Professional Documents

Culture Documents

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

Uploaded by

sreejukumar27Copyright:

Available Formats

You might also like

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan83% (6)

- Win Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document8 pagesWin Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)anas zubir100% (2)

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- Bob B. Barchi: B.S. Computer ScienceDocument1 pageBob B. Barchi: B.S. Computer ScienceAnonymous 9MXNxiNo ratings yet

- ZF TraducirDocument25 pagesZF TraducirJose Rafael Ramos ChiquilloNo ratings yet

- Sears Owners Manual Model No 944.529181 Craftsman 1150 Series BS Engine 27in Two Stage Snow Thrower - SmallDocument43 pagesSears Owners Manual Model No 944.529181 Craftsman 1150 Series BS Engine 27in Two Stage Snow Thrower - Smalledahan64% (11)

- No. Additional Tower Crane Operation Rev-02Document4 pagesNo. Additional Tower Crane Operation Rev-02sreejukumar27No ratings yet

- No. Precasst Façade Panel Erection Works Rev-01Document13 pagesNo. Precasst Façade Panel Erection Works Rev-01sreejukumar27No ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- Electrical Panel InstallationDocument2 pagesElectrical Panel InstallationKrishna PatilNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- JET Fan InstallationDocument2 pagesJET Fan InstallationKrishna Patil100% (2)

- Duct InstallationDocument2 pagesDuct InstallationKrishna PatilNo ratings yet

- AHU AssemblyDocument3 pagesAHU AssemblyKrishna Patil100% (1)

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- ISK Ssessment ORM: Inventory of Work Activities FormDocument5 pagesISK Ssessment ORM: Inventory of Work Activities Form林诗倩100% (1)

- No. Installation Maintenence & Dismantling of PM HoistDocument24 pagesNo. Installation Maintenence & Dismantling of PM Hoistsreejukumar27No ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Waaree Jsa Form2Document11 pagesWaaree Jsa Form2bboneyt1No ratings yet

- Jsa For Cable Laying & TermnationDocument7 pagesJsa For Cable Laying & Termnationsakthi venkat0% (1)

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA For CWL - SRU R1, JSA No. 18Document5 pagesJSA For CWL - SRU R1, JSA No. 18Nikunja mohantyNo ratings yet

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- VRF InstallationDocument3 pagesVRF InstallationKrishna PatilNo ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- LiftingDocument2 pagesLiftingnaalifeshow143No ratings yet

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Jsa Npe .Document4 pagesJsa Npe .Gan KusumaNo ratings yet

- Copper PipingDocument2 pagesCopper PipingKrishna PatilNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Activity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesDocument13 pagesActivity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesH.J KENo ratings yet

- Hira Fan & Components Lifting ShiftingDocument4 pagesHira Fan & Components Lifting ShiftingBilal QureshiNo ratings yet

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Hazard Assessment and Control FormDocument7 pagesHazard Assessment and Control FormRajalakshmi GajapathyNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- LBK - JSA Drilling - 04012022 - EnglishDocument5 pagesLBK - JSA Drilling - 04012022 - EnglishHSE BGP HONo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- FCU InstallationDocument3 pagesFCU InstallationKrishna PatilNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- STL Varun Ehs M A02 Hira R0Document6 pagesSTL Varun Ehs M A02 Hira R0lsm projectNo ratings yet

- No. Precasst Façade Panel Erection Works Rev-01Document13 pagesNo. Precasst Façade Panel Erection Works Rev-01sreejukumar27No ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- No. Additional Tower Crane Operation Rev-02Document4 pagesNo. Additional Tower Crane Operation Rev-02sreejukumar27No ratings yet

- No. Installation Maintenence & Dismantling of PM HoistDocument24 pagesNo. Installation Maintenence & Dismantling of PM Hoistsreejukumar27No ratings yet

- Eoecdo 6 H 2 RW 65 DelDocument64 pagesEoecdo 6 H 2 RW 65 Delsreejukumar27No ratings yet

- Operating Systems Lecture NotesDocument34 pagesOperating Systems Lecture NotesDilshad BegumNo ratings yet

- IASlistDocument72 pagesIASlistruchirNo ratings yet

- HistoryDocument12 pagesHistoryemircoinNo ratings yet

- 10 1016@j Cep 2019 107771Document42 pages10 1016@j Cep 2019 107771zjNo ratings yet

