Professional Documents

Culture Documents

Boom Lift Safe Work Procedure Template

Boom Lift Safe Work Procedure Template

Uploaded by

azozinlcCopyright:

Available Formats

You might also like

- Indonesia Market Outlook 2024 by NielsenIQ & MECDocument37 pagesIndonesia Market Outlook 2024 by NielsenIQ & MECdiancahayanii100% (1)

- AML Gold - Precious Metal Sector Case StudiesDocument5 pagesAML Gold - Precious Metal Sector Case Studiesjabir pkNo ratings yet

- 2.25 - Fall Protection PlanDocument5 pages2.25 - Fall Protection PlanWAQAS AHMEDNo ratings yet

- Safe Work Method StatementDocument5 pagesSafe Work Method StatementAnonymous RmzEd3jANo ratings yet

- Mobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On ChecksDocument1 pageMobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On Checksfaisal nadeemNo ratings yet

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocument7 pagesMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorNo ratings yet

- Hazard Identification and Task Risk Assessment (HITRA) FormDocument6 pagesHazard Identification and Task Risk Assessment (HITRA) FormAhmedNo ratings yet

- Company: (Name, Contact Person & Phone) : Safe Work Method StatementDocument5 pagesCompany: (Name, Contact Person & Phone) : Safe Work Method StatementMartine OtienoNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- SQE-010-F-006 (HSR09) Site Health Safety Task Sheet Form V4.0Document5 pagesSQE-010-F-006 (HSR09) Site Health Safety Task Sheet Form V4.0Yogesh AroraNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- c3 Jha - English Final 2-3-2021Document3 pagesc3 Jha - English Final 2-3-2021Alje Adrian SantosNo ratings yet

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- Environmental Incident Investigation Closeout Report - 005Document13 pagesEnvironmental Incident Investigation Closeout Report - 005Ahmad RazaNo ratings yet

- Wildfire Aide Memoire: Primary Secondary FloaterDocument3 pagesWildfire Aide Memoire: Primary Secondary Floatersimon_pilkingto3222No ratings yet

- 2013 Boring Crew JsaDocument2 pages2013 Boring Crew JsaZYS ConstructionNo ratings yet

- 009 ABGJHA009 Concrete WorksDocument4 pages009 ABGJHA009 Concrete WorksALBILAL HSENo ratings yet

- Part E-Organisation Supplied Information-LMW Region-CN0440Document2 pagesPart E-Organisation Supplied Information-LMW Region-CN0440Amir SachsNo ratings yet

- HITRA For Confined SpaceDocument5 pagesHITRA For Confined SpaceAhmedNo ratings yet

- HITRA For Confined Space 30-R-01 SkirtDocument6 pagesHITRA For Confined Space 30-R-01 SkirtAhmedNo ratings yet

- HITRA For PiggingDocument6 pagesHITRA For PiggingAhmedNo ratings yet

- HITRA Worked - Corrogated Sheets +weatherDocument8 pagesHITRA Worked - Corrogated Sheets +weatherAhmedNo ratings yet

- 210528M - Particular Size DistributionDocument26 pages210528M - Particular Size DistributionTharusha ImalkaNo ratings yet

- Safe Work Method Statement: Work Activity: General LiftingDocument15 pagesSafe Work Method Statement: Work Activity: General LiftingMazhar Kaleem100% (1)

- Safe Work Method Statement TemplateDocument5 pagesSafe Work Method Statement Templatemelik zewdeaNo ratings yet

- Project Construction EHSS RISK Assessment-1Document11 pagesProject Construction EHSS RISK Assessment-1shoaib akhtarNo ratings yet

- AD-19-06 Rev 2 OHS Technical QuestionnaireDocument15 pagesAD-19-06 Rev 2 OHS Technical QuestionnairejesusNo ratings yet

- Fire Alarm Incident Report 02 April 2024Document3 pagesFire Alarm Incident Report 02 April 2024Mohsin RazaNo ratings yet

- JSA For Elevator InstallationDocument9 pagesJSA For Elevator InstallationHamid RazaNo ratings yet

- Risk AssessementDocument2 pagesRisk Assessementmelik zewdeaNo ratings yet

- Andi Bau Onggong - Investigation ReportDocument6 pagesAndi Bau Onggong - Investigation ReportAndi OnggongNo ratings yet

- Al Jaber Steel Company - Permit Work FormDocument13 pagesAl Jaber Steel Company - Permit Work Formpradeep.sdc97No ratings yet

- 06-05-2021 - Turaif - First Aid Injuries - Investigation ReportDocument6 pages06-05-2021 - Turaif - First Aid Injuries - Investigation ReportMohamedNo ratings yet

- Near Miss#rmco-Ir-005 ReportDocument6 pagesNear Miss#rmco-Ir-005 ReportQADEER SHANNo ratings yet

