Professional Documents

Culture Documents

Verj Final

Verj Final

Uploaded by

Mohammed SalamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Verj Final

Verj Final

Uploaded by

Mohammed SalamCopyright:

Available Formats

Installation Instruction

Instruction Number: 412778 Rev.: J

Instruction for Microwave Parabolic Antennas 6ft diameter (1.8m)

DA, UA, SU, SD, SDF

PA, PAL, PAD, SP, PAX,

DAX, UDA, UXA, SDX, SUX

PADX, SPX

UL/ULX

These Installation Instructions are valid for antennas in the following version:

• Reflector 1.8 m diameter (6 ft)

• waveguide feed single or dual polarized

• pipe mount for installation on 115mm diameter

• antenna offset to the left or the right

• safety collar for easy installation

• 2 spindles for fine adjustment of azimuth and elevation of ± 5 degrees

• 1 sway bar

• reflector with shroud, aperture covered by a flexible planar radome, or reflector without shroud (see antenna

models above)

Taking into account a slight reduction of the operational windspeed, the antenna can be

installed without sway bar if additional fixing points for a sway bar are not available.

It is important to mount the antenna exactly as described in this installation instruction.

The installed antenna shall be inspected once per year by qualified personnel.

RFS disclaims all responsibility for antenna malfunction due to improper or unsafe installation.

This installation instruction has been written for qualified, skilled personnel.

We reserve the right to alter details, especially with respect to technical improvement.

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 1 of 19

www.rfsworld.com

1. Tools required for installation

Tools are not included with antenna:

• Hoisting device for 250 daN (2500N or 250kg) • Tape-measure

• Water balance and compass • 2 ropes

•Torque wrench from 0,5 to 240Nm • Nail set or punch for Ø 6 mm

• Wrenches for hexagon bolts: • Shackle

M5(8), M6(10), M10(17), M12(19), M14(21), • Mallet

M16(24), M20(30)*

*(values in brackets=openings of spanners)

2. Antenna Offset

Hoisting eye

at the top

Offset left

Hoisting eye

at the top

Offset right

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 2 of 19

www.rfsworld.com

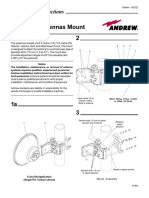

3. Assembly of the mount

For easy operation of the bolted joints, « Anti Seize » Installation Paste must be applied to all

threads of bolts and fine adjustment spindles. After this, keep the lubricated threads free of dust

and dirt! (Fastener torque specification see table attached)

3.1 Brackets installation on Backring

After complete brackets and stiffening

plates installation, torque tightens each

M12 bolted joints.

3.2 Pre-assembly of the T-mount (example of a left offset installation)

Perpendicularity Check

90⁰

90⁰

(Rear view)

After perpendicularity check between the 3

parts of the T-Mount, torque tightens the

M12 bolts to lock the assembly. (Without

square, you can do it with a sheet of paper).

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 3 of 19

www.rfsworld.com

3.3 T-Mount installation on the Backring (example of a left offset installation)

Nut M16

Put the reflector on wooden beams to

avoid distorting and dusting

4. Shroud installation (only for antennas with shroud)

4.1 Installation of the RF Gasket on the Reflector

• Dismount the Hoisting Eye located at the top of the Reflector

• The rim of the reflector must be clean and dry

• The wire mesh is directed to the center of the reflector

• Stick on the RF gasket tape 360° in a way (all the mounting holes are covered by the

tape

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 4 of 19

www.rfsworld.com

4.2 Installation of shroud panels (for antennas equipped with

shroud, except for UL6 and ULX6)

(Short shroud length)

6 hex screws M6x16

24 hex screws M6x25 12 washers 6.4Ø18 4 hex screws M6x25

48 washers 6.4Ø18 6 spring washers M6 8 washers 6.4Ø18

24 spring washers M6 6 nuts M6 4 spring washers M6

24 nuts M6 4 nuts M6

(Long shroud length)

