Professional Documents

Culture Documents

Visual Inspection

Visual Inspection

Uploaded by

vellinemaxCopyright:

Available Formats

You might also like

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathNo ratings yet

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Suli HartoNo ratings yet

- Visual Inspection Report Aruna Nusa Safarian 0716040057 2Document8 pagesVisual Inspection Report Aruna Nusa Safarian 0716040057 2romanosky11No ratings yet

- C and K SystemDocument3 pagesC and K SystemKamal AlkurdiNo ratings yet

- XLR Connectors: Part Number GuideDocument13 pagesXLR Connectors: Part Number Guidedouglas camposNo ratings yet

- Thick Film Network Resistor: Brief IntroductionDocument5 pagesThick Film Network Resistor: Brief IntroductionJACOB DE LA CRUZ CAUICHNo ratings yet

- 64 Pin Euro ConnectorsDocument2 pages64 Pin Euro ConnectorsAchyuth ShettigarNo ratings yet

- Touareg 4.2Document36 pagesTouareg 4.2zozo0424No ratings yet

- LCS 2Document1 pageLCS 2nutral powertechNo ratings yet

- Tourline PDFDocument9 pagesTourline PDF2022A Micha Michela FitrianaNo ratings yet

- Dial Indicators: SERIES 1 - Back Plunger TypeDocument1 pageDial Indicators: SERIES 1 - Back Plunger Typesomkiat kongprasiatNo ratings yet

- STD PinDocument1 pageSTD Pinshubham.yantrikNo ratings yet

- ASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Document2 pagesASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Lora BoydNo ratings yet

- For Samples Only: 110 105 15 ApproxDocument1 pageFor Samples Only: 110 105 15 ApproxrichardNo ratings yet

- CA Si LV en Industrial Transformers PCC ExtractDocument8 pagesCA Si LV en Industrial Transformers PCC ExtracttgghareebNo ratings yet

- Model Test 1Document1 pageModel Test 1Nirlesh KothariNo ratings yet

- 32 90 Fluidos EletroerosaoDocument1 page32 90 Fluidos EletroerosaoPaulo HenriqueNo ratings yet

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocument1 pageM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- Luz Piloto 30MMDocument1 pageLuz Piloto 30MMJerNo ratings yet

- PLC - Ctrinh (Ups)Document4 pagesPLC - Ctrinh (Ups)Trần Đức HoàngNo ratings yet

- CSWIP Visual Inspection PIPE REPORTDocument4 pagesCSWIP Visual Inspection PIPE REPORTNaga RajanNo ratings yet

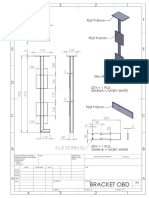

- Bracket ObdDocument1 pageBracket ObdHarry laksanaNo ratings yet

- Varistor para Luminarias Cree 20d - 1-3003069Document16 pagesVaristor para Luminarias Cree 20d - 1-3003069Gabriel SanjurNo ratings yet

- R Series Ex D: Stainless SteelDocument6 pagesR Series Ex D: Stainless SteelTran DucNo ratings yet

- YC100-508-3P SpecDocument1 pageYC100-508-3P SpecNenad PavlovićNo ratings yet

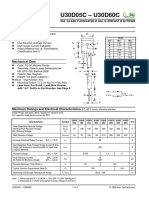

- U30D05C - U30D60C: Add "-LF" Suffix To Part Number, See Page 4Document4 pagesU30D05C - U30D60C: Add "-LF" Suffix To Part Number, See Page 4quangNo ratings yet

- cataloge đầu khí kosa PDFDocument7 pagescataloge đầu khí kosa PDFNguyễn Hữu ĐồngNo ratings yet

- HE Series Spec Guide (SG-HE-08)Document8 pagesHE Series Spec Guide (SG-HE-08)Shouzab AbbasNo ratings yet

- Product Guide - Section XLRDocument33 pagesProduct Guide - Section XLRManny LeblancNo ratings yet

- MBRF2040CTDocument2 pagesMBRF2040CTvejiye7055No ratings yet

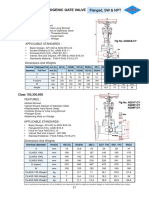

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- NGK Resistor Covers Decoding EnglishDocument3 pagesNGK Resistor Covers Decoding EnglishKostiantyn UsenkoNo ratings yet

