Professional Documents

Culture Documents

Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record Activity

Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record Activity

Uploaded by

muradOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record Activity

Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record Activity

Uploaded by

muradCopyright:

Available Formats

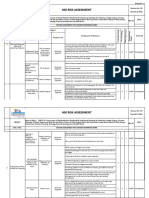

Document Reference

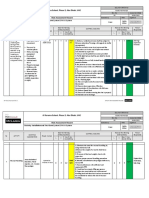

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

1

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

2

1

2 Manual Handling 1 Improper Operatives Med 1. Work briefing must be conduct before Low Supervisor,

Manual Handling involved in work 3 4 12 starting the activity. 1 4 4 Foreman,

technique 2. Eliminate the need for manual handling by Site Eng.

2 Wrong Posture using mechanical aid.

3 Poor visibility 3. Operatives must be trained for safe manual

4 Lack of access & handling

egress 4. If unsure of the load weight, check with

5 Back aches supervisor.

6 Slippery surfaces 5. Ensure proper manual handling procedure

6. Ensure adherence with sufficient and

appropriate PPE.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

3

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

4

7. Limit load carrying to 20kg per person

8. Supervisor must make sure while manual

handling loads individual task and

environment to be considered to reduce the

risk of manual handling.

9. Manual Handling assessment will be carried

by SAF 68

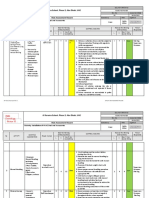

3 Material storing 1 Loose & Operatives 3 4 12 Med 1. Ensure accesses are kept clear at all times. 1 4 4 Low Supervisor,

unsecured Staff/storekeeper 2. Housekeeping to be carried out regularly Foreman,

material throughout the day when required Site Eng.

2 smoking at 3. Supervisor to ensure operatives are stacking

storage area material neatly and stacks are stable and in a

3 Incorrect storage safe condition

&improper 4. Provide adequate lighting especially during

materials stacking night hours

4 Fire 5. Appropriate space is allowed around storage

5 Slip, Trip & Fall areas for employees to move around safely

without the risk being trapped between

stacked materials.

6. No smoking signage must be displayed in

storage area and strictly to be followed

smoking policy

7. Fire extinguisher must be available in storage

area in fore point.

8. Emergency number must display in storage

area

9. Fragile materials must be stored in a safe

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

5

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

6

manner with caution signage.

.

4 Installation of Operatives 3 4 12 Med 1) Ensure all plugs, handles tap, and other 1 4 4 Low Site

Sanitary wares item a) Injury from slips involved accessories are correctly fitted to sanitary engineer

like Wall hang toilet, trips and falls. Supervisor

Console Lavatory, ware.

b) Injury falling 2) Test for correct operation including Foreman

Kitchen sink and

from step ladders

hand dryers flushing of toilet and emptying of water

c) Injury from

manual handling through plugs and overflows.

3) Visually inspect pipe work and joints for

leaks and damage.

4) Ensure the area to be dismantled and exit

points are clear of obstruction and that safe

access and egress is maintained.

5) Locate and isolate all water supplies to

the Toilet.

6) Locate and isolate electrical supply to the

Toilet.

7)Area will be kept tidy to minimize trip

hazards.

8) Ensure all operatives are experienced

kitchen and bathroom fitters.

9) Rounded sides, with no sharp edges,

prevent the risk of cuts. The sleek,

tamperproof designs provide additional

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

7

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

8

safety.

10. PPE in use

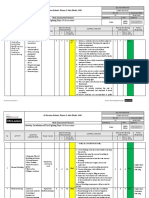

5 Use of Ladder Falling from height Operatives/ 3 4 12 Medi Ladder is not to use daily basis but in certain 1 4 4 Low Site Engr

Staff/ um cases where there is very narrow place and Sup

Working on even podium ladder not possible to fix in that Foreman

Uneven ground cases Ladder can use if permission granted from

McLaren Safety

Falling objects 1) Only light work, off short duration and work in

which the operative can maintain secure hand

and foot hold can be undertaken form a ladder

2) Never try to overreach with any ladders

3) Check the ladder is of suitable quality for

industrial use and is in good condition

4) Maintain a minimum of 3 points of contact

with stepladders at all times (feet/thighs/hands)

If possible avoid the use of stepladders at a

working height of 2 meters and more.

5) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the

step ladder is orientated to provide maximum

stability.

