Professional Documents

Culture Documents

LECTURE NOTE 1 - Working Stress Design and Serciceability Requirement

LECTURE NOTE 1 - Working Stress Design and Serciceability Requirement

Uploaded by

Augosto FraceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LECTURE NOTE 1 - Working Stress Design and Serciceability Requirement

LECTURE NOTE 1 - Working Stress Design and Serciceability Requirement

Uploaded by

Augosto FraceCopyright:

Available Formats

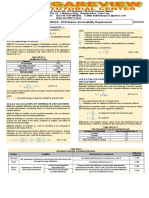

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

CODE PROVISIONS 429.6 FLEXURE

For investigation of stresses at service loads,

409.3.1 MINIMUM BEAM DEPTH straight-line theory (for flexure) shall be used

For non-prestresses beams not supporting or with the following assumptions.

attached to partitions or other construction

likely to be damaged by large deflection, 429.6.1 Strains vary linearly as the distance from

overall beam depth h shall satisfy the limits in the neutral axis, except for deep flexural

Table 409.3.1.1, unless the calculated deflection members with overall depth-span ratios greater

limits of Section 409.3.2 are satisfied than 2/5 for continuous spans and 4/5 for simple

spans, a nonlinear distribution of strain shall be

Table 409.3.1.1 considered.

Minimum Depth of Non-Prestressed Beams

Support Condition Minimum h 429.6.2 Stress-strain relationship of concrete is a

Simply Supported 𝐿/16 straight line under service loads within

One end continuous 𝐿/18.5 permissible service load stresses.

Both end continuous 𝐿/21

Cantilever 𝐿/18 429.6.3 In reinforced concrete members,

Expressions applicable for normal weight concrete resists no tension. 429.6.4 It shall be

concrete and 𝑓𝑦 = 420 MPa. For other cases, permitted to take the modular ratio 𝑛 = 𝐸𝑠/𝐸𝑐,

minimum h shall be modified in accordance as the nearest whole number (but NOT less than

with 409.3.1.1.1 through 409.3.1.1.3, as 6). Except for calculations for deflections, value

appropriate. of n for lightweight concrete shall be assumed

to be the same as for normal weight concrete

409.3.1.1.1 For 𝑓𝑦 other than 420 MPa, the of the same strength.

expression in Table 409.3.1 shall be multiplied by

(0.40 + fy /700). 429.6.5 In doubly reinforced flexural members,

409.3.1.1 For non-prestressed beams not an effective modular ratio of 2𝐸𝑠/𝐸𝑐 shall be

satisfying Section 409.3.1 and for prestressed used to transform compression reinforcement

beams immediate and time dependent for stress computations. Compressive stress in

deflections shall be calculated in accordance such reinforcement shall NOT exceed

with Section 424.2 and shall not exceed the permissible tensile stress.

limits in Section 424.2.2

419.2.2 MODULUS OF ELASTICITY

419.2.2.1 Modulus of elasticity 𝐸𝑐 for concrete

shall be permitted to be taken as

𝒘𝒄 𝟏.𝟓 𝟎. 𝟎𝟒𝟑√𝒇′𝒄 (𝑖𝑛 𝑀𝑃𝑎)

for values of 𝑤𝑐 between 1,440 and 2,560 kg/m³.

For normal weight concrete, 𝐸𝑐 shall be

permitted to be taken as

429.4 PERMISSIBLE SERVICE LOAD STRESSES 𝑬𝒄 = 𝟒, 𝟕𝟎𝟎√𝒇′𝒄 (𝑖𝑛 𝑀𝑃𝑎)

429.4.1 Stresses in concrete shall not exceed:

Flexure ------------------------------------------𝟎. 𝟒𝟓𝒇′𝒄 419.2.3 MODULUS OF RUPTURE OF CONCRETE

429.4.2 Tensile stress in reinforcement 𝑓𝑠 shall not 419.2.3.1 Modulus of rupture, fr, for concrete

exceed shall be calculated by:

For Flexural reinforcement -------------------𝟎. 𝟓𝟎𝒇𝒚 𝒇𝒓 = 𝟎. 𝟔𝟐𝝀√𝒇′𝒄 (419.2.3.1)

where the value of λ is in accordance with

Section 419.2.4 (Lightweight Concrete)