- Intake Kyn Toyota 1zrDocument2 pagesIntake Kyn Toyota 1zrALiito KNo ratings yet

- Cswip 31 Practical PDFDocument4 pagesCswip 31 Practical PDFJigar PrajapatiNo ratings yet

- World Low Voltages and PlugsDocument4 pagesWorld Low Voltages and Plugsmiha sredNo ratings yet

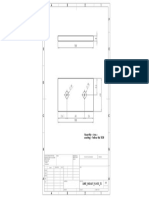

- 500 KVA DRAWING FINAL-Review RPDDocument9 pages500 KVA DRAWING FINAL-Review RPDRahmat HidayatNo ratings yet

- Electricals BoqDocument10 pagesElectricals BoqA M JNo ratings yet

- CSWIP Practical Plate AnswersDocument31 pagesCSWIP Practical Plate AnswersSha Zha100% (1)

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Nashaat DhyaaNo ratings yet

- MIL Style RV4: PrecisionDocument3 pagesMIL Style RV4: PrecisionRaul S. CotrinaNo ratings yet

- D10843570ADocument1 pageD10843570AGaurav VashishtNo ratings yet

- Small Parts Schematic SJ FSRDocument2 pagesSmall Parts Schematic SJ FSRalejibaNo ratings yet

- Her 1603Document3 pagesHer 1603gonthenkNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- ReleiDocument16 pagesReleistarostrugaNo ratings yet

- Coding KeyDocument2 pagesCoding KeyIgorTNo ratings yet

- Lenovo 720-15IKB - Wistron Bohol LB720LB721 16877-1Document105 pagesLenovo 720-15IKB - Wistron Bohol LB720LB721 16877-1Victor BlancoNo ratings yet

- AC10 AC60: Air Filter + Regulator + LubricatorDocument5 pagesAC10 AC60: Air Filter + Regulator + LubricatorElsonMilanNo ratings yet

- Gaugeable Tube Fittings and Adapter Fittings (MS-01-140 Rev - AE en-US Catalog)Document1 pageGaugeable Tube Fittings and Adapter Fittings (MS-01-140 Rev - AE en-US Catalog)Gabriel BatistaNo ratings yet

- Appendix 3 Example Report E9Document3 pagesAppendix 3 Example Report E9Laith SalmanNo ratings yet

- T Series PartsListDocument4 pagesT Series PartsListmohammad alhajNo ratings yet

- Limit Mount Plate T2Document1 pageLimit Mount Plate T2Himindra ChaaubeNo ratings yet

- Lecture 2Document12 pagesLecture 2Dr. Saad Saffah HresheeNo ratings yet

- Cambridge IGCSE (9-1) : PHYSICS 0972/41Document16 pagesCambridge IGCSE (9-1) : PHYSICS 0972/41dowanahamidNo ratings yet

- Engineering Data Screen Openings For Strainers: Purpose Filtration LevelDocument6 pagesEngineering Data Screen Openings For Strainers: Purpose Filtration LeveldschrisNo ratings yet

- Jawapan Soalan Pahang FizikDocument2 pagesJawapan Soalan Pahang Fizikyktay2No ratings yet

- Civil - Highway Lab Manual - 2018Document17 pagesCivil - Highway Lab Manual - 2018Altamash NadimallaNo ratings yet

- Q1-W5-D5-Separating Mixtures - DistillationDocument4 pagesQ1-W5-D5-Separating Mixtures - DistillationHeidi Dalyagan DulnagonNo ratings yet

- List & Properties of UK Strcutral Steel Shapes No Sheet DescriptionDocument65 pagesList & Properties of UK Strcutral Steel Shapes No Sheet DescriptionThắngg TrịnhhNo ratings yet

- Surveying Observation, Surveying, ObservationDocument63 pagesSurveying Observation, Surveying, Observationthanasekar665No ratings yet

- United States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Document43 pagesUnited States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Erin GokNo ratings yet

- Scaffold Development Using 3D Printing With A Starch-Bsed PolymerDocument8 pagesScaffold Development Using 3D Printing With A Starch-Bsed PolymerLucas BaruzoNo ratings yet

- LFA Live Fluid Analyzer PDFDocument5 pagesLFA Live Fluid Analyzer PDFdiegoNo ratings yet

