Professional Documents

Culture Documents

Selection of VSD

Selection of VSD

Uploaded by

Mohamed Mostafa0 ratings0% found this document useful (0 votes)

3 views14 pagesSELECTION OF VSD

Original Title

(3) SELECTION OF VSD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSELECTION OF VSD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views14 pagesSelection of VSD

Selection of VSD

Uploaded by

Mohamed MostafaSELECTION OF VSD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 14

SELECTION OF VSD

SELECTION OF VSD

Before selecting a VSD, pump and motor

should be sized.

SELECTION OF VSD

VSDs are rated in terms of KVA (Kilo-Volt-

Ampere).

So we have to calculate KVA to be supplied.

We need to look at only the highest

frequency because machine operates mostly

at that point .

SELECTION OF VSD

The motor is 300 Hp, 2267V and 94A at

50 Hz.

What will be the rated KVA at 60 Hz ?

SELECTION OF VSD

Motor volts at 60 Hz :

2267 * (60/50) = 2720 V

What about Current at 60 Hz ?

SELECTION OF VSD

Current remains SAME even if the

frequency changes.

KVA of Motor at 60 Hz will be :

(2720 * 94 * 1.732) / 1000 = 442 KVA

So VSD’s KVA is 442 ?

SELECTION OF VSD

NO !

The voltage drop in cable has to be considered.

Suppose cable is 6000m long and drop is

21v/1000m

So total drop for 6000m = 21 * 6 = 126v

This voltage has to added with motor voltage.

Now motor voltage is 2720 + 126 = 2846v

SELECTION OF VSD

The SURFACE VOLTAGE = 2846 v

The VSD should supply 2846v to motor :

KVA = (2846 * 94 * 1.732) / 1000 = 463 kva

From table, 518 is near to 463 KVA.

What about 518 KVA Electro speed drive ?

Can we use it ?

SELECTION OF VSD

We can’t.

Because the VSDs output to motor is 2846 V

at 60 Hz. The problem is VSDs maximum

output voltage is 480V.

So a STEP UP Transformer is required

between VSD and MOTOR.

SELECTION OF VSD

No equipment in the world is 100% efficient.

Transformer is not 100% efficient.

So 2 - 4 % of transformer losses has to be

included in VSDs KVA demand.

Now VSDs KVA = 463 + 4% (463) = 481 kva.

Is it correct KVA of VSD ?

SELECTION OF VSD

The rating of VSD is based on output of VSD.

It isn’t 100% efficient.

Suppose it is 98% efficient, 490 KVA has to

be the input and we will get 481 KVA output.

So we have to look into the table to get VSD

rating preferably more than or nearer to 481

KVA.

KVA = (Drive Rated Input Voltage/1000)

(Rated output Amps) (1.732)

2250-VT KVA = .48012(313) (1.732) = 260

SELECTION OF VSD

VSD selection procedure in short :

1) First select a pump .

2) Select the motor based on BHP.

3) Calculate the surface voltage.

4) Determine the total KVA including cable &

X’former losses.

5) Select the required VSD based on KVA.

THE END

You might also like

- Acidizing ESP With HCL AcidDocument2 pagesAcidizing ESP With HCL AcidMohamed MostafaNo ratings yet

- 250 To 5000 Watts PWM DC - AC 220V Power InverterDocument14 pages250 To 5000 Watts PWM DC - AC 220V Power InverterSerge Alain Koffi67% (3)

- Drive Sizing KVADocument4 pagesDrive Sizing KVAerickelsafan0% (1)

- Sizing Transformers With Large Motor LoadsDocument6 pagesSizing Transformers With Large Motor LoadsRajendra Prasad Shukla50% (2)

- Motor Operated Potentiometer: 82436 (Rev. G)Document4 pagesMotor Operated Potentiometer: 82436 (Rev. G)erhan erenNo ratings yet

- 2d Driver 220w Ds-Eug-240sxxxdv - Rev.eDocument14 pages2d Driver 220w Ds-Eug-240sxxxdv - Rev.eMonicaBaqueNo ratings yet

- Variable Speed Multi-Turn Actuators: For Sophisticated Modulating and Open-Close Operation in Industrial Valve AutomationDocument4 pagesVariable Speed Multi-Turn Actuators: For Sophisticated Modulating and Open-Close Operation in Industrial Valve AutomationPravin KohaleNo ratings yet

- DECS15Document1 pageDECS15Ramakrishnan AlagarsamyNo ratings yet

- Ficha Técnica InversorDocument3 pagesFicha Técnica InversorRodrigo MorenoNo ratings yet

- Datasheet EC3A E SeriesDocument2 pagesDatasheet EC3A E SeriesmehrdadgeminiNo ratings yet

- NEC CalculationDocument6 pagesNEC CalculationCatrina FedericoNo ratings yet

- Growatt SPF 6000 DVMDocument2 pagesGrowatt SPF 6000 DVMRaphael JimenezNo ratings yet

- NEC Design Calculation (Commercial Building and Motor)Document10 pagesNEC Design Calculation (Commercial Building and Motor)ruel delacruzNo ratings yet