- WAH & Confined Space Rescue Plan Formats 1Document2 pagesWAH & Confined Space Rescue Plan Formats 1soumyajeet NayakNo ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- File DokumenDocument3 pagesFile DokumenJalan SantaiNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument6 pagesReview Safe Work Permit Hazard ChecklistSuud SenanNo ratings yet

- Work Permit Sample For Contractro TresDocument6 pagesWork Permit Sample For Contractro TresretheepNo ratings yet

- Blank Risk Assessment TemplateDocument3 pagesBlank Risk Assessment TemplateAzzan HumaidNo ratings yet

- Book 1Document115 pagesBook 1Dheeraj MenonNo ratings yet

- Sow Lab Mechanical ElectricalDocument18 pagesSow Lab Mechanical Electricalazhar khanNo ratings yet

- RA 13 Belle Vue AvenueDocument5 pagesRA 13 Belle Vue AvenueJoshHumphreyNo ratings yet

- Supporting Document Title Permit To Work: Part 1: Project Information (Maklumat Projek)Document2 pagesSupporting Document Title Permit To Work: Part 1: Project Information (Maklumat Projek)syedNo ratings yet

- Transportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesDocument8 pagesTransportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesazerNo ratings yet

- 000-P310-RA-Format-CCTV, ANPR InstallationDocument10 pages000-P310-RA-Format-CCTV, ANPR InstallationMITHUN RAJNo ratings yet

- Risk Assessment (RA) Form RevDocument3 pagesRisk Assessment (RA) Form RevRafiullah Khan100% (1)

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- PTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateDocument301 pagesPTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateRizky Pratama NNo ratings yet

- PTW General Work - 2020, FilledDocument4 pagesPTW General Work - 2020, FilledPalaniappan SolaiyanNo ratings yet

- JHA For Mobile Crane 1 PDFDocument6 pagesJHA For Mobile Crane 1 PDFSethu MathanNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Freddrick DouglasDocument4 pagesFreddrick Douglasngolo1No ratings yet

- Risk Assesment For Lab Building and Assosiated Projects - Demolition Works - 28 Feb 2023Document23 pagesRisk Assesment For Lab Building and Assosiated Projects - Demolition Works - 28 Feb 2023Elavarasan JayachandranNo ratings yet

- Incident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerDocument14 pagesIncident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerJayvee Baradas ValdezNo ratings yet

- Appendix F - Sample FLRADocument5 pagesAppendix F - Sample FLRAkrisNo ratings yet

- Tra Ag Piping MTRXDocument2 pagesTra Ag Piping MTRXranjan703No ratings yet

- Csep RC#42Document3 pagesCsep RC#42ashish kumarNo ratings yet

- JHA Dispenser Replacement and CalibrationDocument5 pagesJHA Dispenser Replacement and CalibrationHSE AmlaakNo ratings yet

- TL 300 4th Ave Ganong ST Geotechnical ReportDocument54 pagesTL 300 4th Ave Ganong ST Geotechnical ReportHugo FernandezNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Affiliation To CSCDocument2 pagesAffiliation To CSCazozinlcNo ratings yet

- Mobilization Plan Kafd-2Document15 pagesMobilization Plan Kafd-2azozinlcNo ratings yet

- Volume IV Liza Phase 1 OSRPDocument281 pagesVolume IV Liza Phase 1 OSRPazozinlcNo ratings yet

- Volume III - Liza Phase 1 ESMPDocument128 pagesVolume III - Liza Phase 1 ESMPazozinlcNo ratings yet

- Advice Note - AN8 - CEMP Planning Guidance Note v2 January 2022Document4 pagesAdvice Note - AN8 - CEMP Planning Guidance Note v2 January 2022azozinlcNo ratings yet

- 6.10 - Construction Environment Management Plan - CheckedDocument32 pages6.10 - Construction Environment Management Plan - CheckedazozinlcNo ratings yet

- Paints, CoatingsDocument9 pagesPaints, CoatingsazozinlcNo ratings yet

- Fire Safety & Evacuation PlanDocument20 pagesFire Safety & Evacuation PlanazozinlcNo ratings yet

- Caution Wet Paint2Document1 pageCaution Wet Paint2azozinlcNo ratings yet

- ReversingsafelyDocument2 pagesReversingsafelyazozinlcNo ratings yet

- Greencap Factsheet Property-Risk-22Document2 pagesGreencap Factsheet Property-Risk-22azozinlcNo ratings yet

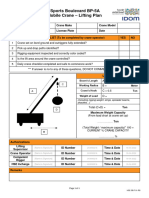

- Mobile Crane Lifting PlanDocument1 pageMobile Crane Lifting PlanazozinlcNo ratings yet