- Black HoleDocument14 pagesBlack HoleSagarKasarlaNo ratings yet

- ET ZC 235 Manufacturing Processes: BITS PilaniDocument925 pagesET ZC 235 Manufacturing Processes: BITS PilaniSanjay PandiyanNo ratings yet

- Distillation SequencingDocument39 pagesDistillation SequencingSohail Aziz Ahmad MalikNo ratings yet

- Airbus A320 Hydraulic System Description: ArticleDocument2 pagesAirbus A320 Hydraulic System Description: ArticleWellington OliveiraNo ratings yet

- Impedance Control: Robotics 2Document16 pagesImpedance Control: Robotics 2Karen ImmanuelNo ratings yet

- Sample Sci Lab CalendarDocument1 pageSample Sci Lab CalendarclayivanNo ratings yet

- Polymer Compositions InjectionDocument14 pagesPolymer Compositions InjectionJessiNo ratings yet

- Bearing Pad 400 X 400 X 52 MM (Ss400 Yield 235 Mpa)Document3 pagesBearing Pad 400 X 400 X 52 MM (Ss400 Yield 235 Mpa)AlvinbriliantNo ratings yet

- Ebara Pum 80 SQPBDocument4 pagesEbara Pum 80 SQPBMichael RefhandoNo ratings yet

- DC Arc FurnaceDocument7 pagesDC Arc FurnaceManojlovic VasoNo ratings yet

- ElasticityDocument7 pagesElasticityMajeed KhanNo ratings yet

- A Block Flow DiagramDocument35 pagesA Block Flow DiagramJerry SimonNo ratings yet

- 18-0022 Elliot JA22Document33 pages18-0022 Elliot JA22basemNo ratings yet

- VCB$SF 6Document3 pagesVCB$SF 6karthikumarNo ratings yet

- ENGINEERING 3014 Engineering ChemistrySummerDocument2 pagesENGINEERING 3014 Engineering ChemistrySummerKevin HuangNo ratings yet

- Meeting 6 - Evaporation - English For THPDocument4 pagesMeeting 6 - Evaporation - English For THPAlvianNo ratings yet

- Week # 9 MR Chapter 7: - Tutorial #9Document30 pagesWeek # 9 MR Chapter 7: - Tutorial #9Gábor MátyásiNo ratings yet

- Fluid Flow PhenomenaDocument13 pagesFluid Flow PhenomenaRaven ShadeNo ratings yet

- Structural Steel DesignDocument32 pagesStructural Steel Designshaluka100% (1)

- Nptel Learning Courses Structural Health Monitoring of CompositesDocument305 pagesNptel Learning Courses Structural Health Monitoring of Compositesaurora borealissNo ratings yet

Visual Inspection

Visual Inspection

Uploaded by

vellinemaxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visual Inspection

Visual Inspection

Uploaded by

vellinemaxCopyright:

Available Formats

VISUAL INSPECTION PLATE REPORT

WELD FACE

Name: Dwi Agus Yuliyanto Signature: Test piece identification: plate sample 6I Face

Code/Specification used: WE.WI-PPNS Welding process: MMA/SMAW Joint type: Single V Butt Joint

Welding position : 2G Length and Thickness of plate: 300 x 10 mm Date: 15-September-2020

M

E A B

234 Arc Strikes

W=16

A

S

U Cap Undercut L= 32

R

E

F 25

R

O D=1 D=1,5 D=2

M 22 82 112

L=12 L=8 L=10 Spatter

T

H 134 L=2

I

S

D

A

T

U

M

E

D

G

E

Notes: Cap height : 4 mm Toe Blend : Poor

VISUAL INSPECTION PLATE REPORT

WELD ROOT

Name: Dwi Agus Yuliya Signature: Test piece identification: Plate Sample 6I Root

Code/Specification used: WE.WI-PPNS Welding process: MMA / SMAW Joint type: Single V Butt Joint

Welding position : 2G Length and Thickness of plate: 300 mm x 100 mm Date: 15- September-2020

