Professional Documents

Culture Documents

402 Window Schedule & Details

402 Window Schedule & Details

Uploaded by

D HOLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

402 Window Schedule & Details

402 Window Schedule & Details

Uploaded by

D HOLCopyright:

Available Formats

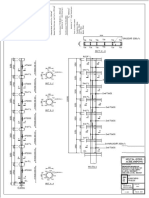

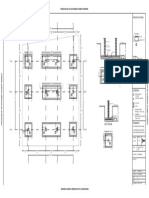

WINDOW SCHEDULE

WINDOW NUMBER Ex W1 Ex W2 Ex W3 W3 W4 W5 W6 W7

4 550

1 790 830 830 400 2 190 3 407 900

2 275 2 275

TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW

450

587

830

830

850

1 460

EXTERIOR VIEW

1 760

1 800

587

2 100

2 100

2 100

2 100

2 100

2 100

2 100

2 100

415 415 415 415

895 895

1 650

1 270

1 270

1 250

587

640

340

UFFL UFFL UFFL UFFL UFFL UFFL UFFL UFFL

300

QUANTITY 1 1 1 2 3 1 1 1

RENOVATION STATUS Existing Existing Existing New New New New New

TOP HUNG ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH SLIDING ALUMINIUM WINDOW. STILES TO BE SLIDING ALUMINIUM WINDOW. STILES TO BE FIXED PANE ALUMINIUM WINDOW. STILES TO BE FIXED PANE ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, FIXED PANE ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, BOTTOM & TOP HUNG ALUMINIUM WINDOW. STILES TO BE

DESCRIPTION SLIDING ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

TOP, BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES. BOTTOM & SIDES. SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM

FRAME TYPE CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED

APPROVED APPROVED APPROVED

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED

APPROVED

FRAME FINISH POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY

6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART

6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. PG-SMARTGLASS X1

GLAZING SIMILAR APRROVED PG-SMARTGLASS X1 PLUS OR SIMILAR APRROVED

N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR

PG-SMARTGLASS X1 PLUS OR SIMILAR APRROVED PLUS OR SIMILAR APRROVED

N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR

APRROVED APRROVED APRROVED APRROVED

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED

HANDLE AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL. AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL.

FOR APPROVAL. FOR APPROVAL. FOR APPROVAL.

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL. AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL.

FOR APPROVAL.

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS.

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED WINDOW REVEAL AND PLASTERED WINDOW REVEAL AND INNER SILL.

WINDOW REVEAL AND INNER SILL. PLASTERED OUTER WINDOW SILL. WINDOW REVEAL AND INNER SILL. PLASTERED OUTER WINDOW SILL. SEAL

LINTEL TYPE PLASTERED OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO

SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO

PLASTERED OUTER WINDOW SILL. SEAL PROPERLY PLASTERED OUTER WINDOW SILL. SEAL PROPERLY PLASTERED OUTER WINDOW SILL. SEAL PROPERLY

PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO

INNER SILL. PLASTERED OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE AROUND PLASTERED OUTER WINDOW SILL. SEAL PROPERLY

MANUFACTURER'S SPECIFICATIONS WITH SILICONE AROUND FRAME, ACCORDING TO WITH SILICONE AROUND FRAME, ACCORDING TO WITH SILICONE AROUND FRAME, ACCORDING TO FRAME, ACCORDING TO MANUFACTURER'S SPECIFICATIONS WITH SILICONE AROUND FRAME, ACCORDING TO

MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

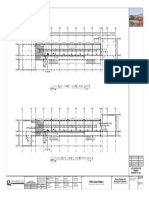

WINDOW SCHEDULE

WINDOW NUMBER W8 W9 W10 W11 W12 W13 W14 W15

4 170 4 112

800 1 258 2 000 1 975 3 000

2 085 2 085 700 2 712 700

400

TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW

450

600

300

1 351

1 352

1 366

1 455

EXTERIOR VIEW

1 752

1 760

2 100

2 100

2 100

2 100

2 302

1 800

2 100

1 650

1 700

400

645

340

UFFL UFFL UFFL UFFL UFFL UFFL

550

UFFL UFFL

QUANTITY 1 1 1 1 4 4 1 2

RENOVATION STATUS New New New New New New New New

TOP HUNG ALUMINIUM WINDOW. STILES TO BE TOP HUNG ALUMINIUM WINDOW. STILES TO BE FIXED PANE ALUMINIUM WINDOW. STILES TO BE CONTINUOUS FIXED PANE ALUMINIUM WINDOW. STILES TO BE CONTINUOUS FIXED PANE ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, TOP HUNG ALUMINIUM WINDOW. STILES TO BE