419.2.4 Lightweight Concrete 419.2.4.1 To

account for the properties of lightweight

ENGR. AUGOSTO D. FRACE, ME-CE 1

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

concrete, a modification factor λ is used as a 𝑰𝒄𝒓 ≤ 𝑰𝒆 ≤ 𝑰𝒈

𝟑

multiplier of √𝑓′𝑐 in all applicable provisions of 𝑴𝒄𝒓 𝑴𝒄𝒓 𝟑

𝑰𝒆 = ( ) 𝑰𝒈 + [𝟏 − ( ) ] 𝑰𝒄𝒓 (424.2.3.6𝑎)

this Code. 419.2.4.2 The value of λ shall be 𝑴𝒂 𝑴𝒂

based on the composition of the aggregate in where:

the concrete mixture in accordance with Table 𝐼𝑐𝑟 = Moment of inertia of cracked section

transformed to concrete.

419.2.4.2 or as permitted in Section 419.2.4.3. 𝐼𝑒 = Effective moment of inertia for computation

of deflection.

𝐼𝑔 = Moment of inertia of gross concrete section

about the centroidal axis, neglecting

reinforcement.

𝑀𝑐𝑟 = Cracking moment.

𝑀𝑎 = Maximum moment in member at stage

419.2.4.3 If the measured average splitting deflection is computed.

tensile strength of lightweight concrete, fct , is

used to calculate λ, laboratory test shall be

conducted in accordance with ASTM C330M to Cracking Moment, 𝑴𝒄𝒓 , is calculated by:

𝒇𝒓𝑰𝒈

establish the value of fct ,and the corresponding 𝑴𝒄𝒓 = (424.2.3.5𝑏)

𝒚𝒕

value of fcm and λ shall be calculated by:

𝒇𝒄𝒕 where:

𝝀= ≤ 𝟏. 𝟎 (419.2.4.3) 𝑦𝑡 = Distance from centroidal axis of gross

𝟎. 𝟓𝟔√𝒇𝒄𝒎

section, neglecting reinforcement.

The concrete mixture tested in order to

calculate λ shall be representative of that to be

424.2.3.6 For continuous one-way slabs and

used in the Work.

beams, Ie shall be permitted to be taken as the

where:

average of values obtained from Eq. 424.2.3.5a

𝑓𝑐𝑚 = measured average compressive strength

for the critical positive and negative moment

of concrete, MPa

sections.

424.2.3 CALCULATION OF IMMEDIATE

424.2.3.7 For prismatic one-way slabs and

DEFLECTIONS

beams, Ie shall be permitted to be taken as the

424.2.3.1 Immediate deflections shall be

value obtained from Eq. 424.2.3.5a at mid-span

calculated using methods or formulas for elastic

for simple and continuous spans, and at the

deformations, considering effects of cracking

support for cantilevers.

and reinforcement on member stiffness.

424.2.4 CALCULATION OF TIME-DEPENDENT

424.2.3.2 Effect of variation of cross-sectional

DEFLECTIONS

properties, such as haunches, shall be

424.2.4.1.1 Unless values from a more

considered when calculating deflections.

comprehensive analysis, additional

timedependent deflection resulting from creep

424.2.3.3 Deflections in two-way slab system

and shrinkage of flexural members shall be

shall be calculated taking into account size and

calculated as the product of the immediate

shape of the panel, conditions of support, and

deflection caused by the sustained load and

nature of restraints at the panel edges.

the factor 𝜆Δ .

𝝃

424.2.3.4 Modulus of elasticity, Ec, shall be 𝝀𝚫 = (424.2.4.1.1)

𝟏 + 𝟓𝟎𝝆′

permitted to be calculated in accordance with

where:

section 419.2.2.

𝜉 = Time-dependent factor for sustained load

𝜆∆ = Multiplier used for additional deflection due

424.2.3.5 For non-prestressed members,

to long-term effects

effective moment of inertia, Ie, shall be

calculated by Eq. 424.2.3.5a (show below)

424.2.4.1.2 In the equation above, 𝜌′ shall be

unless obtained by a more comprehensive

calculated at mid-span for simple and

analysis, but 𝐼𝑒 shall not be greater than 𝐼𝑔 .