- Air Arms S400 ISS10Document12 pagesAir Arms S400 ISS10api-3695814No ratings yet

- FSB - 030413Document3 pagesFSB - 030413Vijay BhureNo ratings yet

- DSP Lab 1Document3 pagesDSP Lab 1Anonymous PfQKLcTtNo ratings yet

- Carbide InsertsDocument45 pagesCarbide InsertsAndriya NarasimhuluNo ratings yet

- Ao, Wang - 2016 - Ultimate Torsional Strength of Cracked Stiffened Box Girders With A Large Deck OpeningDocument15 pagesAo, Wang - 2016 - Ultimate Torsional Strength of Cracked Stiffened Box Girders With A Large Deck Openingkharis abdullahNo ratings yet

- Internet of ThingsDocument31 pagesInternet of ThingsBabita NaagarNo ratings yet

- 1932 Oct 23 Ogden Standard-Examiner - Ogden City UTDocument1 page1932 Oct 23 Ogden Standard-Examiner - Ogden City UTMatt NovakNo ratings yet

- Slope Instability From Ground-Water Seepage by Muniram Budhu, Member, Asee, and Roger GobinDocument3 pagesSlope Instability From Ground-Water Seepage by Muniram Budhu, Member, Asee, and Roger GobinBhaskar RanjanNo ratings yet

- Agenda Cbe 2012Document22 pagesAgenda Cbe 2012Santhoshkumar RayavarapuNo ratings yet

- Latihan Soal SUBNETTING CCNADocument11 pagesLatihan Soal SUBNETTING CCNAverry67% (3)

- Fieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksDocument3 pagesFieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksBeaumont Serene Del ReigoNo ratings yet

- Indoor Air Quality & Hvac Systems: ME116P Industrial Power Plant EngineeringDocument63 pagesIndoor Air Quality & Hvac Systems: ME116P Industrial Power Plant EngineeringlynNo ratings yet

- CPM (Critical Path Method)Document23 pagesCPM (Critical Path Method)sarprajkatreNo ratings yet

- Instruction Manual, Aikawa DDR AW26-400 Remodeling / ModificationDocument10 pagesInstruction Manual, Aikawa DDR AW26-400 Remodeling / ModificationhenryhariyadiNo ratings yet

- Metal Inelasticity in ABAQUS - L3 - Direct Cyclic Procedure PDFDocument7 pagesMetal Inelasticity in ABAQUS - L3 - Direct Cyclic Procedure PDFFahrgerusteNo ratings yet

- Ista 3BDocument12 pagesIsta 3Bduygu9merve100% (1)

- Analisis Perencanaan Tebal Perkerasan Lentur Dengan Metode Bina Marga (Studi Kasus: Jalan Luar Lingkar Timur Surabaya)Document10 pagesAnalisis Perencanaan Tebal Perkerasan Lentur Dengan Metode Bina Marga (Studi Kasus: Jalan Luar Lingkar Timur Surabaya)Saya AkuNo ratings yet

- Design and Fabrication of Angular DrillingDocument8 pagesDesign and Fabrication of Angular DrillingvasanthNo ratings yet

- Viar Vor Rwy 16Document1 pageViar Vor Rwy 16Amitoj SinghNo ratings yet

- Metallurgical Volume 1Document196 pagesMetallurgical Volume 1Ugadi SunilNo ratings yet

- Freedos Is A Complete, Free, Dos-Compatible Operating System. Use This Cheat Sheet To Help You With The Most Common CommandsDocument2 pagesFreedos Is A Complete, Free, Dos-Compatible Operating System. Use This Cheat Sheet To Help You With The Most Common CommandsSelvakumarNo ratings yet

- Telecommunication CablesDocument3 pagesTelecommunication CablesZulfequar R. Ali KhanNo ratings yet

- Test of Ozone Resistance and Plastic Deformation: Group StandardDocument4 pagesTest of Ozone Resistance and Plastic Deformation: Group Standardali soydaşNo ratings yet

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

Uploaded by

sreejukumar27Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

No. Installation and Dismantling of Mechanical Loading Platform Rev-01

Uploaded by

sreejukumar27Copyright:

Available Formats

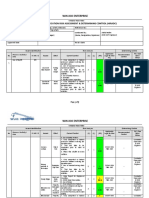

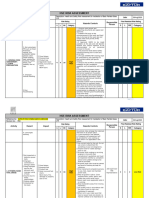

ENVIRONMENTAL, HEALTH AND SAFETY RISKS ANALYSIS

Title: Installation / dismantling and Use of Mechanical loading Platform Doc. No. / Revision: L&W-BBC-RA-049 Rve-01

Company: L&W Construction Private Limited Analysis Conducted by: L&W RA Team

Mr. Padmanaban (CM) ,Mr. Naveen (P&M engineer )

Site: BIETC Campus

Approved by: Mr. Nandagopalan, Project Manager Reviewed by: Name: K. Saravanan, Sr. Safety officer

Date: 4-Dec-19 Sign: Date: 04-12-2019 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health Environmental Impacts / Initial Risk Ratings Control Measures Law / Residual Risk Person-In-Charge (PIC)

& Safety Hazards Health & Safety Risks Compliance Ratings

L S R L S R

1 Mobilisation of Men & H-Health and fitness issues H-Sickness / Disability 3 4 12(M) 1. All lifting crew Medical fitness certificate Yes 1 3 3(L)

Equipment S-Untrained Worker S-Accidents / Incidents 2. Health Safety Environment Induction Training to be conducted at site

S-Unauthorised entry of S-Security Issues 3. Job specefic In-House training.

worker to site 4. Before start work all the workmen attend the tool box meeting

5. Before commencement to work Permit To Work system to be implemented Engineer

6. Non-use of mobile phone in restricted areas.

7. Job Specific Personal Protective Equipment (PPE)

8. ID Card for all workers

2 Loading and Unloading of S - Fall of Person when S - Major Injuries 4 3 12 1. All the workers trained on RA & SWP of Installation of Loading Platform Yes 3 2 6

Mechanical Platform from unloading and unloading from

lorry or trailer trailer bed and high floor 2. Access to be provided through ladder to climb on the trailer bed/top of

(Day & Night) containers with hand rail & Protection around the body.

3. Check the condition of incoming trailer.

4. Appoint banksman with trailer or lorry Site Engineer / EHS

5. Ladder should be placed properly in 1:4 ratios and it should be tied on both top

& bottom.

6. All the work related PPE should be worn while executing the activity.

7. Dedicated supervisor to ensure the job activity

S - Pinch point S - Minor injury, injury to 3 3 9 1. While applying sling t Mechanical Platform, do not keep hand and fingers in

finger between material and sling

2. While material Yes 2 2 4 Site Engineer / EHS

positioning do not put hand in-between gap of member

3. Ensure proper wooden packing/ supports given to material while positioning.

S - Tripping hazard S - Minor injury 3 3 9 1. Ensure proper house keeping at lifting zone and Installation to prevent the Yes 2 2 4 Site Engineer / EHS

tripping

2. All path way, pedestrain walk way and road free from obstructions.

Likelihood (L) Severity (S) Risk Rating (R) Required Action

1 <Improbable> - Extremely unlikely to occur 1 <Minor> - Minor: No lost time / NOT significant Index Rating

2 <Remote> - Unlikely to occur 2 <Appreciable> - Non reportable minor injury; < 3 days MC 1-7 Low No Action Required

3 <Occasional> - Could possibly or known to occur 3 <Serious> - Reportable serious injury; > 3 days MC 8 - 14 Medium Action Required

4 <Probable> - Likely to occur more than once 4 <Major> - 1 fatality; 3 to 7 days of works delay 15 - 19 High Find Alternative Method

5 <Frequent> - Common or repeating occurrences 5 <Catastrophic> - Multiple fatality; > 7 days of works delay 20 - 25 Very High NOT Acceptable / Stop Work

L W Construction Private Limited

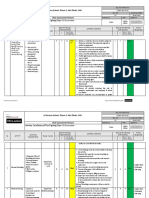

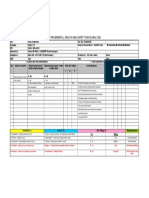

ENVIRONMENTAL, HEALTH AND SAFETY RISKS ANALYSIS

Title: Installation / dismantling Use of Mechanical loading Platform Doc. No. / Revision: L&W-BBC-RA-049 Rve-01