6) Stepladders/ladders has to be used on leveled

ground/firm base

7) Ensure that during using ladder from the top 2

steps is blocked to avoid climb on that.

8) The ladder securely fixed to prevent slipping

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

9

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

10

outwards or sideways or securely footed at all

times.

9) Person must hold the ladder while another

operative working on it

10) Do not carry any materials in one hand while

climbing or getting down from ladder

11) Ensure the area under the ladder is

barricaded especially if it is being used in a public

area.

12) Ensure the ladder is electrical insulated

podium type if working in live services

6 Use of power Damaged Operatives and 3 4 12 Medi 1. All portable electrical equipment must be 1 4 4 Low Supervisor

tools such as Drill Sockets & cable staff um PAT tested and color coded. Make sure the Foreman

machine/Grinder insulation. test dates are visible on the equipment. Site Eng.

Electrocution 2. Ensure all disk shall be appropriate and

Electric shock expiry date is over.

Short circuit & 3. Ensure all power tools are in good condition

Burns and appropriately maintained

Trip/Fall 4. Damaged industrial sockets and power

Noise cables must be removed.

Hearing loss 5. Ensure the electrical cable is not damaged

Vibration and has not been repaired with insulating

Dust tape or unsuitable connectors.

6. Ensure cables from power tools shall be

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

11

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

12

organized so as not to present a tripping

hazard

7. Only trained competent operatives to

operate the power tools.

8. Ensure proper and regular maintenance of

equipment that takes account of noise

9. Ensure proper hearing protection always.

10.Make sure people use the right tool for the

job and are trained to use it correct

11. Power tools must be 110 Volt

7 Spillage/ soil Operatives using 3 4 12 Medi 1. Ensure that all chemical substances have a 1 4 4 Low Supervisors

contamination solvent um COSHH assessment Foreman,

2. Refer SDS prior to any handling of hazardous Site Eng.

Skin irritation substances and ensure SDS is easily

accessible at site while working with

Acute/Chronic chemicals.

adverse heath 3. Ensure chemicals are properly stacked.

effect. 4. Ensure all chemical containers are properly

labeled.

5. Spill kits to be available at site.

6. Competent person to oversee the storage,

use and disposal of hazardous materials.

Use of Glue - 7. Ensure that correct welfare/first aid facilities

Hazardous are available in the area i.e. washing

Substance facility/eye wash.

8. Proper and adequate PPE to be used always

9. Ensure all chemical containers are properly

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

13

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

14

labeled.

10.Adjust work schedules so that workers are

not overexposed to a hazardous chemical.

11.Wear respiratory protection

12.Wash hand properly before eating

13.Ensure smoking is prohibited in premises

14.Ensure appropriate Firefighting equipment’s

are in place and easily accessible

15.Ensured COSHH permit obtained by

supervisor

8 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be updated and informed 1 4 4 Low Site Eng.

condition Sand Storm visitors to work force if there is any prediction about Sup

Fog adverse weather. Foreman

Slippery surface 2 No activity shall be allowed during adverse

Risk of weather condition on site

electrocution 3 Protect the Power tools/DB from rain water to

Flying debris, avoid short circuit.

Slip, Tripping and 4 Ensure during adverse weather or Foggy

fall weather no lifting operation and no vehicle

movement.

5 After clear the weather make sure all power

tools are safe to use.

6 No work at height during high wind and rain

7 In case of emergency, call McLaren/Emergency

number

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

15

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

16

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

Poor visibility Operatives/staff

4. Industrial safe torches to be available for

due to darkness emergency situations

Working at night 5. High visibility Traffic Vest for personnel’s in

/ poor Medi Supervisor

9 time 3 4 12 night shift 1 4 4 Low

illumination um Foreman

Lone worker .

10 Use of Hand tools Improper 3 3 9 Medi 1. Hand tools should be visually inspected for 1 3 3 Low

selection of um defects, prior to use.

hand tools. 2. Never use damaged, blunt or broken tools to

Damaged and avoid injury.