M Arc strike

E

A

A 275 L=5 B

S W=5

U

R

E

43

F

Lack of root penetration Burn through Poor stop/start

R

O

M 85 170 250

L=5 L =5 L =5

T

H

I

S

L = 80 160 L= 4 230 L =3 280 L =3

D

A

Lack of root Lack of root Lack of root fusion

T Linear Misalignment

U

penetration fusion + poor stop/start

32

M

D=1 L=20

E

D 110 Mechanical

G W=18

damage

E

Notes: :Linear misalignment: 1 mm Toe blend: Poor

WELD INSPECTION REPORT/SENTENCE SHEET

PRINT FULL NAME Dwi Agus Yuliyanto

SPECIMEN NUMBER Sample 6I

Face Defects

EXTERNAL DEFECTS Defects Noted Code or Specification Reference

Defect Type Accumulative Maximum Section/ Accept/Reject

o

Total Allowance Table N

1 2 3 4 5

Reinforcement (Height) 4 mm H = 2 mm 1 Reject

Reinforcement (Appearance) - - - -

Incomplete filling - ≤ 15mm 6 Accept

Slag Inclusions - ≤ 50 mm 2 Accept

Length = 30 mm Length = max 50mm

Undercut 3 Reject

Depth = 4,5 mm Depth = max 1mm

Surface Porosity - Ø ≤ 1.5 mm 4 Accept

Cracks - Not permitted 5 Accept

Lack of fusion - < 15 mm 6 Accept

Arc strikes 512 mm2 Not permitted 7 Reject

Mechanical damage - D = 1.5mm 8 Accept

Misalignment - H = 1.5 mm 9 Accept

Spatter 2 mm Requires removal - Requires removal

Root Defects

Misalignment 1mm H = 1.5 mm 9 Accept

Penetration (Height) 2 mm H ≤ 3 mm 10 Accept

Lack of Root Penetration 9 mm Not permitted 11 Reject

Lack of Root Fusion 6 mm < 50 mm 12 Accept

Length = max 50mm

Root Concavity - 15 Accept

Depth = max 3mm

Root Undercut - Not permitted 3 Accept

Cracks - Not permitted 5 Accept

2

Mechanical damage 360 mm , D=1 mm D = 1.5mm 8 Accept

Porosity - Ø ≤ 1.5 mm 4 Accept

Burn-through 5 mm Not permitted 13 Reject

This * pipe/plate has been examined to the requirements of code/specification WE.WI-PPNS

and is * accepted/rejected accordingly.

Signature

......................................................... Date 15 September 2020

*Delete which is not applicable. Use the other side for any comments.

Comments:

+ Request Penetrant NDT testing to confirm crack and true length.

+ Large amount of spatter on weld face. Recommend cleaning, then re-inspection.

+++ Recommend arc strikes are ground flush prior to MPI testing for crack detection.

Seek advice on repair upon test results.

This completes the practical Butt Welded Plate Butt Joint Inspection Assessment.

You might also like

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathNo ratings yet

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Suli HartoNo ratings yet

- Visual Inspection Report Aruna Nusa Safarian 0716040057 2Document8 pagesVisual Inspection Report Aruna Nusa Safarian 0716040057 2romanosky11No ratings yet

- C and K SystemDocument3 pagesC and K SystemKamal AlkurdiNo ratings yet

- XLR Connectors: Part Number GuideDocument13 pagesXLR Connectors: Part Number Guidedouglas camposNo ratings yet

- Thick Film Network Resistor: Brief IntroductionDocument5 pagesThick Film Network Resistor: Brief IntroductionJACOB DE LA CRUZ CAUICHNo ratings yet

- 64 Pin Euro ConnectorsDocument2 pages64 Pin Euro ConnectorsAchyuth ShettigarNo ratings yet

- Touareg 4.2Document36 pagesTouareg 4.2zozo0424No ratings yet

- LCS 2Document1 pageLCS 2nutral powertechNo ratings yet

- Tourline PDFDocument9 pagesTourline PDF2022A Micha Michela FitrianaNo ratings yet

- Dial Indicators: SERIES 1 - Back Plunger TypeDocument1 pageDial Indicators: SERIES 1 - Back Plunger Typesomkiat kongprasiatNo ratings yet

- STD PinDocument1 pageSTD Pinshubham.yantrikNo ratings yet

- ASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Document2 pagesASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Lora BoydNo ratings yet

- For Samples Only: 110 105 15 ApproxDocument1 pageFor Samples Only: 110 105 15 ApproxrichardNo ratings yet

- CA Si LV en Industrial Transformers PCC ExtractDocument8 pagesCA Si LV en Industrial Transformers PCC ExtracttgghareebNo ratings yet

- Model Test 1Document1 pageModel Test 1Nirlesh KothariNo ratings yet

- 32 90 Fluidos EletroerosaoDocument1 page32 90 Fluidos EletroerosaoPaulo HenriqueNo ratings yet