- Huayu MicroinversorDocument4 pagesHuayu MicroinversorEdgar MartinezNo ratings yet

- MicroinverterDocument4 pagesMicroinvertersukirajNo ratings yet

- Kollmorgen Next Step Microstepping Drive SpecsheetDocument1 pageKollmorgen Next Step Microstepping Drive SpecsheetElectromateNo ratings yet

- Assun Motor Catalogue-2020Document137 pagesAssun Motor Catalogue-2020MiguelNo ratings yet

- ValereVrectifierDataSheet0404 Hoja Tec V2500Document8 pagesValereVrectifierDataSheet0404 Hoja Tec V2500Carlos SalazarNo ratings yet

- Abigail AnneDocument18 pagesAbigail AnneMaan BarreraNo ratings yet

- 2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsDocument2 pages2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsmachevallieNo ratings yet

- Ubiquiti POE-48-24W-G Data SheetDocument6 pagesUbiquiti POE-48-24W-G Data SheetJMAC SupplyNo ratings yet

- 3BSE054914 en E AC 800M and S800 IO - Power Supplies & VotersDocument4 pages3BSE054914 en E AC 800M and S800 IO - Power Supplies & VotersCarlos Alberto SouzaNo ratings yet

- Instruction Manual Codes 273S.A/3-/4 - /5: Technical CharacteristicsDocument4 pagesInstruction Manual Codes 273S.A/3-/4 - /5: Technical Characteristicsamskroud brahimNo ratings yet

- 6.6 KW High Power Density Bi-Directional On-Board Charger: Powering More, Consuming LessDocument4 pages6.6 KW High Power Density Bi-Directional On-Board Charger: Powering More, Consuming Lessn tanevarNo ratings yet

- Max8770gtl 1178390Document48 pagesMax8770gtl 1178390ruben riveraNo ratings yet

- High-Output-Drive, 10Mhz, 10V/Μs, Rail-To-Rail I/O Op Amps With Shutdown In Sc70Document18 pagesHigh-Output-Drive, 10Mhz, 10V/Μs, Rail-To-Rail I/O Op Amps With Shutdown In Sc70Hugo AcuñaNo ratings yet

- Autonics SPB DatasheetDocument5 pagesAutonics SPB DatasheetWahyu Nur Dwi Cahyo HaryonoNo ratings yet

- Brake Res CalcDocument4 pagesBrake Res CalcDwiMaryantoNo ratings yet

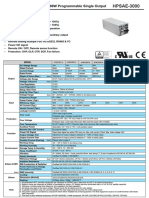

- Hpsae 30000 24Document6 pagesHpsae 30000 24Sina MehrabafiNo ratings yet

- Speed Control MotorDocument32 pagesSpeed Control MotorMASOUD0% (1)

- Power Factor: Basics and Benefits of ImprovementDocument11 pagesPower Factor: Basics and Benefits of Improvementkamaal100% (1)

- IP2000-21 (MUC) FichaTecnicaDocument2 pagesIP2000-21 (MUC) FichaTecnicaa19070017No ratings yet

- Qa11 075 18Document2 pagesQa11 075 18bruno buinNo ratings yet

- SOLAR POWER INVERTER - 1KW-6KW: User'S ManualDocument19 pagesSOLAR POWER INVERTER - 1KW-6KW: User'S ManualPMV DeptNo ratings yet

- Etc Ahe2815sf-MstrDocument11 pagesEtc Ahe2815sf-MstrBaCresNo ratings yet

- S8VK-C DataSheet en 201303 T058-E1-01Document16 pagesS8VK-C DataSheet en 201303 T058-E1-01Raphael Paulino BertiNo ratings yet

- Basler AVR AVC63-12Document4 pagesBasler AVR AVC63-12Dario GuzmanNo ratings yet

- MOSO Driver 24V 150WDocument9 pagesMOSO Driver 24V 150WMuhammad SholehNo ratings yet

- Driver Elcom Easy 600Document31 pagesDriver Elcom Easy 600Diego DiegoNo ratings yet

- 2U Rack Mount Inverter 3kVA: YK-PSW3KVA Series Pure Sine Wave InverterDocument2 pages2U Rack Mount Inverter 3kVA: YK-PSW3KVA Series Pure Sine Wave InverterDr.Ahmed GhareebNo ratings yet

- YK PSW3kVA 2U Rack Mount Inverter 3kVA Datasheet v1.6Document2 pagesYK PSW3kVA 2U Rack Mount Inverter 3kVA Datasheet v1.6Dr.Ahmed GhareebNo ratings yet

- Conext SW Inverter Charger SW 4024 120 Et 240 - Fiche TechniqueDocument2 pagesConext SW Inverter Charger SW 4024 120 Et 240 - Fiche TechniqueGhislain ClicheNo ratings yet

- Growatt 10kva 12kva Data SheetDocument2 pagesGrowatt 10kva 12kva Data SheetJohn JohnstoneNo ratings yet

- Inversor Solar SchneiderDocument2 pagesInversor Solar SchneiderEfrain VernazaNo ratings yet

