Professional Documents

Culture Documents

Calcium Silicate Pipe Block Insulation

Calcium Silicate Pipe Block Insulation

Uploaded by

abdeslem mouloudj0 ratings0% found this document useful (0 votes)

2 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views1 pageCalcium Silicate Pipe Block Insulation

Calcium Silicate Pipe Block Insulation

Uploaded by

abdeslem mouloudjCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

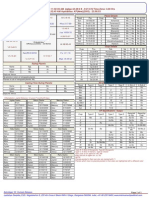

Thermal Insulation Products - Calcium Silicate

Calcium Silicate Pipe & Block Insulation

Calcium silicate high temperature insulation board and pipe cover are manufactured using

an industry preferred filter press method which provides accurate dimensional tolerances and superior

compressive and flexural strength. These attributes facilitate installation and provide exceptional

resistance to mechanical abuse. Calcium silicate insulation is asbestos free and meets or exceeds all

of the requirements of ASTM C533, type I & II.

APPLICATIONS

Calcium silicate insulation is recommended for use on equipment and piping operating at

temperature from ambient to 121℃ indoors and protected outdoors up to 649℃. It is ideally suited

for industrial use in areas such as the petrochemical and power generating industries where energy

conservation, process control, personal protection and fire protection are prerequisites.

TYPES

Calcium silicate block and pipe insulation fitting are available.

Density:

170 kg/M3 , 220~240 kg/M3, 250 kg/M3

Length: 2 ft(600/610mm), 3ft(915mm)

Thickness: 25~75mm (Single Layer)

Max.Service Temperature: 650℃ / 1000℃

PARAMETERS OF PHYSICAL PROPERTIES:

Product Name: Calcium Silicate

ITEMS Result of Test

Density (kgs / m3) 220

Thermal conductivity (acerage temp. 70 ℃) W/(m.k) 0.056

Compression Strength at 5% deformation (Mpa) 0.6

Flexural Strength <min.>(Mpa) 0.3

Linear Shrinkage (max.) (%) 2

Moisture content(max.)(%) 7.5

Max Service Temp (℃) 650

Sealumet (Australia) Pty Limited

Mailing Address : PO Box 2218, Warwick, Perth, WA, 6024

Warehouse : Unit 2, 6 Langar Way, Landsdale, Perth, WA - 6065

Telephone : +618 6201 6153, Fax : +618 9303 4560

E-mail: enquiries@sealumet.com Website: www.sealumet.com

DISCLAIMER

These data sheets are based on specifications, data and test results at time of publication. No guarantee as to completeness, accuracy or results is either expressed or implied. The suitability for

an intended use is the responsibility of the user. As choice of material, method of application and site conditions are beyond our control we accept no liability for direct or consequential damages.

Any material proved to be defective within the published shelf life* will be replaced. *From date of supply. Revision 1.0; 022018

You might also like

- Sol3e Adv Progress Test Answer Keys BDocument9 pagesSol3e Adv Progress Test Answer Keys Bridik katin100% (3)

- Computational Propaganda Political Parties, Politicians, and Political Manipulation On Social Media (Samuel C - Woolley, Philip N. Howard)Document273 pagesComputational Propaganda Political Parties, Politicians, and Political Manipulation On Social Media (Samuel C - Woolley, Philip N. Howard)João SousaNo ratings yet

- Method Statement Stone ColumnDocument10 pagesMethod Statement Stone ColumnSantosh ZunjarNo ratings yet

- Revision Guide For Anthology TextsDocument11 pagesRevision Guide For Anthology TextsIbra Elmahdy100% (2)

- Strategic Marketing Plan For WalmartDocument22 pagesStrategic Marketing Plan For WalmartEsther Kakai100% (1)

- Architecture and Arts: Ielts Vocabulary Topic 3: ArchitectureDocument4 pagesArchitecture and Arts: Ielts Vocabulary Topic 3: ArchitectureLong NguyenNo ratings yet

- POWER BI TutorialDocument77 pagesPOWER BI TutorialAashirtha S100% (3)

- Vertex - Destiny's GateDocument7 pagesVertex - Destiny's GateBogdan Catrinoiu100% (2)

- Clinker Reactivity - Chemistry - 17may18Document54 pagesClinker Reactivity - Chemistry - 17may18Nihar Ranjan Tripathy100% (4)

- COHR QBH FiberOpticCable DL DS 1020Document7 pagesCOHR QBH FiberOpticCable DL DS 1020Yomba BorisNo ratings yet

- QBH Fiber Optic Cable Diode Lasers DsDocument7 pagesQBH Fiber Optic Cable Diode Lasers DsvahidvataniNo ratings yet

- Custom Made Movement Joint ProfileDocument2 pagesCustom Made Movement Joint Profileemrah turerNo ratings yet