7 hex screws M6x16

14 washers 6.4Ø18

7 spring washers M6

7 nuts M6

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 5 of 19

www.rfsworld.com

4.3 Installation of shroud panels (for UL6 and ULX6)

1. Shroud panels assembly

3x 9 hex screws M6x16

2. Put shroud panel assembly on reflector 3x 18 washers 6.4Ø18

3x 9 spring washers M6

3x 9 nuts M6

4. Reflector / shroud panel assembly 3. Shroud panel reinforcement

plate assembly x3

3x 4 hex screws M6x25

3x 8 washers 6.4Ø18

3x 4 spring washers M6

3x 4 nuts M6

24 hex screws M6x25

48 washers 6.4Ø18

24 spring washers M6

24 nuts M6

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 6 of 19

www.rfsworld.com

4.4 Hoisting Eye installation

4.5 Radome protection installation on Shroud rim (for antennas

equipped with shroud)

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 7 of 19

www.rfsworld.com

5. Feed Installation (For DBUX and UL/ULX antenna, see specific feed installation

instruction)

The feed is a precision component that should be handled with special care during

installation. For instance, always carry the feed, supporting casting plate side. Any

damage may degrade the antenna’s performance. Repair of feeds is not possible in

the field.

5.1 Guy wire assembly and reflector hole obturation

• For feed systems without guy wires (6 ft models with frequency

codes 34-35-36-44), install the 3 obturation plugs on the reflector

• For feed systems equipped with guy wires, insert the 3 guy wires

in the mounting holes from the rear of the reflector

• Move the feed assembly partway through the reflector connecting

ring

• Hook the guy wires into rotatable ring

• Move the feed and decide the polarization (refer to next section).

• No adjustment is needed for

feed with SL guy wires Tension for feed system

Feed system

delivered with SL guy wires

without guy wires

• Adjust the MW guy wires

according to following steps

1. If the springs begin to tighten up

when the feed moves in, back off

and adjust nuts on the guy wire

assembly. The nuts should be far

enough back on the guy wire

screws to allow the feed to be Rotatable

installed without putting tension on Install the 3 plugs ring

the guy wire springs.

Ø20 mm from the

2. Fix the feed on to the reflector No

3. Bring the adjusting nut on each

rear of the reflector

adjustment

assembly up to the washer behind needed

the guy wire spring until each one

just begins to tighten (67 mm

dimension as shown).

4. Keep the length “a” of all guy wires

approximately the same by

adjusting each one a little at a time. Feed system

5. Keep the guy assembly from

twisting while tightening the

Deliveryed with MW guy wires

adjusting nut about 6 to 8 mm

forward to a dimension of 59-61

mm as shown.

6. Tighten the lock nuts onto the

backs of the adjusting nuts.

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 8 of 19

www.rfsworld.com

5.2 Polarization choice and feed installation

5.1.1 Single polarization – for antennas equipped with shroud

Use following steps to choose or change feed polarization

1. Remove the screws and other hardware if feed was already installed

2. Carefully rotate the feed to choose the polarization

3. Vertical polarization: Align the scale on the feed plate to the mark on the top of the

reflector ring

4. Horizontal polarization: align the scale to the mark on the side of the reflector ring

5. Install the hardware and lock the screws

TOP Antenna TOP Antenna

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 9 of 19

www.rfsworld.com

5.1.2 Dual polarization – For antennas equipped with shroud

• Align the scale on the feed plate to the mark on the top of the reflector ring

• Install the hardware and lock the screws

5.1.3 Single polarization – For antenna not equipped with shroud

Vertical polarization Horizontal polarization

• Remove the 4 5/16 nuts

and lock washers if feed

was already installed

• Carefully rotate the feed to

choose the polarization

• Install the hardware and

lock the nuts

5.1.4 Dual polarization – For antenna not equipped with shroud

• Install the hardware and

lock the 4 5/16 nuts

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 10 of 19

www.rfsworld.com

6. Radome Installation (for antennas equipped with Shroud. See specific

installation instruction for Extreme radome)

Take care to not kinking of planar radomes during installation.

