Professional Documents

Culture Documents

02-Side Boom-Tec00548

02-Side Boom-Tec00548

Uploaded by

Mujahid AyyubOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02-Side Boom-Tec00548

02-Side Boom-Tec00548

Uploaded by

Mujahid AyyubCopyright:

Available Formats

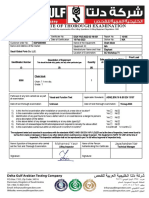

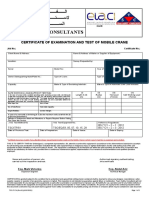

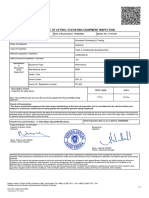

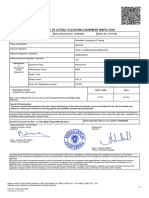

CERTIFICATE OF THOROUGH EXAMINATION

OF SIDE BOOM / PIPE LAYER

Certificate Registration No.: JO-2024-03-14820-02/MAS Place of Inspection: C.A.T Yard - Musaffah

Name and address of owner for whom the examination CONTRACTING AND TRADING COMPANY – C.A.T

was made: P.O BOX 108199, Abu Dhabi, UAE

Name and address of the manufacturer / supplier of the CATERPILLAR - USA

equipment: Model: PL87

Certificate no. of proof load test applied on manufacture

TRME_LE_28 Rev.0 Dt. 24.09.2014

N/A

including name of testing authority:

Description and distinguishing mark or number of pedestal Serial No: CAT0PL87CTEC00548

crane: Chassis No: CAT0PL87CTEC00548

Owners distinguishing mark or number: TEC00548

Date of last recorded examination of crane (if seen):

Name of person conducting the examination and of his Not Available

employer:

Date crane was first put into use (if known): 12 / 2019

Parts not accessible for thorough examination: NA

Parts that require opening at or before the next

NA

Warranty and Limitation of Liability: Statements or findings made in TRME reports are opinions based on the tests conducted and are

not to be construed as representations of fact. Due to the limitations of testing methods in evaluating all of the factors that determine

examination:

Particulars of defects or deficiencies found in the crane

the overall component quality, no guarantee is made nor liability assumed by TRME for the component quality or serviceability.

particularly those, which affect its safe operation and the i. Wire ropes, sheaves and hook block should be properly

repairs that are required if any: maintained after every use.

i. Immediately

ii. Within a specified time (which must be stated) to

enable the crane to be used with safety.

(If no such repairs are required the word “none” is to be entered).

Safe working load subject to the repairs renewals and Length of Jib Radius Test Load Safe

alterations specified above: (m) (m) (t) Working

In the case of a crane with variable operating radii, including a Load (t)

crane with a derricking jib, the safe working load at various radii is 8.5 m / 28 ft 1.2 Functionally 82.0

to be stated. Tested

Hoist Rope: 19.0 mm x 8 falls. 8.5 m / 28 ft 4.0 Functionally 25.0

Boom Rope: 19.0 mm Tested

Counter Weight: 10,844 kg 8.5 m / 28 ft 8.5 10.0 10.0

RECORD OF INSPECTION

Date of inspection: 25/03/2024 Date of next load test: 24/03/2025

Suitable for service: Yes No Date of next thorough examination: 24/03/2025

Reference standard: BS 7121-14:2005 / ANSI / ASME B30.14:2015 / ISO8813:1992

Defects and corrective action (if applicable): Limit switches shall be fixed and thorough examined before use

I CERTIFY THAT the item described above was examined in the prescribed manner and all parameters mentioned

above were correct at the time of inspection.

Name of the competent person: MOHAMED ASLAM Reviewed by: AHMED SAID

Signature / stamp:

▪ This document complies with ILO Convention No. 152.

▪ This document complies with the requirements of the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER).

▪ This document complies with the LEEA code of practice for the safe use of lifting equipment.

TÜV Rheinland Middle East P.O. Box 27483, Abu Dhabi

www.tuv.com Tel: +971 2 659-1500 / Fax: +971 2 659-5953

www.tuv.com/me Email: energy@uae.tuv.com Page 1 of 2

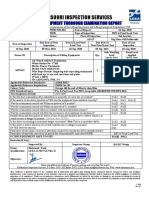

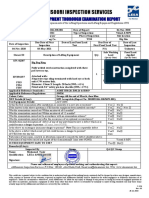

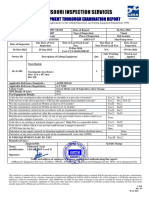

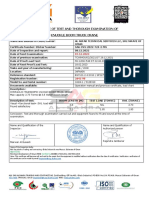

CERTIFICATE OF THOROUGH EXAMINATION

OF SIDE BOOM / PIPE LAYER

Certificate Registration No.: JO-2024-03-14820-02/MAS Place of Inspection: C.A.T Yard - Musaffah