DESCRIPTION CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

SLIDING ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

SIDE HUNG ALUMINIUM WINDOW. STILES TO BE CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

WIDTH TOP, BOTTOM & SIDES. WIDTH TOP, BOTTOM & SIDES. BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES.

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM

FRAME TYPE APPROVED

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED

APPROVED

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM APPROVED

APPROVED

FRAME FINISH POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY

6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART

6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. PG-SMARTGLASS X1 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART N OF SANS 10400. PG-

GLAZING N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR

SIMILAR APRROVED

N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR

PLUS OR SIMILAR APRROVED SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR APRROVED SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR APRROVED SMARTGLASS X1 PLUS OR SIMILAR APRROVED

N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR

APRROVED APRROVED APRROVED

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED

HANDLE FOR APPROVAL.

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL.

FOR APPROVAL.

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL.

APPROVAL. APPROVAL.

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED FOR APPROVAL.

FOR APPROVAL.

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS.

PLASTERED WINDOW REVEAL AND INNER SILL. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED WINDOW REVEAL AND INNER PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PLASTERED WINDOW REVEAL PLASTERED WINDOW REVEAL AND INNER SILL.

LINTEL TYPE PLASTERED OUTER WINDOW SILL. SEAL PROPERLY PLASTERED OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO PLASTERED OUTER WINDOW SILL. SEAL PROPERLY SILL. PLASTERED OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE AROUND FRAME, OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE AND INNER SILL. PLASTERED OUTER WINDOW SILL. SEAL PROPERLY WITH SILICONE PLASTERED OUTER WINDOW SILL. SEAL PROPERLY

WITH SILICONE AROUND FRAME, ACCORDING TO MANUFACTURER'S SPECIFICATIONS WITH SILICONE AROUND FRAME, ACCORDING TO ACCORDING TO MANUFACTURER'S SPECIFICATIONS AROUND FRAME, ACCORDING TO MANUFACTURER'S AROUND FRAME, ACCORDING TO MANUFACTURER'S AROUND FRAME, ACCORDING TO MANUFACTURER'S SPECIFICATIONS WITH SILICONE AROUND FRAME, ACCORDING TO

MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS SPECIFICATIONS SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

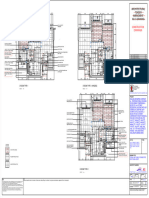

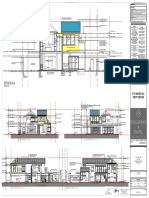

WINDOW SCHEDULE

GLAZING GENERAL NOTES: GENERAL NOTES:

WINDOW NUMBER W17 W18 W19

1. The contractor is responsible for checking all levels & dimensions on site when setting out & prior to commencing ALL DIMENTIONS TO BE CONFIRMED ON SITE

38 x 38mm SAP CCA treated H3 slats fixex to beams construction. Read only figured dimensions & do not scale. Any discrepancies are to be reported in writing to dws : sa prior to BEFORE ANY WORK IS PUT IN HAND.

with self taping wood screws. Sand until smooth, ensure 76 76 76 continuation of work. ALL GLAZING TO BE IN ACCORDANCE WITH

76 76 76 76 AAAMSA.