Kinking will destroy the radomes, which are non-repairable.

• Unpack the radome and carefully stretch it over the shroud aperture

• For radomes with RFS logo, align it with the vertical axis of the antenna

• For radomes without RFS logo, the central air vent mosquito net aperture must be oriented

towards the antenna top

• Attach J-bolt with springs and smooth radome down as the springs are attached, but do not

displace the edge protector on the shroud rim

• Align the length of the springs to approximately 135 mm at each J-bolt, this will provide proper

radome tension .

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 11 of 19

www.rfsworld.com

7. Sway Bar assembly

Tighten the assembly,

keeping the mounting bracket

free in rotation without a gap

8. Lifting antenna and hoisting on the tower

Before antenna hoisting on the pylon, it is mandatory that all the bolted joint of the T-Mount structure have

been torque tighten, otherwise the installation on the pipe support could be problematic.

Antenna Antenna

equipped not equipped

with shroud with shroud

2 ropes fixed on the mount for optimal balance to avoid

antenna collision with tower structure

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 12 of 19

www.rfsworld.com

9. Safety collar installation on pipe support

10. Antenna installation on pipe

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 13 of 19

www.rfsworld.com

10.1 Azimuth spindle installation

2 brass nuts M8

2 spherical washers C8.4

2 conical seats D9.6

Screws M8x30

Washer 8.4

SL nut M8

Azimuth

spindle

M8x200

11. Elevation adjustment

Loosen M20

nuts of the

elevation

pivots

Loosen or tighten M16

brass nuts on the elevation

spindle to adjust elevation

After elevation adjustment, torque tighten the 2 M20 and 2 M16 nuts

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 14 of 19

www.rfsworld.com

12. Azimuth adjustment

If the 1/2 nuts of the U-Bolts are already torque tighten, loosen each nut by 1 turn

Loosen or tighten M8 brass nuts

on the azimuth spindle to adjust Loosen 1/2 nuts of the

azimuth U-bolts, except the U-

Bolt of the safety collar

After azimuth adjustment, lock the first nut on the U-bolt with the torque value specified on the

torque table (the U-bolt threads must have been greased before torque tightening), then fix the

second nut against the first one. Do not use two wrenches to fix the second nut.

13. Sway Bar positioning and attachment

• After complete azimuth and

elevation adjustment, angle

the sway bar respecting the

max angle indicated.

• Fix the sway bar fixing

clamp on the tower

structure (see figures

below).

• Then torque tighten each

bolted joints of the sway bar

articulation to suppress

residual gap.

Max

+/-25°

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 15 of 19

www.rfsworld.com

Sway bar installation on tower without optional Sway bar installation on tower with optional kit :

sway bar fixing kit SMA-SKO-UNIVERSAL-L

Screw M20x60 Angle tower structure

Washer 21 (to drill Ø21 for attachment) Refer to install. Instruction provided with this sway bar fixing kit

Nut M20

SL washer 20

Fixing clamp Washer 21

sway bar

(L-Profile

60x60)

Washer 21

SL washer 20

Nut M20

Screw M20x60 Pipe Ø 60 up to 114 mm or L-profile 60x60 up to

Washer 21 110x110 mm

14. Polarization fine adjustment

After adjustment, torque tighten the feed screws or nuts

14.1 Polarization adjustment – for antennas with shroud, 120mm feed system

Loosen the 4 M5 screws and carefully rotate feed to adjust polarization

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 16 of 19

www.rfsworld.com

14.2 Polarization adjustment – for antennas with shroud, 9 inch feed system

Loosen the 4 M6 screws and carefully rotate feed to adjust polarization

14.3 Polarization adjustment – for antennas with shroud, 14.5 inch feed system

Loosen the 8 M6 screws and carefully rotate feed to adjust polarization

14.4 Polarization adjustment – for antennas not equipped with shroud

Loosen the 4 5/16 nuts & lock washers and carefully rotate feed to adjust polarization

15. Final Check

When the installation of the antenna has been completed, it is necessary to make

sure that the installation instructions have been followed in all aspects.