- SUMESPS48Document8 pagesSUMESPS48azozinlcNo ratings yet

- Loler Thourogh Exam.Document1 pageLoler Thourogh Exam.azozinlcNo ratings yet

- Risk Assessment ExampleDocument2 pagesRisk Assessment ExampleazozinlcNo ratings yet

- Leea 010Document40 pagesLeea 010azozinlcNo ratings yet

- Risk AssessmentAUCshortDocument62 pagesRisk AssessmentAUCshortazozinlcNo ratings yet

- L3 Man HACCPDocument11 pagesL3 Man HACCPazozinlcNo ratings yet

- Leea 034Document4 pagesLeea 034azozinlcNo ratings yet

- 3-HAZARD IDENTIFICATIONxyzDocument80 pages3-HAZARD IDENTIFICATIONxyzazozinlcNo ratings yet

- Excavation Permit Form 2Document2 pagesExcavation Permit Form 2azozinlcNo ratings yet

- 0511 REGmaterialspptDocument29 pages0511 REGmaterialspptazozinlcNo ratings yet

- Managing Food Safety Technical UpdateDocument8 pagesManaging Food Safety Technical UpdateazozinlcNo ratings yet

- Forklift Operator Daily ChecklistDocument2 pagesForklift Operator Daily ChecklistazozinlcNo ratings yet

- Ijsrp p1787Document5 pagesIjsrp p1787azozinlcNo ratings yet

- Cold Work Permit Form 2Document2 pagesCold Work Permit Form 2azozinlcNo ratings yet

- Cold Work Permit FormDocument2 pagesCold Work Permit FormazozinlcNo ratings yet

- Excavation Permit FormDocument2 pagesExcavation Permit FormazozinlcNo ratings yet

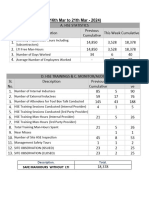

- HSE StatisticsDocument2 pagesHSE StatisticsazozinlcNo ratings yet

- Gerund or Infinitive ReviewDocument2 pagesGerund or Infinitive ReviewSotiris AthanasiouNo ratings yet

- Bouvet FactsDocument5 pagesBouvet FactsRich BlackettNo ratings yet

- HanumanstaleDocument449 pagesHanumanstaleBhaskar Gundu100% (2)

- Case Presentation 2Document27 pagesCase Presentation 2Sathish SPNo ratings yet

- CSS Physics Past Papers 2014-2023Document27 pagesCSS Physics Past Papers 2014-2023Ubaid khokhar100% (1)

- Classification of FolkdanceDocument2 pagesClassification of FolkdanceMica CasimeroNo ratings yet

- POD 2.0 User Manual - EnglishDocument97 pagesPOD 2.0 User Manual - Englishpjf626No ratings yet

- 5th Canto-The Creative Impetus-Book 1Document545 pages5th Canto-The Creative Impetus-Book 1itineo2012No ratings yet

- Blockis Recorder FingeringsDocument12 pagesBlockis Recorder Fingeringscandido.abrantes75No ratings yet

- Rathmore Parish NewsletterDocument2 pagesRathmore Parish Newsletterapi-199024311No ratings yet

- Mechanotechnology Question Memo N3 DownloadDocument22 pagesMechanotechnology Question Memo N3 DownloadMonaheng DimoNo ratings yet

- LBO ModelingDocument66 pagesLBO Modelingalexander ThielNo ratings yet

- Ipo Sylabus and BooksDocument3 pagesIpo Sylabus and BooksNaseema Chan ShaikNo ratings yet

- Lunch Dinner MenuDocument5 pagesLunch Dinner MenueatlocalmenusNo ratings yet

- Zombie: The Coil RulebookDocument137 pagesZombie: The Coil RulebookGnomeMadeIon100% (4)

- FH6000 Alarm ListDocument90 pagesFH6000 Alarm ListAbdul Leon100% (1)

- UnivariateRegression 3Document81 pagesUnivariateRegression 3Alada manaNo ratings yet

- RETDEM - Wearing of Appropriate PPEsDocument4 pagesRETDEM - Wearing of Appropriate PPEsYo MamaNo ratings yet

- STARBUCKS Market AnalysisDocument11 pagesSTARBUCKS Market AnalysisMirela GrNo ratings yet

- Situational Leadership in EducationDocument22 pagesSituational Leadership in EducationRoss Thorburn100% (1)

- Hold Up The Light Lyrics OnlyDocument2 pagesHold Up The Light Lyrics OnlyRoylyn Joy CarlosNo ratings yet

- Paperwise Exemption Syllabus17-1Document2 pagesPaperwise Exemption Syllabus17-1ShubhamNo ratings yet

