Professional Documents

Culture Documents

Metachem Ind

Metachem Ind

Uploaded by

cpchintanpatel53Copyright:

Available Formats

You might also like

- 2.2.5. Relative DensityDocument2 pages2.2.5. Relative DensitySunderchauhanNo ratings yet

- C617 CappingDocument6 pagesC617 CappingTavo Suarez C100% (1)

- Muy Buenos 3110Document17 pagesMuy Buenos 3110Jesus MorenoNo ratings yet

- CAPE Chemistry Unit 2Document27 pagesCAPE Chemistry Unit 2Audi SweetangelNo ratings yet

- EverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008Document3 pagesEverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008chuckreyesNo ratings yet

- Astm D4952 - 09Document2 pagesAstm D4952 - 09Muhannad NasifNo ratings yet

- STOCK OPNAME Lab Mikrobiologi 2021 BahanDocument2 pagesSTOCK OPNAME Lab Mikrobiologi 2021 BahanDani Puji UtomoNo ratings yet

- TFSP Ver3-2-02Document74 pagesTFSP Ver3-2-02Murali Krishna ThotaNo ratings yet

- Copper Sulfate: Identification of Petitioned Substance Trade NamesDocument18 pagesCopper Sulfate: Identification of Petitioned Substance Trade Namesweb erapeeNo ratings yet

- Glaze ForwardDocument24 pagesGlaze Forwardaonegodman100% (2)

- Nutrient Solutions and Water Quality For Soilless CulturesDocument30 pagesNutrient Solutions and Water Quality For Soilless Culturesjaime silvaNo ratings yet

- Determination of Chloride: Modification of The Volhard MethodDocument2 pagesDetermination of Chloride: Modification of The Volhard MethodAnjanie SharmaNo ratings yet

- Sharjah Standards of FE (STP)Document2 pagesSharjah Standards of FE (STP)hychauhan1No ratings yet

- Environmental Engineering Laboratory Open-Ended Lab Report: 2 Marks CommentsDocument10 pagesEnvironmental Engineering Laboratory Open-Ended Lab Report: 2 Marks CommentsMOHAMAD NOOR AZIZI ZAINUDINNo ratings yet

- Chemical Consumption Format FRM-QCDocument7 pagesChemical Consumption Format FRM-QCVinay PalNo ratings yet

- CG101 Solubility Table 2 19Document2 pagesCG101 Solubility Table 2 19celesweejh09No ratings yet

- Sample of Mass Balance MPDocument23 pagesSample of Mass Balance MPLeizel Ann GorgonioNo ratings yet

- 16 Jan 2018 120406610T5T1AY7BAnnexure-AdditionalAttachmentsFilePart1Document27 pages16 Jan 2018 120406610T5T1AY7BAnnexure-AdditionalAttachmentsFilePart1Husnain ArshadNo ratings yet

- Experiment 1 Inorganic CompundDocument5 pagesExperiment 1 Inorganic Compundpriyanshaprasad1No ratings yet

- Sodium BicarbonateDocument63 pagesSodium BicarbonateSridhar RaparthiNo ratings yet

- S-155 IC Application Note NoDocument1 pageS-155 IC Application Note NothangNo ratings yet

- Personal Care DETERGENTS BROCHUREDocument12 pagesPersonal Care DETERGENTS BROCHURERickgableNo ratings yet

- Parameters TimeDocument9 pagesParameters TimeSontu BardhanNo ratings yet

- Case StudyDocument19 pagesCase Studymohamed ibrahim nasrNo ratings yet

- Nutrisi Melon DG BHN ImporDocument6 pagesNutrisi Melon DG BHN ImporMujirah SuzanaNo ratings yet

- Alluring Acacia AccordDocument1 pageAlluring Acacia Accords224wcjzs7No ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument12 pagesTablas de Solubilidad de Compuestos InorganicosardsfafrfNo ratings yet

- Horcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Document10 pagesHorcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Luis EduardoNo ratings yet

- Comparison Between Conventional Circuit With Preleach Thickener, Preleach Filtration and Milling in RaffinateDocument73 pagesComparison Between Conventional Circuit With Preleach Thickener, Preleach Filtration and Milling in Raffinatejoseph kafumbila100% (1)

- A Method For Calculating The Composition of Nutrient SolutionsDocument14 pagesA Method For Calculating The Composition of Nutrient SolutionsJose LuisNo ratings yet

- Paraloid Au-608 TBZDocument6 pagesParaloid Au-608 TBZCHIRE SARAYASI MANUELNo ratings yet

- Anorthite Hydrolysis: Mike Borr Geol 428 Geochemistry NDSU Fall 2012Document25 pagesAnorthite Hydrolysis: Mike Borr Geol 428 Geochemistry NDSU Fall 2012yuri huamanguillas saenzNo ratings yet

- Controllable Synthesis of Fluorescent Carbon Dots and Their Detection Application As NanoprobesDocument13 pagesControllable Synthesis of Fluorescent Carbon Dots and Their Detection Application As NanoprobesNAILIL HIDAYAHNo ratings yet

- 2.2. 5. Relative Density 20205eDocument2 pages2.2. 5. Relative Density 20205evafaashkNo ratings yet

- Medias: Yeast Mannitol AgarDocument7 pagesMedias: Yeast Mannitol AgarKhadijaNo ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument7 pagesTablas de Solubilidad de Compuestos InorganicosBRYAN ANTONIO PEREZ BARAJASNo ratings yet

- Organic Lab ManualDocument76 pagesOrganic Lab ManualAnish KumarNo ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument7 pagesTablas de Solubilidad de Compuestos InorganicosVALERIA BARRAGAN AVALOSNo ratings yet

- Controllable Synthesis of Fluorescent Carbon (Yang Et Al, 2013)Document13 pagesControllable Synthesis of Fluorescent Carbon (Yang Et Al, 2013)Nixson Manosalva ElguetaNo ratings yet

- Ijerph 16 02458Document21 pagesIjerph 16 02458bemgba.nyakumaNo ratings yet

- Ellman - Tissue Sulfhydryl Groups - 1959Document8 pagesEllman - Tissue Sulfhydryl Groups - 1959Victor MendesNo ratings yet

- Product List BTGDocument1 pageProduct List BTGwaykurniaNo ratings yet

- Mass Balance For CS2 PlantDocument3 pagesMass Balance For CS2 PlantAshish GoelNo ratings yet

- Common Names of Chemical Compounds and Formula SSCDocument5 pagesCommon Names of Chemical Compounds and Formula SSCSubin M MNo ratings yet

- Formulasi AB MixDocument2 pagesFormulasi AB Mixbahrul.hidayah@yahoo.comNo ratings yet

- P FD FileDocument18 pagesP FD FileJAYESH6No ratings yet

- BP Kiln Feed BurnabilityDocument2 pagesBP Kiln Feed BurnabilityJuliano. PQMNo ratings yet

- Product List Updated Feb 2022Document4 pagesProduct List Updated Feb 2022Yogi TDRNo ratings yet

- Sulphuric Acid Mono54-6Document89 pagesSulphuric Acid Mono54-6werdna67No ratings yet

- DocxDocument7 pagesDocxJasmin YangNo ratings yet

- Black Hill Coking CoalDocument1 pageBlack Hill Coking Coalnaresh adusumilliNo ratings yet

- Daftar Alat Dan Bahan Lab KimiaDocument5 pagesDaftar Alat Dan Bahan Lab KimiaOzinasution NasutionNo ratings yet

- Mineral Water Calculator v5Document7 pagesMineral Water Calculator v5mauricio0327No ratings yet

- Formula BookDocument31 pagesFormula BookJonathan Candelier100% (1)

- Appendix III: Equivalent Weight of Substances Required in Volumetric Analysis - Engineering360Document3 pagesAppendix III: Equivalent Weight of Substances Required in Volumetric Analysis - Engineering360Waleed EmaraNo ratings yet

- NullDocument1 pageNullapi-25932006No ratings yet

- Hidrotek - 5 Stage Reverse Osmosis: Daily Runing Cost of Only 0.10cDocument1 pageHidrotek - 5 Stage Reverse Osmosis: Daily Runing Cost of Only 0.10cDavid VellaNo ratings yet

