Professional Documents

Culture Documents

Class NKK Checklist USA

Class NKK Checklist USA

Uploaded by

cicilhar89Copyright:

Available Formats

You might also like

- Readers Theater Life FlightDocument5 pagesReaders Theater Life FlightCaurrine Monsalud93% (14)

- Volo's Guide To Monsters - 1Document7 pagesVolo's Guide To Monsters - 1Saz100% (1)

- Crane Inspection PDFDocument2 pagesCrane Inspection PDFAniekanNo ratings yet

- Head Strong: The Bulletproof Plan To Activate Untapped Brain Energy To Work Smarter and Think Faster-In Just Two Weeks - Dave AspreyDocument5 pagesHead Strong: The Bulletproof Plan To Activate Untapped Brain Energy To Work Smarter and Think Faster-In Just Two Weeks - Dave Aspreyzikibuse25% (4)

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- STI SP001 SPCC Plan Inspection Form WISCONSINDocument2 pagesSTI SP001 SPCC Plan Inspection Form WISCONSINCarlos Molina100% (1)

- Global E-Business and CollaborationDocument36 pagesGlobal E-Business and CollaborationTouhid AnikNo ratings yet

- USCG ChecklistDocument2 pagesUSCG Checklistcicilhar89No ratings yet

- Protection Relay Verification and Inspection Switchgear DataDocument11 pagesProtection Relay Verification and Inspection Switchgear DatamomoNo ratings yet

- p0344 NeonDocument6 pagesp0344 NeonCarlos Awo OsaureNo ratings yet

- Neon P0016Document5 pagesNeon P0016Carlos Awo OsaureNo ratings yet

- 41 2os03Document8 pages41 2os03Miguel Angel RodriguezNo ratings yet

- Fire Pump Hydrant Inspection ChecklistDocument2 pagesFire Pump Hydrant Inspection Checklistkukuh nugNo ratings yet

- CMC-3 Fault TroubleshootingDocument12 pagesCMC-3 Fault TroubleshootingCoil98No ratings yet

- Ogis-Fm (6) - Ewo-F28-Engine Room Watch Takeover ChecklistDocument1 pageOgis-Fm (6) - Ewo-F28-Engine Room Watch Takeover ChecklistZipronNo ratings yet

- Nfpa-2001-2018 Check ListDocument2 pagesNfpa-2001-2018 Check ListMarcio BritoNo ratings yet

- Equipment Test Electrical SystDocument2 pagesEquipment Test Electrical SystPingarilhoNo ratings yet

- BeepparkkeeperDocument64 pagesBeepparkkeeperJan Carlos Gómez CarmonaNo ratings yet

- Analysis and Identification Of: Basic Problems in Engines: Symptom Probable Cause AnalysisDocument2 pagesAnalysis and Identification Of: Basic Problems in Engines: Symptom Probable Cause AnalysisEvelyn Sánchez RomeroNo ratings yet

- Technical Analysis 1: Lg/Med Track ExcavatorsDocument6 pagesTechnical Analysis 1: Lg/Med Track ExcavatorsKang AdingNo ratings yet

- SMP of MCC & PCC RoomDocument4 pagesSMP of MCC & PCC Roomsanjay sharmaNo ratings yet

- UPS, DC Panel and BatteriesDocument2 pagesUPS, DC Panel and Batteriesyibelta abebeNo ratings yet

- Barrier-Preventative-Maintenance-Visits TELISAI HIGHWAYDocument9 pagesBarrier-Preventative-Maintenance-Visits TELISAI HIGHWAYjohnNo ratings yet

- Contoh/Example Tipe / Type Toyota Nomor Identifikasi Kendaraan / No. Mesin / Engine No. Nomor Plat / License No. D. 1326 SY Atau 1000 KMDocument3 pagesContoh/Example Tipe / Type Toyota Nomor Identifikasi Kendaraan / No. Mesin / Engine No. Nomor Plat / License No. D. 1326 SY Atau 1000 KMBagus PangestuNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- APT-8S / APT-9S: WarningDocument2 pagesAPT-8S / APT-9S: WarningSk PanggongNo ratings yet

