Professional Documents

Culture Documents

Gulf Geartek - Hd-Sept2021 - 20211102102844

Gulf Geartek - Hd-Sept2021 - 20211102102844

Uploaded by

magadali78140 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

gulf geartek- hd-sept2021_20211102102844 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageGulf Geartek - Hd-Sept2021 - 20211102102844

Gulf Geartek - Hd-Sept2021 - 20211102102844

Uploaded by

magadali7814Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

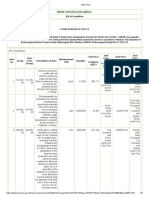

Gulf GEARTEK HD

(Previously Known as Gulf EP Lubricant HD)

Heavy-duty industrial gear oil

Product Description

Gulf GEARTEK HD series are high performance extreme pressure gear oils developed for lubrication of heavy

duty industrial gears working under severe operating conditions. These are blended from high quality base stocks

and sulphur-phosporous type extreme pressure additive system that gives excellent load carrying capability to

provide protection against shock loading and wear. The high thermo-oxidative stability of the oil helps resist high

temperature deposit formation and oil thickening. In addition, these oils also possess excellent water separation

characteristics and offer resistance to foaming. These oils exceed the performance requirements of various

industry specifications viz. DIN 51517 Part 3, ISO 12925-1 Type CKD, AGMA 9005 E-02, David Brown S1.53

101(E) and US Steel 224.

Features & Benefits

• Excellent load carrying capability protects gears against scuffing and wear and offers long equipment life

and reduced maintenance costs

• High thermo-oxidative stability helps resist deposit formation, provides enhanced system cleanliness and

enables longer service intervals

• Provides effective rust and corrosion protection to all gearbox components

• Excellent demulsibility property enables trouble-free operation in conditions encountering water/ moisture

Applications

• Wide range of industrial spur, helical, bevel and steel-on-steel worm gears

• Heavy-duty industrial enclosed gears operating under heavy or shock loading conditions and requiring

extreme pressure performance

• Journal and roller contact industrial bearings operating at low speeds and high loads

• Suitable for splash, mist and circulating systems

• Marine gear applications

Specifications, Approvals & Typical Properties

ISO Viscosity Grade 68 100 150 220 320 460 680 1000

Meets the following Specifications

DIN 51517 Part 3, ISO 12925-1 Type CKD, X X X X X X X X

AGMA 9005 E-02,

David Brown S1.53 101(E) X X X X X X X X

US Steel 224 X X X X X X X

Typical Properties

Test Parameters ASTM Method Typical values

Viscosity @ 40 ºC, cSt D 445 68.2 100.2 148.7 218.8 315.7 461.3 682.4 990.0

Viscosity Index D 2270 98 97 97 96 95 95 91 90

Flash Point, ºC D 92 224 230 240 242 246 252 256 260

Pour Point, ºC D 97 -15 -15 -12 -12 -12 -9 -6 -3

Density @ 15ºC, Kg/l D 1298 0.884 0.889 0.893 0.897 0.901 0.905 0.909 0.925

FZG, fail load stage DIN 51354 Part II >12 >12 >12 >12 >12 >12 >12 >12

Rust Test D 665A/B Pass Pass Pass Pass Pass Pass Pass Pass

Copper Corrosion D 130 1a 1a 1a 1a 1a 1a 1a 1a

Emulsion test @ 54 oC D 1401 Pass - - - - - - -

30minute max @ 82 oC - Pass Pass Pass Pass Pass Pass Pass

Sept 2021

You might also like

- Materials Selection For Hydrocarbon and Chemical Plants PDFDocument425 pagesMaterials Selection For Hydrocarbon and Chemical Plants PDFchao xingNo ratings yet

- Standard Stone Masonry Slope Protection NEW-ModelDocument1 pageStandard Stone Masonry Slope Protection NEW-Modelpea yangNo ratings yet