Check ( If Defect

CHECKLIST Condition Found and Affects Safe

Recommendations Operation of Crane

If Any

Critical Points YES NO

1 CERTIFICATION is certification available for wire ropes, hook Previous TPI Certs not

blocks, slings, shackles and other replaceable items.

available

TRME_LE_28 Rev.0 Dt. 24.09.2014

2 GENERAL CONDITION, Give a general view of the condition of the Do proper cleaning and

crane take into consideration paintwork, oil spillage, general

appearance, maintenance etc.

maintenance after every use

3 WIRE ROPES As Applicable. What is the general condition of the Shall be maintained properly

wire ropes were any defects located which affect the cranes safe

operation? If any give defect, which rope and location.

as per the manufacturer

recommended after every use

4 BOOM & TELESCOPE SECTION, Check condition of boom

sections, wear pads, fixings, heel pins, sheaves, paint condition etc.

Non-Telescopic Boom,

Satisfactory

Check operation of boom telescope cylinder(s) listen for unusual

sounds which could indicate internal problems. Note any sign of

yielding (drifting) especially under load, is/are lock valve(s) operating

correctly?

5 STABILIZERS, Check condition of stabilizer(s), observe and listen

for unusual sounds, which would indicate internal problems. Check

Counter Weight Stabilizers

available-Satisfactory

hydraulic cylinders for cracks, wear, leak or distortions

Warranty and Limitation of Liability: Statements or findings made in TRME reports are opinions based on the tests conducted and are

6 BOOM HOIST CYLINDER(S), Check condition of boom hoist Satisfactory

not to be construed as representations of fact. Due to the limitations of testing methods in evaluating all of the factors that determine

cylinders, observes and listens for unusual sounds, which would

indicate internal problems. Check cylinder(s) for cracks scouring

the overall component quality, no guarantee is made nor liability assumed by TRME for the component quality or serviceability.

distortions which could affect its safe operation. Check pivot points

and fixings for wear. Note any sign of yielding (drifting) especially

under load is/are the lock valve(s) working correctly?

7 HOOK BLOCKS, Check for correct reeving, condition of sheaves,

sheave pins hooks, hook retaining devices, safety catches, side

Anti-Two Block shall be fixed

Use only manufacturer

plates, lubrication etc. Is the hook block(s) correctly marked as to

weight(s) and capacity(s) etc. recommend spare parts.

8 SLEW MOTION, Check operation of slew or swing motion, drive and

brake, look and listen for unusual noises or jerky motions which

N/A

would indicate internal problems. Check inner and outer circle slew

ring bolts for any indication of loose bolts (indicate if a torque wrench

was used). Check slew ring bearing for excessive wear (indicate if

slew ring deflections were taken).

9 OPERATORS CAB(S) and CONTROLS, Check condition of

operators cab(s) and operation of all controls and monitoring

Clean well after every use

equipment. Check the PTO operation.

REMARKS Add any additional information which is required to fully explain any deficiencies reported above or any additional deficiencies not included

above. Please use additional plain paper if required!

RESULTS

Safe to operate.

On the date to which the gear shown in the above mentioned item was tested and thoroughly examined no defects or permanent deformation

were found and that safe working load is as shown.

Not safe to operate.

On the date to which the gear shown in the above mentioned item was tested and thoroughly examined following defects or permanent

deformations were found which are or can become a danger to persons:

TÜV Rheinland Middle East P.O. Box 27483, Abu Dhabi

www.tuv.com Tel: +971 2 659-1500 / Fax: +971 2 659-5953

www.tuv.com/me Email: energy@uae.tuv.com Page 2 of 2

You might also like

- Jib Service Crane For RTG-Terminal 2Document7 pagesJib Service Crane For RTG-Terminal 2YasirNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Chainblock-Terminal 1Document11 pagesChainblock-Terminal 1YasirNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument9 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Spreader Beam-02Document1 pageSpreader Beam-02Moustafa AshrafNo ratings yet

- Cert - Mobile Crane 30T - LOLER - Model Rok300Document2 pagesCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument5 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument4 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- Aft CraneDocument7 pagesAft CraneRobert KeithNo ratings yet

- Air Winch VisualDocument10 pagesAir Winch VisualRanjithNo ratings yet

- Form - 11 E450AJ Boom Lift - 300092303Document1 pageForm - 11 E450AJ Boom Lift - 300092303Arif KhanNo ratings yet