Company: L&W Construction Private Limited Analysis Conducted by: L&W RA Team

Mr. Padmanaban (CM) ,Mr. Naveen (P&M engineer )

Site: BIETC Campus

Approved by: Mr. Nandagopalan, Project Manager Reviewed by: Name: K. Saravanan, Sr. Safety officer

Date: 2-Dec-19 Sign: Date: 02-12-2019 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health Environmental Impacts / Initial Risk Ratings Control Measures Law / Residual Risk Person-In-Charge (PIC)

& Safety Hazards Health & Safety Risks L S R Compliance L Ratings

S R

3 Installation of Mechanical S - Dropping of load due to S - Serious Injury 4 2 8(M) 1. Ensure the crane working condition Yes 2 2 4(L)

Platform Use Tower crane, improper rigging 2. Rigger/ Signal man to properly secure all loads

F-15, Mobile crane

S- Crane collapes due to over S- Property Damege 3 3 9(M) before lifting/ follow the method of safe lifting operation Yes 2 2 4(L)

loaded 3. Workers must follow safe handling procedure- Method of handling procedure

4. Ensure Competent Opertaor with third party certificate and crane operator

licence

5. Follow the safe work load chart as per manucturerer Specification

6. Ensure SWLI and limit switches are functioning.

7. Avoid lifting suspended load over human

8. Sound hooter during workers walking under loads

9. Use certified Lifting gears.(3rd Party certificates )

10. Before use ensure the lifting gear In Good condition.

11. Ground condition to be compacted

12. Ensure the inspection & Maintenece of crane prior to use

S- Mechanical platform Collision S- Serious Injury 4 5 20(VH) 1. Assign Dedicated competent lifting supervisor for lifting operation . Yes 4 2 8(M)

with other object due to poor S- Property Damage

communication 2. Ensure SWL Indicator and limit switches are functioning.

3. Competent Opertaor with third party certificate.

4. Follow the manufacturere load chart for lifting the loads

5. Regular Inspection and maintenence to be done.

6. During the lifting operation lifting supervisor will monitor continuesly.

7. Proper communication to be done with signalman and crane operator. prior to

start each lifting operation. Lifting Supervisor

8. Above 12M/S wind speed ,Both crans operations will be stopped. Lifting Team

9. Wind speed 12M/S for safe operation and it it was recomended by Engineer

manufacturer.

10. Wind speed will be continuesly observed by Lifting supervisor and ensured by

Safety personnel .

11. No loose material on the mechanical platform .

12. Appoint competent lifting crew.

13. All the lifting gears shoud be have 3rd party certificate and ensure the phisical

condition of the lifting gear prior to use

14. Ensure SWLI and limit switches are functioning.

Likelihood (L) Severity (S) Risk Rating (R) Required Action

1 <Improbable> - Extremely unlikely to occur 1 <Minor> - Minor: No lost time / NOT significant Index Rating

2 <Remote> - Unlikely to occur 2 <Appreciable> - Non reportable minor injury; < 3 days MC 1-7 Low No Action Required

3 <Occasional> - Could possibly or known to occur 3 <Serious> - Reportable serious injury; > 3 days MC 8 - 14 Medium Action Required

4 <Probable> - Likely to occur more than once 4 <Major> - 1 fatality; 3 to 7 days of works delay 15 - 19 High Find Alternative Method

5 <Frequent> - Common or repeating occurrences 5 <Catastrophic> - Multiple fatality; > 7 days of works delay 20 - 25 Very High NOT Acceptable / Stop Work

L W Construction Private Limited

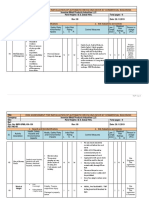

ENVIRONMENTAL, HEALTH AND SAFETY RISKS ANALYSIS

Title: Installation / dismantling Use of Mechanical loading Platform Doc. No. / Revision: L&W-BBC-RA-049 Rve-01

Company: L&W Construction Private Limited Analysis Conducted by: L&W RA Team

Mr. Padmanaban (CM) ,Mr. Naveen (P&M engineer )

Site: BIETC Campus

Approved by: Mr. Nandagopalan, Project Manager Reviewed by: Name: K. Saravanan, Sr. Safety officer