870 955 600 all timber surfaces are clean, dry & smooth. Apply 3

2. The contractor is responsible for the glazing being executed in strict conformance with glass manufacturerʼs SAGGA

coats Woodoc Water-borne Marine Exterior Matt Sealer. recommendations & all in accordance with the National Building Regulations Part N, SANS 10137, SANS 1263-1 & AAAMSA SANS10160

TOP OF WINDOW TOP OF WINDOW TOP OF WINDOW Colour to be achieved with Woodoc Stain concentrate 38 Selection Guide for Safety Glazing Materials. A certificate of compliance is to be issued to dws : sa on completion of the work. SANS10137

as per manufacturer specifations. Colour: Oak, test 38 38 SANS 10400 PART N

38

sample to be provided for approval. 3. The contractor is responsible for providing a warranty for laminated glass & | or the hermetically sealed glazing units against SANS 1263

587

600

610

228 x 76mm SAP CCA treated H3 Beam bolted to steel delamination & colour degradation for a period of not less than 5 years, to be issued to dws :sa. PROVISION SHOULD BE MADE FOR

coloumn with appropriated bolt and washers as per eng STRUCTURAL SUPPORT WHERE APPLICABLE.

1 200

4. All Safety Glazing materials [individual panes] are to be permanently marked. Such marking shall be visible after glazing. QUANTITIES TO BE CONFIRMED ON PLANS.

152

EXTERIOR VIEW specifications. Sand until smooth, ensure all timber

1 760

587

600

surfaces are clean, dry & smooth. Apply 3 coats 5. In the case of structural glazing written proof is to be provided that all stages of fabrication & installation have been executed

2 100

2 100

2 100

Woodoc Water-borne Marine Exterior Matt Sealer. with disciplined quality assurance in accordance with the relevant parts of SANS ISO 9000. Written confirmation of compatibility

Colour to be achieved with Woodoc Stain concentrate of structural sealant with extrusion surface, glazing tape & glass is to be supplied by the structural sealant manufacturer

1 490

as per manufacturer specifations. Colour: Oak, test together with the regular relevant test reports regarding the adhesion of the sealant to the aluminium frame in accordance with

587

sample to be provided for approval. ASTM/C 794-80 [Standard Test for Adhesion-in-Peel of Elastomeric Joint Sealants]

900

152 x 38mm SAP CCA treated H3 Beam bolted to steel

6. Glass sizes & thickness is to be designed for the relevant wind load, to be confirmed by a suitably qualified competent

340

UFFL UFFL UFFL

coloumn with appropriated bolt and washers as per eng person. Any deviations from the schedules are to be reported in writing to dws : sa prior to manufacture.

specifications. Sand until smooth, ensure all timber 10 10 10 10 10 10 10

surfaces are clean, dry & smooth. Apply 3 coats 76 76 76 76 76 76 76 76

10 10

Woodoc Water-borne Marine Exterior Matt Sealer. 50mm x 50mm glavanized handrail, welded to post

QUANTITY 1 1 1 Colour to be achieved with Woodoc Stain concentrate as per manufacturer specifications.

900

50

RENOVATION STATUS New New New as per manufacturer specifations. Colour: Oak, test

sample to be provided for approval. 25 850 25

25

25mm x 25mm glavanized handrail, 10mm x 10mm glavanized square post, welded to

TOP HUNG ALUMINIUM WINDOW. STILES TO BE TOP HUNG ALUMINIUM WINDOW. STILES TO BE TOP HUNG ALUMINIUM WINDOW. STILES TO BE

DESCRIPTION Steel column strictly according to eng specifications. welded to post as per manufacturer base plate as per manufacturer specifications.

100

CONTINUOUS WIDTH TOP, BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES. CONTINUOUS WIDTH TOP, BOTTOM & SIDES. specifications.

250

Colour to be confirmed.

25

700

615

CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM CREALCO SWIFT 38 ALUMINIUM FRAME OR SIM New steel I section to be specified by engineer to run 25mm x 25mm glavanized square post, welded to

FRAME TYPE APPROVED APPROVED APPROVED 25mm x 25mm glavanized square base plate as per manufacturer specifications.

1 000

along bottom edge of concrete roof slab and be

100

supported by square hollow section on corner. Timber post, welded to base plate as per

FRAME FINISH POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY POWDER COATING : COLOUR MATT ANTHRACITE GREY manufacturer specifications. 30 x 10mm Horizontal galvanized flatbar welded to

1 000

pergola to fix to inside of I- Section. I section to carry

10

post as per manufacturer specifications

700

weight of slab above. To be hot dip galvanised and 500mm high wall as per engineer

25

6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART 6.38 mm CLEAR SAFETY GLASS. GLAZING AS PER PART

750

750

300mm high wall as per engineer specifications

specifications and design. Plaster

1 000

GLAZING N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR N OF SANS 10400. PG-SMARTGLASS X1 PLUS OR SIMILAR painted black. and design. Plaster and paint to match dwelling

Min 1m high painted mild steel balustrade. Refer to and paint to match dwelling

300

300

APRROVED APRROVED APRROVED FIRST STOREY UFFL

balustrade detail.

AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED AS PER ALUMINIUM SUPPLIER. SAMPLE TP BE SUBMITTED

HANDLE FOR APPROVAL. FOR APPROVAL. FOR APPROVAL. FIRST STOREY UFFL

300

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS. FIRST STOREY UFFL Concrete slab as per engineer Concrete slab as per engineer specifications and

PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. PLASTERED WINDOW REVEAL AND INNER SILL. floor tiles specifications and design design

LINTEL TYPE PLASTERED OUTER WINDOW SILL. SEAL PROPERLY PLASTERED OUTER WINDOW SILL. SEAL PROPERLY PLASTERED OUTER WINDOW SILL. SEAL PROPERLY

WITH SILICONE AROUND FRAME, ACCORDING TO WITH SILICONE AROUND FRAME, ACCORDING TO WITH SILICONE AROUND FRAME, ACCORDING TO

MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS MANUFACTURER'S SPECIFICATIONS

Window Schedule Detail 1: Pergola Detail 2: Interior Balustrade Detail 3: Balcony Balustrade

Scale 1:50 Scale 1:25 Scale 1:20 Scale 1:20

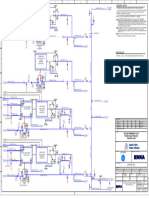

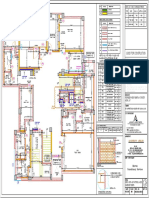

GENERAL NOTES: BUILDING WORK: AREA SCHEDULE REVISIONS

PROJEK PROJECT

All work to comply with SANS 10400 and Building regulations. All work to be in accordance with local municipal DESCRIPTION AREA TOTAL Additions and Alterations to the

COPYRIGHT RESERVED BY HOLLOWAY & DAVEL ON ALL DESIGNS AND

authorities' regulations. Figured dimentions to be taken in preferance to scaled dimensions. All levels and ERF SIZE 828 m² Rev no. Description Date

DOCUMENTATION.

dimensions to be checked on site before building work commences. Contractors shall be deemed to have Existing Dwelling on

NO DRAWINGS TO BE SCALED. acquinted themselves with site conditions prior to commencement of work. ERF 922

ALL MEASUREMENTS, HEIGHTS AND LEVELS TO BE VERIFIED ON SITE LEVELS: Levels and dimensions: The building are to be laid out and erected in the position and to the levels as EX. GROUND STOREY 314.9m² CLIENT / CLIENT REPRESENTATIVE :

PRIOR TO COMMENCEMENT OF CONSTRUCTION AND ADAPTED TO indicated on the plan & site layout plan. The contractor, sub-contractors and suppliers must verify all dimensions Mr. H Koch

Fernkloof Drive, , Hermanus

GROUND STOREY W/C ADDITION 4.3m²

SUGGESTED BUILDING WORK. and levels on-suite before commencing any work. Land surveyor to confirm all boundary pegs and to check all IT IS AGREED THAT THE CLIENT, BY ITS SIGNATURE TO THIS DRAWING, for

ANY DISCREPANCY OR CONTRADICTION TO BE DISCUSSED WITH THE NEW GROUND FLOOR R/C ROOF 5.5m²

levels before construction commences. Top soil shall be removed from the area to be build upon, all grading ACCEPTS AND APPROVES INFORMATION CONTAINED HEREIN. Mr. H Koch

ARCHITECT IMMEDIATELY.

ALL DIMENSIONS INDICATED ON PLAN TO BE SET OUT ON A LEVEL leveling to be done by contractor. NEW GROUND STOREY 324.7m² TEK. NO. DRWG. NR.

MATERIALS: Material used in the erection of a building shall be suitable for the purpose for which it is to be used. SKAAL As Indicated SCALE

HORIZONTAL PLANE .