- 2.what Is Partnership Briefly State Special Features of A Partnership On The Basis of Which Its Existence Can Be Determined Under The Indian Partnership ActDocument162 pages2.what Is Partnership Briefly State Special Features of A Partnership On The Basis of Which Its Existence Can Be Determined Under The Indian Partnership ActJohn Wesley100% (1)

- 21 Rev Der PR51Document7 pages21 Rev Der PR51takoNo ratings yet

- The Effects of New Technology On Parents Child Relationship in Dina, JhelumDocument4 pagesThe Effects of New Technology On Parents Child Relationship in Dina, JhelumThe Explorer IslamabadNo ratings yet

- Test 1 Rectification and Subsidiary Books 21.05.2019Document2 pagesTest 1 Rectification and Subsidiary Books 21.05.2019bhumikaaNo ratings yet

- Polyglot BeginningsDocument30 pagesPolyglot BeginningsJefferson Netto100% (4)

Boom Lift Safe Work Procedure Template

Boom Lift Safe Work Procedure Template

Uploaded by

azozinlcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boom Lift Safe Work Procedure Template

Boom Lift Safe Work Procedure Template

Uploaded by

azozinlcCopyright:

Available Formats

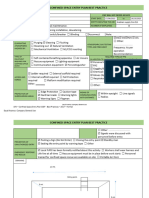

Safe Work Method Statement

Company: (Name, Contact Person & Phone)

Project/Site: Principal Contractor:

Job Task: Boom Lift – Working from SWMS No.:

Date Created: Revision Number: Review Date:

Workers Involved in Developing this SWMS

Print Name: Signature: Print Name: Signature:

Relevant Australian Standards / Codes of Practice / Legislation

Material Safety Data Sheets Required

Plant & Equipment Required

Licenses / Competencies Required

Hot Work Permit ☐ Yes Confined Space Permit ☐ Yes Crane Lift Plan / Permit ☐ Yes Other Permit ☐ Yes

Applicable Permit Number(s):

PPE Required:

High Risk Work: ☐Structural Collapse ☐Confined Spaces ☐Work in Tunnel ☐Explosives

☐Fall from Heights > 2m ☐Demolition of Structures ☐Excavation >1.5m ☐Mobile Plant ☐Drowning

☐Asbestos ☐Pressurised Gas Pipes/Mains ☐Electrical ☐Traffic ☐Tilt-up/Precast Concrete

☐Telecommunication Towers ☐ Contaminated/Flammable Atmosphere ☐ Extremes of Artificial Temperature ☐ Chemical/Fuel/Refrigerant Lines

Task/Location Specific Risks: ☐Ground Conditions ☐Noise ☐Water Pollution ☐Weather

☐Access & Egress ☐Compressed Air ☐Cultural / Heritage Area ☐Soil Pollution ☐Obstacles / Buildings

☐Overhead Obstructions ☐Quick Cut Saw ☐Snakes / Vermin ☐Rotating Machinery ☐

☐Underground Services ☐Angle Grinder ☐Dust ☐Fatigue ☐

☐Pedestrians / Workers ☐Hot Work / Burns ☐Significant Trees ☐Exposure to UV ☐

☐Unauthorised Persons ☐Poor Lighting ☐Flora & Fauna ☐Ignitions Sources ☐ Other (refer to hazard prompt list)

Safe Work Method Statement

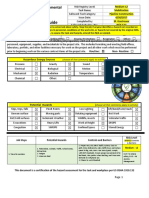

Step 1

Consequences

5 – Severe Potential to be fatal. Permanent disability. Destruction of property or plant.

4 – Major Serious injury. Long term disability. Major damage to plant, property or environment.

3 – Moderate Potential for injury resulting in medical attention. Damage to plant, property or environment.

2 – Minor Injury requiring First Aid treatment and / or short term discomfort.

1 – Negligible Cause a near miss, needs to be reported

Hse-Documents.com BOOM LIFT – WORKING FROM Page 1 of 4

Step 2

Potential (Likelihood)

A – Almost Certain This event is expected to occur in most circumstances

B – Likely The event will probably occur in most circumstances

C – Possible The event might occur at some time

D – Unlikely The event could occur at some time

E - Rare The event may occur only in exceptional circumstances

Step 3

Matrix Consequences

Potential 1 – Negligible 2 – Minor 3 – Moderate 4 – Major 5 – Severe

A – Almost Certain M (9) S (15) S (19) H (24) H (25)

B – Likely L (7) M (11) S (18) S (21) H (23)

C – Possible L (5) L (6) M (13) S (17) H (22)

D – Unlikely L (3) L (4) M (10) M (14) S (20)

E - Rare VL (1) L (2) M (8) M (12) S (16)

Legend

Risk Rating

High Activity to be re-planned and/or re-designed. If this is not possible, an independent Hazard Assessment of the activity is to be completed by the Project Manager prior to completing the SWMS

Significant Activity Must be reviewed by Senior Site Management Representative and have identified risk controls built into the SWMS and work procedure

Medium Site Supervisor must review method of task.