- Check List For Electronic Memory GaugeDocument1 pageCheck List For Electronic Memory GaugeMohamed TalaatNo ratings yet

- Temporary Electrical System Inspection ChecklistDocument11 pagesTemporary Electrical System Inspection Checklistscyper89No ratings yet

- 730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesDocument4 pages730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesFabrizio JesúsNo ratings yet

- Machine Operation Recorder FunctionDocument32 pagesMachine Operation Recorder FunctionMohammad SulistiawanNo ratings yet

- Electrical AlarmsDocument6 pagesElectrical AlarmsCiprian MariusNo ratings yet

- AC, UPS Andbattery Acceptance Criteria For EEPHQDocument20 pagesAC, UPS Andbattery Acceptance Criteria For EEPHQDanielNo ratings yet

- Manual BRIODocument2 pagesManual BRIOrifki wahyudiNo ratings yet

- 33 Inst. Field Qua AuditDocument4 pages33 Inst. Field Qua Auditgajendrabanshiwal8905No ratings yet

- 10MLD GandhinagarDocument3 pages10MLD GandhinagarBUKA RAMAKANTHNo ratings yet

- DS - Oil Breakdown Voltage Tester - DTA 100 C - BAUR - En-GbDocument2 pagesDS - Oil Breakdown Voltage Tester - DTA 100 C - BAUR - En-GbAmit PaulNo ratings yet

- SMP of A ACBDocument3 pagesSMP of A ACBsanjay sharmaNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- Crane InspectionDocument3 pagesCrane InspectionHSSE AL THAIL GROUPNo ratings yet

- Deck M-Plan (S-0834-MP) (Annually) 29dec.20Document9 pagesDeck M-Plan (S-0834-MP) (Annually) 29dec.20MV Span Asia 21No ratings yet

- YMM220003 DDocument130 pagesYMM220003 DVinicius NevesNo ratings yet

- Alternator InstructionsDocument2 pagesAlternator InstructionsMahmoudNo ratings yet

- Instruction Manual: Energy MeterDocument2 pagesInstruction Manual: Energy MeterIshwar ranawatNo ratings yet

- Instruction Manual: Energy MeterDocument4 pagesInstruction Manual: Energy MeterTekaNo ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- Analyze Problem Coupler O2 Sensor BKUDocument10 pagesAnalyze Problem Coupler O2 Sensor BKUmutiara.dewiNo ratings yet

- As 105644 KV-8000 C 600T82 GB WW 1079-1Document32 pagesAs 105644 KV-8000 C 600T82 GB WW 1079-1Deni SafaraniNo ratings yet

- SCX550E SM 2-2 For TNDocument68 pagesSCX550E SM 2-2 For TNilonk antonieNo ratings yet

- 11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDocument1 page11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDominique KomeyNo ratings yet

- المحاضرة الرابعة:إختبارات محولات التوزيعDocument53 pagesالمحاضرة الرابعة:إختبارات محولات التوزيعوليد موسىNo ratings yet

- 211-05 Steering Column Post Switch PICKUP JMCDocument11 pages211-05 Steering Column Post Switch PICKUP JMCRusonegroNo ratings yet

- Diagnostic Trouble Code (DTC) 035 Left Front Wheel Speed Sensor FaultDocument32 pagesDiagnostic Trouble Code (DTC) 035 Left Front Wheel Speed Sensor Faultseocheol007No ratings yet

- BaurDocument3 pagesBaurmunggangNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbNOVASKY De Paula e CarvalhoNo ratings yet

- Index: Starting Up and Shutting Down The SystemDocument10 pagesIndex: Starting Up and Shutting Down The SystemKelum BuddhikaNo ratings yet

- PPM - Power Tool ChecklistDocument1 pagePPM - Power Tool ChecklistmayurchaturNo ratings yet