- One Bath One Stage Dyeing of Polyester / Cellulosic Blends.Document31 pagesOne Bath One Stage Dyeing of Polyester / Cellulosic Blends.sanjay shettiNo ratings yet

- Salt AnalysisDocument25 pagesSalt AnalysisAditya Nanda0% (1)

- Process Systems Engineering Studies For The Synthesis of Catalytic Biomass-To-Fuels StrategiesDocument2 pagesProcess Systems Engineering Studies For The Synthesis of Catalytic Biomass-To-Fuels StrategiesJonathan Riveros RojasNo ratings yet

- Coal Spec Wahana 6300 GarDocument1 pageCoal Spec Wahana 6300 GarAmatơ Hà ThànhNo ratings yet

- 1 TRADING PRODUCT LIST - Rev-01Document3 pages1 TRADING PRODUCT LIST - Rev-01aeryvishal4No ratings yet

- Additives for High Performance Applications: Chemistry and ApplicationsFrom EverandAdditives for High Performance Applications: Chemistry and ApplicationsNo ratings yet

- Homogeneous Catalysis: Mechanisms and Industrial ApplicationsFrom EverandHomogeneous Catalysis: Mechanisms and Industrial ApplicationsNo ratings yet

- Investigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationDocument8 pagesInvestigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationPhuc NguyenNo ratings yet

- Acid Rain Explanation TextDocument2 pagesAcid Rain Explanation TextIndah Dwi Cahayany100% (2)

- Low Sulphur Fuel Oil (LSFO)Document7 pagesLow Sulphur Fuel Oil (LSFO)asep supriyadiNo ratings yet

- Rubber Bloomong PDFDocument13 pagesRubber Bloomong PDFAjit SamalNo ratings yet

- Sulfur Dioksida Biomarker PDFDocument223 pagesSulfur Dioksida Biomarker PDFWayan Tanjung AryasaNo ratings yet

- Using Alchemically Prepared Herbs To Augment The Eight Temples MeditationDocument3 pagesUsing Alchemically Prepared Herbs To Augment The Eight Temples Meditationfmezz2000No ratings yet

- 100 Potassium PermanganateDocument7 pages100 Potassium Permanganateeng20072007No ratings yet

- Hydroponic NutrientsDocument9 pagesHydroponic NutrientsDhanraj PatilNo ratings yet

- Reactions of Non-Metals With OxygenDocument18 pagesReactions of Non-Metals With Oxygen18118100% (1)

- Qualitative Organic Analysis PDFDocument75 pagesQualitative Organic Analysis PDFAbhi RamNo ratings yet

- Ecology G 12Document209 pagesEcology G 12Samuel LegissaNo ratings yet

- Pre-Sulfiding On-Line Sulfiding ProceduresDocument8 pagesPre-Sulfiding On-Line Sulfiding ProceduresIrma Brennan0% (1)

- Chapter 1 Chemical Reactions and EquationsPreviewDocument48 pagesChapter 1 Chemical Reactions and EquationsPreviewAparNo ratings yet

- 101-110 RunkelDocument10 pages101-110 RunkelJohn Sebastian Bell-ScottNo ratings yet

- Lassaigne'S Tests: Elemental Analysis: EjgcaroDocument4 pagesLassaigne'S Tests: Elemental Analysis: EjgcaroRex KorrNo ratings yet

- 5070 s11 QP 11Document16 pages5070 s11 QP 11chuasioklengNo ratings yet

- Sulfur Dioxide Handling ManualDocument16 pagesSulfur Dioxide Handling ManualManfred VonNo ratings yet

- Mineral ResourcesDocument6 pagesMineral ResourcesharrisNo ratings yet

- 10th Chemical Reaction and Equation Questions With Solution 03Document3 pages10th Chemical Reaction and Equation Questions With Solution 03Vaibhav SunnyNo ratings yet

- Encyclopedia of Biodiversity Volume 1Document952 pagesEncyclopedia of Biodiversity Volume 1Georgi Zuhkov100% (2)

- Sulphur Solidification and FormingDocument37 pagesSulphur Solidification and FormingAnonymous qPt2MHzXTNo ratings yet

- Technical Note VulcanizationDocument26 pagesTechnical Note VulcanizationVinodh Kumar0% (1)

- Chapter 2Document8 pagesChapter 2Megan SchmidtNo ratings yet

- Kinetics of Zinc Sulfide Concentrate Direct Leaching in Pilot Plant Scale and Development of Semi-Empirical ModelDocument10 pagesKinetics of Zinc Sulfide Concentrate Direct Leaching in Pilot Plant Scale and Development of Semi-Empirical ModelTacachiri Chocamani JaimeNo ratings yet

- Risk Assessment of Sulphur RecoveryDocument6 pagesRisk Assessment of Sulphur RecoveryTejasNo ratings yet

Metachem Ind

Metachem Ind

Uploaded by

cpchintanpatel53Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metachem Ind

Metachem Ind

Uploaded by

cpchintanpatel53Copyright:

Available Formats

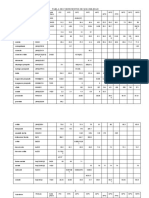

Annexure-I

List of Products

Sr. MT/Month

Name of the Product

NO.

(A) Reactive Dyes

1 Reactive Blue 198. 50

2 Reactive Blue FNG. 50

3 Reactive Blue 19. 40

4 Reactive Blue 49. 50

5 Reactive Blue 220 50

6 Reactive Blue 221 50

7 Reactive Blue 222 50

Total (A) 340

(B) Dyes Intermediates

8 PNCBOSA 30

9 Chloranil Condense 30

10 Blue HEGN (198) Base 25

11 Aniline 2:4 DSA. 30

12 Aniline 2:5 DSA 30

13 Oxy-Sulphone 30

14 M. Acid 20

15 Blue - 49 BASE 20

16 Metanillic acid 20

17 4-Sulpho Anthralinic Acid 50

18 4-Sulpho Hydrazone 50

19 Sulpho O.A.V.S./ Sulpho V.S./ Sulpho J- Acid/ 30

Sulpho Gamma Acid

20 3;5 DABA 10

Total (B) 375

Total (A + B) 715

M/s. Metachem Industries, Khambhat 1

List of Raw Materials

Sr. Product name Raw Materials Name MT/Month

no.