It is especially important to check that all bolted joints are torque tightly locked.

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 17 of 19

www.rfsworld.com

Installation Paste for Threads

Installation Paste <<Anti-seize>> is provided with the antenna.

It is used for lubricating and corrosion preventing on all threads of stainless-steel bolts, U-bolts, and spindles.

The installation paste must be applied to all threads

of bolts and fine adjustment spindles. After this, keep the

lubricated threads free of dust and dirt!

Fastener torque specifications are valid for bolts with

installation paste only.

Example: Casting-mount Example: Steel-mount

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 18 of 19

www.rfsworld.com

Table of Torques

For final Nut and Bolt joints tightening

On Microwave Parabolic Antennas

Attention: The values in the following table are valid for nuts and bolts which

have been greased according to the paste installation instructions.

Torques to apply on GREASED hardware

Main nuts & bolts, tie-bolts with clamps M5 5 Nm

M6 8 Nm

M8 17 Nm

M10 35 Nm

M12 50 Nm

M16 140 Nm

M20 / 24 240 Nm

U-Bolt and V-Bolt M6 8 Nm

M8 17 Nm

M10 20 Nm

M12 50 Nm

M14 95 Nm

M16 125 Nm

M20 210 Nm

1/2 - 13 75 Nm

Brass Nut of fine adjustment M8 5 Nm

(Azimuth and Elevation fine adjustment) M10 10 Nm

M12 17 Nm

M16 50 Nm

M20 80 Nm

M24 115 Nm

Feed fixing screws M3 1 Nm

M4 2.5 Nm

M5 5 Nm

M6 8 Nm

Torques to apply on NON-GREASED hardware

Nuts with self-locking compound M8 17 Nm

M10 35 Nm

Screws to fix plastic radome B4.2 3 Nm

We reserve the right to alter details, especially with respect to technical improvement.

Radio Frequency Systems

200 Pondview Drive

Meriden, CT 06450

Technical Support: 1-800-659-1880 Page 19 of 19

www.rfsworld.com

You might also like

- 15F2284 Manual A320 v2016 (Vigente)Document23 pages15F2284 Manual A320 v2016 (Vigente)Joe ReyNo ratings yet

- Pulper Rotor ManualDocument10 pagesPulper Rotor ManualhenryhariyadiNo ratings yet

- SainSmart Genmitsu CNC Router 3018-User ManualDocument26 pagesSainSmart Genmitsu CNC Router 3018-User ManualFernando MarcanoNo ratings yet

- Mosley TA-33-M User 2011Document22 pagesMosley TA-33-M User 2011Diego García MedinaNo ratings yet

- RFS 1.8mDocument13 pagesRFS 1.8mMarius Tresor EdiboussieNo ratings yet

- 8ft Antenna (HTT81.221-10)Document15 pages8ft Antenna (HTT81.221-10)guns1976No ratings yet

- User ManualDocument35 pagesUser ManualUdayantha WithanaNo ratings yet

- 4ft Antenna SB4 With Wind Kit 250kmh Reflector Installation (NMT560-03)Document11 pages4ft Antenna SB4 With Wind Kit 250kmh Reflector Installation (NMT560-03)guns1976No ratings yet

- 4ft Antenna SB4 Reflector Installation (NMT480-08)Document11 pages4ft Antenna SB4 Reflector Installation (NMT480-08)guns1976No ratings yet

- 4ft Antenna SB4-142 Reflector Installation (NMT564-01)Document11 pages4ft Antenna SB4-142 Reflector Installation (NMT564-01)guns1976No ratings yet

- ETATRACK Active 1500: Installation GuideDocument19 pagesETATRACK Active 1500: Installation GuideVishwanath KetkarNo ratings yet

- R 9 PDFDocument16 pagesR 9 PDFAlexandru MaiorNo ratings yet

- XR3C 6 Element Triband Yagi 20-15-10MDocument18 pagesXR3C 6 Element Triband Yagi 20-15-10Msboonuy331No ratings yet

