Professional Documents

Culture Documents

Landtek Leep Hardness 23

Landtek Leep Hardness 23

Uploaded by

shoukatzakiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Landtek Leep Hardness 23

Landtek Leep Hardness 23

Uploaded by

shoukatzakiCopyright:

Available Formats

Leeb Hardness Tester

HM-6580 (Enhanced Type)

Model: HM-6560 (Functional Type, Separate)

HM-6561 (Functional Type, Integral)

Applications

Applicable to Die cavity of molds, Inspection of bearing

Enhanced and other mass produced parts on a production line,

Type

Failure analysis of pressure vessel, steam generator and

other equipment, Inspection of installed machinery,

permanent parts of assembled systems and heavy work

pieces, Testing surface of a small hollow space, etc.

HM-6580

Measuring and Converting Ranges

Converting Ranges

Material HB

HL HRC HRB HS HV

Separated Design, 30D² 10D²

Adapt to measurement Steel & Cast St. 300~900 20.0~68.0 38.4~99.5 80~647 32.5~99.5 80~940

of small space. C.W. Tool Steel 300~840 20.4~67.1 80~898

ST. STEEL 300~800 19.6~62.4 46.5~101.7 85~655 80~802

Gray Cast Iron 360~650 93~334

Nodular Cast Iron 400~660 131~387

Cast Aluminum 174~560 20~159

Brass 200~550 13.5~95.3 40~173

Bronze 300~700 60~290

HM-6560 Copper 200~690 45~315

Features

* HM-6580 applies solid aluminum alloy housing, while

HM-6560/HM-6561 applies light weight ABS-plastic

housing.

* Palm size for narrow space.

* Test at any angle, even upside down.

Integrated Design

* Hardness scales HRB, HRC, HV, HB, HS,HL.

Easy Carrying

Greater Mobility * Able to store 50 groups including single measured value,

impact direction, material and hardness scale etc.

* User recalibration function allowed.

HM-6561 * Manual or automatic power off.

* Low battery indication.

* Use RS-232 data output to connect with PC.

* Provide Bluetooth data output choice.

Specifications & Accessories

Model HM-6580 HM-6560 HM-6561

Display LCD

Materials 9 different common materials ( Steel & Cast Steel, C. W. Tool Steel, Stainless Steel,

Gray Cast Iron, Nodular Cast Iron, Cast Aluminum, Brass, Bronze, Copper )

Measuring Range 170~960 (HLD) 200~900 (HLD)

Accuracy Display Error ±0.8%

Repeatability ±0.6 % ±0.8 %

Conversion HL-HRC-HRB-HB-HV-HSD

Memory 50 Data Can Be Stored And Re-readable

Impact device Probe D, Weight: 75 g

Storage Temperature -30 ~ 60 °C

Operating Temperature -10 ~ 50 °C

Conditions Humidity <90 %RH

Power Supply 2x1.5V AA (UM-3) Battery 4x1.5V AAA (UM-4) Battery 2x1.5V AAA (UM-4) Battery

Dimensions 130x76x32mm 120x62x30mm 146x65x36mm

Weight 340 g (Not Including Batteries) 164 g (Not Including Batteries) 130 g (Not Including Batteries)

Standard Accessories Main Unit, Standard Test Block, Small Support Ring, Carrying Case (B09), Manual Book, Cleaning Brush

Probe With Cable Probe Bluit-in

Optional Accessories Support Rings Set, Impact Body, RS-232C Data Cable with Software, Bluetooth Data Adapter with Software

Supporting Ring Set

NO. Model Sketch of Supporting Ring Remarks

1 Z10-15 For Testing Cylindrical Outside Surface R10~R15

2 Z14.5-30 For Testing Cylindrical Outside Surface R14. 5~R30

3 Z25-50 For Testing Cylindrical Outside Surface R25~R50

4 HZ11-13 For Testing Cylindrical Outside Surface R11~R13

5 HZ12.5-17 For Testing Cylindrical Outside Surface R12. 5~R17

6 HZ16.5-30 For Testing Cylindrical Outside Surface R16. 5~R30

7 K10-15 For Testing Spherical Outside Surface SR10~SR15

8 K14.5-30 For Testing Spherical Outside Surface SR14. 5~SR30

9 HK11-13 For Testing Spherical Outside Surface SR11~SR13

10 HK12.5-17 For Testing Spherical Outside Surface SR12. 5~SR17

11 HK16.5-30 For Testing Spherical Outside Surface SR16. 5~SR30

12 UN For testing cylindrical outside surface, radius adjustable R10~∞

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Portable Dynamic Hardness TesterDocument3 pagesPortable Dynamic Hardness TestercommandoNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Moldmax Hh-Eng P 1609 E6Document8 pagesMoldmax Hh-Eng P 1609 E6gurtekinkubra8No ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Aço Uddeholm CalmaxDocument12 pagesAço Uddeholm CalmaxDanilo SilvaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- 100Cr6Document1 page100Cr6JasonNo ratings yet