- شهادة معايرة مارينةDocument4 pagesشهادة معايرة مارينةصلاح جابرNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 01-51437 - Certificate of Lifting Elevating Equipment InspectionDocument1 page01-51437 - Certificate of Lifting Elevating Equipment Inspectiongovindraj87No ratings yet

- Turn Buckle VisualDocument8 pagesTurn Buckle VisualRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument4 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- Over Head Crane Certificates - 250-082678Document1 pageOver Head Crane Certificates - 250-082678YasirNo ratings yet

- 01-51436 - Certificate of Lifting Elevating Equipment InspectionDocument1 page01-51436 - Certificate of Lifting Elevating Equipment Inspectiongovindraj87No ratings yet

- 1201 Lifting Machine & Tackles 40 TDocument1 page1201 Lifting Machine & Tackles 40 Tmt1742k4No ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- ELEVATOR ConstructionDocument2 pagesELEVATOR ConstructionSHARAFUDHEEN TKNo ratings yet

- Crane 100T-00022 KECDocument1 pageCrane 100T-00022 KECRajuNo ratings yet

- 18 - Fork Lift Defect - OptDocument4 pages18 - Fork Lift Defect - OptMoataz NazeemNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Concrete PumpsDocument2 pagesConcrete PumpsSHARAFUDHEEN TKNo ratings yet

- 23-1 ShackleDocument2 pages23-1 ShackleAkhilNo ratings yet

- Water Tanker Front1Document2 pagesWater Tanker Front1engr.haseebbalochNo ratings yet

- TPI WinchDocument2 pagesTPI Winchppandey84No ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Crawler Crane ChecklistDocument2 pagesCrawler Crane ChecklistAnuraj100% (1)

- Inspiripg, Safety: ProgressiveDocument1 pageInspiripg, Safety: ProgressiveTanweer KhanNo ratings yet

- TB0022 Lifting Equipment Load Test + Visual + MpiDocument1 pageTB0022 Lifting Equipment Load Test + Visual + MpikhalilNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Daelm Tank 0010-1Document1 pageDaelm Tank 0010-1Mansour AlfarsiNo ratings yet

- Crane 85T-7976 KECDocument1 pageCrane 85T-7976 KECRajuNo ratings yet

- Hooks-Report UpdatedDocument2 pagesHooks-Report UpdatedAkhilNo ratings yet

- ForkliftDocument2 pagesForkliftSHARAFUDHEEN TKNo ratings yet

- Sag724 2Document2 pagesSag724 2Usman AliNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- 14.03.2024 MM Handler F-15Document1 page14.03.2024 MM Handler F-15Susil Kumar SahooNo ratings yet

- Asc 20n 0649 c1 (Block Cutting Machine)Document1 pageAsc 20n 0649 c1 (Block Cutting Machine)AkhilNo ratings yet

- CB 12-02 Technical DocumentsDocument10 pagesCB 12-02 Technical DocumentsMOURAD B.MNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- Mis Eg 23 25715Document1 pageMis Eg 23 25715Moustafa AshrafNo ratings yet

- BOP Plate VisualDocument1 pageBOP Plate VisualRanjithNo ratings yet

- 28399-A-002 Super Sack (00160570)Document1 page28399-A-002 Super Sack (00160570)RanjithNo ratings yet

- RollerDocument2 pagesRollerengr.haseebbalochNo ratings yet

- Sketch 4Document1 pageSketch 4Mujahid AyyubNo ratings yet

- Registration Card - 04.12.2024Document1 pageRegistration Card - 04.12.2024Mujahid AyyubNo ratings yet

- Lifting Sketch New-22Document1 pageLifting Sketch New-22Mujahid AyyubNo ratings yet

- Lifting Sketch-05Document1 pageLifting Sketch-05Mujahid AyyubNo ratings yet

- 2026 Rigger Technician Interview Questions Answers GuideDocument12 pages2026 Rigger Technician Interview Questions Answers GuideMujahid AyyubNo ratings yet

- Lifting Sketch New-23Document1 pageLifting Sketch New-23Mujahid AyyubNo ratings yet

- 4300 Ag CS U40000004 - P1 - Geo TechnicalDocument171 pages4300 Ag CS U40000004 - P1 - Geo TechnicalMujahid AyyubNo ratings yet

- Steel Wire Rope Slings - Page-16Document1 pageSteel Wire Rope Slings - Page-16Mujahid AyyubNo ratings yet

- PM15 5Document2 pagesPM15 5Mujahid AyyubNo ratings yet

- Excavator Operation RADocument4 pagesExcavator Operation RAMujahid AyyubNo ratings yet