Low Some action may be required, Supervisor to determine and monitor

Very Low Minimal risk, monitor where work changes

Hse-Documents.com BOOM LIFT – WORKING FROM Page 2 of 4

Safe Work Method Statement

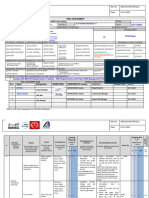

Job Step Potential Hazard Risk Rating Control Residual Risk Person Responsible for Controls

What can cause harm at each step

Break the job into steps S (17) Describe the control measures and how they will be used M (8) EXAMPLE

High risk work is to be kept to its own cell

Only workers trained in correct manual handling techniques to complete task

Manual Handling S M [insert responsible person]

Team lifts and mechanical lifting devices to be used where possible

Work area to be kept clear of trip hazards at all times

Preparation

Appropriate PPE to be worn at all times

Slips, trips, falls Cuts, lacerations, abrasions M L [insert responsible person]

Daily checks and log book entries to be completed by competent operator, all faults and

service requirements to be reported to the site supervisor.

Noise M Correctly attenuated hearing protection to be used at all times when unit is in use L [insert responsible person]

Ensure operator trained and competent.

All tools to be checked & in working order.

Fume inhalation from resigns in disc or from materials S M [insert responsible person]

All cords to be inspected prior to use.

Work area to be well ventilated when in operations

Slips, trips, falls Cuts, Work area to be kept clear of trip hazards at all times

M L [insert responsible person]

lacerations, punctures Appropriate PPE to be worn at all times -including long clothing.

Moving plant onto site

Guards to be in place and eye protection to be used at all times when unit in use.

Foreign body in eye Noise M Erect safe defined work zones or have spotter in place as required L [insert responsible person]

Correctly attenuated hearing protection to be used at all times when unit is in use

Hse-Documents.com BOOM LIFT – WORKING FROM Page 3 of 4

All electrical tools to be tested & tagged in accordance with AS 3760 & 3012.

Electrocution H Tested and tagged RCD protection to be used S [insert responsible person]

All cables checked for damage prior to use

Safety Harness with competent operator to be used at all times

Refer to 'Safety Harness Use' SWMS

Working from basket whilst aloft Fall from heights H S [insert responsible person]

Fall safety equipment to be inspected daily prior to use, faults reported, lanyards to be

attached to the certified anchor point

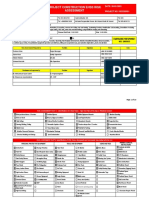

Have you considered the site specific hazards? e.g. IN PREPARING A SAFE WORK METHOD STATEMENT YOU MUST:

- lay of the land 1. Consider any site specific potential hazards and include any identified risks in Safe Work Method Statement (SWMS)

- obstacles (buildings, workers, excavations, plant) 2. Assess the risk

- changes to site conditions 3. Insert controls using the hierarchy of controls for the hazards identified i.e. Elimination, Substitution (materials, equipment, and chemicals), Isolation, Engineering (guarding), Administration (training) or PPE

- other contractors’ work in progress 4. Review the residual risk to ensure controls are adequate to safely perform the work

Have you considered weather conditions? Eg. 5. Document the matters contained in items 1 – 4, above, in this SWMS

- wind 6. Complete the SWMS and Delete these notes to demonstrate that you have considered all relevant matters

- rain

7. Ensure that all workers involved in the job task have read, understood and signed off on the SWMS

- heat

8. Ensure that work is carried out in a safe manner in accordance with the SWMS

- cold etc

NB: If you are unsure of anything seek professional advice. Master Builders WHS department can assist members in developing and implementing safety plans, including SWMS.

Have you considered job specific details?

- different material

- different equipment

Any other factor that may make affect the risks associated with performing this task?

I, the undersigned Supervisor, confirm that I have checked all qualifications provided and verify that they are applicable and current. I have also ensured that all inductions have taken place and that all tools and equipment are properly maintained and safe to use. I have issued all

relevant permits and have ensured to the best of my ability that the work area is safe and that the work will not damage any property or injure any persons.