- O - RRN"'": Intermediate ProjectDocument3 pagesO - RRN"'": Intermediate ProjectPeeters GuyNo ratings yet

- CPJ 200 J1 j1-08 Troubleshootingmod r1 2012-09-10Document33 pagesCPJ 200 J1 j1-08 Troubleshootingmod r1 2012-09-10ngocbienk56No ratings yet

- Aboalazaim ELectrical EngineerDocument2 pagesAboalazaim ELectrical EngineerMaddy El MaghrabyNo ratings yet

- PCT200 Commissioning CHARGERDocument1 pagePCT200 Commissioning CHARGERWilmer PatricioNo ratings yet

- Equipment Test Main Propulsion UnitDocument3 pagesEquipment Test Main Propulsion UnitPingarilhoNo ratings yet

- AL Electrical Certification Level 2: Field Assessment ChecklistDocument2 pagesAL Electrical Certification Level 2: Field Assessment Checklistjuan TorresNo ratings yet

- Organic Elemental Analysis: Ultramicro, Micro, and Trace MethodsFrom EverandOrganic Elemental Analysis: Ultramicro, Micro, and Trace MethodsNo ratings yet

- Introduction To Business ResearchDocument23 pagesIntroduction To Business ResearchKhalid ElGhazouliNo ratings yet

- MCN QuizDocument10 pagesMCN Quizjshaymin8No ratings yet

- The Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleDocument5 pagesThe Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleApril Rose100% (5)

- African Literature - WikipediaDocument1 pageAfrican Literature - Wikipediatem ijeNo ratings yet

- Best Astrologer in DelhiDocument5 pagesBest Astrologer in DelhiastrorajkumarNo ratings yet

- A Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Document99 pagesA Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Hitesh kumar jenaNo ratings yet

- Greenhouse Manual2Document106 pagesGreenhouse Manual2Amit ShresthaNo ratings yet

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- Dissertation Topic MailDocument57 pagesDissertation Topic MailANUPNo ratings yet

- The 7 SealDocument11 pagesThe 7 Sealendalkachew gudeta100% (1)

- CortinaDocument2 pagesCortinatecnicoeletronico23No ratings yet

- The Tale of The Three BrothersDocument2 pagesThe Tale of The Three BrothersDéboraNo ratings yet

- Purposive CommunicationDocument15 pagesPurposive CommunicationJm SalvaniaNo ratings yet

- Services Procurement Data SheetDocument5 pagesServices Procurement Data Sheetrollingstone3mNo ratings yet

- Banking Law On Secrecy of Bank DepositsDocument29 pagesBanking Law On Secrecy of Bank DepositsbrendamanganaanNo ratings yet

- Api 577 Q 114Document31 pagesApi 577 Q 114Mohammed YoussefNo ratings yet

- (!court: Laepublic of Tbe !lbilippines FflanilaDocument14 pages(!court: Laepublic of Tbe !lbilippines FflanilaGladys Bustria OrlinoNo ratings yet

- Rekayasa IdeDocument21 pagesRekayasa IdelilyNo ratings yet

- Ca17 Activity 1Document2 pagesCa17 Activity 1Mark Kenneth CeballosNo ratings yet

- (With Script) June 2021 Saturday WSF Teaching GuideDocument3 pages(With Script) June 2021 Saturday WSF Teaching GuideMichael T. BelloNo ratings yet

- Gorillas 191314 0Document2 pagesGorillas 191314 0Marisabel SernaNo ratings yet

- A User-Friendly Classification: The Irregular Verbs in EnglishDocument10 pagesA User-Friendly Classification: The Irregular Verbs in EnglishPabloNo ratings yet

- Keyword: 50s Music Title: Great 50s Songs For Different Moods: ContentDocument1 pageKeyword: 50s Music Title: Great 50s Songs For Different Moods: Contentaditya_bb_sharmaNo ratings yet

- 17 Artikel Analisis Komponen Produk Wisata Di Kabupaten KarawangDocument10 pages17 Artikel Analisis Komponen Produk Wisata Di Kabupaten KarawangPutri NurkarimahNo ratings yet