1 Reactive Blue 198 Blue HEGN (198) W/C 54.50

(HEGN) Soda Ash 21.0

Aniline 2:4 DSA 10.0

Cy. Chloride 8.25

S.B.C. 4.75

Celsolin Oil 0.50

2 Reactive Blue FNG Blue Base 198 W/C 63.50

Soda Ash 30.0

Aniline 2: 5 DSA 14.0

Cynuric Chloride 10.40

Celsolin Oil 0.50

MBVS Ester 15.0

Sodium Bicarbonate 11.50

3 Reactive Blue 19 Oxy Sulphone 31.0

Oleum (23%) 32.0

Sulfuric Acid (98%) 7.6

Salt 34.8

CaCO3 6.4

Oxilic Acid 3.6

Soda Bicarbonate 4.0

4 Reactive Blue 49 Blue 49 W/C 27.5

Soda Ash 10.0

Cy. Chloride 5.0

Metanilic Acid 5.0

5 Reactive Blue 220 Sulpho OAVS 13.5

Sodium Nitrite 3.5

HCl (30%) 27.5

4-Sulpho Hydrazone 19.5

Caustic Lye (48%) 4.5

Soda Ash 5.0

6 Reactive Blue 221 6-Acetyl OAPSA 11.5

CS Lye (48%) 2.0

HCl (30%) 61.5

Sodium nitrite 3.5

Sulphamic acid 0.1

Sodium acetate 5.0

Soda Ash 10.0

4-Sulpho Hydrazone 15.0

Copper sulphate 12.5

CS Flakes 16.0

Salt 32.5

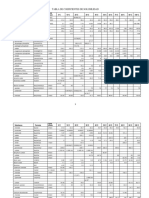

M/s. Metachem Industries, Khambhat 2

Cyanuric Chloride 7.5

Tamol 0.4

N-Ethyl MBVS 12.8

Soda Bi Carb 7.8

Dicamol 2.3

7 Reactive Blue 222 MPDSA 6.8

Cyanuric Chloride 6.6

Soda ash 6.5

Celsolin Oil 0.2

M.B.V.S. 10.0

NaHCO3 6.5

NaNO2 5.0

HCl (30%) 18.0

H-Acid 10.5

Sodium Acetate 14.8

S. T. A. 10.0

Dyes Intermediates

8 PNCBOSA PNCB 21.5

65% Oleum 23.6

Salt 30.0

9 Chloranil E.D.A. 150.0

Condense PNCBOSA 30.0

SBC 16.2

HCl (30%) 45.0

Ac. Acid 3.0

C.I.P. 15.0

Soda Ash 15.0

Chloranil 12.0

10 Blue HEGN (198) Sulfuric Acid (98%) 9.4

Base Oleum (23%) 70.0

Chlo. Cond. 25.0

Sodium per Sulfate 18.8

11 Aniline 2, 4 DSA Sulphanilic Acid 25.5

Oleum 23% 75.0

12 Aniline 2, 5 DSA Metanilic Acid 25.5

Sulfuric Acid (98%) 30.0

Oleum 65% 36.0

Hyflow 0.3

Activated Carbon 1.4

Sodium Sulphate 25.5

13 Oxy Sulphone Bromamine Acid 25.5

M/s. Metachem Industries, Khambhat 3

M.B. V.S. Acid 16.5

Soda Bi carbonate 25.5

CUCl2 0.3

Celsolin Oil 0.3

Copper Bronze 0.2

HCl (30%) 60.0

Salt 7.5

14 M. Acid Macitinline Acid 11.4

H2SO4 56.0

W.N.A. 17.6

NaOH 3.0

Iron Powder 30.0

Ac. Acid 7.0

Soda Ash 7.0

Ac. Carbon 0.5

HCl 30.0

Hydro Powder 0.3

15 Blue 49 Base Bromamine Acid 20.0

M-Acid 32.5

Soda Ash 13.6

Cuprous Oxide 2.0

Celsolin Oil 0.3

Coomon Salt 7.6

Dicamol 0.8

N2 Gas 1.3

HCl (30%) 54.0

16 Metanilic Acid Nitro benzene 18.0

Oleum (65%) 19.6

Soda Ash 1.0

Lime Stone Powder 22.0

Iron Powder 2.5

HCl (30%) 2.0

Soda Ash 3.5

Sulphuric Acid 1.8

17 4 O.N.T. 90.0

SulphoAnthranilic Oleum (65%) 99.0

Acid Sulfuric Acid (70%) 175.0

NaOH 107.5

18 4 4 SulphoAnthranilic Acid 50.0

Sulphohydrazene HCl (30%) 110.0

Sodium Nitrite 15.0

Sodium bisulphite 42.5

Caustic Soda 24.0

Benzaldehyde 30.0

19 Sulfo OAVS OAVS 37.5

Oleum Acid (65%) 66.4

Sulphuric Acid 54.4

M/s. Metachem Industries, Khambhat 4

KCl 19.5

20 3,5 DABA Benzoic Acid 12.0

Nitric Acid 10.9

Sulphuric Acid(98%) 23.4

Iron Powder 16.4

HCl (30%) 19.5

Soda Ash 9.0

M/s. Metachem Industries, Khambhat 5

Annexure-II

Manufacturing Process

(A) Reactive Dyes

1. Reactive Blue 198

Manufacturing Process:

Blue 198(HEGN) base W/C condensate with Cynuration of aniline 2:4 DSA& then

clarify, standardize& spray dryer.

Chemical Reaction:

M/s. Metachem Industries, Khambhat 6

Mass Balance:

Mass Balance of Reactive Blue 198 (HEGN)

INPUT KG OUTPUT KG

Blue HEGN (198) W/C 1090

Soda Ash 50 Base Slurry

Water 3700

Aniline 2:4 DSA 200

Soda Ash 120

Cy. Chloride 165

S.B.C. 95 Cyanuration

Celsolin Oil 10

Ice 1800

Water 1000

Soda Ash 250

Condensation

RO permeate reuse 4180

R/O

Drying loss 3300

Spray Drying

Reactive Blue 198 (HEGN) 1000

Total 8480 8480

M/s. Metachem Industries, Khambhat 7

2. Reactive Blue FNG

Manufacturing Process:

Blue 198 base W/C condense with Cynuration of aniline 2:5 DSA & then cond. With

M.B.V.S ester then clarify & std. & spray dryer.

Mass Balance:

Mass Balance of Reactive Blue FNG

INPUT KG OUTPUT KG

Blue Base 198 W/C 1270

Soda Ash 55 Base Slurry

Water 3500

Aniline 2: 5 DSA 280

Soda Ash 270

Cynuric Chloride 208

S.B.C. 150 Cyanuration

Celsolin Oil 10

Ice 1750

Water 1000

Soda Ash 275 1st

Condensation

MBVS Ester 300

Sodium Bicarbonate 80 M B V S Solution

Water 550

2nd

Condensation

RO permeate reuse 5408

R/O

Drying loss 3290

Spray Drying Reactive Blue 198

(HEGN) 1000

Total 9698 9698

M/s. Metachem Industries, Khambhat 8

3. Reactive Blue 19

Manufacturing Process:

Esterification of Oxy-sulphonedry powder in presence of Oleum (23%) & sulphuric

Acid (98%) at 35 ͦC for 36 hrs. When reaction is over dump ester/mass in brian

solution at 0 ͦC to 2 ͦC slowly. After dumping over check PPT & then filter in F.P.

check spot of filtrate. After filtration give air to tight press cake. Dump press cake

in reaction with water of 10 ͦC. Then take pH 4.0 to 4.5 by CaCO3. Then filter slurry.

Collect filtrate in another vessel. Charge oxilic acid &take pH 4.0 to 4.5 by soda bi

carbonate. Then clarify slurry and collect filtration in R/O & then spray dryer.

Mass Balance:

Mass Balance of Reactive Blue 19

INPUT KG OUTPUT KG

Oxy Sulphone 775

Oleum (23%) 800 Esterfication SO2 Gas 350

Sulfuric Acid (98%) 190

Water 3550 Drawning & Effluent to ETP 3200

Salt 870 Filteration

Water 3250 Gypsum Sludge 550

1st Slurry

CaCO3 160

Oxilic Acid 90

Soda Bicarbonate 100 2nd Slurry

Water 650

RO permeate reuse 2135

R/O

Drying loss 3200

Spray Dryer

Reactive Blue 19 1000

Total 10435 10435

M/s. Metachem Industries, Khambhat 9

4. Reactive Blue 49

Manufacturing Process:

Dump B-49 base press W/c in vessel with cold water 15 ͦC & take pH 7.0 to 7.2.

Check clear solution. Check real base by N. V. Then cool to 0 ͦC to 2 ͦC by external

chilling. Charge Cy. Chloride close main hole and stir for ½ hrs. Take pH 7.0 to 7.2

by soda solution and maintain for 4 hrs. Check N. V. of solution. It is 0.2%. If okay

then charge metanilic acid clear solution as fast as possible. Maintain pH 7.0 to 7.2

by soda solution. If pH stable start slowly heat up to 35 ͦC to 40 ͦC. check sample

and clarify.

Chemical Reaction:

Blue 49

O NH 2 O NH 2

N

SO 3 H Cl Cl 0 °C - 2 °C SO 3 H

+ N N

CH 3 CH 3

N

HN NH 2 Cl O HN NH Cl

O

CH 3 CH 3 CH 3 N N

CH 3

SO 3 H SO 3 H Cl

O NH 2

NH 2 NH 2

SO 3 H

+ +

CH 3 SO 3 H

N

O HN NH Cl SO 3 H

(50%) (50%)

CH 3 N N

CH 3

SO 3 H Cl

0 °C - 5 °C

O NH 2

SO 3 H

CH 3

N

O HN NH NH

CH 3 N N

CH 3

SO 3 H Cl SO 3 H

M/s. Metachem Industries, Khambhat 10

Mass Balance:

Mass Balance of Reactive Blue 49

INPUT KG OUTPUT KG

Blue 49 W/C 550

Soda Ash 200

Cy. Chloride 100 Condensation

Metanilic Acid 100

Water 2000

Water 200 Solid Waste 10

Clarifier

Drying loss 2140

Spray Drying

Reactive Blue 49 1000

Total 3150 3150

M/s. Metachem Industries, Khambhat 11

5. Reactive Blue 220

Manufacturing Process:

4 sulphohydrazine is coupled with sulpho OAVS ester Diazo and product is

complexed with copper sulphate and spray dryer.