ALL BRICKWORK TO BE SET OUT USING A PROFILE MARKED 85mm C/C. TIMBER: All timber used in the erection of a building shall be treated against termite and woon borer attack and GETEKEN Daleen Holloway DRAWN 2024_06_402_REV 9

5922 THE CONTRACTOR IS RESPONSIBLE FOR THE CORRECT SETTING OUT fungal decay in accordance with the requirements of SANS 10005 and shall bear the product certification mark of EXISTING FIRST STOREY 53.1m²

OF THE BUILDING WORK ON SITE WITH PARTICULAR REFERENCE TO Christiaan Davel - Professional Architect Daleen Holloway - Professional Senior NAGESIEN Christiaan Davel CHECKED TITEL TITLE

a body certified by the south african national accrediting system.

SITE BOUNDARIES, SERVITUTES AND BUILDING LINES.

FINISH FLOOR LEVEL: Finished floor level of dwelling to be min. of 255mm above back of footway level at sewer FIRST STORY ADDITIONS 13.1m² SACAP Registration - PrArch 38855809 Architectural Technologist

Window Schedule & Details

THE CONTRACTOR IS TO BUILD IN APPROVED D.P.C's TO ALL EXTERNAL SACAP Registration - PSAT 20714 DATUM 2024/04/19 DATE

WALLS, UNDER FLOORS AND UNDER WINDOW CILLS. connection. It is recommended that garage floor level min of 170mm above back of footway level at driver TOTAL NEW FIRST STOREY 66.2m²

entrance if any. Unit 4, Myrtle House www.hollowayanddavel.com

QUALITY OF ALL MATERIAL AND CRAFTMANSHIP TO COMPLY WITH THE PROJECT STATUS:

RELEVANT S.A.B.S STANDARDS. OTHER: Floors in any laundry, kitchen, shower room, bathroom or room containing a toilet pan or urinal must TOTAL COMBINED FLOOR AREA 390.9 m² NOTE : THIS DRAWING IS NOT VALID FOR CONSTRUCTION UNLESS FOR COUNCIL 2 Church Street, Hermanus 7200

THE CONTRACTOR SHOULD HAVE A FULL SET OF DRAWINGS AVAILABLE comply with sans 10400 J. Any combustible material to be 200mm away from chimney flue. The requirements of STAMPED ACCORDINGLY

ON SITE AT ALL TIMES. the national by-laws and any other applicable authority must be complied with. The builders must comply with the TOTAL NEW BUILDING FOOTPRINT 324.7 m² Daleen Holloway - PrSnrArch T Christiaan Davel - PrArch

THE CONTRACTOR IS RESPONSIBLE FOR HIS OWN QUALITY CONTROL. SACAP Registration - PrArch 38855809

NHBRC by-laws. All reinforced concrete slabs and stairs are to be cast strictly to structural engineer's SACAP Registration - PSAT 20714

IF IN DOUBT ASK DONT ASSUME

ALL FLOOR LEVELS SHOWN ON THIS DRAWING REFER TO UNFINISHED

specifications and details. TOTAL COVERAGE 324.7m² 39.2 % daleen@hollowayanddavel.com christiaan@hollowayanddavel.com

FLOOR LEVELS.

LOCALITY PLAN PAINT: All painted colours to be approved by client before applying to wall. 079 502 6645 082 923 3515

GSPublisherVersion 73.32.79.5

Not to Scale

You might also like

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- Rabbit AnancraftDocument16 pagesRabbit Anancraftmatheus100% (4)

- Craft Passion - Rhino - Crochet PatternDocument19 pagesCraft Passion - Rhino - Crochet PatternOanh Nguyễn Thị Phương100% (4)

- KNOCKOUT KNITS: New Tricks For Scarves, Hats, Jewelry, and Other AccessoriesDocument5 pagesKNOCKOUT KNITS: New Tricks For Scarves, Hats, Jewelry, and Other AccessoriesCrafterNewsNo ratings yet

- First Floor Framing Plan & Beam - Slab DetailDocument1 pageFirst Floor Framing Plan & Beam - Slab DetailMOHD IMRANNo ratings yet