- Opera Omnia Desiderii Erasmi 1.1Document704 pagesOpera Omnia Desiderii Erasmi 1.1Professore2100% (1)

- Answer Module 1Document3 pagesAnswer Module 1endroNo ratings yet

Class NKK Checklist USA

Class NKK Checklist USA

Uploaded by

cicilhar89Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Class NKK Checklist USA

Class NKK Checklist USA

Uploaded by

cicilhar89Copyright:

Available Formats

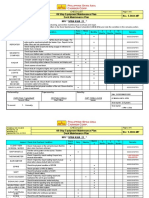

M.V.

: HARMONICS

Date: 04 JAN 2023

Checked by the C/O, C/E ,1/AE

Confirmed by the MASTER

Checklist for Port State Control (UNITED STATES)

No. Item Typical deficiency Result

□ There are leakages of oil, water and exhaust gas or main engine not cleanliness. There are no leakages.M/E is clean.All pressure

□ The jacketed high press. FO pipes, other pipe and valves are not in good order. pipe and valves are in good order.M/E staring

□ The starting system is not in good order. system is good order.There is no

□ The vessel experienced a reduction or an equipment failure in approaching to port or while transiting US waters. experience.Remote,local or automotive control

1 Main Engines □ The remote, local or automatic control system are not in good order. system are in good order.All safety alarm devices

□ The safety and alarm devices function are not in good order or fault alarms are indicated. are in good order and no fault alarms.M/E is

□ Main Engine is inoperative. operative.All crankcase door,cyl;

□ The crankcase, crankcase door, cylinder jacket, piston, foundation bolts or chock liners are not in good order. jacket,piston,foundation bolt and chock liners are in

□ The temporary repairs have been conducted. good order.There are no temporary repairs.

□ The fire detector is not in good order.

□ The test kits for fire detectors and it's test procedure are not provided onboard. All fire detectors are in good order and test

□ Crews are not familiar with the operation. procedures are provided.Crews are familiar with the

2 Fire detection and alarm system operation.The fire alarm system is in good order and

□ The fire alarm system is not in good order or fault alarms are indicated. no fault alarm.All inspection and maintenances are

□ The periodical inspection or maintenances in accordance with a manufacture's instruction have not been carried out properly or not recorded. recorded.The manual call point is in good order.

□ The manual call point is not in good order.

□ There are leakages of oil, water with wastage and corrosion holes, or pumps not cleanliness. There are no leakages of oil,water in wastage and

3 Pumps □ The operations including the remote control are not in good order. corrosion holes.All pump operations are in good

□ The temporary repairs have been conducted. order.There are no temporary repairs.

□ There are leakages of oil, water and exhaust gas or generator engines not cleanliness. There are no leakages in generator engines and

4 Generator Engines fitted with protection covers properly. All generator

□ The protection cover is not properly fitted. engines are operational.

□ The self closing doors are fitted with holdback hook, ropes or wedge or not self-closed. Checked all fire doors. Found self-closing, gastight

5 Fire Doors

□ The fire door is not gastight. and not fitted with holdback hook, ropes or wedge.

Both Lifeboat and rescueboat engines are able to

start by its own idividual battery. Batteries

and battery chargers are functioning well and

□ The engine can not be started by No.1 & No.2 batteries or manual starting system within 2 minutes. checked regularly on Saturday routine.

□ The battery and battery charger are not in good order. The cable condition

□ The cable condition or it's penetrations is not in good order. and it's penetrations are in good order.

□ The cooling system is not in good order. Cooling system is in good order.

6 Lifeboats/Rescue boat □ The hull body including skates and fender are not in good condition. The hull body including skates and fender are in

good order.

□ The periodical inspections or repairs have not been properly carried out by authorized service providers or shipboard personnel or not recorded. The preidodical inspections are recorded.