Defective Hand 3. Select right tools for right Job Site Engr

tools. 4. Ensure no Homemade or makeshift tools to Supervisor

Hand injuries Operatives/Staff be used at site Foreman

Pinch point 5. Remove from service any tool that shows

Ergonomics signs of damage or defect

Repetitive 6. Ensure Hand tools are Stored in accordance

strain injury with the manufacturer’s instructions.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-038

Rev. No. Assessment Date

00 05/04/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of Sanitary Fixtures & Mixers Safety

Prabir

Officer

17

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

18

7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

5 Approved By: Name Vishnu Mohan Position _____PM____ Signature _____ ____ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

6

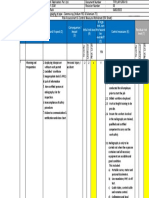

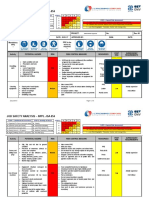

7 RISK ASSESSMENT & CONTROL GUIDELINES

8

9 1. Executing Steps:

0 1.1. Planning

1 a) Construction and HSE team must ensure that hazard identification is complete.

2 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

3 have well established legal requirements, potentially high risks).

4 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

5 potential high risks.

6 1.2. Risk Assessment

7 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

8 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

9 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

0 1.3. Risk Assessment Process

1 The process of carrying out a risk assessment should be as follows.

2 1. Identify the hazards.

3 2. Identify who might be harmed and how.

4 3. Evaluate the risk and implement the control measures.

5 4. Record the significant findings.

6 5. Review the assessment and update if necessary.

7 1.4. Examination of the Hazards and Risk Associated

8 Competent staff must be used in examining the risk associated with the identified hazard.

9 Competent staff should examine following aspect to determine the risk involved:

0 o Examine the existing control measures in place.

1 o Identify employees at risk.

2 o Likelihood of risk.

3 o Severity

4 o Risk level and their tolerability.

5 1.5. Evaluating the risk:

6 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

7 access the risks.

8 1.5.1. Risk Rating Score

9 Risk rating score is a combination of two factors.

0 The severity of the risk that could injure persons or cause damage to plant.

1 The likelihood of the risk that it could happen (Probability).

2

3 RISK RATING = LIKELIHOOD X SEVERITY

4 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

5 the table below. SEVERITY

6

No Injury Minor Moderate Major Catastrophic

7

(1) Injury (2) Injury (3) Injury (4) (5)

8

9 1 2 3 4 5

Rarely (1)

0

1 Unlikely (2) 2 4 6 8 10

2 LIK

ELI Possible (3) 3 6 9 12 15

3

4 HO Likely (4) 4 8 12 16 20

5 OD

Almost

6 5 10 15 20 25

Certain (5)

7 RISK LEVEL:

Low Medium High

8

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

9

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (17)

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan75% (12)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan89% (9)

- Risk Assessment For Pressure TestingDocument13 pagesRisk Assessment For Pressure TestingAnandu Ashokan83% (6)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan95% (19)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 pagesRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan82% (11)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan83% (6)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (13)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation and Testing of ACS (RA33)Document11 pagesRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- Site Master FileDocument59 pagesSite Master FileMohammed Zubair100% (3)

- Appendix 4 - HIRADC - Site Clearing - Excavation - 00Document3 pagesAppendix 4 - HIRADC - Site Clearing - Excavation - 00Abdul Hafiz Abdul Rahman100% (2)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- JSA-009 Sand Blasting - Coating 2Document6 pagesJSA-009 Sand Blasting - Coating 2Omar DhiebNo ratings yet

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Project Risk Assessment For Design and ConstructionDocument32 pagesProject Risk Assessment For Design and ConstructionAjas Aju100% (33)

- Risk Assessment For Harmonic Measurement Study ProcedureDocument13 pagesRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- 16 Risk Assessment ManagementDocument5 pages16 Risk Assessment ManagementBasit HaswareNo ratings yet

- HSE-TBRA-OP11 - Transportation of Cargo To Client Site Rev2Document4 pagesHSE-TBRA-OP11 - Transportation of Cargo To Client Site Rev2hseassistant.cgaNo ratings yet

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Vacuum Test Risk AssessmentDocument6 pagesVacuum Test Risk AssessmentJohn Mark Macoy100% (1)

- Microsoft Word Viewer - Risk-AssessmentDocument6 pagesMicrosoft Word Viewer - Risk-AssessmentsunilNo ratings yet

- HSE-TBRA-OP08 - Loading Cargo Onto Vessel and Removing Backloads To Staging AreaDocument8 pagesHSE-TBRA-OP08 - Loading Cargo Onto Vessel and Removing Backloads To Staging Areahseassistant.cgaNo ratings yet

- Risk Assessment Aluminum CladdingDocument6 pagesRisk Assessment Aluminum Claddingkannanjaduzz100% (1)