Supervisor Name Supervisor Signature Date _______________

Hse-Documents.com BOOM LIFT – WORKING FROM Page 4 of 4

You might also like

- Indonesia Market Outlook 2024 by NielsenIQ & MECDocument37 pagesIndonesia Market Outlook 2024 by NielsenIQ & MECdiancahayanii100% (1)

- AML Gold - Precious Metal Sector Case StudiesDocument5 pagesAML Gold - Precious Metal Sector Case Studiesjabir pkNo ratings yet

- 2.25 - Fall Protection PlanDocument5 pages2.25 - Fall Protection PlanWAQAS AHMEDNo ratings yet

- Safe Work Method StatementDocument5 pagesSafe Work Method StatementAnonymous RmzEd3jANo ratings yet

- Mobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On ChecksDocument1 pageMobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On Checksfaisal nadeemNo ratings yet

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocument7 pagesMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorNo ratings yet

- Hazard Identification and Task Risk Assessment (HITRA) FormDocument6 pagesHazard Identification and Task Risk Assessment (HITRA) FormAhmedNo ratings yet

- Company: (Name, Contact Person & Phone) : Safe Work Method StatementDocument5 pagesCompany: (Name, Contact Person & Phone) : Safe Work Method StatementMartine OtienoNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- SQE-010-F-006 (HSR09) Site Health Safety Task Sheet Form V4.0Document5 pagesSQE-010-F-006 (HSR09) Site Health Safety Task Sheet Form V4.0Yogesh AroraNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- c3 Jha - English Final 2-3-2021Document3 pagesc3 Jha - English Final 2-3-2021Alje Adrian SantosNo ratings yet

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- Environmental Incident Investigation Closeout Report - 005Document13 pagesEnvironmental Incident Investigation Closeout Report - 005Ahmad RazaNo ratings yet

- Wildfire Aide Memoire: Primary Secondary FloaterDocument3 pagesWildfire Aide Memoire: Primary Secondary Floatersimon_pilkingto3222No ratings yet

- 2013 Boring Crew JsaDocument2 pages2013 Boring Crew JsaZYS ConstructionNo ratings yet

- 009 ABGJHA009 Concrete WorksDocument4 pages009 ABGJHA009 Concrete WorksALBILAL HSENo ratings yet

- Part E-Organisation Supplied Information-LMW Region-CN0440Document2 pagesPart E-Organisation Supplied Information-LMW Region-CN0440Amir SachsNo ratings yet

- HITRA For Confined SpaceDocument5 pagesHITRA For Confined SpaceAhmedNo ratings yet

- HITRA For Confined Space 30-R-01 SkirtDocument6 pagesHITRA For Confined Space 30-R-01 SkirtAhmedNo ratings yet

- HITRA For PiggingDocument6 pagesHITRA For PiggingAhmedNo ratings yet

- HITRA Worked - Corrogated Sheets +weatherDocument8 pagesHITRA Worked - Corrogated Sheets +weatherAhmedNo ratings yet

- 210528M - Particular Size DistributionDocument26 pages210528M - Particular Size DistributionTharusha ImalkaNo ratings yet

- Safe Work Method Statement: Work Activity: General LiftingDocument15 pagesSafe Work Method Statement: Work Activity: General LiftingMazhar Kaleem100% (1)

- Safe Work Method Statement TemplateDocument5 pagesSafe Work Method Statement Templatemelik zewdeaNo ratings yet

- Project Construction EHSS RISK Assessment-1Document11 pagesProject Construction EHSS RISK Assessment-1shoaib akhtarNo ratings yet

- AD-19-06 Rev 2 OHS Technical QuestionnaireDocument15 pagesAD-19-06 Rev 2 OHS Technical QuestionnairejesusNo ratings yet

- Fire Alarm Incident Report 02 April 2024Document3 pagesFire Alarm Incident Report 02 April 2024Mohsin RazaNo ratings yet

- JSA For Elevator InstallationDocument9 pagesJSA For Elevator InstallationHamid RazaNo ratings yet

- Risk AssessementDocument2 pagesRisk Assessementmelik zewdeaNo ratings yet

- Andi Bau Onggong - Investigation ReportDocument6 pagesAndi Bau Onggong - Investigation ReportAndi OnggongNo ratings yet

- Al Jaber Steel Company - Permit Work FormDocument13 pagesAl Jaber Steel Company - Permit Work Formpradeep.sdc97No ratings yet

- 06-05-2021 - Turaif - First Aid Injuries - Investigation ReportDocument6 pages06-05-2021 - Turaif - First Aid Injuries - Investigation ReportMohamedNo ratings yet

- Near Miss#rmco-Ir-005 ReportDocument6 pagesNear Miss#rmco-Ir-005 ReportQADEER SHANNo ratings yet

- WAH & Confined Space Rescue Plan Formats 1Document2 pagesWAH & Confined Space Rescue Plan Formats 1soumyajeet NayakNo ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- File DokumenDocument3 pagesFile DokumenJalan SantaiNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument6 pagesReview Safe Work Permit Hazard ChecklistSuud SenanNo ratings yet

- Work Permit Sample For Contractro TresDocument6 pagesWork Permit Sample For Contractro TresretheepNo ratings yet

- Blank Risk Assessment TemplateDocument3 pagesBlank Risk Assessment TemplateAzzan HumaidNo ratings yet