□ The rescue boat or lifeboat is not ready to use. Both Lifeboat and

□ The type approval certificate is not available onboard. rescueboat engines are tested regularly on saturday

□ The window including its wiper is not in good condition. routine and both of them are operational and ready

to use.

Type approval certificate is available.

The window is good condition.

□ There are leakages of oil, water or steam from pipes, valves or heaters with wastage and corrosion holes in E/R.

□ The insulation or anti-splashing tape of pipes or valves in E/R is not in good condition.

7 Pipes □ The soft patches, doublers, cement box or temporary repairs are found. Found no leakage on deck and engine room.

No abnormal vibrations observed

□ There are leakages of oil, water or steam from pipes, valves or heaters with the grime, wastage and corrosion holes in deck and cargo hold spaces.

□ The abnormal vibration are found or flange bolts are not properly tightened.

□ There are leakages of water or oil from pumps and it's line with wastage and corrosion holes.

□ The sufficient delivery pressure is not maintained or sea water can not be delivered.

8 Emergency fire pump, fire pump and its piping Checked and found all in good order.

□ Emergency fire pumps or other fire pumps inoperative.

□ The pipes or valves with open-shut indicators are not in good order.

□ The selection mode for fixed local application is kept in manual mode position.

□ Fixed fire extinguishing installation is inoperative.

□ Local fire fighting system sprinkle nozzle can not spray water fog to protect areas. Fixed local application is kept in auto mode.Fixed

□ The all gauges, meters, indicators, or sensors are not in good order. fire extinguishing installation is operative.Local fire

□ The CO2 cylinders are not properly secured or not in good condition. fighting system sprinkle nozzle spray water fog to

□ The control panel and its lamp are not in good order. protect areas.All gauges,meters,indicators or

9 Fixed fire extinguishing installation □ The foam concentrate/analysis or quantity of foam-forming liquid is not in good order. sensors are in good order.Not installed CO2

□ The periodical inspection and maintenance have not been carried out properly or not recorded. system.All lamps are in good order.Quantity of

□ The pilot line for CO2 discharge valve has been disconnected or not in good condition. foam-foaming liquid is in good order.All inspections

□ The pipes, hoses and valves for supply of water, CO2 or foam liquid are not set properly. and maintenance are recorded.Not installed CO2

□ The proper instruction manual by languages crews understand or diagram has not been posted at the operating station. system.

□ The safety pins on CO2 bottles have not been handled as per maker's instructions.

□ There are leakages from the pipes, valves, CO2 hoses or tanks with wastage and corrosion holes.

□ There are leakages of oil from steering gear system.

□ The steering gear pump is not in good order.

10 Steering Gear System including emergency steering gear □ In NFU mode, steering gear system is not in good order. Steering gear system is in good order. Found no

leakage. Handrails, gratings are provided.

□ The handrails, gratings or nonslip surfaces are not provided to ensure working access to steering gear and controls including starter panel or they are not in good condition.

□ The hydraulic oil of the storage tank for steering gear is not recharged sufficiently.

No Abbreviation NK Category

1 APP Air Pollution Prevention

2 BRG Navigational Equipment & Safety Navigation

3 CAG Cargo Handling Gear

4 DOC Certificate & Documents

5 DRI Drills

6 ELC Electrical Equipment

7 FFA Fire Fighting Appliances

8 GRB Garbage

9 HUL Hull Construction and machinery & piping on deck

10 ISP International Ship and Port Facility Security

11 LLI Load Line

12 LSA Life Saving Appliances

13 MCN Machinery in Engine Room

14 MLC Maritime Labour Convention, 2006

15 OPP Oil Pollusion Prevention

16 RAI Radio Installation

17 SOP Shipboard Operation

18 SPP Sewage Pollusion Prevention

You might also like

- Readers Theater Life FlightDocument5 pagesReaders Theater Life FlightCaurrine Monsalud93% (14)

- Volo's Guide To Monsters - 1Document7 pagesVolo's Guide To Monsters - 1Saz100% (1)