Mass Balance:

Mass balance of Reactive Blue 220

INPUT KG OUTPUT KG

Sulpho OAVS 270

Sodium Nitrite 70

Diazotization of

HCl (30%) 550

Supho OAVS

Water 1400

Ice 1900

4-Sulpho Hydrazone 390

Caustic Lye (48%) 90 4 - Sulpho

Soda Ash 100 Hydrazone

Ice 1250 Solution

Water 1050

Copper sulphate 150

Coupling

Steam 350

RO permeate reuse 3450

R/O

Drying loss 3120

Spray Drying

Reactive Blue 220 1000

TOTAL 7570 7570

M/s. Metachem Industries, Khambhat 12

6. Reactive Blue 221

Manufacturing Process:

4 SulphoHydrazone is coupled with 6-Acetyl OAPSAdiazo and product is complexed

with copper sulphate. Then mass is filtered and w/cake is hydrolysis & base is

condensed with N-ethyl meta base ester and spray dryer.

Chemical Reaction:

M/s. Metachem Industries, Khambhat 13

Mass Balance:

Mass Balance of REACTIVE BLUE 221

INPUT KG OUTPUT KG

6-Acetyl OAPSA 230

CS Lye (48%) 40

HCl (30%) 580

Sodium nitrite 70

Diazotization of 6-

Sulphamic acid 2

Acetyl OAPSA

Sodium acetate 100

Soda Ash 50

Water 750

Ice 850

4-Sulpho Hydrazone 300

HCl (30%) 650 4-Sulpho

Soda ash 100 Hydrazone

Ice 800 Solution

Water 700

Copper sulphate 250

CS Flakes 320 Coupling

Hot water 580

Salt 650 Isolation & Effluent 3400

Soda ash 50 Filteration

Cyanuric Chloride 150

Tamol 7 Base Cyanuration

Water 2000

N-Ethyl MBVS 255

Condensation

Soda Bi Carb 155

Dicamol 45 Solid waste 100

Clarifier

RO permeate reuse 2000

R/O

Drying loss 3184

Spray Drying

Reactive Blue 221 1000

Total 9684 9684

M/s. Metachem Industries, Khambhat 14

7. Reactive Blue 222

Manufacturing Process:

MPDSA is cynurated with cynuric chloride at 5 ͦC& further condensed with M.B.V.S.

Ester. Then this product diazotized & coupled with H-acid to getcoupling mass-1.

S.T.acid is diazotized & further coupled with coupling mass-1 to get coupling mass-

2 which spraydried.

Chemical Reaction:

M/s. Metachem Industries, Khambhat 15

Mass Balance:

Mass Balance of Reactive Blue 222

INPUT KG OUTPUT KG

MPDSA 135

Cyanuric Chloride 132

Soda ash 60 Cyanuration of

Celsolin Oil 3 MPDSA

Water 750

Ice 750

M.B.V.S. 200

M. B. V. S. Cle.

NaHCO3 60

Solution

Water 400

NaHCO3 70

Condensation 1

NaNO2 50

Diazotization of

HCl (30%) 300

Cond. Mass

Ice 750

H-Acid 210

Soda Ash 70 H-Acid Cle.

Ice 210 Solution

Water 380

Sodium Acetate 145

Coupling 1

S. T. A. 200

HCl (30%) 60

S.T.A.

NaNO2 50

Diazotization

Ice 380

Water 380

Sodium Acetate 150

Coupling 2

RO permeate reuse 1915

R/O

Drying loss 2980

Spray Drying

Reactive Blue 222 1000

Total 5895 5895

M/s. Metachem Industries, Khambhat 16

(B) Dyes Intermediates

8. PNCBOSA

Manufacturing Process:

PNCB is sulphonated in presence of Oleum (65%) at 120 ͦc to 125 ͦC. Maintain for 8

hrs. then dump s/mass in water & salting & filter &C.F.

Mass Balance:

Mass balance of PNCBOSA

INPUT KG OUTPUT KG

PNCB 715 SO2 Gas 80

Sulphonation

65% Oleum 785

Ice 1200 Spent Acid (30 - 35%) 2500

Dumping

Water 2800

Salt 1000 Effluent 3795

Isolation

Water 1400

PNCBOSA (As is real 1525

Wet Cake of

basis 1000 Kg)

PNCBOSA

Total 7900 7900

M/s. Metachem Industries, Khambhat 17

9. Chloranil Condense

Manufacturing process:

PNCBOSA is condensed with E.D.A. at 116ͦC& the mass is then isolate with HCl.

Product obtain is then reduction with C.I.P. when reaction is over filter red. Mass &

collect liq. This liq. Clarify & further condense with chloranil at 60ͦC. When reaction

over filter the mass & dry & Pulv. final product obtained.

Chemical Reaction:

Mass Balance:

Mass balance of Chloranil Condense

INPUT KG OUTPUT KG

E.D.A. 5000

PNCBOSA 1000 E.D.A. E.D.A. Recovered 4400

SBC 250 Condensation

Water 1800

HCl (30%) 1500 Effluent 6990

Isolation

Water 2500

Ac. Acid 100

C.I.P. 500 Iron Sludge 1250

Reduction

Soda Ash 500

Water 3500

Chloranil 400 Effluent 4500

SBC 290 Chlo. Cond.

Water 2000

Drying Loss 1200

Drying

Chloranil Condensate 1000

Total 19340 19340

M/s. Metachem Industries, Khambhat 18

10. Blue HEGN (198) Base

Manufacturing process:

Chlo. Cond is cyclisation in presence of Oleum (23%), Sulphuric acid (98%) &

sodium per sulphate at 18ͦC, when reaction over dump this mass in cold water

(20'c)as fast aspossible. Then temp. goes up to 50ͦC. When dumping over stir for

15minutes & start filter. Then wash with tap water up to congo paper faint. Then

dump press cake invessel & take pH 5.0 to5.5by soda ash & then spray dry and

final product obtain.

Chemical Reaction:

(I) Cyclisation:-

SO3Na O

NH2CH2CH2NH O NH

+

NH O NHCH2CH2NH2

O SO3Na

( Chlo. Cond )

NH2 CL O SO3H

NH O NHCH2CH2NH2

NH2CH2CH2NH O NH

SO3H O CL NH2

[ Blue HEGN (198) Base ]

M/s. Metachem Industries, Khambhat 19

Mass Balance:

Mass Balance of Blue HEGN (198) Base

INPUT KG OUTPUT KG

Sulfuric Acid (98%) 375

Oleum (23%) 2800 SO2 Gas 90

Cyaclization

Chlo. Cond. 1000

Sodium per Sulfate 750

Ice 2500 Effluent 11305

Water 3000 Drawning

Water 3000 Slurry

Soda Ash 150 Preparation

Drying loss 1180

Drying

Reactive Blue 198 (HEGN) 1000

Total 13575 13575

M/s. Metachem Industries, Khambhat 20

11. Aniline 2,4 DSA

Manufacturing process:

Sulphalinic Acid is sulphonated with Oleum (23%) at different temp. & then this

mass is dump in water. Aniline 2:4 DSA is isolated & cool. Filter slurry in Nutch &

wash & C.F.

Chemical Reaction:

NH 2 NH 2

SO 3 H

+ H 2S 2O 7

+ H2O

+ SO 3

Oleum Water Sulphur Trioxide

SO 3 H SO 3 H

Sulphanilic Acid Aniline 2, 4-Disulphonic Acid

Mass Balance:

Mass balance of Aniline 2, 4 DSA

Input KG Output KG

Sulphanilic Acid 850

Oleum 23% 2500 Sulphonation SO2 Gas 50

Water 3000 Drawning

Spent sulfuric acid(45-50%) 4200

Filtration &

Water 1000 Effluent 1450

Washing

Wet Cake of Aniline 2:4 DSA (As is real 1650

Aniline 2:4 DSA basis 1000 Kg)

Total 7350 7350

M/s. Metachem Industries, Khambhat 21

12. Aniline 2,5 DSA

Manufacturing process:

Metalinic acid is sulphonated with sulphuric acid &Oleum(65%). Then mass is

dump in water give tri sulphonic acid is hydrolised to get aniline 2:5 DSA. It is

isolatedwith salt & filter & wash &C.F.

