Professional Documents

Culture Documents

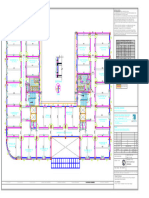

UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window Schedule

UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window Schedule

Uploaded by

D HOLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window Schedule

UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window Schedule

Uploaded by

D HOLCopyright:

Available Formats

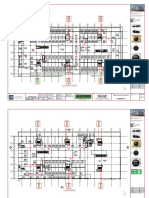

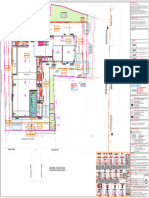

GENERAL NOTES:

COPYRIGHT RESERVED BY HOLLOWAY & HOUND ON ALL DESIGNS AND

DOCUMENTATION.

NO DRAWINGS TO BE SCALED.

ALL MEASUREMENTS, HEIGHTS AND LEVELS TO BE VERIFIED ON SITE PRIOR TO

COMMENCEMENT OF CONSTRUCTION AND ADAPTED TO SUGGESTED BUILDING WORK.

ANY DISCREPANCY OR CONTRADICTION TO BE DISCUSSED WITH THE ARCHITECT

IMMEDIATELY.

ALL DIMENSIONS INDICATED ON PLAN TO BE SET OUT ON A LEVEL HORIZONTAL PLANE .

ALL BRICKWORK TO BE SET OUT USING A PROFILE MARKED 85mm C/C.

THE CONTRACTOR IS RESPONSIBLE FOR THE CORRECT SETTING OUT OF THE BUILDING

WORK ON SITE WITH PARTICULAR REFERENCE TO SITE BOUNDARIES, SERVITUTES AND

BUILDING LINES.

THE CONTRACTOR IS TO BUILD IN APPROVED D.P.C's TO ALL EXTERNAL WALLS, UNDER

FLOORS AND UNDER WINDOW CILLS.

QUALITY OF ALL MATERIAL AND CRAFTMANSHIP TO COMPLY WITH THE RELEVANT S.A.B.S

STANDARDS.

THE CONTRACTOR SHOULD HAVE A FULL SET OF DRAWINGS AVAILABLE ON SITE AT ALL

TIMES.

THE CONTRACTOR IS RESPONSIBLE FOR HIS OWN QUALITY CONTROL.

ALL FLOOR LEVELS SHOWN ON THIS DRAWING REFER TO UNFINISHED FLOOR LEVELS.

GENERAL:

Boundry pegs to be pointed out by

DRAINAGE:

All sewers to be 100mm dia. PVC

owner.

min. fall 1:60, Max fall 1:10.

Contractor must check all levels,

dimentions, steps

Open end of vent pipe to be min.

etc. on site, and report all

2,0m above any opening.

discrepancies to the designer.

All work to comply with the National

Stub vents to be fitted with an

Building Regulations

approved 2-way vent-valve.

FLOORS AND SLABS: Stacks in ducts to be accessable for

Ground floor slab: 85mm thick,

GENERAL NOTE GENERAL NOTE 20MPa minimum concrete, perfectly

cleaning purpouses.

All internal doors All glass doors and floor to level, min 150mm above gl. on All bends and

properly compacted

junctions in sewer to

be fitted with ie's, all re's under

to to be floor to ceiling fixed window panes to be hardcore: 25mm thick screed and

paving to be fitted with marked

finishes as indicated.

ceiling height lamenated safety glass covers.

These floors must be cast on min

Protect drain under foundations in

50mm. thick

accordance with SANS 10400

polystyrene foam and foam is to be

installed around

All waste fittings to have reseal traps

perimeter of room to insulate floor

and pipe to be fully accessable if

from wall.

under floors, with ie's either end or

clamped to wall.