- Crane Inspection PDFDocument2 pagesCrane Inspection PDFAniekanNo ratings yet

- Head Strong: The Bulletproof Plan To Activate Untapped Brain Energy To Work Smarter and Think Faster-In Just Two Weeks - Dave AspreyDocument5 pagesHead Strong: The Bulletproof Plan To Activate Untapped Brain Energy To Work Smarter and Think Faster-In Just Two Weeks - Dave Aspreyzikibuse25% (4)

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- STI SP001 SPCC Plan Inspection Form WISCONSINDocument2 pagesSTI SP001 SPCC Plan Inspection Form WISCONSINCarlos Molina100% (1)

- Global E-Business and CollaborationDocument36 pagesGlobal E-Business and CollaborationTouhid AnikNo ratings yet

- USCG ChecklistDocument2 pagesUSCG Checklistcicilhar89No ratings yet

- Protection Relay Verification and Inspection Switchgear DataDocument11 pagesProtection Relay Verification and Inspection Switchgear DatamomoNo ratings yet

- p0344 NeonDocument6 pagesp0344 NeonCarlos Awo OsaureNo ratings yet

- Neon P0016Document5 pagesNeon P0016Carlos Awo OsaureNo ratings yet

- 41 2os03Document8 pages41 2os03Miguel Angel RodriguezNo ratings yet

- Fire Pump Hydrant Inspection ChecklistDocument2 pagesFire Pump Hydrant Inspection Checklistkukuh nugNo ratings yet

- CMC-3 Fault TroubleshootingDocument12 pagesCMC-3 Fault TroubleshootingCoil98No ratings yet

- Ogis-Fm (6) - Ewo-F28-Engine Room Watch Takeover ChecklistDocument1 pageOgis-Fm (6) - Ewo-F28-Engine Room Watch Takeover ChecklistZipronNo ratings yet

- Nfpa-2001-2018 Check ListDocument2 pagesNfpa-2001-2018 Check ListMarcio BritoNo ratings yet

- Equipment Test Electrical SystDocument2 pagesEquipment Test Electrical SystPingarilhoNo ratings yet

- BeepparkkeeperDocument64 pagesBeepparkkeeperJan Carlos Gómez CarmonaNo ratings yet

- Analysis and Identification Of: Basic Problems in Engines: Symptom Probable Cause AnalysisDocument2 pagesAnalysis and Identification Of: Basic Problems in Engines: Symptom Probable Cause AnalysisEvelyn Sánchez RomeroNo ratings yet

- Technical Analysis 1: Lg/Med Track ExcavatorsDocument6 pagesTechnical Analysis 1: Lg/Med Track ExcavatorsKang AdingNo ratings yet

- SMP of MCC & PCC RoomDocument4 pagesSMP of MCC & PCC Roomsanjay sharmaNo ratings yet

- UPS, DC Panel and BatteriesDocument2 pagesUPS, DC Panel and Batteriesyibelta abebeNo ratings yet

- Barrier-Preventative-Maintenance-Visits TELISAI HIGHWAYDocument9 pagesBarrier-Preventative-Maintenance-Visits TELISAI HIGHWAYjohnNo ratings yet

- Contoh/Example Tipe / Type Toyota Nomor Identifikasi Kendaraan / No. Mesin / Engine No. Nomor Plat / License No. D. 1326 SY Atau 1000 KMDocument3 pagesContoh/Example Tipe / Type Toyota Nomor Identifikasi Kendaraan / No. Mesin / Engine No. Nomor Plat / License No. D. 1326 SY Atau 1000 KMBagus PangestuNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- APT-8S / APT-9S: WarningDocument2 pagesAPT-8S / APT-9S: WarningSk PanggongNo ratings yet

- Check List For Electronic Memory GaugeDocument1 pageCheck List For Electronic Memory GaugeMohamed TalaatNo ratings yet

- Temporary Electrical System Inspection ChecklistDocument11 pagesTemporary Electrical System Inspection Checklistscyper89No ratings yet