Date: 2-Dec-19 Sign: Date: 02-12-2019 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health Environmental Impacts / Initial Risk Ratings Control Measures Law / Residual Risk Person-In-Charge (PIC)

& Safety Hazards Health & Safety Risks L S R Compliance L Ratings

S R

S- Workman work On edge S - Serious injury / fataality 4 5 20 V(H) 1. Provide Rope Barricade when perform the work 2 5 10 (M) Engineer/ Task

S- Person falling from height 2. Hard Barricade to be installed once the platform installation done for both end supervisor / EHS

S- Material Fallig from Height 3. All workman to be used safety Harness and 100 % tie of when work on edge personnel

4. Below of the Loading platform area to be barricaded with warning sign. Yes

5. Do not keep any material on edge of the floor and on theplatform as well.

6. All to be followed the proper installation method

S - Hit by object due to improper S - Major injuries, fractures 3 4 12 (M) 1. Do not walk or work under the suspended load Yes 2 2 4 Site Engineer / EHS

lifting operation. 2. Deploy trained and experienced manpower for the task

3. While fixing ensure materials away from the lifting workers

1. All the lifting gears shoud be have 3rd party certificate. Yes 2 2 4(L) Rigger / Signal man

S - Failure of lifting gears due to S - Serious injury / fatality 3 4 12(M) 2. Daily inspection of lifting gear and ensure that lifting gears are in free from and Safety Personel

improperway of store Material damage defect.

lifting gears 3. Lifting supervisor to supervise all lifting activities

4. Use right lifting gears for activity.

5. Before lift lifting supervisor to be ensured the safe rigging method

S - Jib/Load struck against S - Machine or load 3 3 9(M) 1. Limit switches to be installed for trollys . Yes 2 2 4(L) Crane contractor

crane mast / Boom / structur damage 2. Ensure trolley limit switches are functioning TC operator

S- Falling of load due to S - Persons crushed by 3. Crane operator and lifting supervisor / rigger to Safety Personel

improper securing and rigging dropping load communicate by walkie-talkie

4. Lifting supervisor to properly supervise all lifting Safety Personel

activities Rigger

5. Use Tag line to guide the loads

6. Follow safe work load chart

S - Manual handling S - Serious injury 4 5 8(M) 1. Lifting team to be identifyed and aware about the pinch areas Yes 2 2 4(L) Respective plant

during installation S - Property Damage 2. Do not load materials if unfavorable wind presents supervisor

S - Loose materials S - Blocking access way 4 2 8(M) 3. Use Mandatory PPE Yes 2 2 4(L) Engineer

S- Improper stacking 4. Third party certificate for operator Competence. Foreman

5. Materials must be stacked properly without the risk of sliding or collapsing Safety Personel

6. Loose Material to be secured properly before lifting operation. Foreman

7. Don’t touch the lifted material when start lifting and unloading. Foreman

S - Hit by object due to improper S - Major injuries, fractures 3 4 12(M) 1. Materials must be stacked at designated area Yes 2 2 4(L) Site Engineer / EHS

lifting and stacking materials

2. Sufficient illumination to be provided in working area during night work. (50

Lux level)

S - Pinch point S - Minor injury, injury to 3 3 9 1. When perform the installation work workman should be aware about the Jack

finger rotation motion Yes 2 2 4 Site Engineer / EHS

2. Ensure proper wooden packing/

supports given to material while positioning.

S - Tripping & Fall When Install S - Minor injury/Major Injury 3 3 9 1. Ensure proper house keeping at lifting zone and Installation to prevent the Yes 2 2 4 Site Engineer / EHS

the Platform tripping.

2. All path way, pedestrain walk way and road free from obstructions.

S-Sliping Hazard when istall the S - Minor injury 3 3 9(M) 1.Platform to be whold properly when perform the installationwork Yes 2 2 4(L) Site Engineer / EHS /

platform 2.Platform installation area to be barricaded Foreman

3 Direct supervisor by supervisor/Foreman

4. Regular visual check to be done for the Installed

Jack Pin and Platform extracting lock nuts

5.. No lifting operation during Heavy wind condition

Likelihood (L) Severity (S) Risk Rating (R) Required Action

1 <Improbable> - Extremely unlikely to occur 1 <Minor> - Minor: No lost time / NOT significant Index Rating