ENGR. AUGOSTO D. FRACE, ME-CE 2

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

continuous spans, and at the support for 𝟏 𝟐

𝒃𝒙 = 𝒏𝑨𝒔 (𝒅 − 𝒙)

cantilevers. 𝟐

For midspan for simple and continuous span • Doubly reinforced beam (DRB):

𝑨′𝒔 𝟏 𝟐

𝝆′ = 𝒃𝒙 + (𝟐𝒏 − 𝟏)𝑨′𝒔 (𝒙 − 𝒅′) = 𝒏𝑨𝒔 (𝒅 − 𝒙)

𝒃𝒅 𝟐

For cantilever Cracked Section moment of inertia (𝑰𝒄𝒓 = 𝑰𝑵.𝑨. )

𝑨𝒔 • Singly reinforced

𝝆′ = 𝒃𝒙𝟑

𝒃𝒅 𝑰𝒄𝒓 = + 𝒏𝑨𝒔 (𝒅 − 𝒙)𝟐

424.2.4.1.3 In the equation above, values of the 𝟑

time dependent factor for sustained load, ξ, • Doubly reinforced

shall be in accordance with Table 424.2.4.1.3 𝒃𝒙𝟑

𝑰𝒄𝒓 = + (𝟐𝒏 − 𝟏)𝑨′ 𝒔 (𝒙 − 𝒅′ )𝟐 + 𝒏𝑨𝒔 (𝒅 − 𝒙)𝟐

(shown below) 𝟑

Actual stresses

• General flexure formula

𝑴𝒚

𝒇=

𝑰

• Concrete stress at extreme compression

fiber

𝑴𝒂 𝒙

FLEXURAL ANALYSIS (WSD) 𝒇𝒄 =

𝑰𝒄𝒓

• Tension steel

TRANSFORMED AREA METHOD 𝒇𝒔 𝑴𝒂 (𝒅 − 𝒙)

=

𝒏 𝑰𝒄𝒓

A. Uncracked Stage (𝒇𝒕 ≤ 𝒇𝒓 𝒐𝒓 𝑴𝒂 ≤ 𝑴𝒄𝒓 ) • Compression steel

Rectangular Section 𝒇′𝒔 𝑴𝒂 (𝒙 − 𝒅′)

=

𝟐𝒏 𝑰𝒄𝒓

FLEXURAL DESIGN (WSD)

𝒇 𝒓 𝑰𝒈

𝑴𝒄𝒓 =

𝒚𝒕

B. Cracked Stage (𝒇𝒕 > 𝒇𝒓 𝒐𝒓 𝑴𝒂 > 𝑴𝒄𝒓 )

Procedure

Transformed Area Method Step 1: Calculate the actual expected moment

Rectangular Section (𝑀𝑎 ) to be carried by the beam at service level

Step 2: Solve for the balanced moment

capacity

𝒅𝒇𝒄

𝒙𝒃𝒂𝒍 =

𝒇

𝒇𝒄 + 𝒔

𝒏

𝟏

𝑪𝒃𝒂𝒍 = 𝒇𝒄 (𝒃 ∙ 𝒙𝒃𝒂𝒍 )

𝟐

𝟏

𝑴𝒃𝒂𝒍 = 𝑪𝒃𝒂𝒍 (𝒅 − 𝒙𝒃𝒂𝒍 )

𝟑

• 𝑴𝒂 ≤ 𝑴𝒃𝒂𝒍 , 𝒅𝒆𝒔𝒊𝒈𝒏 𝒂𝒔 𝑺𝑹𝑩

• 𝑴𝒂 > 𝑴𝒃𝒂𝒍 , 𝒅𝒆𝒔𝒊𝒈𝒏 𝒂𝒔 𝑫𝑹𝑩

Step 3: Design as SRB (𝑴𝒂 ≤ 𝑴𝒃𝒂𝒍 )

Location of the neutral axis from extreme

compression fiber

• Singly reinforced beam (SRB):

ENGR. AUGOSTO D. FRACE, ME-CE 3

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

EXERCISE PROBLEMS

Problem 1:

A decorative beam with a tubular section is

simply supported on a span of 4.5 m. The tubular

section has an outside diameter of 600 mm and

an inside diameter of 300 mm. The allowable

cracking stress is 3.2 MPa.

a. Determine the cracking moment

b. In addition to the weight, determine the

Locate the neutral axis

concentrated load at midspan that the

𝒃𝒙𝟑 𝒃𝒙𝟐 (𝒅 − 𝒙) 𝒏𝑴𝒂 (𝒅 − 𝒙)

+ = beam can support.

𝟑 𝟐 𝒇𝒔

𝑴𝒂 c. If the 300 mm hollow core were replaced

𝑨𝒔 =

𝟏 by 300 mm square section, calculate the

𝒇𝒔 (𝒅 − 𝒙)

𝟑 cracking moment.