- 730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesDocument4 pages730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesFabrizio JesúsNo ratings yet

- Machine Operation Recorder FunctionDocument32 pagesMachine Operation Recorder FunctionMohammad SulistiawanNo ratings yet

- Electrical AlarmsDocument6 pagesElectrical AlarmsCiprian MariusNo ratings yet

- AC, UPS Andbattery Acceptance Criteria For EEPHQDocument20 pagesAC, UPS Andbattery Acceptance Criteria For EEPHQDanielNo ratings yet

- Manual BRIODocument2 pagesManual BRIOrifki wahyudiNo ratings yet

- 33 Inst. Field Qua AuditDocument4 pages33 Inst. Field Qua Auditgajendrabanshiwal8905No ratings yet

- 10MLD GandhinagarDocument3 pages10MLD GandhinagarBUKA RAMAKANTHNo ratings yet

- DS - Oil Breakdown Voltage Tester - DTA 100 C - BAUR - En-GbDocument2 pagesDS - Oil Breakdown Voltage Tester - DTA 100 C - BAUR - En-GbAmit PaulNo ratings yet

- SMP of A ACBDocument3 pagesSMP of A ACBsanjay sharmaNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- Crane InspectionDocument3 pagesCrane InspectionHSSE AL THAIL GROUPNo ratings yet

- Deck M-Plan (S-0834-MP) (Annually) 29dec.20Document9 pagesDeck M-Plan (S-0834-MP) (Annually) 29dec.20MV Span Asia 21No ratings yet

- YMM220003 DDocument130 pagesYMM220003 DVinicius NevesNo ratings yet

- Alternator InstructionsDocument2 pagesAlternator InstructionsMahmoudNo ratings yet

- Instruction Manual: Energy MeterDocument2 pagesInstruction Manual: Energy MeterIshwar ranawatNo ratings yet

- Instruction Manual: Energy MeterDocument4 pagesInstruction Manual: Energy MeterTekaNo ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- Analyze Problem Coupler O2 Sensor BKUDocument10 pagesAnalyze Problem Coupler O2 Sensor BKUmutiara.dewiNo ratings yet

- As 105644 KV-8000 C 600T82 GB WW 1079-1Document32 pagesAs 105644 KV-8000 C 600T82 GB WW 1079-1Deni SafaraniNo ratings yet

- SCX550E SM 2-2 For TNDocument68 pagesSCX550E SM 2-2 For TNilonk antonieNo ratings yet

- 11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDocument1 page11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDominique KomeyNo ratings yet

- المحاضرة الرابعة:إختبارات محولات التوزيعDocument53 pagesالمحاضرة الرابعة:إختبارات محولات التوزيعوليد موسىNo ratings yet

- 211-05 Steering Column Post Switch PICKUP JMCDocument11 pages211-05 Steering Column Post Switch PICKUP JMCRusonegroNo ratings yet

- Diagnostic Trouble Code (DTC) 035 Left Front Wheel Speed Sensor FaultDocument32 pagesDiagnostic Trouble Code (DTC) 035 Left Front Wheel Speed Sensor Faultseocheol007No ratings yet

- BaurDocument3 pagesBaurmunggangNo ratings yet

- DS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbDocument3 pagesDS - Oil Breakdown Voltage Tester - DPA 75 C - BAUR - En-GbNOVASKY De Paula e CarvalhoNo ratings yet

- Index: Starting Up and Shutting Down The SystemDocument10 pagesIndex: Starting Up and Shutting Down The SystemKelum BuddhikaNo ratings yet

- PPM - Power Tool ChecklistDocument1 pagePPM - Power Tool ChecklistmayurchaturNo ratings yet

- O - RRN"'": Intermediate ProjectDocument3 pagesO - RRN"'": Intermediate ProjectPeeters GuyNo ratings yet

- CPJ 200 J1 j1-08 Troubleshootingmod r1 2012-09-10Document33 pagesCPJ 200 J1 j1-08 Troubleshootingmod r1 2012-09-10ngocbienk56No ratings yet