Chemical Reaction:

NH 2 NH 2

SO 3 H

+ H 2 SO 4

+ H 2O + SO 3

HO 3 S + H 2S 2O 7 HO 3 S Water Sulphur Trioxide

SO 3 H

Metanilic Acid

Aniline 2, 4, 5-Trisulphonic Acid

NH 2 NH 2

SO 3 H SO 3 H

+ H 2O

+ H 2 SO 4

HO 3 S HO 3 S Sulphuric Acid

SO 3 H

Aniline 2, 5-Disulphonic Acid

Aniline 2, 4, 5-Trisulphonic Acid

Mass Balance:

Mass balance of Aniline 2, 5 DSA

Input KG Output KG

Metanilic Acid 850

Sulfuric Acid (98%) 1000 Sulphonation SO2 Gas 80

Oleum 65% 1200

Hyflow 10

Activated Carbon 45 Spent Acid 5185

Hydrolysis

Steam 850

Water 3100

Water 1600 Solid waste 250

Clarification

Sodium Sulphate 850

Isolation

Steam 700

Filtration & Effluent 3070

Centrifuge

Wet Cake of Aniline 2:5 DSA (As is 1620

Aniline 2:5 DSA real basis 1000 Kg)

Total 10205 10205

M/s. Metachem Industries, Khambhat 22

13. Oxy Sulphone

Manufacturing process:

Bromamine acid is condense with meta base cond. & cuprous chloride & S.B.C. at

72 ͦC for 10 hrs. When reaction over transfer cond. / mass in MS + RL+BL vessel.

Then charge HCl to get pH 1.5 to 1.0. Then heat 90 C for boil up. Then cool to 70

C and filter slurry in F. P. when filter over. Give wash of 5% salt solution gradually.

Then give air and dump F. P. Take water and charge press cake & spray dryer.

Final Powder obtain.

Chemical Reaction:

(I) Bromamine Condensation:-

O NH2

NH2

SO 3H + NaHCo3

+ CuCl2

SO 2CH2CH2OH

O Br

( Bromamine Acid ) ( M. Base Condense )

O NH2

SO 3H

O NH

SO 2CH2CH2OH

( Oxy. Sulphone )

M/s. Metachem Industries, Khambhat 23

Mass Balance:

Mass balance of Oxy Sulphone

Input KG Output KG

Bromamine Acid 850

M.B. V.S. Acid 550

Soda Bi carbonate 850

Bromamine

CUCl2 10

Condensation

Celsolin Oil 10

Copper Bronze 5

Water 1000

HCl (30%) 2000

Salt 250 Isolation Effluent 7275

Water 2000

Water 2000

Slurry

Drying Loss 1250

Drying

Oxy Sulphone 1000

Total 9525 9525

M/s. Metachem Industries, Khambhat 24

14. M. Acid

Manufacturing process:

Macitinline acid is nitrated by nitric acid & H2SO4. Then isolate N. Mass in chilled

water. Filter &C.F. Nitro w/cake. Then this nitro w/cake reduction in presence of

C.I.powder & acetic acid at 80ͦC. Then filter reduction Mass & collect amino

solution. Check N.V.& set N.V. 7.0 to7.5%. Isolate by HCl (30%) at 3.0 to3.5pH.

Check f/l. Then heat 75ͦC& check f/l 0.2% to0.3%.

Chemical Reaction:

(I) Sulphonation:-

CH3

CH3

H2S2O7 SO3H

+ + H2SO4

H3C CH3 H2SO4

H3C CH3

( Mesitylene Acid )

(II) Nitration:-

CH3

CH3

O 2N SO 3H

SO 3H 2(HNO3) + 2(H2O) + H2SO4

+ H2SO4 H3C CH3

H3C CH3

NO 2

(III) Reduction:-

CH3 CH3

SO 3H H2 N SO 3H

O 2N

Fe/HCl/H2O

+ Na2CO3 CH3

H3C CH3 H3 C

NO2 NH2

2,4,6 Trimethyl m Phenylene

diamine

[M-Acid]

M/s. Metachem Industries, Khambhat 25

Mass Balance:

Mass balance of M. Acid

Input KG Output KG

Macitinline Acid 570

H2SO4 2800 Nitration NO2 200

W.N.A. 880

Water 1500

Isolation

Ice 2200

Spent Acid 4500

Filteration & C. F.

NaOH 150

Nitro slurry

Water 1500

Iron Powder 1500 Iron Sludge 2900

Ac. Acid 350

Soda Ash 350 Reduction

Ac. Carbon 25

Water 650

Isolation

HCl 1500 Effluent 4540

Filteration & C. F.

Hydro Powder 15

Drying Loss 850

Drying

M Acid 1000

Total 13990 13990

M/s. Metachem Industries, Khambhat 26

15. Blue 49 Base

Manufacturing process:

Bromammine acid is condense with M. Acid at 8.5 to 9.0pH in presence of copper

oxide & nitrogen gas purging. At 72ͦC slowly by slowly external heating. The

reaction take 12 to 15hrs.check unreacted bromamine content. If nil then charge

common salt & Dicamol & stop stirrer. Filter mass & wash press cake by hot water.

Collect filtrate in another vessel. Charge HCl (30%) to get pH 4.0 to 4.2 to isolate

M-acid. Start filter in F.P. &collect filtrate in another vessel. (Press cake is recover

m-acid use for next batch). Check volume & take pH 1.0 by HCl(30%) charging.

Check spot & startfilter. Give wash of 30% HClsolution gradually.Give slow air &

dump F.P. Cake in vessel with water. Take pH 4.5 by soda ash & spray dryer.

Chemical Reaction:

(I) Bromamine Condensation:-

NH2 SO3H

O

SO3H H3C CH3

+ + CuO + N2 gas + Na2Co3

H2N NH2

O Br CH3

( Bromamine Condensation ) ( M- Acid )

O NH2

SO3Na

CH3

O NH NH2

H3C CH3

SO3Na

( Blue 49 Base )

M/s. Metachem Industries, Khambhat 27

Mass Balance:

Mass Balance of Blue 49 Base

INPUT KG OUTPUT KG

Bromamine Acid 1000

M-Acid 1625

Soda Ash 500

Cuprous Oxide 100

Condensation of

Celsolin Oil 15

Bromamine Acid

Coomon Salt 380

Dicamol 40

N2 Gas 65

Water 3200

Wash Water 1500 Solid Waste 950

Filteration

HCl (30%) 1500 Recovered M-Acid 1150

1st Isolation

Wash Water 2500

HCl (30%) 1200 Waste Water 11850

2nd Isolation

Wash Water 2200

Water 1800

Slurry

Soda Ash 180

Drying loss 2855

Spray Drying

Blue 49 Base 1000

Total 17805 17805

M/s. Metachem Industries, Khambhat 28

16. Metanilic Acid

Manufacturing process:

Nitro Benzene reacted with Oleum (65%) at 105 ͦCfor 4 hrs. Maintain Check TLC &

acidity. Then dump S/mass water + lime powder + Soda ash solution slowly at 60

C to 80 C. Take pH 7.0 by lime powder & stir for 1 hrs. Filter slurry in nutch &

wash with hot water. Collect nitro solution. Check N V and real. Then reduction of

nitro solution in presence of iron powder & HCl. Heat mass up to 95 C and check

clear spot and A. R. + B. R. by N. V. ok. Then charge soda ash to get pH 8.5 to

9.0 to –Ve test. Filter mass in F. P. and wash with hot water and receive amino

solution & check N. V. & real charge sulphuric acid slowly to get pH 1.5 Material

isolate. Check F/L & filter slurry in nutch. Then C. F. & Dry in SFD

Chemical Reaction:

(I) Sulphonation:-

NO2

NO2 NO2

H2S2O7 + Na2CO3

+ H2SO4

SO3H

SO3Na

(II) Reduction:-

NO2 NH2

+ 2Fe + HCl + Fe2O3 + NaCl + CO2 + H2O

SO3Na

SO3Na

( Aniline 2 Sulphonic Acid )

Metalinic Acid

M/s. Metachem Industries, Khambhat 29

Mass Balance:

Mass Balance of Metanilic Acid

INPUT KG OUTPUT KG

Nitro benzene 900 SO2 Gas 40

Sulphonation

Oleum (65%) 980

Soda Ash 50

Lime Stone Powder 1100 Drawning CO2 Gas Evap. 150

Water 500

Hot Water 500 Gypsum Sludge 3120

Filteration

Iron Powder 125

HCl (30%) 100 CO2 Gas Evap. 50

Reduction

Soda Ash 175

Water 750

Hot water 700 Iron Sludge 450

Filteration

Sulphuric Acid 90 CO2 Gas evap. 25

Isolation

Water 2400

Filteration & Wastewater to ETP 2385

Centrifugation

Drying loss 1150

Drying

Metanilic Acid 1000

Total 8370 8370

M/s. Metachem Industries, Khambhat 30

17. 4 SulphoAnthranilic Acid

Manufacturing process:

O.N.T. is sulphonated with sulphuric acid (98%) and leum (65%) at 65 C maintain

for 12 hrs. Then S/mass is dilute in water and hydrolyze by NaOH and water. Then

clarify it, isolate material by 70% sulfuric acid then filter & C.F.