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocument1 pageM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- Luz Piloto 30MMDocument1 pageLuz Piloto 30MMJerNo ratings yet

- PLC - Ctrinh (Ups)Document4 pagesPLC - Ctrinh (Ups)Trần Đức HoàngNo ratings yet

- CSWIP Visual Inspection PIPE REPORTDocument4 pagesCSWIP Visual Inspection PIPE REPORTNaga RajanNo ratings yet

- Bracket ObdDocument1 pageBracket ObdHarry laksanaNo ratings yet

- Varistor para Luminarias Cree 20d - 1-3003069Document16 pagesVaristor para Luminarias Cree 20d - 1-3003069Gabriel SanjurNo ratings yet

- R Series Ex D: Stainless SteelDocument6 pagesR Series Ex D: Stainless SteelTran DucNo ratings yet

- YC100-508-3P SpecDocument1 pageYC100-508-3P SpecNenad PavlovićNo ratings yet

- U30D05C - U30D60C: Add "-LF" Suffix To Part Number, See Page 4Document4 pagesU30D05C - U30D60C: Add "-LF" Suffix To Part Number, See Page 4quangNo ratings yet

- cataloge đầu khí kosa PDFDocument7 pagescataloge đầu khí kosa PDFNguyễn Hữu ĐồngNo ratings yet

- HE Series Spec Guide (SG-HE-08)Document8 pagesHE Series Spec Guide (SG-HE-08)Shouzab AbbasNo ratings yet

- Product Guide - Section XLRDocument33 pagesProduct Guide - Section XLRManny LeblancNo ratings yet

- MBRF2040CTDocument2 pagesMBRF2040CTvejiye7055No ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- NGK Resistor Covers Decoding EnglishDocument3 pagesNGK Resistor Covers Decoding EnglishKostiantyn UsenkoNo ratings yet

- Intake Kyn Toyota 1zrDocument2 pagesIntake Kyn Toyota 1zrALiito KNo ratings yet

- Cswip 31 Practical PDFDocument4 pagesCswip 31 Practical PDFJigar PrajapatiNo ratings yet

- World Low Voltages and PlugsDocument4 pagesWorld Low Voltages and Plugsmiha sredNo ratings yet

- 500 KVA DRAWING FINAL-Review RPDDocument9 pages500 KVA DRAWING FINAL-Review RPDRahmat HidayatNo ratings yet

- Electricals BoqDocument10 pagesElectricals BoqA M JNo ratings yet

- CSWIP Practical Plate AnswersDocument31 pagesCSWIP Practical Plate AnswersSha Zha100% (1)

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Nashaat DhyaaNo ratings yet

- MIL Style RV4: PrecisionDocument3 pagesMIL Style RV4: PrecisionRaul S. CotrinaNo ratings yet

- D10843570ADocument1 pageD10843570AGaurav VashishtNo ratings yet

- Small Parts Schematic SJ FSRDocument2 pagesSmall Parts Schematic SJ FSRalejibaNo ratings yet

- Her 1603Document3 pagesHer 1603gonthenkNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- ReleiDocument16 pagesReleistarostrugaNo ratings yet

- Coding KeyDocument2 pagesCoding KeyIgorTNo ratings yet

- Lenovo 720-15IKB - Wistron Bohol LB720LB721 16877-1Document105 pagesLenovo 720-15IKB - Wistron Bohol LB720LB721 16877-1Victor BlancoNo ratings yet

- AC10 AC60: Air Filter + Regulator + LubricatorDocument5 pagesAC10 AC60: Air Filter + Regulator + LubricatorElsonMilanNo ratings yet

- Gaugeable Tube Fittings and Adapter Fittings (MS-01-140 Rev - AE en-US Catalog)Document1 pageGaugeable Tube Fittings and Adapter Fittings (MS-01-140 Rev - AE en-US Catalog)Gabriel BatistaNo ratings yet

- Appendix 3 Example Report E9Document3 pagesAppendix 3 Example Report E9Laith SalmanNo ratings yet

- T Series PartsListDocument4 pagesT Series PartsListmohammad alhajNo ratings yet

- Limit Mount Plate T2Document1 pageLimit Mount Plate T2Himindra ChaaubeNo ratings yet