- A 11Document1 pageA 11Yaw KrahNo ratings yet

- Bcag A-8Document1 pageBcag A-8Jerson TierraNo ratings yet

- Roof Deck Power Layout: Bureau of DesignDocument1 pageRoof Deck Power Layout: Bureau of DesignJuan IstilNo ratings yet

- Ec1-10 GRD and 2nd Drivers Quarter Fdas LayoutDocument1 pageEc1-10 GRD and 2nd Drivers Quarter Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Fourth Floor LVL Framing Plan & Beam - Slab DetailDocument1 pageFourth Floor LVL Framing Plan & Beam - Slab DetailMOHD IMRANNo ratings yet

- B014 0 Soporte de Losa Cisterna Nivel 8.89Document1 pageB014 0 Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- B014 B Soporte de Losa Cisterna Nivel 8.89Document1 pageB014 B Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- Thermo IEC Multi RF Series Service ManualDocument83 pagesThermo IEC Multi RF Series Service ManualystloveNo ratings yet

- Section and Elevation 23-02-24 RV 03Document1 pageSection and Elevation 23-02-24 RV 03krhimanshu0505No ratings yet

- WD Santion DrawingDocument1 pageWD Santion Drawing1SI18AT026 PRATHEEK GANGADHARA MOOTAGINo ratings yet

- 070-0576-00 Rev D DrawingsDocument2 pages070-0576-00 Rev D DrawingsRama Tenis CopecNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- NP p1b Teth DWG Civ 0112.01.ifr RNCDocument6 pagesNP p1b Teth DWG Civ 0112.01.ifr RNCSipaseut OudomsoukNo ratings yet

- Process SW Panel 1 กระบี่1Document1 pageProcess SW Panel 1 กระบี่1Pithoon UngnaparatNo ratings yet

- BW. SER. HIJ. AR. 0.01 (BUILDING PLAN) - ModelDocument1 pageBW. SER. HIJ. AR. 0.01 (BUILDING PLAN) - ModelSHUBHAM SINGHNo ratings yet

- J-02C 28F LOCKERS (With RF Id)Document2 pagesJ-02C 28F LOCKERS (With RF Id)john Patrick valinoNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Vie Pc01 STN DWG MP Ppa 01108 0Document1 pageVie Pc01 STN DWG MP Ppa 01108 0Ashish BhartiNo ratings yet

- Drawing PlanDocument1 pageDrawing PlanJoshua SitholeNo ratings yet

- HB-D1817-AR-131 - Typical Unit Plan of 3room Type With Tiling LayoutDocument1 pageHB-D1817-AR-131 - Typical Unit Plan of 3room Type With Tiling Layoutme kwc36No ratings yet

- BNBN - CD - WineryDocument12 pagesBNBN - CD - WineryAlex YoungNo ratings yet

- Franklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDocument1 pageFranklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDanica Mae AmicayNo ratings yet

- Ld-859b-Mep Drawings - 15.02.2023Document9 pagesLd-859b-Mep Drawings - 15.02.2023Sharique BaigNo ratings yet

- (Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPDocument1 page(Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPKhelen ThoudamNo ratings yet

- Nenmong Tranphucduy FinallyDocument1 pageNenmong Tranphucduy FinallyPhúc DuyNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- DFE-B01-ELE-DWG-LTG-005 - LIGHTING LAYOUT - MCC PLANT TERRACE FLOOR (DB) - Copy-TERRACE PLANDocument1 pageDFE-B01-ELE-DWG-LTG-005 - LIGHTING LAYOUT - MCC PLANT TERRACE FLOOR (DB) - Copy-TERRACE PLANElectrical PCBL TeamNo ratings yet

- BAKSDocument1 pageBAKSJay-ra DaligdigNo ratings yet

- CCE Microonda M-190 120V Diagrama Esquematico PDFDocument1 pageCCE Microonda M-190 120V Diagrama Esquematico PDFJose UzcateguiNo ratings yet

- Detail A Option 2 Option 1: 5000 12cm 12cmDocument1 pageDetail A Option 2 Option 1: 5000 12cm 12cmCasmir TayagNo ratings yet

- Power Layout Circuit - R1Document1 pagePower Layout Circuit - R1Electrical PCBL TeamNo ratings yet