2 <Remote> - Unlikely to occur 2 <Appreciable> - Non reportable minor injury; < 3 days MC 1-7 Low No Action Required

3 <Occasional> - Could possibly or known to occur 3 <Serious> - Reportable serious injury; > 3 days MC 8 - 14 Medium Action Required

4 <Probable> - Likely to occur more than once 4 <Major> - 1 fatality; 3 to 7 days of works delay 15 - 19 High Find Alternative Method

5 <Frequent> - Common or repeating occurrences 5 <Catastrophic> - Multiple fatality; > 7 days of works delay 20 - 25 Very High NOT Acceptable / Stop Work

L W Construction Private Limited

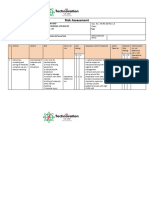

ENVIRONMENTAL, HEALTH AND SAFETY RISKS ANALYSIS

Title: Installation / dismantling Use of Mechanical loading Platform Doc. No. / Revision: L&W-BBC-RA-049 Rve-01

Company: L&W Construction Private Limited Analysis Conducted by: L&W RA Team

Mr. Padmanaban (CM) ,Mr. Naveen (P&M engineer )

Site: BIETC Campus

Approved by: Mr. Nandagopalan, Project Manager Reviewed by: Name: K. Saravanan, Sr. Safety officer

Date: 2-Dec-19 Sign: Date: 02-12-2019 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

Activity Description Environmental Aspects / Health Environmental Impacts / Initial Risk Ratings Control Measures Law / Residual Risk Person-In-Charge (PIC)

& Safety Hazards Health & Safety Risks L S R Compliance L Ratings

S R

4 Using Of Mechanical Loading S- Material Falling from height S- Major Injury and Fatality 4 5 20(VH) 1. Don’t keep loose material on edge of the loading Platform Yes 2 5 10(M) Site Engineer / EHS /

Platform for Loading and 2. When loading of material , all to be secured properly. Foreman

unloading of Materials , Blocks 3. Do not overload follow SWL Max

, debrises 4. Below of the platform area to be barricaded properly with signage

5. No one allowed walk or work under the suspended load

6. Ensure 3rd Party inspection prior to use.

S- Man Falling from Height S- Major Injury and Fatality 4 5 20(VH) 1. Use safety Harness when work on edge of the floor Yes 2 5 10 Site Engineer / EHS /

2. Do not open the platform end door Foreman

3. Provide Barricade when not use the platform

4. Do not stand on platform when perform the lifting work

5. Platform should be inspected and certified by third party.

6. Do not over stack the material above platform height.

S- Platform collaps due to S- Major Injury and Fatality 4 5 20(VH) 1. Do not over load follow load limit Yes 2 5 10 Site Engineer / EHS /

overload 2. Do not store material on the platform Foreman

3. Daily visual inspection to be done prior to use

4. Follow the operational instruction.

5. If there is no activity the platform entrance to be barricaded.

6. Display the SWL signage on the platform

5 On-Site Emergency 1. Follow Emergency Response Plan Yes 3 2 6(L) Project Manager

S- Accidents/Incidents/ S-Minor/ Major Injuries 4 4 16(H) 2. Dedicated On-Site First-Aid facility. Safety Officer

H- Health Issues H-Minor/ Major Sickness 3. Emergency vehicle/Ambulance to be availabel full time at site.

H- Snake bites. S/H-Fatality 4. Sudden access to near - by hospital for emergency

treatment and anti-venom treatment facility

Likelihood (L) Severity (S) Risk Rating (R) Required Action

1 <Improbable> - Extremely unlikely to occur 1 <Minor> - Minor: No lost time / NOT significant Index Rating

2 <Remote> - Unlikely to occur 2 <Appreciable> - Non reportable minor injury; < 3 days MC 1-7 Low No Action Required

3 <Occasional> - Could possibly or known to occur 3 <Serious> - Reportable serious injury; > 3 days MC 8 - 14 Medium Action Required

4 <Probable> - Likely to occur more than once 4 <Major> - 1 fatality; 3 to 7 days of works delay 15 - 19 High Find Alternative Method

5 <Frequent> - Common or repeating occurrences 5 <Catastrophic> - Multiple fatality; > 7 days of works delay 20 - 25 Very High NOT Acceptable / Stop Work

Following situation are consider while during the Aspect / Impact& HIRA for each activity and potential emergency situation.