DPC under all walls (except free

standing), floors &

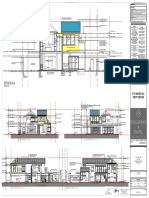

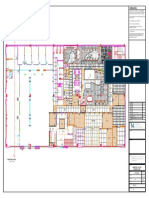

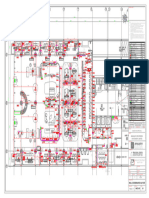

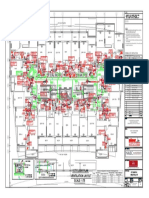

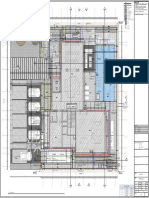

D - 01 D-02 D-03 595

D-04 D - 05 window sills & to all vertical changes

in floor levels.

Any sewer pipe not deeper than

350mm under ground level (il.-.46) to

be covered with a concrete slab, wide

and strong enough to protect the

930 1840 4565 Laminated with FOUNDATIONS AND sewer, with min 100mm soil between

Safety Glass BRICKWORK pipe and concrete.

1250 1210

framless joints

600

1

1 1

All foundations to be minimum 10MPa

concrete (2 sacks cement: The radius at the centerline of bend

4 wheelbarrows river sand: 5 of the foot of discharge stack, shall be

wheelbarrows 22mm stone) not less than 300mm and other bends

1840 2500 at least 200mmx600mm, min. 600mm.

4560

200mm under ground level

915 925 1140 1140 1140 1140 Ceiling 1250 1195 605 595 935 950 or to eng. details. Where any waste or soil branches

Level 2.500 Lintel height

Ceiling height Ceiling height Ceiling height height NOTE: THESE ARE MINIMUM are connected to a stack the centre

U/S Floor slab 930 U/S REQUIREMENTS ONLY line of the waste branch shall not

U/S Floor slab U/S Floor slab

Level 2.500 Level 2.500 Level 2.500 Level 2.500 Floor slab intersect the stack within 200mm

Lintels to be supported min. 150mm below the centre line of the soil

Laminated Laminated Laminated Laminated Laminated Laminated Laminated Laminated for openings up to branch.

MEASURE WINDOW Laminated Safety Glass

MEASURE WINDOW Safety Glass Safety Glass MEASURE WINDOW Safety Glass Safety Glass Safety Glass Safety Glass MEASURE Safety Glass Safety Glass 3,0m and at least 220mm for

ON SITE BEFORE openings up to 4,8m. Sewer connection : as shown: with

ON SITE BEFORE ON SITE BEFORE WINDOW MEASURE WINDOW rodding eye ormanhole within 1,5m

MANUFACTURING MANUFACTURING MANUFACTURING ON SITE ON SITE BEFORE

2100

2500

Brickforce to built in every course from connection.

2500

2500

2500

BEFORE MANUFACTURING below floor level and above

MANUFACTURING window level, every third course

between, in continuous bands.

Counter height

Level 0.000 Level 0.000 Level 0.000 Level 0.000 Level 0.000

FFL FFL FFL FFL FFL

CATALOGUE NR. SOLID MERANTI DOOR GENERAL NOTES: CATALOGUE NR. CUSTOM MADE ALUMINIUM DOOR GENERAL NOTES: CATALOGUE NR. CUSTOM MADE ALUMINIUM DOOR GENERAL NOTES: CATALOGUE NR. CUSTOM MADE ALUMINIUM DOOR GENERAL NOTES: CATALOGUE NR. SOLID MERANTI DOOR GENERAL NOTES:

DESCRIPTION SOLID MERANTI HARDWOOD DOOR

ALL DIMENTIONS TO BE

CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

DESCRIPTION ALUMINIUM DOOR WITH SLIDING PANEL

ALL DIMENTIONS TO BE

CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

DESCRIPTION ALUMINIUM DOORS WITH SLIDING PANELS

ALL DIMENTIONS TO BE

CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

DESCRIPTION ALUMINIUM DOOR WITH SLIDING PANEL

ALL DIMENTIONS TO BE

CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

DESCRIPTION INTERNAL HOLLOWCORE DOOR

ALL DIMENTIONS TO BE

CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

IF IN DOUBT ASK

GLAZING N/A

IN HAND.

ALL GLAZING TO BE IN

ACCORDANCE WITH

GLAZING CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN

IN HAND.