- Tds Akron HydraulicDocument2 pagesTds Akron HydraulicluizzNo ratings yet

- Post Lab 26-31Document8 pagesPost Lab 26-31Christian Paulo D. PichayNo ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Gulf Harmony Hvi April22 - 20220407195423Document2 pagesGulf Harmony Hvi April22 - 20220407195423AbhishekNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Gulf Harmony AW: High Performance Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW: High Performance Anti-Wear Hydraulic Oilatripathi2009No ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- Gulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW Plus: Premium Quality Anti-Wear Hydraulic OilHarsh AiwaleNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- PDS - GulfSea Hydraulic HVI Plus 68Document2 pagesPDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- 2611 Gulf EP Lubricant HD 220Document1 page2611 Gulf EP Lubricant HD 220Jasper ShaonNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- PDS_Drydene_GearAll_EP_Series_0322-01Document1 pagePDS_Drydene_GearAll_EP_Series_0322-01txto2881No ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet

- Gulf HarmonyDocument1 pageGulf HarmonyRina Gazel EndracaNo ratings yet

- Hydroflux Ep tcm14-62558Document1 pageHydroflux Ep tcm14-62558Azis GPBNo ratings yet

- 5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3Document2 pages5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3tauhidrockNo ratings yet

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDocument1 pageTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- Top Dog Global Mineral 30018 1Document2 pagesTop Dog Global Mineral 30018 1tdoukas101No ratings yet

- Agip OSO: Characteristics (Typical Figures)Document2 pagesAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Gulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating OilsDocument1 pageGulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating Oilsatripathi2009No ratings yet

- Repsol Telex E 46,68Document2 pagesRepsol Telex E 46,68ibrahim maulanaNo ratings yet

- Giant 3030 15W40Document1 pageGiant 3030 15W40ibrahim maulanaNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Super Tauro PAG: LubricantsDocument1 pageSuper Tauro PAG: LubricantsSaurav SharmaNo ratings yet

- PDS Eng SHPDVDS3Document1 pagePDS Eng SHPDVDS3Yasen YordanovNo ratings yet

- Gac 265Document2 pagesGac 265mohamad mostafaviNo ratings yet

- WL Turbo X1 PDSDocument1 pageWL Turbo X1 PDSAung Myat ThuNo ratings yet

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanNo ratings yet

- Brosur Lubline Hi-Temp MC 2495 XRT (English)Document1 pageBrosur Lubline Hi-Temp MC 2495 XRT (English)Deltalube Tangerang100% (1)

- Abs 70Document2 pagesAbs 70mohamad mostafaviNo ratings yet

- Q8 Goya DDocument3 pagesQ8 Goya DMoutaz IsmailNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Gac 250Document2 pagesGac 250mohamad mostafaviNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- PDS KomAirDocument2 pagesPDS KomAireffendi.successNo ratings yet

- Decathlon Extreme Synthetic Gear OilDocument1 pageDecathlon Extreme Synthetic Gear OilDon HowardNo ratings yet

- gulf-synthetic-gear-oilDocument1 pagegulf-synthetic-gear-oilAbdo EissaNo ratings yet

- SL Way OilDocument1 pageSL Way OilAxel Mahya AvichenaNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Gulfmar Select - PDS - 4Document2 pagesGulfmar Select - PDS - 4magadali7814No ratings yet

- Automatic Filter Type 6.46 With Centrifuge en BOLLFILTERDocument5 pagesAutomatic Filter Type 6.46 With Centrifuge en BOLLFILTERmagadali7814No ratings yet

- TB012-Resulting BN of Blended Trunk Piston Engine Oils-V2Document2 pagesTB012-Resulting BN of Blended Trunk Piston Engine Oils-V2magadali7814No ratings yet

- Emergent Specifications For Passenger Car Engine Oils: M. Deegan ILSAC Chair 4/12/2022Document12 pagesEmergent Specifications For Passenger Car Engine Oils: M. Deegan ILSAC Chair 4/12/2022magadali7814No ratings yet

- TB009-Recommended Greases For Gear and Wire-Rope ApplicationsDocument4 pagesTB009-Recommended Greases For Gear and Wire-Rope Applicationsmagadali7814No ratings yet

- Worksheet 2 PH Measurement and Buffer PreparationDocument15 pagesWorksheet 2 PH Measurement and Buffer PreparationAkeysha CarreonNo ratings yet