Environment: Normal, Abnormal (including start up & shutdown as applicable.

OHS: Routine, Nonroutine & Potential emergency situation.

L W Construction Private Limited

You might also like

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan83% (6)

- Win Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document8 pagesWin Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)anas zubir100% (2)

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- Bob B. Barchi: B.S. Computer ScienceDocument1 pageBob B. Barchi: B.S. Computer ScienceAnonymous 9MXNxiNo ratings yet

- ZF TraducirDocument25 pagesZF TraducirJose Rafael Ramos ChiquilloNo ratings yet

- Sears Owners Manual Model No 944.529181 Craftsman 1150 Series BS Engine 27in Two Stage Snow Thrower - SmallDocument43 pagesSears Owners Manual Model No 944.529181 Craftsman 1150 Series BS Engine 27in Two Stage Snow Thrower - Smalledahan64% (11)

- No. Additional Tower Crane Operation Rev-02Document4 pagesNo. Additional Tower Crane Operation Rev-02sreejukumar27No ratings yet

- No. Precasst Façade Panel Erection Works Rev-01Document13 pagesNo. Precasst Façade Panel Erection Works Rev-01sreejukumar27No ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- Electrical Panel InstallationDocument2 pagesElectrical Panel InstallationKrishna PatilNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- JET Fan InstallationDocument2 pagesJET Fan InstallationKrishna Patil100% (2)

- Duct InstallationDocument2 pagesDuct InstallationKrishna PatilNo ratings yet

- AHU AssemblyDocument3 pagesAHU AssemblyKrishna Patil100% (1)

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- ISK Ssessment ORM: Inventory of Work Activities FormDocument5 pagesISK Ssessment ORM: Inventory of Work Activities Form林诗倩100% (1)

- No. Installation Maintenence & Dismantling of PM HoistDocument24 pagesNo. Installation Maintenence & Dismantling of PM Hoistsreejukumar27No ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Waaree Jsa Form2Document11 pagesWaaree Jsa Form2bboneyt1No ratings yet

- Jsa For Cable Laying & TermnationDocument7 pagesJsa For Cable Laying & Termnationsakthi venkat0% (1)

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA For CWL - SRU R1, JSA No. 18Document5 pagesJSA For CWL - SRU R1, JSA No. 18Nikunja mohantyNo ratings yet

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- VRF InstallationDocument3 pagesVRF InstallationKrishna PatilNo ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- LiftingDocument2 pagesLiftingnaalifeshow143No ratings yet

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Jsa Npe .Document4 pagesJsa Npe .Gan KusumaNo ratings yet

- Copper PipingDocument2 pagesCopper PipingKrishna PatilNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Activity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesDocument13 pagesActivity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesH.J KENo ratings yet

- Hira Fan & Components Lifting ShiftingDocument4 pagesHira Fan & Components Lifting ShiftingBilal QureshiNo ratings yet

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Hazard Assessment and Control FormDocument7 pagesHazard Assessment and Control FormRajalakshmi GajapathyNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- LBK - JSA Drilling - 04012022 - EnglishDocument5 pagesLBK - JSA Drilling - 04012022 - EnglishHSE BGP HONo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- FCU InstallationDocument3 pagesFCU InstallationKrishna PatilNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- STL Varun Ehs M A02 Hira R0Document6 pagesSTL Varun Ehs M A02 Hira R0lsm projectNo ratings yet

- No. Precasst Façade Panel Erection Works Rev-01Document13 pagesNo. Precasst Façade Panel Erection Works Rev-01sreejukumar27No ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- No. Additional Tower Crane Operation Rev-02Document4 pagesNo. Additional Tower Crane Operation Rev-02sreejukumar27No ratings yet

- No. Installation Maintenence & Dismantling of PM HoistDocument24 pagesNo. Installation Maintenence & Dismantling of PM Hoistsreejukumar27No ratings yet

- Eoecdo 6 H 2 RW 65 DelDocument64 pagesEoecdo 6 H 2 RW 65 Delsreejukumar27No ratings yet

- Operating Systems Lecture NotesDocument34 pagesOperating Systems Lecture NotesDilshad BegumNo ratings yet