Chemical Reaction:

CH 3

CH3 COOH

NO 2

NO 2 NH2

Sulphonation Hydrolysis

+ H2SO 4 + H2SO 4.SO 3

-2SO 3

Sulphuric Acid Oleum

Ortho Nitro Toluene -2H2O

SO 3H SO 3H

4-Sulpho Anthranilic Acid

Mass Balance:

Mass balance of 4 Sulpho Anthranilic Acid

Input KG Output KG

O.N.T. 1800

Oleum (65%) 1980 Sulphonation

Sulfuric Acid 1000

Water 2700 Dil Sul. Acid (40-45%) 4850

Dumping

Water 3500

Hydrolysis

NaOH 2150

Sulfuric Acid (70%) 2500

Isolation

Wash Water 1800 Filteration & Spent Acid (32-35%) 10430

Centrifugation

Drying Loss 1150

Drying

4 Sulpho Anthranilic Acid 1000

Total 17430 17430

M/s. Metachem Industries, Khambhat 31

18. 4 SulphoHydrazone

Manufacturing process:

4 Sulpho Anthranilic Acid is diazotize by sodium nitrite and HCl. Then it is coupled

by S. B. S. in presence of C. S. Lye (48%). Then mass is reacting with

benzaldehyde & HCl to get product.

Chemical Reaction:

(I) Diazotisation:-

COOH COOH

NH2 N=NCL

+ NaNo2 + 2(HCl)

SO3H SO3H

( 4- Sulpho Anthralanic Acid )

(II) Reduction:-

COOH

COOH

NHNH2

N=N-CL + SBS + NaOH

SO 3H

SO 3H

(III) Condensation:-

COOH

COOH CHO

N=N-CH

NHNH2

+

SO3H

SO 3H

(Benzaldehyde)

( 4- Sulpho Hydrozone )

M/s. Metachem Industries, Khambhat 32

Mass Balance:

Mass balance of 4 Sulpho hydrazene

Input KG Output KG

4 Sulpho Anthranilic Acid 1000

HCl (30%) 1200

Diazotization

Sodium Nitrite 300

Ice 1700

Sodium bisulphite 850

Coupling

Caustic Soda 480

Benzaldehyde 600 SO2 Gas 300

HCl (30%) 1000 Benzolation CO2 Gas 250

Ice 1900

Wash Water 480 Filtration & Effluent 6830

Centrifuge

Drying Loss 1130

Drying & Packing

4 Sulpho Hydrozene 1000

Total 9510 9510

M/s. Metachem Industries, Khambhat 33

19. Sulpho OAVS / Sulpho VS / Sulpho J Acid / Sulpho gamma Acid

Manufacturing process:

OAVS is sulphonated with Sulphuric acid (98%), oleum (65%) at 140 ͦC then dump

s. mass in cold water below 10 ͦC to 15 ͦC. Then salting by KCl & check F/L& filter &

C.F.

Chemical Reaction:

Sulpho OAVS

(I) Sulphonation:-

NH2 NH2

OCH3

OCH3 H2S2O7

+ H2SO4 HO3S

SO2CH2CH2OSO 3H

SO 2CH2CH2OSO 3H

( OAVS ) ( Sulpho OAVS )

Sulpho VS

(I) Sulphonation:-

NH2 NH2

H2S2O7 SO3H

+ H2SO4

SO2CH2CH2OSO 3H SO2CH2CH2OSO 3H

( Sulpho V.S )

Sulpho J Acid

(I) Sulphonation:-

OH

OH

H2S2O7

+ H2SO4

H 2N H 2N SO 3H

SO 3H

SO3H

( J. Acid )

( Sulpho J- Acid )

M/s. Metachem Industries, Khambhat 34

Sulpho gamma Acid

(I) Sulphonation:-

OH OH

NH2 H2S2O7 NH2

+ H2SO4

NO3S HO 3S SO 3H

( Gamma Acid )

( Sulpho Gamma Acid )

Mass Balance:

Mass Balance of Sulfo OAVS

INPUT KG OUTPUT KG

OAVS 1250 SO2 282

Sulphonation

Oleum Acid (65%) 2212

Sulphuric Acid 1812

KCl 650

Water 1500 Dumping

Ice 2500

Wash water 1500 Filtration & Spent acid (32-35%) 9642

Centrifuge

Wet cake of Sulpho OAVS (As is 1500

Sulpho OAVS real basis1000 Kg)

Total 11424 11424

M/s. Metachem Industries, Khambhat 35

20. 3:5 DABA

Manufacturing process:

Benzoic acid is nitrated in presence of Nitric acid & Sulphuric acid. When reaction

over transfer n/mass in water & isolated. Filter & C.F. Then reduction of nitro

compound in presence of iron powder &HCl (30%). Then maintain temp up to

reduction over. When reduction overcharge soda ash to -ve iron test. Then filter

mass in F.P. & wash with water. Collect amino in isolation vessel. Isolate by HCl

(30%) &filter & get final product.

Chemical Reaction:

(I) Nitration:-

COOH COOH

HNO3

+

H2SO4

O 2N NO2

(II) Reduction:-

COOH

COOH

Fe/HCl/H2O

+ H2 N

Na2CO3 NH2

O 2N NO2

( 3:5 DABA )

M/s. Metachem Industries, Khambhat 36

Mass Balance:

Mass Balance of 3,5 DABA

INPUT KG OUTPUT KG

Benzoic Acid 1200

Nitric Acid 1090 Nitration NO2 Gas 180

Sulphuric Acid(98%) 2336

Water 2500

Drawning

Wash Water 1000 Filtration & Spent Acid(35-40%) 3744

Centrifuge Effluent 1500

Iron Powder 1636

HCl (30%) 1000 Iron Sludge 4000

Reduction

Soda Ash 900

Water 1800

HCl (30%) 950 Waste water to ETP 2952

Isolation

Filtration &

Centrifuge

Drying loss 1036

Drying

3,5 DABA 1000

Total 14412 14412

M/s. Metachem Industries, Khambhat 37

Annexure-III

Water Balance Diagram

Total fresh water consumption

233.0 KLD (123 KLD Fresh water + 110 KLD recycle)

Domestic Process Scrubber Washing Utility Greenbelt

5.0 128 10.0 25.0* 50.0 15.0

Soak pit

4.0

7.0

Boiler Cooling

SBS (30-35%)

10.0 40

25

4.0 Steam

Ice 30

Water

retained with

RM 71

Total Volume 233

Water/steam

loss

Dyes Dyes 1.0

Spent

6.0 Blow

H2SO4 Intermediates 89

down

55 144

50 25

RO Permeates

Drying Loss 83 water 44 25

12.0

Spray drying 10

Drying

for product Bleed

Loss 39 3.0

recovery off

77

ETP

77+ 3.0 + 25.0 +25.0 + 1.0+ 10 =141

Permeates

RO water 85.0*

141

Evaporation Salt

Spray Dryer

loss 54.25 1.75

56.0

M/s. Metachem Industries, Khambhat 38

Break up of Water Consumption& Waste Water Generation

Sr. Source Water Waste Water

No. Consumption generation

(KLD) (KLD)

1. Domestic 5.0 4.0

2. Green Belt 15 --

3. Industrial

A Process 128 102

B Scrubber 10 3.0

C Boiler 10 1.0

D Cooling 40 10

E Washing 25 25

Total Industrial 213 141

Total (1 +2 + 3) 233 145

Less recycle 110 --

Actual fresh water 123 --

consumption

M/s. Metachem Industries, Khambhat 39

Annexure-IV

Hazardous waste details

Sr. Type of Category Quantity Method of Disposal

No. Waste No. as per Proposed

HWM rules,

2016

1. ETP Waste 35.3 200 MT/month Collection, Storage, Transportation,

Disposal at TSDF site.