- 1.dioda SemikonduktorDocument12 pages1.dioda SemikonduktorBaginda PurbaNo ratings yet

- Epoxy Terrazzo Flooring PDFDocument3 pagesEpoxy Terrazzo Flooring PDFBalaji RavikumarNo ratings yet

- BluestarDocument49 pagesBluestar39629425No ratings yet

- OriginDocument8 pagesOriginAkashShuklaNo ratings yet

- Laundry Blues: By: Ms. Babita Verma Associate Professor Government College For Girls, ChandigarhDocument9 pagesLaundry Blues: By: Ms. Babita Verma Associate Professor Government College For Girls, Chandigarhveeramalai rathinavel0% (1)

- IscarDocument158 pagesIscarDOBJAN100% (1)

- Solid Waste ManagementDocument4 pagesSolid Waste ManagementRuzzel CarbajalNo ratings yet

- Journal of Constructional Steel Research: Tianhua Zhou, Yanchun Li, Hanheng Wu, Yan Lu, Lujie RenDocument14 pagesJournal of Constructional Steel Research: Tianhua Zhou, Yanchun Li, Hanheng Wu, Yan Lu, Lujie RenHusnik Maulidya Tungga DewiNo ratings yet

- Basic in ElectricityDocument26 pagesBasic in ElectricityShang Divina EbradaNo ratings yet

- Damage Tolerance and Durability of Fiber - Metal Laminates For Aircraft StructuresDocument56 pagesDamage Tolerance and Durability of Fiber - Metal Laminates For Aircraft StructuresppqqNo ratings yet

- Pelaporan Penggunaan Dan Management Bahan Kimia Periode Januari - Maret 2022Document12 pagesPelaporan Penggunaan Dan Management Bahan Kimia Periode Januari - Maret 2022Pratama AbadiNo ratings yet

- Eavemaster Fascia SoffitDocument8 pagesEavemaster Fascia SoffitJackyNo ratings yet

- Bond Energy of Various CompDocument3 pagesBond Energy of Various CompdhananjayanvNo ratings yet

- KAR Products - Gloss White Aerosol PaintDocument7 pagesKAR Products - Gloss White Aerosol Paintjaredf@jfelectric.comNo ratings yet

- Isrm SM Hardness and Abrasiveness of Rock - 1978Document9 pagesIsrm SM Hardness and Abrasiveness of Rock - 1978Evandro SantiagoNo ratings yet

- Introduction To Chemical BondingDocument4 pagesIntroduction To Chemical Bondingjust_do_it1No ratings yet

- FT LG DecotileDocument1 pageFT LG DecotileELIBER DIONISIO RODR�GUEZ GONZALESNo ratings yet

- Matin Construction LimitedDocument9 pagesMatin Construction LimitedShahanara AkterNo ratings yet

- Aluminum DeterminationDocument11 pagesAluminum DeterminationanithaNo ratings yet

- Alcohols: - Structure and BondingDocument49 pagesAlcohols: - Structure and BondingJackson UdumaNo ratings yet

- Fatigue Behaviour Study of Laser Hybrid Welded Ecc PDFDocument34 pagesFatigue Behaviour Study of Laser Hybrid Welded Ecc PDFmikruNo ratings yet

- Selectrode: Manufacturers of Custom Welding Lines For Resale Handi-Jig Heat Resistant PuttyDocument2 pagesSelectrode: Manufacturers of Custom Welding Lines For Resale Handi-Jig Heat Resistant Puttymohamed AdelNo ratings yet

- Stainles Steel Transformation PDFDocument22 pagesStainles Steel Transformation PDFAyush MishraNo ratings yet

- Standard Methods For The Examination of Water and Waste WaterDocument16 pagesStandard Methods For The Examination of Water and Waste WaterAnggiet SusilaningtyasNo ratings yet

- A1 Ch19studyguideDocument3 pagesA1 Ch19studyguideJana Aldour100% (2)

- SECTION 03 45 00 Precast Architectural ConcreteDocument30 pagesSECTION 03 45 00 Precast Architectural ConcreteJuanPaoloYbañezNo ratings yet