- ArcMATE 120ic M20iADocument24 pagesArcMATE 120ic M20iABrendisNo ratings yet

- Reflector Bulletin Split Reflector AssemblyDocument3 pagesReflector Bulletin Split Reflector AssemblyMohammad Shoaib ArifNo ratings yet

- Manual - Instalação - UXA6-78BD (TR)Document13 pagesManual - Instalação - UXA6-78BD (TR)Rafael NunesNo ratings yet

- Installation Instruction For Eclipse XPOL Direct MountDocument2 pagesInstallation Instruction For Eclipse XPOL Direct MountKevin_INo ratings yet

- XR 6 11 Element 6 Band Yagi 20-17-15-12-10-6MDocument16 pagesXR 6 11 Element 6 Band Yagi 20-17-15-12-10-6Msboonuy331No ratings yet

- Hyg Dx77a ManualDocument14 pagesHyg Dx77a Manualve7eoeNo ratings yet

- 6366 - MW HOP Installation Guidelines - BhartijDocument26 pages6366 - MW HOP Installation Guidelines - Bhartijlucky chandel100% (1)

- CHIKO Installation Guide Flat RoofDocument17 pagesCHIKO Installation Guide Flat RoofGuille ParejoNo ratings yet

- 8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENDocument30 pages8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENAndrie Purna FNo ratings yet

- Multiband VerticalDocument32 pagesMultiband VerticalToplician AdrianNo ratings yet

- Trango Antenna User Manual ADXX XX SX 1 and 2 FT DiamDocument14 pagesTrango Antenna User Manual ADXX XX SX 1 and 2 FT DiamhussainNo ratings yet

- Instruction Manual: Order No. 500Document4 pagesInstruction Manual: Order No. 500bobbyunlock100% (1)

- Ringspann ClampDocument5 pagesRingspann ClamphamishjbadamsonNo ratings yet

- HS400 Series Single Full Height Turnstile: Service & Installation ManualDocument40 pagesHS400 Series Single Full Height Turnstile: Service & Installation Manualmaqsood ahmadNo ratings yet

- HS400 Series Single Full Height Turnstile: Service & Installation ManualDocument40 pagesHS400 Series Single Full Height Turnstile: Service & Installation Manualmaqsood ahmadNo ratings yet

- Bafang - BBSXX - Installation GuideDocument15 pagesBafang - BBSXX - Installation GuideКонстантин МалышевNo ratings yet

- Retrofit Kit For Adapting From 3WE52 CDO To 3WL1: 3WL9 111-0CA10-0AA0 3WL9 111-0CA16-0AA0Document8 pagesRetrofit Kit For Adapting From 3WE52 CDO To 3WL1: 3WL9 111-0CA10-0AA0 3WL9 111-0CA16-0AA0seil iexNo ratings yet

- Installation Manual FOR Ecodb/Tb/Qb 520-550 Trisector AntennasDocument18 pagesInstallation Manual FOR Ecodb/Tb/Qb 520-550 Trisector AntennasBandalacNicoletaNo ratings yet

- AST 4.5M Full Motion User Manua220210Document28 pagesAST 4.5M Full Motion User Manua220210prasetyohardiNo ratings yet

- 1.8 Channel MasterDocument18 pages1.8 Channel MasterLarry Tembu100% (1)

- 12M4DXDocument7 pages12M4DXjavier.carroNo ratings yet

- Aaaaaaaaaaaa PDFDocument8 pagesAaaaaaaaaaaa PDFtahatekriNo ratings yet

- 62 12110 InstallationDocument39 pages62 12110 InstallationCircle ChanNo ratings yet

- Carter Products Jet Bandsaw Guide Conversion Kit Installation InstructionsDocument2 pagesCarter Products Jet Bandsaw Guide Conversion Kit Installation Instructionstravis_gant3547No ratings yet

- XR5 9 Element 5 Band Yagi 20-17-15-12-10MDocument16 pagesXR5 9 Element 5 Band Yagi 20-17-15-12-10Msboonuy331No ratings yet