Step 4: Design as DRB (𝑴𝒂 > 𝑴𝒃𝒂𝒍 )

Problem 2:

Precast joist with typical section as shown are

cast using a concrete strength f’c=27.5 MPa.

The resulting tensile strength, ft=2.75 MPa. The

joist are to be simply supported on a span of 6m.

Unit weigth of concrete is 24 kN/m^3.

For Tension steel reinforcement (𝐴𝑠 )

i. Solve for 𝐴𝑠1 from balanced condition

𝑴𝒃𝒂𝒍

𝑨𝒔𝟏 =

𝟏

𝒇𝒔 (𝒅 − 𝒙𝒃𝒂𝒍 )

𝟑 a. Find the cracking moment

ii. Solve for 𝐴𝑠2 from excess of 𝑀𝑎 and 𝑀𝑏𝑎𝑙 b. How much additional uniform load can

(𝑴𝒂 − 𝑴𝒃𝒂𝒍 )

𝑨𝒔𝟐 = the joist carry if the cracking moment is

𝒇𝒔 (𝒅 − 𝒅′) 50 kN-m?

iii. Solve for total area of tension c. If the joist is reinforced with 3-25 mm

reinforcement diameter bars with their centroid at 435

𝑨𝒔 = 𝑨𝒔𝟏 + 𝑨𝒔𝟐

mm from the top, determine the

For Compression steel reinforcement (𝐴′𝑠 )

cracking moment. Use n=8.

i. Solve for 𝐴′𝑠 from balanced condition

and use 𝑀 = (𝑀𝑎 − 𝑀𝑏𝑎𝑙 )

Problem 3:

ii. If 𝑓′𝑠 ≥ 𝑓𝑠 , use 𝑓′𝑠 = 𝑓𝑠

Consider the T beam shown. The beam is simply

𝟐𝒏𝒇𝒄 (𝒙𝒃𝒂𝒍 − 𝒅′)

𝒇′𝒔 = supported at a span of 6m and with 2 m

𝒙𝒃𝒂𝒍

overhang. The beam carries a dead load of 15

𝟐𝒇𝒔 (𝒙𝒃𝒂𝒍 − 𝒅′)

𝒇′𝒔 = kN/m excluding the weight of the beam and a

𝒅 − 𝒙𝒃𝒂𝒍

uniform live load of 10 kN/m. Compressive

iii. Solve for 𝐴′𝑠

strength of concrete is 28 MPa and yield

𝟐𝒏(𝑴𝒂 − 𝑴𝒃𝒂𝒍 )

𝑨′𝒔 = strength of 420 MPa. Calculate the following:

𝒇′𝒔 (𝟐𝒏 − 𝟏)(𝒅 − 𝒅′)

a. Cracking moment

b. Critical moment of inertia

c. Compressive stress on concrete

d. Tensile stress on steel

e. Capacity ratio of concrete under

compressive stress

f. Section curvature at cracking

ENGR. AUGOSTO D. FRACE, ME-CE 4

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

load of 18 kN/m. Use a minimum with of 250 mm.

Use 20 mmФ with yield strength of 280 MPa. Use

f’c=21 MPa an use modular ratio n=9.

Sketch the section of the beam.

Problem 8:

It is desired to find the steel reinforcements at

the most critical section in bending of a beam

having a cross section of 400 mm by 600 mm (b

x h) with an effective cover of 85 mm for

reinforcements. F’c= 21 MPa, fs= 140 MPa, n=9.

Determine the required area of steel

Problem 4: reinforcement at the following condition.

A 6 m simply supported beam is reinforced with a) Balanced condition

3-20 mm Ф tension bars is loaded at third points b) If the beam carries a bending moment of

with 20 kN dead load and 12 kN live load. Use 150 kN-m.

f’c=28 MPa and fy=420 MPa. Use WSD, c) If the beam carries a bending moment of

determine the following: 220 kN-m.

a. Instantaneous deflection due to dead

load.

b. Instantaneous deflection due to dead SUPPLEMENTARY PROBLEMS

load and live load.

c. Initial deflection due to full live load Problem 1:

d. Long term deflection, assuming 50% of A reinforced concrete rectangular beam

live load is continuously applied for two having a width of 350 mm and a total depth of

years. 600 mm and effective depth of 530 mm is

reinforced with 4 − 28 mm∅ tension bars.