- Ground Floor Plan FLOOR AREA: 247.68 SQ.M: F.F: N.S-Tiles F.F: N.S-Tiles F.F: N.S-Tiles F.F: MarbleDocument1 pageGround Floor Plan FLOOR AREA: 247.68 SQ.M: F.F: N.S-Tiles F.F: N.S-Tiles F.F: N.S-Tiles F.F: Marblesantosh acharyaNo ratings yet

- Hyunday Het21n04 Chassis 5800-A3MD31-01 DiagramaDocument1 pageHyunday Het21n04 Chassis 5800-A3MD31-01 DiagramaJean Carlo IdrogoNo ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- CR 1Document1 pageCR 1Armand Mikhail TempladoNo ratings yet

- DD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDocument1 pageDD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDavid Adi KaruniaNo ratings yet

- 2Nd Floor Framing Plan Foundation Plan: Two-Storey ResidentialDocument1 page2Nd Floor Framing Plan Foundation Plan: Two-Storey ResidentialByen VillanuevaNo ratings yet

- MPB Arc-8Document1 pageMPB Arc-8Jay Mark GastonesNo ratings yet

- 4 - Painel SaúdeOcup. Abr.24Document1 page4 - Painel SaúdeOcup. Abr.24soquerovergamesNo ratings yet

- D-448 To D-450 CopingRebar P1-P15 GrpADocument3 pagesD-448 To D-450 CopingRebar P1-P15 GrpAChristian MendozaNo ratings yet

- HW Nic Allam DD Ge 005Document1 pageHW Nic Allam DD Ge 005ehab.m.saad88No ratings yet

- Retaining Wall Foundation Below Strom Water - 20240101-4 OF 4Document1 pageRetaining Wall Foundation Below Strom Water - 20240101-4 OF 4Šübhâjîť NãÿâkNo ratings yet

- SX6 SchematicsDocument14 pagesSX6 SchematicsSugeng AriyadiNo ratings yet

- DD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewDocument1 pageDD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewDavid Adi KaruniaNo ratings yet

- B015 0 Soporte de Losa Cisterna Nivel 8.89Document1 pageB015 0 Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- B015 B Soporte de Losa Cisterna Nivel 8.89Document1 pageB015 B Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- CEGP OC053.2023 DW M 001.rev2Document1 pageCEGP OC053.2023 DW M 001.rev2Milagros MuedasNo ratings yet

- SECTION:-'A-A': Key Plan For CraneDocument1 pageSECTION:-'A-A': Key Plan For CraneAde Y SaputraNo ratings yet

- Specifications:: Produced by An Autodesk Student VersionDocument1 pageSpecifications:: Produced by An Autodesk Student VersionBharani MadamanchiNo ratings yet

- Ick Work - Partition Layout (Basement Floor)Document1 pageIck Work - Partition Layout (Basement Floor)Shubham PokhriyalNo ratings yet

- WTC - B2 MLCPDocument1 pageWTC - B2 MLCPVanya AroraNo ratings yet

- Erection Drawing Sample 12Document1 pageErection Drawing Sample 12Jr Rameez RajaNo ratings yet

- Pudpud Hospital Floor PlanDocument1 pagePudpud Hospital Floor PlanvertudazoglynnNo ratings yet

- A06Document1 pageA06Alteina CoradoNo ratings yet

- DS Control-Arch D DSC11Document1 pageDS Control-Arch D DSC11sreeagile.esNo ratings yet

- Roof Level Ga Plan 1: Issued For ConstructionDocument1 pageRoof Level Ga Plan 1: Issued For ConstructionOmer HayatNo ratings yet

- TW Liverpool Layout RLW V1.1Document1 pageTW Liverpool Layout RLW V1.1scribd.2noNo ratings yet

- BoQ 30-10-2023-Rev00 MMDocument32 pagesBoQ 30-10-2023-Rev00 MMD HOLNo ratings yet

- 01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsDocument1 page01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsD HOLNo ratings yet

- 02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsDocument1 page02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsD HOLNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- 04 - House Hugo - Rev 2 - 12.03.2024-Door SCHDocument1 page04 - House Hugo - Rev 2 - 12.03.2024-Door SCHD HOLNo ratings yet

- Vetassess Cover LetterDocument3 pagesVetassess Cover LetterD HOLNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanD HOLNo ratings yet