- Alignment BalanceDocument2 pagesAlignment BalanceCharles MatosNo ratings yet

- Bts3902e Quick GuideDocument20 pagesBts3902e Quick GuideAlexander TyshchenkoNo ratings yet

- 600 WATT Wind Turbine 787769456445 - Install PDFDocument106 pages600 WATT Wind Turbine 787769456445 - Install PDFAnonymous XgX8kTNo ratings yet

- VEC-1862 Instruction Manual Six-Meter Yagi AntennaDocument9 pagesVEC-1862 Instruction Manual Six-Meter Yagi AntennaJuan Ignacio Isla CortesNo ratings yet

- 2. Rewinding of single-phase induction motors (1)Document9 pages2. Rewinding of single-phase induction motors (1)JayaprasadGollaNo ratings yet

- Classic 60 Deck Service Kit 902415Document3 pagesClassic 60 Deck Service Kit 902415pwoody571No ratings yet

- Valuline Antennas Mount 2: Installation InstructionsDocument2 pagesValuline Antennas Mount 2: Installation InstructionsjumivegaNo ratings yet

- 124 - Bench Am5k Manual Standard 11-05-06Document100 pages124 - Bench Am5k Manual Standard 11-05-06Ayman MaezaNo ratings yet

- Commscope - 8' & 10' HX-USX Vertical Antenna Mount InstallDocument16 pagesCommscope - 8' & 10' HX-USX Vertical Antenna Mount Installchris winterNo ratings yet

- Direkt Manual 2018Document6 pagesDirekt Manual 2018danielestrace7No ratings yet

- Instruction Manual: Order No. 386SDocument12 pagesInstruction Manual: Order No. 386SRamónNo ratings yet

- Xr5 JK 2021 VersionDocument18 pagesXr5 JK 2021 VersionLuis CuberoNo ratings yet

- 1VDD006146 GB RMU Safeplus Installation Manual For Side Extension 36kVDocument21 pages1VDD006146 GB RMU Safeplus Installation Manual For Side Extension 36kVVan Light100% (1)

- Specifications: 797F Off-Highway Truck Suspension CylinderDocument12 pagesSpecifications: 797F Off-Highway Truck Suspension CylinderManuel Alejandro Silva VeraNo ratings yet

- Yaestj: Antenna Rotator Model G-450XLDocument12 pagesYaestj: Antenna Rotator Model G-450XLMar CabNo ratings yet

- 7.Wyr-Grid Cabinet Mount Bracket Installation Direct Mount & ElevatedDocument6 pages7.Wyr-Grid Cabinet Mount Bracket Installation Direct Mount & ElevatedMohamed Abdelrahma.No ratings yet

- 70 - Am5k Measuring Head User Manual 4-20ma RevhDocument37 pages70 - Am5k Measuring Head User Manual 4-20ma Revhbaggo81No ratings yet

- 0.6m Class 4 Antenna Installation Manual PDFDocument15 pages0.6m Class 4 Antenna Installation Manual PDFHenry EzeiloNo ratings yet

- Tracvision M9: Standard ConfigurationDocument29 pagesTracvision M9: Standard ConfigurationDaniel MourãoNo ratings yet

- Wireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesFrom EverandWireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesNo ratings yet

- Newsletter 210Document8 pagesNewsletter 210Mohammed SalamNo ratings yet

- Guidance Electronics Unit DatasheetDocument2 pagesGuidance Electronics Unit DatasheetMohammed SalamNo ratings yet

- Saeedi J 2013Document14 pagesSaeedi J 2013Mohammed SalamNo ratings yet

- Indonesian Journal of Science & Technology 6 (2) (2021) 427-440Document14 pagesIndonesian Journal of Science & Technology 6 (2) (2021) 427-440Mohammed SalamNo ratings yet

- Ijertv6n5spl 01Document12 pagesIjertv6n5spl 01Mohammed SalamNo ratings yet

- 08setc 0067Document8 pages08setc 0067Mohammed SalamNo ratings yet

- Articles: BackgroundDocument11 pagesArticles: BackgroundMohammed SalamNo ratings yet