- O.S fl70 - eDocument23 pagesO.S fl70 - ewebergraficNo ratings yet

- (External) Rabbit Lidar - Intro To ReviewingDocument7 pages(External) Rabbit Lidar - Intro To ReviewingErnesto VásquezNo ratings yet

- Toyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramDocument3 pagesToyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramSirleh SalehNo ratings yet

- FLIGHTMECHANICSDocument48 pagesFLIGHTMECHANICSvenkatakrishnan srinivasanNo ratings yet

- Wollongong Free ShuttlebusDocument1 pageWollongong Free ShuttlebusAngel DennyNo ratings yet

- Indian School Muscat: Department of Arabic Class:Ix Lessons TranslationDocument4 pagesIndian School Muscat: Department of Arabic Class:Ix Lessons TranslationDeepak RameshNo ratings yet

- Southwest Airlines Group 2Document20 pagesSouthwest Airlines Group 2junadriann bulaonNo ratings yet

- Partsbook SST82Document33 pagesPartsbook SST82Heri SuryoNo ratings yet

- 2006-2008-Cbf1000-A-7 Cooling SystemDocument22 pages2006-2008-Cbf1000-A-7 Cooling SystemMurariu IonutNo ratings yet

- GOFLDNTANDMD8DCM5934Document6 pagesGOFLDNTANDMD8DCM5934TW ALWINNo ratings yet

- Age of Exploration 2016Document78 pagesAge of Exploration 2016Angelica PazNo ratings yet

- Technical Guide: Heavy Duty Forklift TruckDocument8 pagesTechnical Guide: Heavy Duty Forklift Truckabdelhadi houssinNo ratings yet

- Service Bulletin Category 3: Teledyne Continental Aircraft EngineDocument23 pagesService Bulletin Category 3: Teledyne Continental Aircraft EngineizabelNo ratings yet

- BUAT LATIHAN Is Shared Space Safe For Cyclist - Case Study - Haren - RevisedDocument18 pagesBUAT LATIHAN Is Shared Space Safe For Cyclist - Case Study - Haren - RevisedAlya fitri WahyuniNo ratings yet

- Concrete Conveyor Concrete Conveyor: SystemsDocument6 pagesConcrete Conveyor Concrete Conveyor: SystemsSamuel JuradoNo ratings yet

- Full Ebook of Compendium of Dermatology For Examinations Kabir Sardana Editor Surabhi Sinha Editor Seema Rani Editor Online PDF All ChapterDocument69 pagesFull Ebook of Compendium of Dermatology For Examinations Kabir Sardana Editor Surabhi Sinha Editor Seema Rani Editor Online PDF All Chaptercctlcincwcsp866100% (5)

- Ergonomics + Posture For 2 WheelersDocument187 pagesErgonomics + Posture For 2 WheelerssdsdsdnNo ratings yet

- Pre Assessment For BWTS Regulation (Answer Key)Document2 pagesPre Assessment For BWTS Regulation (Answer Key)Francisco LaddaranNo ratings yet

- Setup: Instruction ManualDocument2 pagesSetup: Instruction ManualnagatoNo ratings yet

- Dream Destination Project 1Document7 pagesDream Destination Project 1api-551400070No ratings yet

- Valenzuela Ao20020017 WMDocument17 pagesValenzuela Ao20020017 WMWelbert SamaritaNo ratings yet

- Derek MahonDocument11 pagesDerek MahondoucefrancescribdNo ratings yet

- Autonomous Vehicles Technological Changes and Ethical ChallengesDocument13 pagesAutonomous Vehicles Technological Changes and Ethical ChallengesV BanerjeeNo ratings yet

- Autumn in South Korea Travel Guide and Itinerary 1Document14 pagesAutumn in South Korea Travel Guide and Itinerary 1api-637966711No ratings yet

- Why I Want To Become A Seaman, Essay SampleDocument1 pageWhy I Want To Become A Seaman, Essay SampleMonNo ratings yet

- 41 098 Maritime Engineering Journal 99Document26 pages41 098 Maritime Engineering Journal 99mohamed madiNo ratings yet

- Welding PositionsDocument2 pagesWelding PositionsSteve Cowan100% (1)

- GTA Vice City Vehicle Spawning Cheats and CodesDocument3 pagesGTA Vice City Vehicle Spawning Cheats and CodesShaguftaNo ratings yet

- Dahan Tower Crane 6015Document1 pageDahan Tower Crane 6015DahanTowerCrane100% (1)

- Honda CRF 250L PDFDocument128 pagesHonda CRF 250L PDFBauroNo ratings yet