ALL GLAZING TO BE IN

ACCORDANCE WITH

GLAZING CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN

IN HAND.

ALL GLAZING TO BE IN

ACCORDANCE WITH

GLAZING CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN

IN HAND.

ALL GLAZING TO BE IN

ACCORDANCE WITH

GLAZING N/A

IN HAND.

ALL GLAZING TO BE IN

ACCORDANCE WITH

DONT ASSUME

ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400

AAAMSA. SAGGA AND AAAMSA. SAGGA AND AAAMSA. SAGGA AND AAAMSA. SAGGA AND AAAMSA. SAGGA AND

SANS10160 SANS10160 SANS10160 SANS10160 SANS10160

SANS10137 SANS10137 SANS10137 SANS10137 SANS10137

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

SANS 1263 SANS 1263 SANS 1263 SANS 1263 SANS 1263

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS

PLASTERED DOOR REVEAL PROVISION SHOULD BE PLASTERED WINDOW REVEAL AND INNER SILL PROVISION SHOULD BE PLASTERED WINDOW REVEAL AND INNER SILL PROVISION SHOULD BE PLASTERED WINDOW REVEAL AND INNER SILL PROVISION SHOULD BE PLASTERED DOOR REVEAL PROVISION SHOULD BE

LINTEL & SILL SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO MADE FOR STRUCTURAL LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL MADE FOR STRUCTURAL LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL MADE FOR STRUCTURAL LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL MADE FOR STRUCTURAL LINTEL & SILL SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO MADE FOR STRUCTURAL

SUPPORT WHERE SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SUPPORT WHERE SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SUPPORT WHERE SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SUPPORT WHERE SUPPORT WHERE

MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

APPLICABLE MANUFACTURER'S SPECIFICATIONS APPLICABLE MANUFACTURER'S SPECIFICATIONS APPLICABLE MANUFACTURER'S SPECIFICATIONS APPLICABLE APPLICABLE

QUANTITIES TO BE QUANTITIES TO BE QUANTITIES TO BE QUANTITIES TO BE QUANTITIES TO BE

IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS IRONMONGERY AS PER DOOR MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS

QUANTITY 1 QUANTITY 3 QUANTITY 1 QUANTITY 1 QUANTITY 4

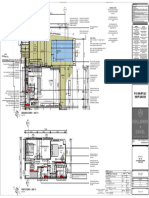

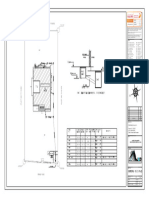

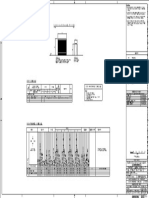

D - 06 W - 01 W - 02

C:\Users\Cwangco\Desktop\Holloway and Daval Architects\3 FICUS STREET\PDF Images\DEMOLITION PLAN EXAMPLE6d47c13d.png

950 1800 1120

Ceiling height

930 870 560 560

Level 2.500 Ceiling height Level 2.500 U/S Floor slab

U/S Floor slab

560

1120

1200

2125

MEASURE WINDOW MEASURE WINDOW

2065

560

930 ON SITE BEFORE ON SITE BEFORE

Level 2.300 Bulkhead height

MANUFACTURING MANUFACTURING

U/S lintol

Counter height

1005

865

MEASURE WINDOW Level 0.000 Level 0.000 32 Clarendon Crescent 021 510 0072 Daleen Holloway - PfSnrArch T

ON SITE BEFORE FFL FFL Ysterplaat 079 502 6645 SACAP Registration - PSAT 20714

Cape Town

MANUFACTURING 7405 daleen@hollowayandhound.com

2200

www.hollowayandhound.com

CATALOGUE NR. CUSTOM MADE ALUMINIUM WINDOW CATALOGUE NR. CUSTOM MADE ALUMINIUM WINDOW

PROJEK PROJECT

Level 0.000 GENERAL NOTES: ALUMINIUM WINDOW WITH OPENING PANELS GENERAL NOTES:

DESCRIPTION ALUMINIUM WINDOW WITH SLIDING PANELS DESCRIPTION

FFL

ALL DIMENTIONS TO BE ALL DIMENTIONS TO BE

CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT

IN HAND. IN HAND.