- 20160323092055-56si7 (55si7) PDFDocument1 page20160323092055-56si7 (55si7) PDFmohammad1361No ratings yet

- C67SDocument1 pageC67SHans GoetheNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089farshid KarpasandNo ratings yet

- Material Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GroupDocument1 pageMaterial Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GrouphdierkeNo ratings yet

- Böhler Fox CM 5 KB: Classifi CationsDocument1 pageBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakNo ratings yet

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocument7 pagesAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- ASSAB Tool Steel Performance Chart A4 enDocument2 pagesASSAB Tool Steel Performance Chart A4 en631052No ratings yet

- Dynapocket mobileHardnessTesterDocument2 pagesDynapocket mobileHardnessTesterengkassemNo ratings yet

- Carbodur 600 B-E6um60Document1 pageCarbodur 600 B-E6um60ali torabiNo ratings yet

- 20160323093435-52CrMoV4 (51CrMoV4)Document1 page20160323093435-52CrMoV4 (51CrMoV4)Martin HristovNo ratings yet

- 20160323093435-52CrMoV4 (51CrMoV4) PDFDocument1 page20160323093435-52CrMoV4 (51CrMoV4) PDFMartin HristovNo ratings yet

- FCD 450-10Document2 pagesFCD 450-10MohammedFaisalGirachNo ratings yet

- A2 Tool Steel PDFDocument7 pagesA2 Tool Steel PDFOscar SaldivarNo ratings yet

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocument2 pagesFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666No ratings yet

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Document2 pagesMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioNo ratings yet

- KH 130 ManualDocument30 pagesKH 130 ManualClaudio SotoNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeMartin HristovNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeMartin HristovNo ratings yet

- 20160323014547-16MnCr5 - 16MnCrS5Document1 page20160323014547-16MnCr5 - 16MnCrS5Chaitanya DattaNo ratings yet

- Aluminium Alloy 6082 - T4 ExtrusionsDocument2 pagesAluminium Alloy 6082 - T4 ExtrusionsRaj DomadiyaNo ratings yet

- L1 34454 en B Boehler Aws E6013 Se en v1Document1 pageL1 34454 en B Boehler Aws E6013 Se en v1brayanNo ratings yet

- Aisi O1: Cold Work Tool SteelDocument7 pagesAisi O1: Cold Work Tool Steeltewiinaba777No ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Cu ZN 10Document2 pagesCu ZN 10wjjt6chgtmNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- High Speed Steel Rolls - Hitachi Metals America, Ltd.Document2 pagesHigh Speed Steel Rolls - Hitachi Metals America, Ltd.hsyna38No ratings yet

- DS Offshore Superelso690cr PDFDocument4 pagesDS Offshore Superelso690cr PDFFernando ReyesNo ratings yet

- Sleipner UddeholmDocument12 pagesSleipner UddeholmKalipse FerreiraNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 pagesAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Ahmad Jasir RasyidiNo ratings yet

- 17-4 Fi Us enDocument10 pages17-4 Fi Us ennaeem akramNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Document2 pagesAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4No ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- ATA Heet: Escalloy 300M-H 300M-H L S Vac-Arc S Vac-ArcDocument2 pagesATA Heet: Escalloy 300M-H 300M-H L S Vac-Arc S Vac-ArcCristiano BeckNo ratings yet

- ASTM A514 GR H Data Sheet 2012 04 02 PDFDocument2 pagesASTM A514 GR H Data Sheet 2012 04 02 PDFRodolfoMarínNo ratings yet

- MT Acciai Speciali: Quality 100Cr6 (EN ISO 683-17)Document1 pageMT Acciai Speciali: Quality 100Cr6 (EN ISO 683-17)pramodh kumarNo ratings yet

- Thyssenkrupp hsm-380 Product Information Precision Steel enDocument3 pagesThyssenkrupp hsm-380 Product Information Precision Steel enParthi NatarajNo ratings yet

- 09.CARBO - ZIBRO 6 AC eDocument1 page09.CARBO - ZIBRO 6 AC eDAVID SOTONo ratings yet

- High Speed Steels: Available Product ShapesDocument4 pagesHigh Speed Steels: Available Product ShapesMilos StamenkovicNo ratings yet

- Boehler2070-Ig de en 1Document1 pageBoehler2070-Ig de en 1Danfer De la CruzNo ratings yet

- 100 CR 62Document4 pages100 CR 62dadNo ratings yet

- SWCH 10aDocument2 pagesSWCH 10asujiyopptsrNo ratings yet

- Arne English 991008Document7 pagesArne English 991008Mas Ist AsNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- Data Table For Grades Special Alloy 50MnDocument3 pagesData Table For Grades Special Alloy 50MnHoLinhNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- JBL - T110 - Spec - Sheet - English PDFDocument2 pagesJBL - T110 - Spec - Sheet - English PDFvikaslashkariNo ratings yet