Problem 5: Material strength are fy = 420 MPa, f′c = 28 MPa,

A reinforced concrete beam has a width of 280 fr = 3.28 MPa and n = 8. Determine the stress in

mm and effective depth of 520 mm. It is concrete and steel caused by a bending

reinforced for tension only with 5-28 mm Ф bars. moment M = 60 kN − m.

f’c=21 MPa and fs=128 MPa. Assume n=9. Use

WSD. Problem 2:

a. Determine the location of the neutral axis A reinforced concrete beam having a width of

b. Calculate the compressive force on the 300 mm and an effective depth of 530 mm is

concrete. reinforced with 5 − 28 mm∅ tension bars.

c. Determine the moment capacity of the Material strength are fs = 128 MPa, f′c = 27 MPa,

beam. and n = 8. Determine the following using

working strength design:

Problem 6: a) Balanced moment capacity of the

A rectangular reinforced concrete beam beam

having a width of 200 mm and effective depth b) Moment capacity of the beam

of 500 mm is subjected to a service moment of

120 kN-m. The beam is reinforced with four 25 Problem 3:

mm Ф bars. Use modular ratio n=8. Use WSD. A rectangular concrete section is reinforced

a. Determine the location of the neutral with 3-25 mm ϕ bars in tension and has a width

axis. of 300 mm and a total depth of 600 mm and

b. Calculate the stress on the concrete effective depth of 540 mm. Use 𝑓′𝑐 = 27.6 𝑀𝑃𝑎

c. Determine the stress on the steel. and 𝑓𝑦 = 414 𝑀𝑃𝑎 and n=8. Calculate the

following:

Example 7: a) Cracking Moment

Design a section of a concrete beam b) Moment of inertia of the cracked section

reinforced for tension only. The beam is simply c) Moment capacity of the section

supported on a span of 7.5 m and carries a total

ENGR. AUGOSTO D. FRACE, ME-CE 5

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

Problem 4:

Consider the beam section shown. Material

strength is fs = 165 MPa, f′c = 27.6 MPa, and n = 8.

Determine the moment capacity of the beam

section.

Problem 5:

A 350mm × 600 mm concrete beam with simple

span of 8 m is design to carry a calculated dead

load of 10 kN/m including its own weight and

service live load of 15 kN/m. The beam is

reinforced with 4-25 mm ∅ bars with an effective

depth to tension bars of 350 mm. Of the total

live load, 20% is sustained in nature while 80 %

will be applied only intermittently over the life of

the structure. The beam will support non-

structural partitions of that would damage if

large deflections were to occur. Material

strengths are f'c = 21 MPa, fy = 345 MPa, and n =

9.

a) Calculate the maximum instantaneous

deflection for DL+LL.

b) Calculate the deflection assuming 20%

of the live load is continuously applied for

5 years.

c) Check the stiffness adequacy of the

beam.

Problem 6:

Determine the instantaneous deflection under

dead loads and live loads for the doubly

reinforced beam shown. The simply supported

beam is 6m long subjected to a uniform dead

load of 7.5 kN/m including its own weight and

live load of 10 kN/m in addition to a

concentrated load dead load of 30 kN at

midspan. Material strengths are fy = 345 MPa,

f′c = 25 MPa, and n = 8.

ENGR. AUGOSTO D. FRACE, ME-CE 6

You might also like

- Chapter 7Document5 pagesChapter 7Wilkenn TuazonNo ratings yet

- Chapter 4 PDFDocument5 pagesChapter 4 PDFtrishia arcillaNo ratings yet

- Beam Deflection NSCP 2015 1Document4 pagesBeam Deflection NSCP 2015 1Lester Neil Lomod100% (3)

- CAUSON Assignment 1MDocument5 pagesCAUSON Assignment 1MEmmanuel CausonNo ratings yet

- 2006 HCS Point Loads NapoliDocument8 pages2006 HCS Point Loads NapoliVálter LúcioNo ratings yet

- TR67 PDFDocument91 pagesTR67 PDFHemantha BalasuriyaNo ratings yet

- 1 Working Stress Design and Serviceability RequirementDocument5 pages1 Working Stress Design and Serviceability RequirementChristian Joseph R. GonzalesNo ratings yet

- REVIEW-MODULE 41-Nov2020-WSD-BeamsDocument3 pagesREVIEW-MODULE 41-Nov2020-WSD-BeamsMa Ella Mae LogronioNo ratings yet

- RCD Lecture Notes 1 Working Stress Design and Serviceability RequirementDocument4 pagesRCD Lecture Notes 1 Working Stress Design and Serviceability RequirementXzk MallaboNo ratings yet