CATALOGUE NR. SOLID MERANTI DOOR GENERAL NOTES:

ALL GLAZING TO BE IN ALL GLAZING TO BE IN MRS MOTAU

FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH

ALL DIMENTIONS TO BE

AAAMSA. SAGGA AND

SANS10160

AAAMSA. SAGGA AND

SANS10160

ERF 1736

DESCRIPTION SOLID MERANTI HARDWOOD DOOR CONFIRMED ON SITE

BEFORE ANY WORK IS PUT

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS SANS10137 PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS SANS10137 28 CHAS BOOTH AVENUE

PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N

IN HAND. LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263

LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263 CAPE TOWN

ALL GLAZING TO BE IN SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO

GLAZING N/A

ACCORDANCE WITH MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

PROVISION SHOULD BE PROVISION SHOULD BE

AAAMSA. SAGGA AND MADE FOR STRUCTURAL MADE FOR STRUCTURAL

SANS10160 SUPPORT WHERE AS PER WINDOW MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE

SANS10137

IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS IRONMONGERY

FINNISH COLOUR TO MATCH EXISTING APPLICABLE APPLICABLE

SANS 10400 PART N

SANS 1263 QUANTITIES TO BE QUANTITIES TO BE

QUANTITY 1 CONFIRMED ON PLANS QUANTITY 1 CONFIRMED ON PLANS

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS TITEL TITLE

LINTEL & SILL PLASTERED DOOR REVEAL PROVISION SHOULD BE AREA SCHEDULE WINDOW & DOOR

SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO MADE FOR STRUCTURAL

MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE AREA TOTAL SCHEDULE

APPLICABLE DESCRIPTION OF STRUCTURE

AS PER WINDOW MANUFACTURER'S SPECIFICATIONS

QUANTITIES TO BE

EXISTING MAIN DWELLING 70.7 m2

IRONMONGERY CONFIRMED ON PLANS

NEW POOL 20.m2 SKAAL AS INDICATED SCALE

QUANTITY 2 2

NEW PERGOLA 20.m GETEKEN DH DRAWN

TOTAL AREA OF UNIT 11 110.7m2 NAGESIEN DH CHECKED

DATUM 24.11.2023 DATE

TOTAL AREA OF ALL UNITS 878.7m2 TEK. NO. DRWG. NR:

ARCHITECTURAL PROFESSIONAL

2 2

DALEEN HOLLOWAY SITE 1675.9m 1675.9m

PSAT 20714 2023_42_006

CONTACT NR: 079 502 6645 TOTAL COVERAGE 52.4%

You might also like

- Structural Drawings 2Document9 pagesStructural Drawings 2Makenson MuscadinNo ratings yet

- Interactions Between Lubricants and CoatingsDocument23 pagesInteractions Between Lubricants and CoatingsBojan PodgornikNo ratings yet

- Groundwater & WellsDocument31 pagesGroundwater & WellsArman Atienza Magcawas17% (6)

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- 02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsDocument1 page02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsD HOLNo ratings yet

- House Wallace Rev8 (2017)Document10 pagesHouse Wallace Rev8 (2017)D HOLNo ratings yet

- Zibagwe OfficesDocument1 pageZibagwe OfficesdereramichaelNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanD HOLNo ratings yet

- A1700 Signage Location and DetailsDocument5 pagesA1700 Signage Location and DetailsJustMoveIt Trucking, OPCNo ratings yet

- ELEVATIONS (1:100) SECTION A-A (1:50) : NotesDocument2 pagesELEVATIONS (1:100) SECTION A-A (1:50) : NotesLubangakene BrianNo ratings yet

- HAJ & Omrah: Partition LayoutDocument1 pageHAJ & Omrah: Partition LayoutDeepak singhNo ratings yet