- Canta Suave - PentatonicosDocument121 pagesCanta Suave - PentatonicosAndres Antonio Martorell GuerraNo ratings yet

- Ude My For Business Course ListDocument51 pagesUde My For Business Course ListShehroz BhuttaNo ratings yet

- Smc10Gpcie-10Bt: Tiger Card™ 10G Pcie 10gbe 10Gbase-T Server AdapterDocument2 pagesSmc10Gpcie-10Bt: Tiger Card™ 10G Pcie 10gbe 10Gbase-T Server Adapterpepe2000No ratings yet

- Placa Asus p4vp-Mx MANUALDocument62 pagesPlaca Asus p4vp-Mx MANUALAlvaro JaraNo ratings yet

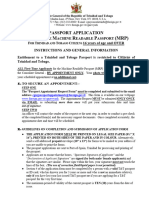

- First Time MRP Adult Application InstructionsDocument3 pagesFirst Time MRP Adult Application InstructionsTacuma JonesNo ratings yet

- CR4 - Thread - Fault Level Calculation of Electrical SystemDocument3 pagesCR4 - Thread - Fault Level Calculation of Electrical SystemParveen SharmaNo ratings yet

- Inflo Data Audit and Analysis May 2020Document37 pagesInflo Data Audit and Analysis May 2020holamundo123No ratings yet

- F N L N: Irst AME AST AMEDocument4 pagesF N L N: Irst AME AST AMEdwaipayan_bhelNo ratings yet

- Lecture On FEM IntroductionDocument81 pagesLecture On FEM IntroductionabuzarNo ratings yet

- CIFS Environment UtilitiesDocument70 pagesCIFS Environment UtilitiesgurureddygNo ratings yet

- Analog ComputersDocument7 pagesAnalog Computerszeronega71No ratings yet

- Sr. Engineer - Vendor Development Department - Coimbatore - Jayem Automotives (P) LTDDocument3 pagesSr. Engineer - Vendor Development Department - Coimbatore - Jayem Automotives (P) LTDRoshini SweatNo ratings yet

- 2G-5G Networks: Evolution of Technologies, Standards, and DeploymentDocument14 pages2G-5G Networks: Evolution of Technologies, Standards, and DeploymentRathore Yuvraj SinghNo ratings yet

- Advanced Topics in Inequalities - Franklyn Wang Et Al. - AoPS 2015 PDFDocument13 pagesAdvanced Topics in Inequalities - Franklyn Wang Et Al. - AoPS 2015 PDFkthekingsNo ratings yet

- Class 1Document39 pagesClass 1Haneesha MuddasaniNo ratings yet

- Cover LetterDocument2 pagesCover LetterRojim OtadoyNo ratings yet

- Lesson 1 Activities 1-3 and Class Exercise 1Document4 pagesLesson 1 Activities 1-3 and Class Exercise 1TheLostMananNo ratings yet

- Lecture Notes in Discrete Mathematics Part 1Document17 pagesLecture Notes in Discrete Mathematics Part 1Moch DedyNo ratings yet

- Declaration and Access Modifiers PDFDocument69 pagesDeclaration and Access Modifiers PDFMurthy MallikarjunaNo ratings yet

- High Current Switching Regulators: DescriptionDocument22 pagesHigh Current Switching Regulators: DescriptionClaudio MartinsNo ratings yet

- Opman NotesDocument10 pagesOpman NotesaegihyunNo ratings yet

- Effective Selling TechniquesDocument48 pagesEffective Selling TechniquesVikram Deshmukh100% (1)

- U.S.N.R./KOCKUMS CANCAR COMPANY, A Canadian v. Raptor Integration Et. Al.Document13 pagesU.S.N.R./KOCKUMS CANCAR COMPANY, A Canadian v. Raptor Integration Et. Al.PriorSmartNo ratings yet

- Commercial RMC PlantDocument38 pagesCommercial RMC PlantREDWOOD ORIGINALNo ratings yet

- Plan For Intelligent Future Safety: KNX CatalogueDocument179 pagesPlan For Intelligent Future Safety: KNX Cataloguemile1966No ratings yet

- Remineralization of Artificial Enamel Lesions by Theobromine PDFDocument7 pagesRemineralization of Artificial Enamel Lesions by Theobromine PDFLjubomirErdoglijaNo ratings yet

- Asp NetDocument91 pagesAsp NetJayant BhardwajNo ratings yet

- Compter Network Notes For B.voc (SD)Document128 pagesCompter Network Notes For B.voc (SD)mukesh244No ratings yet

- ConcreteDocument132 pagesConcreteThái TrầnNo ratings yet