- Working Stress Design and Serviceability RequirementDocument4 pagesWorking Stress Design and Serviceability RequirementSean Kent TagubaNo ratings yet

- Review MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteDocument2 pagesReview MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteJoseph Lanto100% (1)

- Review Module 41 RCD 1Document2 pagesReview Module 41 RCD 1Yang RhiaNo ratings yet

- Section 429 Alternate Design Method: Not MM B To MinimumDocument7 pagesSection 429 Alternate Design Method: Not MM B To Minimumtabsze heyNo ratings yet

- Review Module - Reinforced Concrete Design (Foundation)Document3 pagesReview Module - Reinforced Concrete Design (Foundation)Jessica Lymwell PunzalanNo ratings yet

- Paper No. 609Document15 pagesPaper No. 609ravi kumarNo ratings yet

- Review Module 45-RCD 5 - Part 1 & 2Document2 pagesReview Module 45-RCD 5 - Part 1 & 2Arlyn ConsumeNo ratings yet

- Ultimate Limit States Design: Article 41. Equilibrium Limit StateDocument35 pagesUltimate Limit States Design: Article 41. Equilibrium Limit StateAyad TalibNo ratings yet

- Kippap-Handout-SEC (40 RCD - Footings)Document10 pagesKippap-Handout-SEC (40 RCD - Footings)top1echolocoNo ratings yet

- RCD Gillesania WSDDocument22 pagesRCD Gillesania WSDMoises AddyNo ratings yet

- Toniolo-DiPrisco2017 Chapter CentredAxialForceDocument85 pagesToniolo-DiPrisco2017 Chapter CentredAxialForceÉnio Elias Gonçalves NtambalicaNo ratings yet

- CE135 - 2. Flexural Analysis of Concrete BeamsDocument48 pagesCE135 - 2. Flexural Analysis of Concrete BeamsApril ImNo ratings yet

- WSD Nov 2022Document2 pagesWSD Nov 2022twicetacsNo ratings yet

- BEAMPASKDocument49 pagesBEAMPASKNils Antoine FreundNo ratings yet

- Application of Capacity Spectrum Method Based On ATC 40 and BNBC 1993Document4 pagesApplication of Capacity Spectrum Method Based On ATC 40 and BNBC 1993designer STRNo ratings yet

- w"I/1I4 Ec: 408.6 Modulus of ElasticityDocument1 pagew"I/1I4 Ec: 408.6 Modulus of ElasticityAlskduiNo ratings yet

- 11 Ehe08 PDFDocument7 pages11 Ehe08 PDFDagoberto PereiraNo ratings yet

- Manual of Metal Bellows - 0441e S 56-77!2!04!10!20 - WebDocument11 pagesManual of Metal Bellows - 0441e S 56-77!2!04!10!20 - Webadfafad gfadfNo ratings yet

- Allowable Stress Design of Concrete MasonryDocument6 pagesAllowable Stress Design of Concrete Masonrying_fernandogalvez2015No ratings yet

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDocument16 pagesT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019No ratings yet

- 400x400 Pile Capacity With 6T25 & 12mm LinkDocument9 pages400x400 Pile Capacity With 6T25 & 12mm LinkChan Kin CheungNo ratings yet

- Review Module 44 - RC ONE-WAY SLAB (USD)Document2 pagesReview Module 44 - RC ONE-WAY SLAB (USD)Hannah BelleNo ratings yet

- Code Commentary: Factored Torsion Factored TorsionDocument5 pagesCode Commentary: Factored Torsion Factored TorsionMin KhantNo ratings yet

- EC2-Shear and TorsionDocument9 pagesEC2-Shear and TorsionDonald HamiltonNo ratings yet

- Chapter 6 - Serviceability PDFDocument45 pagesChapter 6 - Serviceability PDFJhe TaguinesNo ratings yet

- Chapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)Document3 pagesChapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)perdhana2000No ratings yet

- RM 27 - Reinforced Concrete Design 1 WSD-Deflection Part 01Document1 pageRM 27 - Reinforced Concrete Design 1 WSD-Deflection Part 01Gayle A LagosNo ratings yet

- Study On Behaviour of Composite Sleepers: Rajendran R, Tensing DDocument5 pagesStudy On Behaviour of Composite Sleepers: Rajendran R, Tensing DFarooq ManiyarNo ratings yet

- Design of Singly Reinforced BeamDocument4 pagesDesign of Singly Reinforced BeamLouise DiazNo ratings yet