- JGSKDLFKJGDDocument8 pagesJGSKDLFKJGDMohammed SalamNo ratings yet

- BCSF Web BrochureDocument5 pagesBCSF Web Brochurebcsf01No ratings yet

- Ipc 80-12-01-10-Reg Images SupercDocument5 pagesIpc 80-12-01-10-Reg Images SupercRussell GouldenNo ratings yet

- Electrical Materials List For Construction ProjectsDocument17 pagesElectrical Materials List For Construction Projectsmuhammad robithNo ratings yet

- Inch Thread PlugDocument10 pagesInch Thread PlugAizen SousukeNo ratings yet

- Types of ThreadsDocument20 pagesTypes of Threadsrethinamk50% (2)

- Valbia Mod 32Document3 pagesValbia Mod 32Termoval ProyectosNo ratings yet

- Chapter 5 Bolted Connection-1Document32 pagesChapter 5 Bolted Connection-1Abaziz Mousa OutlawZzNo ratings yet

- Dgca Module 07 Part 08Document19 pagesDgca Module 07 Part 08iftiNo ratings yet

- Parts List - LH637-60Document5 pagesParts List - LH637-60FranciscoNo ratings yet

- REYHER Catalogue 2014 en Web KsDocument900 pagesREYHER Catalogue 2014 en Web Ksiliaigi_bgNo ratings yet

- Bolt capacity-IS802-5.6Document1 pageBolt capacity-IS802-5.6rammohan100% (1)

- Dimensi & Toleransi Ulir TrapesiumDocument7 pagesDimensi & Toleransi Ulir TrapesiumHadi HendrariyantoNo ratings yet

- AOT. Type T Safety ClampDocument2 pagesAOT. Type T Safety ClampCong BuiNo ratings yet

- Water Pump BreakdownDocument3 pagesWater Pump BreakdownTodd ThielenNo ratings yet

- ThrdsDocument47 pagesThrdsfrancisdimeNo ratings yet

- Astm F467M 1997Document5 pagesAstm F467M 1997Jesse ChenNo ratings yet

- Material Removal Manufacturing Processes: MACH71685 Dr. Liviu Radulescu, P.EngDocument30 pagesMaterial Removal Manufacturing Processes: MACH71685 Dr. Liviu Radulescu, P.EngEthan StoneNo ratings yet

- Second Floor Beams Top Tie BeamsDocument1 pageSecond Floor Beams Top Tie Beamsሳምሶን ወርቁNo ratings yet

- No.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058Document160 pagesNo.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058boris velastegui sanchezNo ratings yet

- Optional EquipmentDocument35 pagesOptional EquipmentESRANo ratings yet

- Design Optimization of Power Screw JackDocument7 pagesDesign Optimization of Power Screw JackTd DammikaNo ratings yet

- How To Make A Cornhole BoardDocument4 pagesHow To Make A Cornhole BoardAndré VeigaNo ratings yet

- QPL MS17825Document162 pagesQPL MS17825topbhhNo ratings yet

- S05 Drillling Compartment PDFDocument60 pagesS05 Drillling Compartment PDFIH MedranoNo ratings yet

- Manual de Partes RL4Document96 pagesManual de Partes RL4anon_828943220No ratings yet

- Lokotrack LT105 S/N 74184 Toc Lokotrack: Tue, 01 Nov 2011 1Document525 pagesLokotrack LT105 S/N 74184 Toc Lokotrack: Tue, 01 Nov 2011 1Jorge Yaipen100% (1)

- Cotter PinsDocument1 pageCotter Pinsdiyanto AntoNo ratings yet

- AGCO 3906313 WU311003-1 Aboard ComputerDocument2 pagesAGCO 3906313 WU311003-1 Aboard ComputerFabianoNo ratings yet

- Stud Bolt Length Table For 6Bx Flange Connections 2.2Document1 pageStud Bolt Length Table For 6Bx Flange Connections 2.2estudiemosNo ratings yet