- Risk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityDocument6 pagesRisk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityAfaan gani InamdarNo ratings yet

- 6 RA - Template - BROGAN r2Document9 pages6 RA - Template - BROGAN r2Daniel100% (1)

- Ra Radiography 10Document1 pageRa Radiography 10alla malikNo ratings yet

- 11 - TRA # Halini-Maint-2022-011 Hot WorkDocument11 pages11 - TRA # Halini-Maint-2022-011 Hot Workmohsin awanNo ratings yet

- HSE-TBRA-OP08 - Loading Dome Onto VesselDocument8 pagesHSE-TBRA-OP08 - Loading Dome Onto Vesselhseassistant.cgaNo ratings yet

- Tra ExcavationDocument7 pagesTra ExcavationBilal50% (2)

- JSA Operational of Generator Set TSKDocument3 pagesJSA Operational of Generator Set TSKrosli muhamadNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument3 pagesRisk Assessment For Concrete Repair Workkeshav chaturvediNo ratings yet

- HIRARC Raised Floor SystemDocument6 pagesHIRARC Raised Floor Systemmohd zulhafizNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- Risk Assessment For NDTDocument14 pagesRisk Assessment For NDTNestor Mijares100% (1)

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- Risk Assessment Concrete WorkDocument10 pagesRisk Assessment Concrete WorkkannanjaduzzNo ratings yet

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting Systemabbas100% (1)

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- Borescope Compressor Maintenance FormDocument12 pagesBorescope Compressor Maintenance Formmohamedtalaat691No ratings yet

- OSHP-CH03 Risk RegisterDocument31 pagesOSHP-CH03 Risk Registerabubakrelsaid90No ratings yet

- Risk Assessment For Anti-TermiteDocument6 pagesRisk Assessment For Anti-TermiteDan SarmientoNo ratings yet

- Battery Rack IstallationDocument3 pagesBattery Rack IstallationIzzy TudtudNo ratings yet

- Risk Assessment: Erection, Altering and Dismantling of Scaffolding WorksDocument8 pagesRisk Assessment: Erection, Altering and Dismantling of Scaffolding WorksmuradNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicmuradNo ratings yet

- Vehicle Fuel Report - 10Document2 pagesVehicle Fuel Report - 10muradNo ratings yet

- 789999Document2 pages789999muradNo ratings yet

- Vehicle Fuel Report 2Document2 pagesVehicle Fuel Report 2muradNo ratings yet

- Vehicle Fuel Report - 6Document2 pagesVehicle Fuel Report - 6muradNo ratings yet

- Risk Assessment/JHA Form: Hot WorkDocument16 pagesRisk Assessment/JHA Form: Hot WorkmuradNo ratings yet

- Vehicle Fuel Report - 2Document2 pagesVehicle Fuel Report - 2muradNo ratings yet

- Vehicle Fuel Report 10Document3 pagesVehicle Fuel Report 10muradNo ratings yet

- 54545555Document4 pages54545555muradNo ratings yet

- Vehicle Fuel Report 3Document2 pagesVehicle Fuel Report 3muradNo ratings yet

- 23221Document3 pages23221muradNo ratings yet

- Vehicle Fuel Report 1Document2 pagesVehicle Fuel Report 1muradNo ratings yet

- Pocurement & Contracting SectionDocument2 pagesPocurement & Contracting SectionmuradNo ratings yet

- 3000000Document2 pages3000000muradNo ratings yet

- FooodddDocument1 pageFooodddmuradNo ratings yet

- DW LT 1Document2 pagesDW LT 1muradNo ratings yet

- MLHQ RQM 1 14Document2 pagesMLHQ RQM 1 14muradNo ratings yet

- 34353Document12 pages34353muradNo ratings yet

- 25748Document2 pages25748muradNo ratings yet

- 24284Document2 pages24284muradNo ratings yet

- 33100Document16 pages33100muradNo ratings yet

- DYE2023H7137GRUPO1Document6 pagesDYE2023H7137GRUPO1Luigi MendozaNo ratings yet

- Multimodal Postoperative Analgesia: Combinations of Analgesics After Abdominal Surgery at Chu - Jra AntananarivoDocument11 pagesMultimodal Postoperative Analgesia: Combinations of Analgesics After Abdominal Surgery at Chu - Jra AntananarivoIJAR JOURNALNo ratings yet