- Social Media Post PromptsDocument19 pagesSocial Media Post PromptsD HOLNo ratings yet

- Unabridged Birth Certificate Service ProvidersDocument2 pagesUnabridged Birth Certificate Service ProvidersD HOLNo ratings yet

- The Profitable Designer Scorecard ReportDocument21 pagesThe Profitable Designer Scorecard ReportD HOLNo ratings yet

- ASOURCE Company Profile 2024Document1 pageASOURCE Company Profile 2024D HOLNo ratings yet

- Panama: Packaging Information Technical SpecificationDocument1 pagePanama: Packaging Information Technical Specificationone borneoNo ratings yet

- 3 Free Scarf Knitting PatternsDocument9 pages3 Free Scarf Knitting PatternsAvangaline Hull100% (1)

- Flutter Cardigan: What You Will NeedDocument5 pagesFlutter Cardigan: What You Will NeedVancea Ioana ElenaNo ratings yet

- ДраконDocument15 pagesДраконАнна П.No ratings yet

- PDF Elmo PatternDocument4 pagesPDF Elmo Patternmorgan.huizinga96No ratings yet

- Skinner 20th Century Furniture DecorativeDocument115 pagesSkinner 20th Century Furniture Decorativeisalan2005No ratings yet

- Mothers and Babies: Your Free ChartDocument2 pagesMothers and Babies: Your Free Chartgiuli3101No ratings yet

- Super Beadwork-QuickEasy-April-May-2011 PDFDocument48 pagesSuper Beadwork-QuickEasy-April-May-2011 PDFSandee Harris100% (2)

- 1 4934105030039962181Document9 pages1 4934105030039962181Maria Yolid Echeverry Cardona100% (2)

- Donkey Amigurumi - Free Stuffed Animal Crochet Pattern - Craft PassionDocument9 pagesDonkey Amigurumi - Free Stuffed Animal Crochet Pattern - Craft PassionLaura Hermosa100% (1)

- NUBE Kawaii CuddlerDocument4 pagesNUBE Kawaii Cuddlermareto torres100% (2)

- TLV Ravelry EngSchedDocument1 pageTLV Ravelry EngSchedchannahk544No ratings yet

- Rosa PoodleDocument7 pagesRosa PoodlePriscila Vanina CórdobaNo ratings yet

- Chicane by Cookie A v2.0Document13 pagesChicane by Cookie A v2.0gladys elibeth100% (3)

- Joethe Elephant Baby Lovey Pattern by Yarn WaveDocument8 pagesJoethe Elephant Baby Lovey Pattern by Yarn WaveArnaud Gdn100% (2)

- Citrus Coaster Citrus Coaster Citrus Coaster Citrus CoasterDocument1 pageCitrus Coaster Citrus Coaster Citrus Coaster Citrus CoasterLinh NguyenNo ratings yet

- Little Chubby Bunny Amigurumi PDF Free PatternDocument9 pagesLittle Chubby Bunny Amigurumi PDF Free PatternSolana Olasso100% (1)

- A Flair For SpringDocument8 pagesA Flair For SpringMonica MazzoniNo ratings yet

- 1 Ene. PomeloDocument3 pages1 Ene. PomeloMaria Margarita Castells100% (3)

- Creepy Hollow by Erynne ChardDocument4 pagesCreepy Hollow by Erynne ChardErynne ChardNo ratings yet

- Make Your Own Haru-Chan and Baby Chioux!Document2 pagesMake Your Own Haru-Chan and Baby Chioux!Engenharia CivilNo ratings yet

- (NT) ZumbiDocument9 pages(NT) Zumbiwrcw4dvz6cNo ratings yet

- Alice in WonderlandDocument40 pagesAlice in WonderlandJess Garcia100% (1)

- Among Us SquirtleDocument12 pagesAmong Us SquirtleSolange Acevedo100% (3)

- Pleated Skirt: Test SquareDocument33 pagesPleated Skirt: Test SquareMonika SalNo ratings yet

- A PDF of Instructions From The Book To Make Sabines Purple Rope Necklace.Document10 pagesA PDF of Instructions From The Book To Make Sabines Purple Rope Necklace.vddidabijoux71% (17)