- Zibagwe OffDocument1 pageZibagwe OffdereramichaelNo ratings yet

- B168082001P00 PDFDocument1 pageB168082001P00 PDFWaleed JaradatNo ratings yet

- Mezz. Basement Floor CCTV Layout: KSK Capital LLCDocument1 pageMezz. Basement Floor CCTV Layout: KSK Capital LLCMD SajjadNo ratings yet

- Hvac Layout - 1F - R1 - CDocument1 pageHvac Layout - 1F - R1 - Cs8n.pzicbNo ratings yet

- Attic Access - TguDocument5 pagesAttic Access - TgujhamiralexNo ratings yet

- J018-GROUND FLOOR PLAN WITH EXTRA BLOCK WALL-ModelDocument1 pageJ018-GROUND FLOOR PLAN WITH EXTRA BLOCK WALL-ModelRAHA EngineerNo ratings yet

- ROAD - A PROFILE (STA: 0+000 TO STA: 0+275) H V : NotesDocument1 pageROAD - A PROFILE (STA: 0+000 TO STA: 0+275) H V : NotesanooppattazhyNo ratings yet

- Ccu HQ Reno: 1000 St. Albans Drive Raleigh, North Carolina 27609Document1 pageCcu HQ Reno: 1000 St. Albans Drive Raleigh, North Carolina 27609Scott NorrisNo ratings yet

- V A L L E Y: Saudi Arabian Oil CompanyDocument1 pageV A L L E Y: Saudi Arabian Oil CompanyThomas JohnNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- GDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Document1 pageGDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Mohd Khairul FitriNo ratings yet

- 2022 10 19 Odessa Grantville-S1Document1 page2022 10 19 Odessa Grantville-S1Mary Gen ReynesNo ratings yet

- Paul Cafe@Marassi Galleria Bahrain SD Mep Emergency Lighting System Layout R 00Document1 pagePaul Cafe@Marassi Galleria Bahrain SD Mep Emergency Lighting System Layout R 00arulselvan22No ratings yet

- Binghati Powr Coordination DrawingDocument1 pageBinghati Powr Coordination Drawingzafrikhan875No ratings yet

- A8.4 Typical Window Details - LDocument1 pageA8.4 Typical Window Details - LVanshika DograNo ratings yet

- Bathroom B-17-Elev.2: Master Bathroom Plans & ElevationsDocument1 pageBathroom B-17-Elev.2: Master Bathroom Plans & ElevationsWinmentolMalisaNo ratings yet

- Approved Plan 1Document1 pageApproved Plan 1sibusiso.chisi9No ratings yet

- Basement Plan CCTV Layout: KSK Capital LLCDocument1 pageBasement Plan CCTV Layout: KSK Capital LLCMD SajjadNo ratings yet

- Access Control SystemDocument1 pageAccess Control SystemMD SajjadNo ratings yet

- Setting Out Plan1686126785318Document1 pageSetting Out Plan1686126785318Jamshed AlamNo ratings yet

- Hvac Layout - 3F - R1 - CDocument1 pageHvac Layout - 3F - R1 - Cs8n.pzicbNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- Facultad de Ingeniería Y ArquitecturaDocument1 pageFacultad de Ingeniería Y ArquitecturaGimena Perez GonzalesNo ratings yet

- Ven-002 - 1st Floor Plan Ventilation Layout (1) - Layout1Document1 pageVen-002 - 1st Floor Plan Ventilation Layout (1) - Layout1ᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- A-400 - Ground & First Floor PlanDocument1 pageA-400 - Ground & First Floor PlanMarven SobrevillaNo ratings yet

- A-1803d - Landscape Sections & Details - 05Document1 pageA-1803d - Landscape Sections & Details - 05karthikeyan dhanasekaranNo ratings yet

- Atk GLW XX DR Ew 000003Document1 pageAtk GLW XX DR Ew 000003BEN BENNo ratings yet

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- Saudi Arabian Oil Company: 965 A SM-255564 002 BDocument1 pageSaudi Arabian Oil Company: 965 A SM-255564 002 Bahmad.suliman.saeedNo ratings yet