- Book 1Document115 pagesBook 1Dheeraj MenonNo ratings yet

- Sow Lab Mechanical ElectricalDocument18 pagesSow Lab Mechanical Electricalazhar khanNo ratings yet

- RA 13 Belle Vue AvenueDocument5 pagesRA 13 Belle Vue AvenueJoshHumphreyNo ratings yet

- Supporting Document Title Permit To Work: Part 1: Project Information (Maklumat Projek)Document2 pagesSupporting Document Title Permit To Work: Part 1: Project Information (Maklumat Projek)syedNo ratings yet

- Transportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesDocument8 pagesTransportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesazerNo ratings yet

- 000-P310-RA-Format-CCTV, ANPR InstallationDocument10 pages000-P310-RA-Format-CCTV, ANPR InstallationMITHUN RAJNo ratings yet

- Risk Assessment (RA) Form RevDocument3 pagesRisk Assessment (RA) Form RevRafiullah Khan100% (1)

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- PTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateDocument301 pagesPTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateRizky Pratama NNo ratings yet

- PTW General Work - 2020, FilledDocument4 pagesPTW General Work - 2020, FilledPalaniappan SolaiyanNo ratings yet

- JHA For Mobile Crane 1 PDFDocument6 pagesJHA For Mobile Crane 1 PDFSethu MathanNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Freddrick DouglasDocument4 pagesFreddrick Douglasngolo1No ratings yet

- Risk Assesment For Lab Building and Assosiated Projects - Demolition Works - 28 Feb 2023Document23 pagesRisk Assesment For Lab Building and Assosiated Projects - Demolition Works - 28 Feb 2023Elavarasan JayachandranNo ratings yet

- Incident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerDocument14 pagesIncident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerJayvee Baradas ValdezNo ratings yet

- Appendix F - Sample FLRADocument5 pagesAppendix F - Sample FLRAkrisNo ratings yet

- Tra Ag Piping MTRXDocument2 pagesTra Ag Piping MTRXranjan703No ratings yet

- Csep RC#42Document3 pagesCsep RC#42ashish kumarNo ratings yet

- JHA Dispenser Replacement and CalibrationDocument5 pagesJHA Dispenser Replacement and CalibrationHSE AmlaakNo ratings yet

- TL 300 4th Ave Ganong ST Geotechnical ReportDocument54 pagesTL 300 4th Ave Ganong ST Geotechnical ReportHugo FernandezNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Affiliation To CSCDocument2 pagesAffiliation To CSCazozinlcNo ratings yet

- Mobilization Plan Kafd-2Document15 pagesMobilization Plan Kafd-2azozinlcNo ratings yet

- Volume IV Liza Phase 1 OSRPDocument281 pagesVolume IV Liza Phase 1 OSRPazozinlcNo ratings yet

- Volume III - Liza Phase 1 ESMPDocument128 pagesVolume III - Liza Phase 1 ESMPazozinlcNo ratings yet

- Advice Note - AN8 - CEMP Planning Guidance Note v2 January 2022Document4 pagesAdvice Note - AN8 - CEMP Planning Guidance Note v2 January 2022azozinlcNo ratings yet

- 6.10 - Construction Environment Management Plan - CheckedDocument32 pages6.10 - Construction Environment Management Plan - CheckedazozinlcNo ratings yet

- Paints, CoatingsDocument9 pagesPaints, CoatingsazozinlcNo ratings yet

- Fire Safety & Evacuation PlanDocument20 pagesFire Safety & Evacuation PlanazozinlcNo ratings yet

- Caution Wet Paint2Document1 pageCaution Wet Paint2azozinlcNo ratings yet

- ReversingsafelyDocument2 pagesReversingsafelyazozinlcNo ratings yet

- Greencap Factsheet Property-Risk-22Document2 pagesGreencap Factsheet Property-Risk-22azozinlcNo ratings yet

- Mobile Crane Lifting PlanDocument1 pageMobile Crane Lifting PlanazozinlcNo ratings yet

- SUMESPS48Document8 pagesSUMESPS48azozinlcNo ratings yet

- Loler Thourogh Exam.Document1 pageLoler Thourogh Exam.azozinlcNo ratings yet

- Risk Assessment ExampleDocument2 pagesRisk Assessment ExampleazozinlcNo ratings yet

- Leea 010Document40 pagesLeea 010azozinlcNo ratings yet

- Risk AssessmentAUCshortDocument62 pagesRisk AssessmentAUCshortazozinlcNo ratings yet

- L3 Man HACCPDocument11 pagesL3 Man HACCPazozinlcNo ratings yet

- Leea 034Document4 pagesLeea 034azozinlcNo ratings yet

- 3-HAZARD IDENTIFICATIONxyzDocument80 pages3-HAZARD IDENTIFICATIONxyzazozinlcNo ratings yet