- My FileDocument2 pagesMy FileSyed Umair RizviNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Amtir-1 Datasheet CesDocument5 pagesAmtir-1 Datasheet Ces'Sebastian OrtizNo ratings yet

- Cermet Trimming Potentiometer: Model 67Document4 pagesCermet Trimming Potentiometer: Model 67keyvan cryptoNo ratings yet

- Eng DS 1773193 1 B-2888555Document4 pagesEng DS 1773193 1 B-2888555diego234.axelNo ratings yet

- Technical Data Sheet - Nylong: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylong: 3D Printing FilamentSteven DonosoNo ratings yet

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocument4 pagesAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoNo ratings yet

- CHDD MQ01ACFxxx Product Overview 1285350Document3 pagesCHDD MQ01ACFxxx Product Overview 1285350Juan Andres MurilloNo ratings yet

- Macor: Machinable Glass Ceramic For Industrial ApplicationsDocument6 pagesMacor: Machinable Glass Ceramic For Industrial ApplicationsRichardNo ratings yet

- SathermDocument2 pagesSathermvaisakhNo ratings yet

- Gorilla Glass Victus PI SheetDocument2 pagesGorilla Glass Victus PI SheetSMITH DESIGN STUDIONo ratings yet

- 1 X 240 15kV WAPDADocument2 pages1 X 240 15kV WAPDAAli ShahzadNo ratings yet

- PP Clyrell Rc213m Random Cast FilmDocument1 pagePP Clyrell Rc213m Random Cast FilmTrung HoNo ratings yet

- Triple Junction GaAsDocument2 pagesTriple Junction GaAsNezar Gassem ElfadillNo ratings yet

- Datasheet Wesgo Ceramics Al500Document2 pagesDatasheet Wesgo Ceramics Al500hemanth_85No ratings yet

- Brosur SMA EMETER-20 - HDPDocument2 pagesBrosur SMA EMETER-20 - HDPadi brwNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Satsearch Datasheet 8zn4jn Azur Space Triple Junction Solar Cell 3g30c Advanced 8 by 4 CMDocument2 pagesSatsearch Datasheet 8zn4jn Azur Space Triple Junction Solar Cell 3g30c Advanced 8 by 4 CMf20230311No ratings yet

- CHDD MQ01ABDxxx Product OverviewDocument2 pagesCHDD MQ01ABDxxx Product OverviewFreddy Rodolfo Rincón SánchezNo ratings yet

- 300w Monocrystalline Silicon Solar Panel: Specification Laminating DataDocument1 page300w Monocrystalline Silicon Solar Panel: Specification Laminating DataRigoberto Hernando Olarte MejiaNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentwidyarahmahNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentSteven DonosoNo ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- Thyseenkrup - Stainless Steel 1-4713Document3 pagesThyseenkrup - Stainless Steel 1-4713dantegimenezNo ratings yet

- Imuthane PET-60D: TDI-Polyether PrepolymerDocument2 pagesImuthane PET-60D: TDI-Polyether PrepolymerfeltofsnakeNo ratings yet

- General Information: 9.6 PP 100 / 20 PP 1.2Document3 pagesGeneral Information: 9.6 PP 100 / 20 PP 1.2vijayNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Om4 MM 8 Fiber MTP Female To LC Upc 3m Fiber Optic Patch Cable Data Sheet 242010Document3 pagesOm4 MM 8 Fiber MTP Female To LC Upc 3m Fiber Optic Patch Cable Data Sheet 242010GLsun MallNo ratings yet

- CM8V-T1A32 768kHz7pF 20ppmTAQCDocument2 pagesCM8V-T1A32 768kHz7pF 20ppmTAQCcafosokNo ratings yet

- Sintered Product - Triaxial CU Test ReportDocument5 pagesSintered Product - Triaxial CU Test ReportwaimyintgeonamicsNo ratings yet

- Baumer PBMN-Flush DS EN 1304 PDFDocument4 pagesBaumer PBMN-Flush DS EN 1304 PDFJose Vicente CentellesNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- WRC SpecificationDocument2 pagesWRC SpecificationTrungThanh TranNo ratings yet

- CS Al 88Document8 pagesCS Al 88mccornejo1617No ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- Rotima 3M 9EDocument4 pagesRotima 3M 9EadanNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa Bhuvan100% (1)

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- ENG DS 834 Accelerometer A2Document4 pagesENG DS 834 Accelerometer A2RahulNo ratings yet

- Commercial Microwave and RF Multilayer MaterialsDocument3 pagesCommercial Microwave and RF Multilayer MaterialsDale XiaoNo ratings yet

- FLEX-03 2.6N - Datasheet - EnglishDocument2 pagesFLEX-03 2.6N - Datasheet - Englishedgars.sk.mrNo ratings yet