- Detail of Common Toilet: Section Elevation C - C' Section Elevation D - D'Document1 pageDetail of Common Toilet: Section Elevation C - C' Section Elevation D - D'RichaNo ratings yet

- For Council Submission Only: General Construction NotesDocument1 pageFor Council Submission Only: General Construction NotesLiana HoetsNo ratings yet

- t76-R-pp-476561-001 - Rev B Utility Ome Building PlanDocument1 paget76-R-pp-476561-001 - Rev B Utility Ome Building PlanTayyab AchakzaiNo ratings yet

- DED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelDocument1 pageDED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelAnwar SalukiNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- Access Control SystemDocument1 pageAccess Control SystemMD SajjadNo ratings yet

- Saudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedWaqarNo ratings yet

- MEP-DD-L11-A2-EL-1101 A2-11th Floor Low Level Power Layout R0Document1 pageMEP-DD-L11-A2-EL-1101 A2-11th Floor Low Level Power Layout R0my.work.ksabNo ratings yet

- 9d3 - Uukumwe School Hall-Roof LayoutDocument1 page9d3 - Uukumwe School Hall-Roof LayoutshaimenneNo ratings yet

- Academic BLK 3 - F2 & f3 PlanDocument1 pageAcademic BLK 3 - F2 & f3 PlanBindu BollempalliNo ratings yet

- Mall & Multiplex - Ground Floor Brickmarking@ Hanumakonda-15424Document1 pageMall & Multiplex - Ground Floor Brickmarking@ Hanumakonda-15424Karan KumarNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- 5076-Al Wasl-Plot 38 1000 Series PlanDocument6 pages5076-Al Wasl-Plot 38 1000 Series Plandubai eyeNo ratings yet

- SANCTION-sanction DWGDocument1 pageSANCTION-sanction DWGpinkbutterflyNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- LEFT ELEVATION (Scale1:100) FRONT ELEVATION (Scale1:100) RIGHT ELEVATION (Scale1:100)Document1 pageLEFT ELEVATION (Scale1:100) FRONT ELEVATION (Scale1:100) RIGHT ELEVATION (Scale1:100)Ogulo JamesNo ratings yet

- Heat Pumps On Roof Level (1: 100) : Fan ScheduleDocument1 pageHeat Pumps On Roof Level (1: 100) : Fan ScheduleSelloNo ratings yet

- R00-O02m06-Acc-Xx-Xx-Sdw-Ar-50031 Kitchen Equipment Floor Plan & Data Sheet Layout For Main KitchenDocument4 pagesR00-O02m06-Acc-Xx-Xx-Sdw-Ar-50031 Kitchen Equipment Floor Plan & Data Sheet Layout For Main KitchenSUNDAR TNo ratings yet

- 1st Floor Working Drawing 27.11.2023Document1 page1st Floor Working Drawing 27.11.2023Shubham SoniNo ratings yet

- BoQ 30-10-2023-Rev00 MMDocument32 pagesBoQ 30-10-2023-Rev00 MMD HOLNo ratings yet

- 02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsDocument1 page02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsD HOLNo ratings yet

- 01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsDocument1 page01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsD HOLNo ratings yet

- 04 - House Hugo - Rev 2 - 12.03.2024-Door SCHDocument1 page04 - House Hugo - Rev 2 - 12.03.2024-Door SCHD HOLNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- 402 Window Schedule & DetailsDocument1 page402 Window Schedule & DetailsD HOLNo ratings yet

- The Profitable Designer Scorecard ReportDocument21 pagesThe Profitable Designer Scorecard ReportD HOLNo ratings yet

- Vetassess Cover LetterDocument3 pagesVetassess Cover LetterD HOLNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanD HOLNo ratings yet

- Unabridged Birth Certificate Service ProvidersDocument2 pagesUnabridged Birth Certificate Service ProvidersD HOLNo ratings yet

- Social Media Post PromptsDocument19 pagesSocial Media Post PromptsD HOLNo ratings yet

- ASOURCE Company Profile 2024Document1 pageASOURCE Company Profile 2024D HOLNo ratings yet