- Chapter 12 PDFDocument17 pagesChapter 12 PDFAdolfo ElizondoNo ratings yet

- Lesson 8 Shear or Diagonal Tension in RC BeamsDocument8 pagesLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioNo ratings yet

- BS5400 Part 4 Training Course - TE EpsomDocument19 pagesBS5400 Part 4 Training Course - TE EpsomjologscresenciaNo ratings yet

- CE Board Nov 2020 - RCD - Set 13Document4 pagesCE Board Nov 2020 - RCD - Set 13Dale MalazzabNo ratings yet

- Ncma Tek: Allowable Stress Design of Concrete Masonry TEK 14-7ADocument6 pagesNcma Tek: Allowable Stress Design of Concrete Masonry TEK 14-7AEmad KhanNo ratings yet

- CE Board Nov 2020 - RCD - Set 8 and 9Document6 pagesCE Board Nov 2020 - RCD - Set 8 and 9Dale MalazzabNo ratings yet

- Chapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 EdDocument5 pagesChapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 Edv pavanNo ratings yet

- Comparison of de Ection Calculations and Span-To-Depth Ratios in BS 8110 and Eurocode 2Document13 pagesComparison of de Ection Calculations and Span-To-Depth Ratios in BS 8110 and Eurocode 2tsuiNo ratings yet

- Shear and Diagonal Tension: GeneralDocument10 pagesShear and Diagonal Tension: GeneralRegine Ignacio SobremonteNo ratings yet

- R2 - Design Formulae For Bending (2014!08!01)Document44 pagesR2 - Design Formulae For Bending (2014!08!01)Abhishek KumarNo ratings yet

- Comparison of de Ection Calculations and Span-To-Depth Ratios in BS 8110 and Eurocode 2Document13 pagesComparison of de Ection Calculations and Span-To-Depth Ratios in BS 8110 and Eurocode 2O SNo ratings yet

- Concrete 14 (FDN 1) Nov 2020Document2 pagesConcrete 14 (FDN 1) Nov 2020Dale MalazzabNo ratings yet

- 1984 WycheDocument15 pages1984 WychetomNo ratings yet

- CM 3.5 LRFD Culvert Flexure DesignDocument21 pagesCM 3.5 LRFD Culvert Flexure DesignNo WoNo ratings yet

- Continuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFDocument35 pagesContinuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFtimNo ratings yet

- Rationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsDocument20 pagesRationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsmirzaNo ratings yet

- Reinforced Concrete DesignDocument8 pagesReinforced Concrete DesignKriza-Ann BrionesNo ratings yet

- Buckling Resistance of Uniform Members in BendingDocument3 pagesBuckling Resistance of Uniform Members in Bendinganuj SinghNo ratings yet

- Review Module 31 - RCD 5 - Part 1Document2 pagesReview Module 31 - RCD 5 - Part 1Kereen Pearl PascuaNo ratings yet

- Concrete Prestressing NotesDocument23 pagesConcrete Prestressing NotesMohammad Iqbal HossainNo ratings yet

- Hydraulics Lecture Notes 4 - Analysis of Gravity DamsDocument3 pagesHydraulics Lecture Notes 4 - Analysis of Gravity DamsAugosto FraceNo ratings yet

- Hydraulics Lecture Notes 3 - Hydrostatic Force On Curve SurfaceDocument2 pagesHydraulics Lecture Notes 3 - Hydrostatic Force On Curve SurfaceAugosto FraceNo ratings yet

- Hydraulics Lecture Notes 5 - Archimedes Principle of BouyancyDocument1 pageHydraulics Lecture Notes 5 - Archimedes Principle of BouyancyAugosto FraceNo ratings yet

- Hydraulics Lecture Notes 2 - Hydrostatic Force On Plane SurfacesDocument2 pagesHydraulics Lecture Notes 2 - Hydrostatic Force On Plane SurfacesAugosto FraceNo ratings yet

- Hydraulics Lecture Notes 1 - Problem ExercisesDocument2 pagesHydraulics Lecture Notes 1 - Problem ExercisesAugosto FraceNo ratings yet

- Hydraulics Lecture Notes 6 - Stability of Floating BodiesDocument2 pagesHydraulics Lecture Notes 6 - Stability of Floating BodiesAugosto FraceNo ratings yet

- RCD Lecture Note 4 - USD of Non-Rectangular Beams PDFDocument2 pagesRCD Lecture Note 4 - USD of Non-Rectangular Beams PDFAugosto FraceNo ratings yet