2. Salt ofSpray 35.3 46 MT/month Collection, Storage,Transportation,

Dryer disposal at TSDF site.

3. Process Iron 26.1 145 MT/month Collection, Storage, Transportation,

Sludge disposal at TSDF site or to Cement

industries for co-processing.

4. Process 26.1 84 MT/month Collection, Storage, Transportation,

Gypsum disposal at TSDF site or to Cement

Waste industries for co-processing.

5. Sodium Bi 26.3 182 Collection, Storage and partly reuse

sulfite KL/Month in-house and partly will be sold to

(30-35%) actual users under Rule-9.

6. UsedOil 5.1 0.5 KL/Year Collection,

Storage,Transportation,sell to

registered re-processors or use for

lubrication within premises.

7. Discarded 33.3 600 Collection, Storage,Transportation,

Containers/ Nos./month Sell to registered recyclers.

Liners/Bag 1.0 MT/month

8. Spent Acid B-15 1430 Collection, Storage,Transportation

MT/month and will be sold to actual users

under Rule-9.

M/s. Metachem Industries, Khambhat 40

Annexure-V

Details of Air Pollution

Sr. Stack Fuel Type Stack APC Probable emission

No. attached to Height, measures

in m

Flue Gas Stacks

1. Steam Boiler Coal/ Bio fuel 30 Multi SPM<150 mg/Nm3

(2 TPH) – 2 10 TPD Cyclone SO2<100 ppm

nos. Dust NOx<50 ppm

(1 stand by) Collector

2. Ho Air Coal/ Bio fuel 30 Bag Filter SPM<150 mg/Nm3

Generator – 2 TPD each SO2<100 ppm

4 Nos. NOx<50 ppm

(4.5 Lakhs

Kcal/hr each)

3. Ho Air Coal/ Bio fuel 30 IN built SPM<150 mg/Nm3

Generator – 14 TPD each Cyclone SO2<100 ppm

2 Nos. Separator & NOx<50 ppm

(25 Lakhs Bag Filter

Kcal/hr each)

4. D G Set HSD – 70 lit/hr. 15 -- SPM<150 mg/Nm3

(500 kVA) SO2<100 ppm

NOx<50 ppm

Process Gas Stacks

1. Process Vessel -- 20 Two Stage SO2<40 mg/Nm3

(Sulphonation) Water

Scrubber &

Alkali

Scrubber

2. Process Vessel -- 20 Two Stage NOx<25 mg/Nm3

(Nitration) Alkali

Scrubber

3. Process Vessel -- 20 Two Stage SO2<40 mg/Nm3

(Isolation) Alkali

Scrubber

4. Spin Flash -- 20 In PM<45 mg/Nm3

Dryer – 4 Nos. builtcyclone

separator&

bag filter

5. Spray Dryer -- 30 In built PM<45 mg/Nm3

For effluent cyclone

(2500 lit/hr.) separator &

bag filter

M/s. Metachem Industries, Khambhat 41

You might also like

- 2.2.5. Relative DensityDocument2 pages2.2.5. Relative DensitySunderchauhanNo ratings yet

- C617 CappingDocument6 pagesC617 CappingTavo Suarez C100% (1)

- Muy Buenos 3110Document17 pagesMuy Buenos 3110Jesus MorenoNo ratings yet

- CAPE Chemistry Unit 2Document27 pagesCAPE Chemistry Unit 2Audi SweetangelNo ratings yet

- EverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008Document3 pagesEverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008chuckreyesNo ratings yet

- Astm D4952 - 09Document2 pagesAstm D4952 - 09Muhannad NasifNo ratings yet

- STOCK OPNAME Lab Mikrobiologi 2021 BahanDocument2 pagesSTOCK OPNAME Lab Mikrobiologi 2021 BahanDani Puji UtomoNo ratings yet

- TFSP Ver3-2-02Document74 pagesTFSP Ver3-2-02Murali Krishna ThotaNo ratings yet

- Copper Sulfate: Identification of Petitioned Substance Trade NamesDocument18 pagesCopper Sulfate: Identification of Petitioned Substance Trade Namesweb erapeeNo ratings yet

- Glaze ForwardDocument24 pagesGlaze Forwardaonegodman100% (2)

- Nutrient Solutions and Water Quality For Soilless CulturesDocument30 pagesNutrient Solutions and Water Quality For Soilless Culturesjaime silvaNo ratings yet

- Determination of Chloride: Modification of The Volhard MethodDocument2 pagesDetermination of Chloride: Modification of The Volhard MethodAnjanie SharmaNo ratings yet

- Sharjah Standards of FE (STP)Document2 pagesSharjah Standards of FE (STP)hychauhan1No ratings yet

- Environmental Engineering Laboratory Open-Ended Lab Report: 2 Marks CommentsDocument10 pagesEnvironmental Engineering Laboratory Open-Ended Lab Report: 2 Marks CommentsMOHAMAD NOOR AZIZI ZAINUDINNo ratings yet

- Chemical Consumption Format FRM-QCDocument7 pagesChemical Consumption Format FRM-QCVinay PalNo ratings yet

- CG101 Solubility Table 2 19Document2 pagesCG101 Solubility Table 2 19celesweejh09No ratings yet

- Sample of Mass Balance MPDocument23 pagesSample of Mass Balance MPLeizel Ann GorgonioNo ratings yet

- 16 Jan 2018 120406610T5T1AY7BAnnexure-AdditionalAttachmentsFilePart1Document27 pages16 Jan 2018 120406610T5T1AY7BAnnexure-AdditionalAttachmentsFilePart1Husnain ArshadNo ratings yet

- Experiment 1 Inorganic CompundDocument5 pagesExperiment 1 Inorganic Compundpriyanshaprasad1No ratings yet

- Sodium BicarbonateDocument63 pagesSodium BicarbonateSridhar RaparthiNo ratings yet

- S-155 IC Application Note NoDocument1 pageS-155 IC Application Note NothangNo ratings yet

- Personal Care DETERGENTS BROCHUREDocument12 pagesPersonal Care DETERGENTS BROCHURERickgableNo ratings yet

- Parameters TimeDocument9 pagesParameters TimeSontu BardhanNo ratings yet

- Case StudyDocument19 pagesCase Studymohamed ibrahim nasrNo ratings yet

- Nutrisi Melon DG BHN ImporDocument6 pagesNutrisi Melon DG BHN ImporMujirah SuzanaNo ratings yet

- Alluring Acacia AccordDocument1 pageAlluring Acacia Accords224wcjzs7No ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument12 pagesTablas de Solubilidad de Compuestos InorganicosardsfafrfNo ratings yet

- Horcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Document10 pagesHorcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Luis EduardoNo ratings yet

- Comparison Between Conventional Circuit With Preleach Thickener, Preleach Filtration and Milling in RaffinateDocument73 pagesComparison Between Conventional Circuit With Preleach Thickener, Preleach Filtration and Milling in Raffinatejoseph kafumbila100% (1)

- A Method For Calculating The Composition of Nutrient SolutionsDocument14 pagesA Method For Calculating The Composition of Nutrient SolutionsJose LuisNo ratings yet

- Paraloid Au-608 TBZDocument6 pagesParaloid Au-608 TBZCHIRE SARAYASI MANUELNo ratings yet

- Anorthite Hydrolysis: Mike Borr Geol 428 Geochemistry NDSU Fall 2012Document25 pagesAnorthite Hydrolysis: Mike Borr Geol 428 Geochemistry NDSU Fall 2012yuri huamanguillas saenzNo ratings yet