- 3 Pressure Ulcer (Bedsores) Nursing Care Plans - NurseslabsDocument12 pages3 Pressure Ulcer (Bedsores) Nursing Care Plans - NurseslabsJOSHUA DICHOSONo ratings yet

- Banksy ART Money HospitalsDocument7 pagesBanksy ART Money HospitalsPaloma Velasco RamírezNo ratings yet

- Assertiveness: Rights of OtherDocument17 pagesAssertiveness: Rights of OtherannuNo ratings yet

- The Effectiveness of Hand Hygiene Education Intervention For Medical Students in Primary Care Settings: Ismailia City, EgyptDocument10 pagesThe Effectiveness of Hand Hygiene Education Intervention For Medical Students in Primary Care Settings: Ismailia City, EgyptVian HertaminaNo ratings yet

- CortisolDocument2 pagesCortisolkitu_alagappan4720No ratings yet

- Code Yellow ChecklistDocument3 pagesCode Yellow ChecklistGreg van BeekNo ratings yet

- 0003IADDocument12 pages0003IADRika AzyenelaNo ratings yet

- Lawley2020 PDFDocument7 pagesLawley2020 PDFSandra Milena Cortes SotoNo ratings yet

- Fundoscopy N PDFDocument6 pagesFundoscopy N PDFshahid12333No ratings yet

- Alabama Association of Realtors Vs HHSDocument13 pagesAlabama Association of Realtors Vs HHSstreiff at redstateNo ratings yet

- MethergineDocument2 pagesMethergineJulie May33% (3)

- Protocol For Heart Rate Variability Biofeedback TrainingDocument13 pagesProtocol For Heart Rate Variability Biofeedback TrainingLevente BalázsNo ratings yet

- Research Paper Topics in EpidemiologyDocument8 pagesResearch Paper Topics in EpidemiologywgizkdvkgNo ratings yet

- Ignatavicius Chapter 59 (Evolve), Ignatavicius Chapter 57 (Evolve), GI CH 56, 57, 58, 59 Ignatavicius, Ignatavicius Chapter 54 (Evolve), Sole Ch 19, Ignatavicius Chapter 63 (Evolve), Sole Ch 16 Flashcards _ QuizletDocument63 pagesIgnatavicius Chapter 59 (Evolve), Ignatavicius Chapter 57 (Evolve), GI CH 56, 57, 58, 59 Ignatavicius, Ignatavicius Chapter 54 (Evolve), Sole Ch 19, Ignatavicius Chapter 63 (Evolve), Sole Ch 16 Flashcards _ QuizletNursyNurseNo ratings yet

- Mahesh Report of Saras DairyDocument49 pagesMahesh Report of Saras DairyRamesh jainNo ratings yet

- Richfeel Spa: India, S First Certified TrichologistsDocument26 pagesRichfeel Spa: India, S First Certified TrichologistsArfaan XhAikhNo ratings yet

- School Form (SF 2 of Saint Gabriel)Document60 pagesSchool Form (SF 2 of Saint Gabriel)Michael DabuNo ratings yet

- Cpi Final Assessment ErmcDocument9 pagesCpi Final Assessment Ermcapi-528037163No ratings yet

- Detecting and Treating Lung Congestion With Kidney.20Document9 pagesDetecting and Treating Lung Congestion With Kidney.20uriel1No ratings yet

- A Semi - Detailed Lesson Plan For Grade 9 Students. Time Frame: 1 HourDocument9 pagesA Semi - Detailed Lesson Plan For Grade 9 Students. Time Frame: 1 Hourharold carbonelNo ratings yet

- English 7: Quarter 3 - Module 3Document32 pagesEnglish 7: Quarter 3 - Module 3Monaliza Pawilan100% (4)

- Engleza Cls A 9 A BDocument4 pagesEngleza Cls A 9 A BAna MariaNo ratings yet

- RC 5 Diagnostic Reference Levels in Medical PractiseDocument67 pagesRC 5 Diagnostic Reference Levels in Medical Practisedwi fitrian saputroNo ratings yet

- Our VisionDocument46 pagesOur VisionDivya KrishnanNo ratings yet

- JSW Intern Ship ReportDocument17 pagesJSW Intern Ship Reportramjanam nishadNo ratings yet

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- Le Fort II Osteotomy and Modified Technique Presentation: Riginal RticleDocument6 pagesLe Fort II Osteotomy and Modified Technique Presentation: Riginal RticleSamuel SuazaNo ratings yet