- Transformer Selection GuideDocument1 pageTransformer Selection GuidebmshivakumarNo ratings yet

- Reflected WaveDocument2 pagesReflected WaveMat MaxNo ratings yet

- Kasvar: User ManualDocument31 pagesKasvar: User ManualKen LeeNo ratings yet

- Se Solaredge Home Wave Inverter Single Phase With Setapp Datasheet NamDocument4 pagesSe Solaredge Home Wave Inverter Single Phase With Setapp Datasheet Namdhester1988No ratings yet

- How To Calculate The Rating of Single PhaseDocument4 pagesHow To Calculate The Rating of Single PhaseacademicNo ratings yet

- SPF 4000T-12000T DVM DatasheetDocument2 pagesSPF 4000T-12000T DVM DatasheetFrancescoNo ratings yet

- 1606 sr008 - en e - 1606 XLS480EDocument23 pages1606 sr008 - en e - 1606 XLS480EJose Luis EduardoNo ratings yet

- Lecture 2 DC DC Chopper StartingDocument40 pagesLecture 2 DC DC Chopper StartingAhmed MahmoudNo ratings yet

- Ieee Mke 1 2020Document61 pagesIeee Mke 1 2020BokeBoke GyiNo ratings yet

- Thayer DC SCR Motor Drive BrochureDocument1 pageThayer DC SCR Motor Drive BrochurebnzelectricianshopNo ratings yet

- Dongan Industrial Control PDFDocument39 pagesDongan Industrial Control PDFElmar Syvill UcatNo ratings yet

- T-5-1 (Voltage Level & Calculation)Document15 pagesT-5-1 (Voltage Level & Calculation)shawon_darkNo ratings yet

- +-12 Volt DC Regulated SupplyDocument4 pages+-12 Volt DC Regulated SupplyAakash SharmaNo ratings yet

- TPC PWF-150-XSDocument4 pagesTPC PWF-150-XStoppowerNo ratings yet

- 7 DC DC SeriesDocument1 page7 DC DC SeriesKirankumar BoddalaNo ratings yet

- User Manual - Charger v1.1 - 20220503 - HESDocument19 pagesUser Manual - Charger v1.1 - 20220503 - HESmiguelolmedo220796No ratings yet

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- EXT-220507 XSIZE Case Study 3 - v04Document2 pagesEXT-220507 XSIZE Case Study 3 - v04Mohamed MostafaNo ratings yet

- 192177-MS Induction Versus Permanent Magnet Motors For ESP ApplicationsDocument15 pages192177-MS Induction Versus Permanent Magnet Motors For ESP ApplicationsMohamed MostafaNo ratings yet

- Torque Setting CriteriaDocument13 pagesTorque Setting CriteriaMohamed MostafaNo ratings yet

- Breifing & De-Briefing 1Document7 pagesBreifing & De-Briefing 1Mohamed MostafaNo ratings yet

- Fea&func1 - ComponentsFSDocument55 pagesFea&func1 - ComponentsFSMohamed MostafaNo ratings yet

- Esp Case StudyDocument81 pagesEsp Case StudyMohamed MostafaNo ratings yet

- (9b) GCS - Troubleshooting Power SemiconductorsDocument4 pages(9b) GCS - Troubleshooting Power SemiconductorsMohamed MostafaNo ratings yet

- Tooling Catalog 30SEP2021Document12 pagesTooling Catalog 30SEP2021Mohamed MostafaNo ratings yet

- SPE171338Document12 pagesSPE171338Mohamed MostafaNo ratings yet

- How A Well Flows - George KingDocument34 pagesHow A Well Flows - George KingMohamed MostafaNo ratings yet

- Power and Control FusesDocument44 pagesPower and Control FusesMohamed MostafaNo ratings yet

- Otc-31839-Ms Understanding ESP Performance Under High Viscous Applications and Emulsion ProductionDocument31 pagesOtc-31839-Ms Understanding ESP Performance Under High Viscous Applications and Emulsion ProductionMohamed MostafaNo ratings yet

- RV 11429 2022 04 24 Non License - SpecificDocument1 pageRV 11429 2022 04 24 Non License - SpecificMohamed MostafaNo ratings yet

- SPE-199091-MS, Electric Submersible Pump Troubleshooting Guide, An Effective Way To Improve System Performance and Reduce Avoidable System FailuesDocument18 pagesSPE-199091-MS, Electric Submersible Pump Troubleshooting Guide, An Effective Way To Improve System Performance and Reduce Avoidable System FailuesMohamed MostafaNo ratings yet

- Basics of Electricity WorkDocument16 pagesBasics of Electricity WorkMohamed MostafaNo ratings yet

- NLS-OPS-FS-PR-13 - Surface Panel NSP-04B - Rev.1.2Document65 pagesNLS-OPS-FS-PR-13 - Surface Panel NSP-04B - Rev.1.2Mohamed MostafaNo ratings yet

- Zenith Surface Choke SpecDocument1 pageZenith Surface Choke SpecMohamed MostafaNo ratings yet

- Tapered-Pump CHDocument1 pageTapered-Pump CHMohamed MostafaNo ratings yet