges Zuesamykarim2009No ratings yet

- (IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WDocument1 page(IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WGuilherme Kazuo OgawaNo ratings yet

- Acarigua, Venezuela Svac/Agv RNAV (GNSS) Rwy 29Document1 pageAcarigua, Venezuela Svac/Agv RNAV (GNSS) Rwy 29said artigasNo ratings yet

- SBFL Vor-Z-Rwy-14 Iac 20171012 PDFDocument1 pageSBFL Vor-Z-Rwy-14 Iac 20171012 PDFRômullo Furtado BeltrameNo ratings yet

- EG AD 2 EGSS 7-5 en 2013-05-02Document1 pageEG AD 2 EGSS 7-5 en 2013-05-02chrisdantusevoNo ratings yet

- Ltci ChartsDocument10 pagesLtci ChartsOnurhan ErgüderNo ratings yet

- SKBO ILS Rwy 13RDocument1 pageSKBO ILS Rwy 13RBobNo ratings yet

- SBSP Rnp-Y-Rwy-17r Iac 20231130Document1 pageSBSP Rnp-Y-Rwy-17r Iac 20231130carine mirandaNo ratings yet

- SBXF TMA FlorianópolisDocument1 pageSBXF TMA Florianópolisazx72No ratings yet

- Lztt/Tat Poprad, Slovakia: Abrag 2D (Abra2D) Orlan 1D (Orla1D) Marka 2D (Mark2D) Udrel 2D (Udre2D) Rnav Arrivals (RWY 27)Document23 pagesLztt/Tat Poprad, Slovakia: Abrag 2D (Abra2D) Orlan 1D (Orla1D) Marka 2D (Mark2D) Udrel 2D (Udre2D) Rnav Arrivals (RWY 27)Tweed3ANo ratings yet

- 05 Optical CoatingsDocument44 pages05 Optical Coatingsaj7scribdNo ratings yet

- Designing With Toroids Max RiedlDocument1 pageDesigning With Toroids Max Riedlaj7scribdNo ratings yet

- Zap Comix #2 Sample Page 2 atDocument1 pageZap Comix #2 Sample Page 2 ataj7scribdNo ratings yet

- TIG200ACDCP (Ahp) Manual 2016.05Document14 pagesTIG200ACDCP (Ahp) Manual 2016.05aj7scribdNo ratings yet

- Frequency Stabilization of Internal-Mirror Helium-Neon LasersDocument3 pagesFrequency Stabilization of Internal-Mirror Helium-Neon Lasersaj7scribdNo ratings yet

- Birchby W.N. - White Light Interference Fringes With A Thick Glass Plate in One Path (1924)Document6 pagesBirchby W.N. - White Light Interference Fringes With A Thick Glass Plate in One Path (1924)aj7scribdNo ratings yet

- ECEN 4616/5616: Class Website With Past Lectures, Various Files, and AssignmentsDocument41 pagesECEN 4616/5616: Class Website With Past Lectures, Various Files, and Assignmentsaj7scribdNo ratings yet

- A Simple, High Power Nitrogen LaserDocument7 pagesA Simple, High Power Nitrogen Laseraj7scribdNo ratings yet

- Management of Anal Irritation: Oxford University HospitalsDocument4 pagesManagement of Anal Irritation: Oxford University Hospitalsaj7scribdNo ratings yet

- Design of Saturable Reactors 31295000058858Document112 pagesDesign of Saturable Reactors 31295000058858aj7scribd100% (1)

- Electronic Design Ebook - Back To Basics - Impedance MatchingDocument24 pagesElectronic Design Ebook - Back To Basics - Impedance Matchingaj7scribdNo ratings yet

- Handbook Noise MeasurementDocument397 pagesHandbook Noise Measurementaj7scribdNo ratings yet

- Assessment of Voice Coil Peak Displacement XMAX 02Document15 pagesAssessment of Voice Coil Peak Displacement XMAX 02aj7scribdNo ratings yet

- Analysis and Simulation of Hybrid Electric Vehicles For Sedan VehicleDocument5 pagesAnalysis and Simulation of Hybrid Electric Vehicles For Sedan VehicleSureshNo ratings yet

- AnimejsDocument27 pagesAnimejsJesus RodriguezNo ratings yet

- MBA II BRM Trimester End ExamDocument3 pagesMBA II BRM Trimester End ExamRadha Mahat0% (1)

- CVE 3rd PTDocument4 pagesCVE 3rd PTAlexa AustriaNo ratings yet

- 2014 Elec HD FS CKTruck 100713 ChevroletDocument247 pages2014 Elec HD FS CKTruck 100713 ChevroletREINALDO GONZALEZNo ratings yet

- Yamaha Nmax Smart Key SystemDocument1 pageYamaha Nmax Smart Key Systemmotley crewzNo ratings yet

- Chem 1-8Document43 pagesChem 1-8Cabacungan, John VinceNo ratings yet

- Kingair 350i Wiring - 21 Air ConditionedDocument68 pagesKingair 350i Wiring - 21 Air ConditionedLaboratorio01 AvionicsNo ratings yet

- VSD Training Nu Blu Data SheetDocument2 pagesVSD Training Nu Blu Data Sheetابرار عمرNo ratings yet

- Mitsubishi Triton BrochureDocument24 pagesMitsubishi Triton BrochureShahbazAhmadNo ratings yet

- Limbo PowerpointDocument10 pagesLimbo Powerpointapi-693306390No ratings yet

- Self-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalDocument7 pagesSelf-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- First Conditional ChainDocument3 pagesFirst Conditional ChainSonia DivileNo ratings yet

- G6 - Year End Exam (2018) - Southern Provincial Department of EducationDocument8 pagesG6 - Year End Exam (2018) - Southern Provincial Department of EducationXiao ShadowlordNo ratings yet

- Sungrow-SG3 0RT-SG4 0RTDocument2 pagesSungrow-SG3 0RT-SG4 0RTchris dascalopoulosNo ratings yet

- 865-RUGC Manuscript-2653-1-10-20200306Document4 pages865-RUGC Manuscript-2653-1-10-20200306Bal Deep SharmaNo ratings yet

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- Microprocessor Book PDFDocument4 pagesMicroprocessor Book PDFJagan Eashwar0% (4)

- 6.003 Homework #13 Solutions: ProblemsDocument9 pages6.003 Homework #13 Solutions: Problemsvaishnavi khilariNo ratings yet

- Project Product DescriptionDocument5 pagesProject Product Descriptionpruebaproiba12No ratings yet

- 624-DEFLECTOR PLATE CHANGING of CSR#3Document4 pages624-DEFLECTOR PLATE CHANGING of CSR#3Buddy HartNo ratings yet

- Fuel EnergizerDocument29 pagesFuel EnergizeratulsemiloNo ratings yet

- E 10durometerDocument14 pagesE 10durometerDika DrogbaNo ratings yet

- Grade 9 Social Studies Textbook CbseDocument3 pagesGrade 9 Social Studies Textbook CbseKurtNo ratings yet

- Internal Combustion Engines - R. K. RajputDocument352 pagesInternal Combustion Engines - R. K. RajputmeetbalakumarNo ratings yet

- UPS KAISE 600-800va - Hoja de DatosDocument2 pagesUPS KAISE 600-800va - Hoja de DatosGermanYPNo ratings yet

- 5S Implementation Manual Part 2Document63 pages5S Implementation Manual Part 2jgprasadNo ratings yet

- Update On School Readiness and Covid-19Document2 pagesUpdate On School Readiness and Covid-19RianaNo ratings yet