- IASlistDocument72 pagesIASlistruchirNo ratings yet

- HistoryDocument12 pagesHistoryemircoinNo ratings yet

- 10 1016@j Cep 2019 107771Document42 pages10 1016@j Cep 2019 107771zjNo ratings yet

- Air Arms S400 ISS10Document12 pagesAir Arms S400 ISS10api-3695814No ratings yet

- FSB - 030413Document3 pagesFSB - 030413Vijay BhureNo ratings yet

- DSP Lab 1Document3 pagesDSP Lab 1Anonymous PfQKLcTtNo ratings yet

- Carbide InsertsDocument45 pagesCarbide InsertsAndriya NarasimhuluNo ratings yet

- Ao, Wang - 2016 - Ultimate Torsional Strength of Cracked Stiffened Box Girders With A Large Deck OpeningDocument15 pagesAo, Wang - 2016 - Ultimate Torsional Strength of Cracked Stiffened Box Girders With A Large Deck Openingkharis abdullahNo ratings yet

- Internet of ThingsDocument31 pagesInternet of ThingsBabita NaagarNo ratings yet

- 1932 Oct 23 Ogden Standard-Examiner - Ogden City UTDocument1 page1932 Oct 23 Ogden Standard-Examiner - Ogden City UTMatt NovakNo ratings yet

- Slope Instability From Ground-Water Seepage by Muniram Budhu, Member, Asee, and Roger GobinDocument3 pagesSlope Instability From Ground-Water Seepage by Muniram Budhu, Member, Asee, and Roger GobinBhaskar RanjanNo ratings yet

- Agenda Cbe 2012Document22 pagesAgenda Cbe 2012Santhoshkumar RayavarapuNo ratings yet

- Latihan Soal SUBNETTING CCNADocument11 pagesLatihan Soal SUBNETTING CCNAverry67% (3)

- Fieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksDocument3 pagesFieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksBeaumont Serene Del ReigoNo ratings yet

- Indoor Air Quality & Hvac Systems: ME116P Industrial Power Plant EngineeringDocument63 pagesIndoor Air Quality & Hvac Systems: ME116P Industrial Power Plant EngineeringlynNo ratings yet

- CPM (Critical Path Method)Document23 pagesCPM (Critical Path Method)sarprajkatreNo ratings yet

- Instruction Manual, Aikawa DDR AW26-400 Remodeling / ModificationDocument10 pagesInstruction Manual, Aikawa DDR AW26-400 Remodeling / ModificationhenryhariyadiNo ratings yet

- Metal Inelasticity in ABAQUS - L3 - Direct Cyclic Procedure PDFDocument7 pagesMetal Inelasticity in ABAQUS - L3 - Direct Cyclic Procedure PDFFahrgerusteNo ratings yet

- Ista 3BDocument12 pagesIsta 3Bduygu9merve100% (1)

- Analisis Perencanaan Tebal Perkerasan Lentur Dengan Metode Bina Marga (Studi Kasus: Jalan Luar Lingkar Timur Surabaya)Document10 pagesAnalisis Perencanaan Tebal Perkerasan Lentur Dengan Metode Bina Marga (Studi Kasus: Jalan Luar Lingkar Timur Surabaya)Saya AkuNo ratings yet

- Design and Fabrication of Angular DrillingDocument8 pagesDesign and Fabrication of Angular DrillingvasanthNo ratings yet

- Viar Vor Rwy 16Document1 pageViar Vor Rwy 16Amitoj SinghNo ratings yet

- Metallurgical Volume 1Document196 pagesMetallurgical Volume 1Ugadi SunilNo ratings yet

- Freedos Is A Complete, Free, Dos-Compatible Operating System. Use This Cheat Sheet To Help You With The Most Common CommandsDocument2 pagesFreedos Is A Complete, Free, Dos-Compatible Operating System. Use This Cheat Sheet To Help You With The Most Common CommandsSelvakumarNo ratings yet

- Telecommunication CablesDocument3 pagesTelecommunication CablesZulfequar R. Ali KhanNo ratings yet

- Test of Ozone Resistance and Plastic Deformation: Group StandardDocument4 pagesTest of Ozone Resistance and Plastic Deformation: Group Standardali soydaşNo ratings yet