- Absorption Water Content and Liquid LimitDocument7 pagesAbsorption Water Content and Liquid LimitChandan BleeNo ratings yet

- Artificial Lift For Guest LectureDocument117 pagesArtificial Lift For Guest LectureZenga Harsya Prakarsa100% (1)

- FMFP2010 - 396 - : Syamsundar - C2005@yahoo - Co.inDocument10 pagesFMFP2010 - 396 - : Syamsundar - C2005@yahoo - Co.inSumanth KoyilakondaNo ratings yet

- Highway Engineering I C: Lecture FourDocument30 pagesHighway Engineering I C: Lecture FourHenok YalewNo ratings yet

- Boundary Layer CorrectionDocument5 pagesBoundary Layer CorrectionmgskumarNo ratings yet

- EGR 280 - Mechanics Problem Set 4Document2 pagesEGR 280 - Mechanics Problem Set 4Christian M. MortelNo ratings yet

- Soil Drainage/Sewerage: Measurement of Construction Works V BQS601Document37 pagesSoil Drainage/Sewerage: Measurement of Construction Works V BQS601nur shafiqahNo ratings yet

- Theory of StructuresDocument15 pagesTheory of StructuresIsabelle LunaNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Vertical Bracket With U BoltDocument2 pagesVertical Bracket With U BoltНемања Караклајић100% (1)

- Linatex Premium Rubber Bandage Spec SheetDocument1 pageLinatex Premium Rubber Bandage Spec SheetPranav KolNo ratings yet

- Labour Requirement For Various Building WorksDocument4 pagesLabour Requirement For Various Building WorksArun Chandra Babu100% (1)

- A Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperDocument4 pagesA Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperAbdul RazzakNo ratings yet

- Heavy EquipmentDocument183 pagesHeavy EquipmentshafiullahNo ratings yet

- Impediments and Solutions To Sustainable, Watershed-Scale Urban Stormwater ManagementDocument16 pagesImpediments and Solutions To Sustainable, Watershed-Scale Urban Stormwater ManagementImran MohammedNo ratings yet

- Site Development Plan Vicinity Map: City of Bislig Province of Surigao Del SurDocument1 pageSite Development Plan Vicinity Map: City of Bislig Province of Surigao Del SurMJian VergaraNo ratings yet

- New Concrete StandardsDocument68 pagesNew Concrete StandardsMohlis Arifin Rukib Wardah0% (1)

- Lec 4-Week 2 - (Design of Storm Sewer)Document18 pagesLec 4-Week 2 - (Design of Storm Sewer)jahanzaibchNo ratings yet

- Geoguide 1 PDFDocument155 pagesGeoguide 1 PDFExile PeachNo ratings yet

- Structural Analysis Chapter 01Document39 pagesStructural Analysis Chapter 01azerai2000No ratings yet

- FULLTEXT01Document165 pagesFULLTEXT01Thiri SanNo ratings yet

- 3-Liquid Retaining StructuresDocument3 pages3-Liquid Retaining StructuresTabish IslamNo ratings yet

- Concrete Mix Design For Bridge Structures - Policy PDFDocument1 pageConcrete Mix Design For Bridge Structures - Policy PDFRVNLPKG6B VBL-GTLMNo ratings yet

- SJB Institute of Technology: Internship Seminar - 2021Document18 pagesSJB Institute of Technology: Internship Seminar - 2021Harshavardhan NarayanswamyNo ratings yet

- Design of FootingDocument8 pagesDesign of FootingRozhelle PedernalNo ratings yet

- Acc PPC - NFR - 23 - 2021Document1 pageAcc PPC - NFR - 23 - 2021Amit VermaNo ratings yet

- Handbook On Railway Construction-401-500Document100 pagesHandbook On Railway Construction-401-500yamegNo ratings yet

- Why Buildings With Shear Wall Are Preferred in Seismic RegionsDocument4 pagesWhy Buildings With Shear Wall Are Preferred in Seismic RegionsAbstruse ConsultnatsNo ratings yet