- Single Mode-Loose Tube Armoured Fiber Optic CableDocument2 pagesSingle Mode-Loose Tube Armoured Fiber Optic Cablesunil kumarNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Optical Cable PDFDocument26 pagesOptical Cable PDFEliaquin Bravo RiosNo ratings yet

- z3T - Dental Cobalt Chrome Alloy (EOS CC SP2)Document1 pagez3T - Dental Cobalt Chrome Alloy (EOS CC SP2)martinm3tNo ratings yet

- Fimo 6 SQMM Earthing CableDocument1 pageFimo 6 SQMM Earthing CabletejveerNo ratings yet

- PVC Cable Compound GranualeDocument5 pagesPVC Cable Compound Granualecherukuri.sriramNo ratings yet

- Manl 11761Document17 pagesManl 11761Mikro IndiaNo ratings yet

- Thick Film Chip Resistor - General PurposeDocument8 pagesThick Film Chip Resistor - General PurposeDarwin SipayungNo ratings yet

- Nouveau Document 2019-03-04 20.55.50Document8 pagesNouveau Document 2019-03-04 20.55.50abdeslem mouloudjNo ratings yet

- PS End Suction Pump Brochure EN Oct18Document6 pagesPS End Suction Pump Brochure EN Oct18abdeslem mouloudjNo ratings yet

- Qdoc - Tips - Sws Gpsa Engineering Data Book 12th EdDocument3 pagesQdoc - Tips - Sws Gpsa Engineering Data Book 12th Edabdeslem mouloudjNo ratings yet

- Data Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: DateDocument2 pagesData Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: Dateabdeslem mouloudjNo ratings yet

- Fabrication, Installation, Commissioning & Testing of Compressed Air System With Associated ComponentsDocument7 pagesFabrication, Installation, Commissioning & Testing of Compressed Air System With Associated Componentsabdeslem mouloudjNo ratings yet

- Science X QP Set BDocument7 pagesScience X QP Set BYogesh KhannaNo ratings yet

- Management Accounting Costing and BudgetingDocument31 pagesManagement Accounting Costing and BudgetingnileshdilushanNo ratings yet

- Case Study KTDocument2 pagesCase Study KTEko Budi ArifiantoNo ratings yet

- Government Polytechnic, Nanded: Title of The ProjectDocument24 pagesGovernment Polytechnic, Nanded: Title of The ProjectPradip GaikwadNo ratings yet

- CBSE Class 7th Science Value Based Questions Chapter 3 Fibre To Fabric PDF Download-1Document10 pagesCBSE Class 7th Science Value Based Questions Chapter 3 Fibre To Fabric PDF Download-1pravin161079No ratings yet

- Arduino S3v3 ManualDocument7 pagesArduino S3v3 ManualJiradech SaiNo ratings yet

- A High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSDocument12 pagesA High-Throughput Method For Dereplication and Assessment Ofmetabolite Distribution Insalviaspecies Using LC-MS/MSkostNo ratings yet

- Kunci-Jawaban Howard AntonDocument41 pagesKunci-Jawaban Howard AntonAlyagariniNo ratings yet

- Planet Details: Astrologer: Dr. Kumara SanjayaDocument1 pagePlanet Details: Astrologer: Dr. Kumara SanjayaDr. MNV KiranbabuNo ratings yet

- Turbo Chargers T3-T4Document1 pageTurbo Chargers T3-T4Andries FerreiraNo ratings yet

- Research and Development in Nigeria's Tertiary Institutions: Issues, Challenges and Way ForwardDocument9 pagesResearch and Development in Nigeria's Tertiary Institutions: Issues, Challenges and Way ForwardInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Prediksi SOal UAS Kelas XII WAJIBDocument14 pagesPrediksi SOal UAS Kelas XII WAJIBDinda Anisa Meldya Salsabila100% (2)

- Determination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentDocument12 pagesDetermination of Chromium VI Concentration Via Absorption Spectroscopy ExperimentHani ZahraNo ratings yet

- Teaching English Through StoryDocument8 pagesTeaching English Through StoryChaerunnisaNo ratings yet

- Rebound HammerDocument6 pagesRebound HammerDira AzmanNo ratings yet

- Report Evaporator Sculptor Behr 120405Document11 pagesReport Evaporator Sculptor Behr 120405gosculptorNo ratings yet

- SchizophreniaDocument39 pagesSchizophreniaChikezie OnwukweNo ratings yet

- CAN For Vehicles HugoProvencher 2Document67 pagesCAN For Vehicles HugoProvencher 2Skyline DvNo ratings yet

- The Masculoskeletal SystemDocument6 pagesThe Masculoskeletal Systemapi-296199660No ratings yet

- EmphysemaDocument10 pagesEmphysemaNader Smadi100% (4)

- Goodman ss-gsz16Document36 pagesGoodman ss-gsz16nam nguyenNo ratings yet