- RCD 1 - Structural Elements and Loads PDFDocument9 pagesRCD 1 - Structural Elements and Loads PDFAugosto FraceNo ratings yet

- RCD 2 - NSCP 2015 Load Provisions and Load Combinations PDFDocument5 pagesRCD 2 - NSCP 2015 Load Provisions and Load Combinations PDFAugosto FraceNo ratings yet

- RCD Lecture Note 8 - Eccentrically Loaded Columns PDFDocument2 pagesRCD Lecture Note 8 - Eccentrically Loaded Columns PDFAugosto FraceNo ratings yet

- RCD Lecture Note 3 - USD of Doubly Reinforced Beams PDFDocument3 pagesRCD Lecture Note 3 - USD of Doubly Reinforced Beams PDFAugosto FraceNo ratings yet

- Appendix ADocument42 pagesAppendix Ayliu8877100% (1)

- Zamac-5 Is ZDC-1Document1 pageZamac-5 Is ZDC-1atul sachanNo ratings yet

- GG WreDocument557 pagesGG WreSuvendu ParidaNo ratings yet

- Methodology CD Work 107-108Document2 pagesMethodology CD Work 107-108DeepakNo ratings yet

- Fig 257-StructuralTeeSlideAssemblyDocument4 pagesFig 257-StructuralTeeSlideAssemblymcohen LCINo ratings yet

- Ground FloorsDocument4 pagesGround FloorsfranbourkeNo ratings yet

- LRPS-3000 TDSDocument2 pagesLRPS-3000 TDSRuwan Sampath WickramathilakaNo ratings yet

- Spillwaysfinalppt 180319085104Document37 pagesSpillwaysfinalppt 180319085104Ann Nazmun SakibNo ratings yet

- Table 7-3 UPC DFUDocument4 pagesTable 7-3 UPC DFUAhmed OsmanNo ratings yet

- Application & Technical Manual 02 Structural SteelDocument65 pagesApplication & Technical Manual 02 Structural SteelTian NgNo ratings yet

- 7 15 Sentrina Alaminos Cost ControlDocument61 pages7 15 Sentrina Alaminos Cost ControlQueenie Perez100% (1)

- Valve Pit (2.5X2.5)Document8 pagesValve Pit (2.5X2.5)rachanaNo ratings yet

- Collapse of The Quebec Bridge 1907Document9 pagesCollapse of The Quebec Bridge 1907BanooNo ratings yet

- Ternate Hospital 1st Partial BillingDocument4 pagesTernate Hospital 1st Partial Billingeduard bulanonNo ratings yet

- Staad BasicsDocument17 pagesStaad BasicsCindy SisonNo ratings yet

- LYSAGHT Powerdek Manual (2003) PDFDocument40 pagesLYSAGHT Powerdek Manual (2003) PDFlim kang hai100% (1)

- Elements of Railway TracksDocument8 pagesElements of Railway TracksKhalid Yousaf100% (2)

- Smith, P. R., Jardine, R. J., & Hight, D. W. (1992) - The Yielding of Bothkennar Clay.Document18 pagesSmith, P. R., Jardine, R. J., & Hight, D. W. (1992) - The Yielding of Bothkennar Clay.Daniel Felipe Rodriguez RamirezNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- CMT Therese Cadungog Number 1.Document4 pagesCMT Therese Cadungog Number 1.Therese Marie CadungogNo ratings yet

- 12 PLAXISBulletinDocument24 pages12 PLAXISBulletinMark ChanNo ratings yet

- Bubble Deck Slab: November 2018Document40 pagesBubble Deck Slab: November 2018Kiran GowdaNo ratings yet

- Subsection ZDocument313 pagesSubsection Zsafeer ahmadNo ratings yet

- Structural Specification - Titus.03Document3 pagesStructural Specification - Titus.03Davie BancoroNo ratings yet

- Assignment 1 - Unit 1Document2 pagesAssignment 1 - Unit 1Kiran Babu100% (1)

- Design Standard: ASME VIII / API 520: Design of Safety ValvesDocument27 pagesDesign Standard: ASME VIII / API 520: Design of Safety ValvesMoe MozhganNo ratings yet

- Revision Test - II: March 2019 Reg. No.Document2 pagesRevision Test - II: March 2019 Reg. No.Venkatram PrabhuNo ratings yet

- J Polymertesting 2008 09 006 PDFDocument8 pagesJ Polymertesting 2008 09 006 PDFShovon HalderNo ratings yet