- Lecture 2Document12 pagesLecture 2Dr. Saad Saffah HresheeNo ratings yet

- Cambridge IGCSE (9-1) : PHYSICS 0972/41Document16 pagesCambridge IGCSE (9-1) : PHYSICS 0972/41dowanahamidNo ratings yet

- Engineering Data Screen Openings For Strainers: Purpose Filtration LevelDocument6 pagesEngineering Data Screen Openings For Strainers: Purpose Filtration LeveldschrisNo ratings yet

- Jawapan Soalan Pahang FizikDocument2 pagesJawapan Soalan Pahang Fizikyktay2No ratings yet

- Civil - Highway Lab Manual - 2018Document17 pagesCivil - Highway Lab Manual - 2018Altamash NadimallaNo ratings yet

- Q1-W5-D5-Separating Mixtures - DistillationDocument4 pagesQ1-W5-D5-Separating Mixtures - DistillationHeidi Dalyagan DulnagonNo ratings yet

- List & Properties of UK Strcutral Steel Shapes No Sheet DescriptionDocument65 pagesList & Properties of UK Strcutral Steel Shapes No Sheet DescriptionThắngg TrịnhhNo ratings yet

- Surveying Observation, Surveying, ObservationDocument63 pagesSurveying Observation, Surveying, Observationthanasekar665No ratings yet

- United States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Document43 pagesUnited States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Erin GokNo ratings yet

- Scaffold Development Using 3D Printing With A Starch-Bsed PolymerDocument8 pagesScaffold Development Using 3D Printing With A Starch-Bsed PolymerLucas BaruzoNo ratings yet

- LFA Live Fluid Analyzer PDFDocument5 pagesLFA Live Fluid Analyzer PDFdiegoNo ratings yet

- Black HoleDocument14 pagesBlack HoleSagarKasarlaNo ratings yet

- ET ZC 235 Manufacturing Processes: BITS PilaniDocument925 pagesET ZC 235 Manufacturing Processes: BITS PilaniSanjay PandiyanNo ratings yet

- Distillation SequencingDocument39 pagesDistillation SequencingSohail Aziz Ahmad MalikNo ratings yet

- Airbus A320 Hydraulic System Description: ArticleDocument2 pagesAirbus A320 Hydraulic System Description: ArticleWellington OliveiraNo ratings yet

- Impedance Control: Robotics 2Document16 pagesImpedance Control: Robotics 2Karen ImmanuelNo ratings yet

- Sample Sci Lab CalendarDocument1 pageSample Sci Lab CalendarclayivanNo ratings yet

- Polymer Compositions InjectionDocument14 pagesPolymer Compositions InjectionJessiNo ratings yet

- Bearing Pad 400 X 400 X 52 MM (Ss400 Yield 235 Mpa)Document3 pagesBearing Pad 400 X 400 X 52 MM (Ss400 Yield 235 Mpa)AlvinbriliantNo ratings yet

- Ebara Pum 80 SQPBDocument4 pagesEbara Pum 80 SQPBMichael RefhandoNo ratings yet

- DC Arc FurnaceDocument7 pagesDC Arc FurnaceManojlovic VasoNo ratings yet

- ElasticityDocument7 pagesElasticityMajeed KhanNo ratings yet

- A Block Flow DiagramDocument35 pagesA Block Flow DiagramJerry SimonNo ratings yet

- 18-0022 Elliot JA22Document33 pages18-0022 Elliot JA22basemNo ratings yet

- VCB$SF 6Document3 pagesVCB$SF 6karthikumarNo ratings yet

- ENGINEERING 3014 Engineering ChemistrySummerDocument2 pagesENGINEERING 3014 Engineering ChemistrySummerKevin HuangNo ratings yet

- Meeting 6 - Evaporation - English For THPDocument4 pagesMeeting 6 - Evaporation - English For THPAlvianNo ratings yet

- Week # 9 MR Chapter 7: - Tutorial #9Document30 pagesWeek # 9 MR Chapter 7: - Tutorial #9Gábor MátyásiNo ratings yet

- Fluid Flow PhenomenaDocument13 pagesFluid Flow PhenomenaRaven ShadeNo ratings yet

- Structural Steel DesignDocument32 pagesStructural Steel Designshaluka100% (1)

- Nptel Learning Courses Structural Health Monitoring of CompositesDocument305 pagesNptel Learning Courses Structural Health Monitoring of Compositesaurora borealissNo ratings yet