- Aboalazaim ELectrical EngineerDocument2 pagesAboalazaim ELectrical EngineerMaddy El MaghrabyNo ratings yet

- PCT200 Commissioning CHARGERDocument1 pagePCT200 Commissioning CHARGERWilmer PatricioNo ratings yet

- Equipment Test Main Propulsion UnitDocument3 pagesEquipment Test Main Propulsion UnitPingarilhoNo ratings yet

- AL Electrical Certification Level 2: Field Assessment ChecklistDocument2 pagesAL Electrical Certification Level 2: Field Assessment Checklistjuan TorresNo ratings yet

- Organic Elemental Analysis: Ultramicro, Micro, and Trace MethodsFrom EverandOrganic Elemental Analysis: Ultramicro, Micro, and Trace MethodsNo ratings yet

- Introduction To Business ResearchDocument23 pagesIntroduction To Business ResearchKhalid ElGhazouliNo ratings yet

- MCN QuizDocument10 pagesMCN Quizjshaymin8No ratings yet

- The Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleDocument5 pagesThe Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleApril Rose100% (5)

- African Literature - WikipediaDocument1 pageAfrican Literature - Wikipediatem ijeNo ratings yet

- Best Astrologer in DelhiDocument5 pagesBest Astrologer in DelhiastrorajkumarNo ratings yet

- A Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Document99 pagesA Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Hitesh kumar jenaNo ratings yet

- Greenhouse Manual2Document106 pagesGreenhouse Manual2Amit ShresthaNo ratings yet

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- Dissertation Topic MailDocument57 pagesDissertation Topic MailANUPNo ratings yet

- The 7 SealDocument11 pagesThe 7 Sealendalkachew gudeta100% (1)

- CortinaDocument2 pagesCortinatecnicoeletronico23No ratings yet

- The Tale of The Three BrothersDocument2 pagesThe Tale of The Three BrothersDéboraNo ratings yet

- Purposive CommunicationDocument15 pagesPurposive CommunicationJm SalvaniaNo ratings yet

- Services Procurement Data SheetDocument5 pagesServices Procurement Data Sheetrollingstone3mNo ratings yet

- Banking Law On Secrecy of Bank DepositsDocument29 pagesBanking Law On Secrecy of Bank DepositsbrendamanganaanNo ratings yet

- Api 577 Q 114Document31 pagesApi 577 Q 114Mohammed YoussefNo ratings yet

- (!court: Laepublic of Tbe !lbilippines FflanilaDocument14 pages(!court: Laepublic of Tbe !lbilippines FflanilaGladys Bustria OrlinoNo ratings yet

- Rekayasa IdeDocument21 pagesRekayasa IdelilyNo ratings yet

- Ca17 Activity 1Document2 pagesCa17 Activity 1Mark Kenneth CeballosNo ratings yet

- (With Script) June 2021 Saturday WSF Teaching GuideDocument3 pages(With Script) June 2021 Saturday WSF Teaching GuideMichael T. BelloNo ratings yet

- Gorillas 191314 0Document2 pagesGorillas 191314 0Marisabel SernaNo ratings yet

- A User-Friendly Classification: The Irregular Verbs in EnglishDocument10 pagesA User-Friendly Classification: The Irregular Verbs in EnglishPabloNo ratings yet

- Keyword: 50s Music Title: Great 50s Songs For Different Moods: ContentDocument1 pageKeyword: 50s Music Title: Great 50s Songs For Different Moods: Contentaditya_bb_sharmaNo ratings yet

- 17 Artikel Analisis Komponen Produk Wisata Di Kabupaten KarawangDocument10 pages17 Artikel Analisis Komponen Produk Wisata Di Kabupaten KarawangPutri NurkarimahNo ratings yet

- Opera Omnia Desiderii Erasmi 1.1Document704 pagesOpera Omnia Desiderii Erasmi 1.1Professore2100% (1)

- Answer Module 1Document3 pagesAnswer Module 1endroNo ratings yet