- Excavation Permit Form 2Document2 pagesExcavation Permit Form 2azozinlcNo ratings yet

- 0511 REGmaterialspptDocument29 pages0511 REGmaterialspptazozinlcNo ratings yet

- Managing Food Safety Technical UpdateDocument8 pagesManaging Food Safety Technical UpdateazozinlcNo ratings yet

- Forklift Operator Daily ChecklistDocument2 pagesForklift Operator Daily ChecklistazozinlcNo ratings yet

- Ijsrp p1787Document5 pagesIjsrp p1787azozinlcNo ratings yet

- Cold Work Permit Form 2Document2 pagesCold Work Permit Form 2azozinlcNo ratings yet

- Cold Work Permit FormDocument2 pagesCold Work Permit FormazozinlcNo ratings yet

- Excavation Permit FormDocument2 pagesExcavation Permit FormazozinlcNo ratings yet

- HSE StatisticsDocument2 pagesHSE StatisticsazozinlcNo ratings yet

- Gerund or Infinitive ReviewDocument2 pagesGerund or Infinitive ReviewSotiris AthanasiouNo ratings yet

- Bouvet FactsDocument5 pagesBouvet FactsRich BlackettNo ratings yet

- HanumanstaleDocument449 pagesHanumanstaleBhaskar Gundu100% (2)

- Case Presentation 2Document27 pagesCase Presentation 2Sathish SPNo ratings yet

- CSS Physics Past Papers 2014-2023Document27 pagesCSS Physics Past Papers 2014-2023Ubaid khokhar100% (1)

- Classification of FolkdanceDocument2 pagesClassification of FolkdanceMica CasimeroNo ratings yet

- POD 2.0 User Manual - EnglishDocument97 pagesPOD 2.0 User Manual - Englishpjf626No ratings yet

- 5th Canto-The Creative Impetus-Book 1Document545 pages5th Canto-The Creative Impetus-Book 1itineo2012No ratings yet

- Blockis Recorder FingeringsDocument12 pagesBlockis Recorder Fingeringscandido.abrantes75No ratings yet

- Rathmore Parish NewsletterDocument2 pagesRathmore Parish Newsletterapi-199024311No ratings yet

- Mechanotechnology Question Memo N3 DownloadDocument22 pagesMechanotechnology Question Memo N3 DownloadMonaheng DimoNo ratings yet

- LBO ModelingDocument66 pagesLBO Modelingalexander ThielNo ratings yet

- Ipo Sylabus and BooksDocument3 pagesIpo Sylabus and BooksNaseema Chan ShaikNo ratings yet

- Lunch Dinner MenuDocument5 pagesLunch Dinner MenueatlocalmenusNo ratings yet

- Zombie: The Coil RulebookDocument137 pagesZombie: The Coil RulebookGnomeMadeIon100% (4)

- FH6000 Alarm ListDocument90 pagesFH6000 Alarm ListAbdul Leon100% (1)

- UnivariateRegression 3Document81 pagesUnivariateRegression 3Alada manaNo ratings yet

- RETDEM - Wearing of Appropriate PPEsDocument4 pagesRETDEM - Wearing of Appropriate PPEsYo MamaNo ratings yet

- STARBUCKS Market AnalysisDocument11 pagesSTARBUCKS Market AnalysisMirela GrNo ratings yet

- Situational Leadership in EducationDocument22 pagesSituational Leadership in EducationRoss Thorburn100% (1)

- Hold Up The Light Lyrics OnlyDocument2 pagesHold Up The Light Lyrics OnlyRoylyn Joy CarlosNo ratings yet

- Paperwise Exemption Syllabus17-1Document2 pagesPaperwise Exemption Syllabus17-1ShubhamNo ratings yet

- 2.what Is Partnership Briefly State Special Features of A Partnership On The Basis of Which Its Existence Can Be Determined Under The Indian Partnership ActDocument162 pages2.what Is Partnership Briefly State Special Features of A Partnership On The Basis of Which Its Existence Can Be Determined Under The Indian Partnership ActJohn Wesley100% (1)

- 21 Rev Der PR51Document7 pages21 Rev Der PR51takoNo ratings yet

- The Effects of New Technology On Parents Child Relationship in Dina, JhelumDocument4 pagesThe Effects of New Technology On Parents Child Relationship in Dina, JhelumThe Explorer IslamabadNo ratings yet

- Test 1 Rectification and Subsidiary Books 21.05.2019Document2 pagesTest 1 Rectification and Subsidiary Books 21.05.2019bhumikaaNo ratings yet

- Polyglot BeginningsDocument30 pagesPolyglot BeginningsJefferson Netto100% (4)