- Controllable Synthesis of Fluorescent Carbon Dots and Their Detection Application As NanoprobesDocument13 pagesControllable Synthesis of Fluorescent Carbon Dots and Their Detection Application As NanoprobesNAILIL HIDAYAHNo ratings yet

- 2.2. 5. Relative Density 20205eDocument2 pages2.2. 5. Relative Density 20205evafaashkNo ratings yet

- Medias: Yeast Mannitol AgarDocument7 pagesMedias: Yeast Mannitol AgarKhadijaNo ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument7 pagesTablas de Solubilidad de Compuestos InorganicosBRYAN ANTONIO PEREZ BARAJASNo ratings yet

- Organic Lab ManualDocument76 pagesOrganic Lab ManualAnish KumarNo ratings yet

- Tablas de Solubilidad de Compuestos InorganicosDocument7 pagesTablas de Solubilidad de Compuestos InorganicosVALERIA BARRAGAN AVALOSNo ratings yet

- Controllable Synthesis of Fluorescent Carbon (Yang Et Al, 2013)Document13 pagesControllable Synthesis of Fluorescent Carbon (Yang Et Al, 2013)Nixson Manosalva ElguetaNo ratings yet

- Ijerph 16 02458Document21 pagesIjerph 16 02458bemgba.nyakumaNo ratings yet

- Ellman - Tissue Sulfhydryl Groups - 1959Document8 pagesEllman - Tissue Sulfhydryl Groups - 1959Victor MendesNo ratings yet

- Product List BTGDocument1 pageProduct List BTGwaykurniaNo ratings yet

- Mass Balance For CS2 PlantDocument3 pagesMass Balance For CS2 PlantAshish GoelNo ratings yet

- Common Names of Chemical Compounds and Formula SSCDocument5 pagesCommon Names of Chemical Compounds and Formula SSCSubin M MNo ratings yet

- Formulasi AB MixDocument2 pagesFormulasi AB Mixbahrul.hidayah@yahoo.comNo ratings yet

- P FD FileDocument18 pagesP FD FileJAYESH6No ratings yet

- BP Kiln Feed BurnabilityDocument2 pagesBP Kiln Feed BurnabilityJuliano. PQMNo ratings yet

- Product List Updated Feb 2022Document4 pagesProduct List Updated Feb 2022Yogi TDRNo ratings yet

- Sulphuric Acid Mono54-6Document89 pagesSulphuric Acid Mono54-6werdna67No ratings yet

- DocxDocument7 pagesDocxJasmin YangNo ratings yet

- Black Hill Coking CoalDocument1 pageBlack Hill Coking Coalnaresh adusumilliNo ratings yet

- Daftar Alat Dan Bahan Lab KimiaDocument5 pagesDaftar Alat Dan Bahan Lab KimiaOzinasution NasutionNo ratings yet

- Mineral Water Calculator v5Document7 pagesMineral Water Calculator v5mauricio0327No ratings yet

- Formula BookDocument31 pagesFormula BookJonathan Candelier100% (1)

- Appendix III: Equivalent Weight of Substances Required in Volumetric Analysis - Engineering360Document3 pagesAppendix III: Equivalent Weight of Substances Required in Volumetric Analysis - Engineering360Waleed EmaraNo ratings yet

- NullDocument1 pageNullapi-25932006No ratings yet

- Hidrotek - 5 Stage Reverse Osmosis: Daily Runing Cost of Only 0.10cDocument1 pageHidrotek - 5 Stage Reverse Osmosis: Daily Runing Cost of Only 0.10cDavid VellaNo ratings yet

- One Bath One Stage Dyeing of Polyester / Cellulosic Blends.Document31 pagesOne Bath One Stage Dyeing of Polyester / Cellulosic Blends.sanjay shettiNo ratings yet

- Salt AnalysisDocument25 pagesSalt AnalysisAditya Nanda0% (1)

- Process Systems Engineering Studies For The Synthesis of Catalytic Biomass-To-Fuels StrategiesDocument2 pagesProcess Systems Engineering Studies For The Synthesis of Catalytic Biomass-To-Fuels StrategiesJonathan Riveros RojasNo ratings yet

- Coal Spec Wahana 6300 GarDocument1 pageCoal Spec Wahana 6300 GarAmatơ Hà ThànhNo ratings yet

- 1 TRADING PRODUCT LIST - Rev-01Document3 pages1 TRADING PRODUCT LIST - Rev-01aeryvishal4No ratings yet

- Additives for High Performance Applications: Chemistry and ApplicationsFrom EverandAdditives for High Performance Applications: Chemistry and ApplicationsNo ratings yet

- Homogeneous Catalysis: Mechanisms and Industrial ApplicationsFrom EverandHomogeneous Catalysis: Mechanisms and Industrial ApplicationsNo ratings yet

- Investigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationDocument8 pagesInvestigation of Straight-Run Diesel Oil Fractions With Sulphur High Content Oxidative DesulphurizationPhuc NguyenNo ratings yet

- Acid Rain Explanation TextDocument2 pagesAcid Rain Explanation TextIndah Dwi Cahayany100% (2)

- Low Sulphur Fuel Oil (LSFO)Document7 pagesLow Sulphur Fuel Oil (LSFO)asep supriyadiNo ratings yet

- Rubber Bloomong PDFDocument13 pagesRubber Bloomong PDFAjit SamalNo ratings yet

- Sulfur Dioksida Biomarker PDFDocument223 pagesSulfur Dioksida Biomarker PDFWayan Tanjung AryasaNo ratings yet

- Using Alchemically Prepared Herbs To Augment The Eight Temples MeditationDocument3 pagesUsing Alchemically Prepared Herbs To Augment The Eight Temples Meditationfmezz2000No ratings yet

- 100 Potassium PermanganateDocument7 pages100 Potassium Permanganateeng20072007No ratings yet

- Hydroponic NutrientsDocument9 pagesHydroponic NutrientsDhanraj PatilNo ratings yet

- Reactions of Non-Metals With OxygenDocument18 pagesReactions of Non-Metals With Oxygen18118100% (1)

- Qualitative Organic Analysis PDFDocument75 pagesQualitative Organic Analysis PDFAbhi RamNo ratings yet

- Ecology G 12Document209 pagesEcology G 12Samuel LegissaNo ratings yet

- Pre-Sulfiding On-Line Sulfiding ProceduresDocument8 pagesPre-Sulfiding On-Line Sulfiding ProceduresIrma Brennan0% (1)

- Chapter 1 Chemical Reactions and EquationsPreviewDocument48 pagesChapter 1 Chemical Reactions and EquationsPreviewAparNo ratings yet

- 101-110 RunkelDocument10 pages101-110 RunkelJohn Sebastian Bell-ScottNo ratings yet

- Lassaigne'S Tests: Elemental Analysis: EjgcaroDocument4 pagesLassaigne'S Tests: Elemental Analysis: EjgcaroRex KorrNo ratings yet

- 5070 s11 QP 11Document16 pages5070 s11 QP 11chuasioklengNo ratings yet

- Sulfur Dioxide Handling ManualDocument16 pagesSulfur Dioxide Handling ManualManfred VonNo ratings yet

- Mineral ResourcesDocument6 pagesMineral ResourcesharrisNo ratings yet

- 10th Chemical Reaction and Equation Questions With Solution 03Document3 pages10th Chemical Reaction and Equation Questions With Solution 03Vaibhav SunnyNo ratings yet

- Encyclopedia of Biodiversity Volume 1Document952 pagesEncyclopedia of Biodiversity Volume 1Georgi Zuhkov100% (2)

- Sulphur Solidification and FormingDocument37 pagesSulphur Solidification and FormingAnonymous qPt2MHzXTNo ratings yet

- Technical Note VulcanizationDocument26 pagesTechnical Note VulcanizationVinodh Kumar0% (1)

- Chapter 2Document8 pagesChapter 2Megan SchmidtNo ratings yet

- Kinetics of Zinc Sulfide Concentrate Direct Leaching in Pilot Plant Scale and Development of Semi-Empirical ModelDocument10 pagesKinetics of Zinc Sulfide Concentrate Direct Leaching in Pilot Plant Scale and Development of Semi-Empirical ModelTacachiri Chocamani JaimeNo ratings yet

- Risk Assessment of Sulphur RecoveryDocument6 pagesRisk Assessment of Sulphur RecoveryTejasNo ratings yet