Professional Documents

Culture Documents

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Uploaded by

saddam4everCopyright:

Available Formats

You might also like

- Welded Master Links With Engineered FlatDocument1 pageWelded Master Links With Engineered FlatjpriceNo ratings yet

- Grillete S-281Document1 pageGrillete S-281Franco Gaston (GR industrial S.R.L.)No ratings yet

- Crosby US 422TDocument1 pageCrosby US 422Tcyril87No ratings yet

- Cold Tuff Fittings: Master LinksDocument1 pageCold Tuff Fittings: Master LinksYOGESH GOPALNo ratings yet

- Grade 100 Alloy Master Links: A-1370 Reeving LinkDocument1 pageGrade 100 Alloy Master Links: A-1370 Reeving LinkKonstantinos SynodinosNo ratings yet

- cb0369 Reid Reidbrace Technical Data Sheet - Nov - 2021 Pin and Clips WebDocument8 pagescb0369 Reid Reidbrace Technical Data Sheet - Nov - 2021 Pin and Clips WebsteventNo ratings yet

- Load Securement: Crosby LEBUS L-140 Standard Ratchet Type Load BindersDocument1 pageLoad Securement: Crosby LEBUS L-140 Standard Ratchet Type Load BindersCarla Flores QuintanaNo ratings yet

- PS PS-1250 DatasheetDocument2 pagesPS PS-1250 DatasheetJose Alberto López MacíasNo ratings yet

- Unit 3a Welding InspectionDocument15 pagesUnit 3a Welding InspectionMarcell John TamioNo ratings yet

- QAP Highmast 42672 D6ac45Document2 pagesQAP Highmast 42672 D6ac45Kritika Chaudhary Chandra MohanNo ratings yet

- Katalog Koncowki Rurowe ABB Wersja en 08.2017Document36 pagesKatalog Koncowki Rurowe ABB Wersja en 08.2017nnNo ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- HVA Capsule Adhesive Anchor Product Data 814698Document20 pagesHVA Capsule Adhesive Anchor Product Data 814698Teodoro MendezNo ratings yet

- Cold Tuff Master LinkDocument1 pageCold Tuff Master LinkSelamet MirantoNo ratings yet

- Assessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015Document31 pagesAssessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015امين100% (2)

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Features: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesDocument2 pagesFeatures: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesKva MurphyNo ratings yet

- ClareDocument9 pagesClareAbdelkader DraïNo ratings yet

- PS-1270F1 Ficha TécnicaDocument2 pagesPS-1270F1 Ficha TécnicaFernando TapiaNo ratings yet

- Battery Performance Specifications: Telecommunications Nebs CompliantDocument6 pagesBattery Performance Specifications: Telecommunications Nebs Compliantlucien altidorNo ratings yet

- Anel A-344 - 67T - CrosbyDocument1 pageAnel A-344 - 67T - CrosbyBeatriz SantosNo ratings yet

- LxemDocument10 pagesLxemtgghareebNo ratings yet

- GE50 Series 40 and Series 46 HeavyDuty SingleStage Pressure Regulators EnglishDocument2 pagesGE50 Series 40 and Series 46 HeavyDuty SingleStage Pressure Regulators EnglishVijo JoseNo ratings yet

- Chapter01 ShacklesDocument48 pagesChapter01 Shacklescalculus pussNo ratings yet

- Turnbuckles, Swivels, & Hoist RingsDocument5 pagesTurnbuckles, Swivels, & Hoist RingscelonevesNo ratings yet

- wedge anchoring clamps Σελίδα 48 και 49Document1 pagewedge anchoring clamps Σελίδα 48 και 49Konstantinos SynodinosNo ratings yet

- RJ45 CAT.5e For PROFINET: Approvals Application AdvantageDocument1 pageRJ45 CAT.5e For PROFINET: Approvals Application Advantageindra putraNo ratings yet

- American Welding SocietyDocument56 pagesAmerican Welding SocietyJUAN RAMOSNo ratings yet

- Shield - Gas Engine Oil Low Ash - Sae 40: Typical Physical PropertiesDocument1 pageShield - Gas Engine Oil Low Ash - Sae 40: Typical Physical Propertiesdave fowlerNo ratings yet

- Module Weld Subsequent Filling PassDocument10 pagesModule Weld Subsequent Filling Passbarry bonzoNo ratings yet

- LESER India Catalogue Type 526 IC API Series PDFDocument12 pagesLESER India Catalogue Type 526 IC API Series PDFyg89No ratings yet

- Vishay Bccomponents: FeaturesDocument18 pagesVishay Bccomponents: FeaturesJose cuelloNo ratings yet

- HG-228 Esticador CrosbyDocument1 pageHG-228 Esticador CrosbyBeatriz SantosNo ratings yet

- WE-Aly-PLSec1-02-09-2010 Rev.1Document1 pageWE-Aly-PLSec1-02-09-2010 Rev.1Ahmed AlyNo ratings yet

- API 6D Valves Bonney Forge PDFDocument12 pagesAPI 6D Valves Bonney Forge PDFSQUALO_122No ratings yet

- 25kv Class Fused Loadbreak Elbow Connector Catalog Ca650070enDocument8 pages25kv Class Fused Loadbreak Elbow Connector Catalog Ca650070enHugo OsunaNo ratings yet

- PNR Porcelain Bushing Brochure 33209 EN A4 202112 R002Document9 pagesPNR Porcelain Bushing Brochure 33209 EN A4 202112 R002setiyawanNo ratings yet

- Saudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingDocument5 pagesSaudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingMahrouz MadoNo ratings yet

- LCOM Spec SheetDocument4 pagesLCOM Spec SheetGabrielGrecoNo ratings yet

- Catalog: Flanged Safety Relief Valves Series 526 CCDocument12 pagesCatalog: Flanged Safety Relief Valves Series 526 CCSuelen SobrinhoNo ratings yet

- Avago HSMS 2820 TR1G DatasheetDocument14 pagesAvago HSMS 2820 TR1G DatasheetTanko SuleNo ratings yet

- VDF Weg DibDocument44 pagesVDF Weg DibSame HeidernNo ratings yet

- CHAPADocument2 pagesCHAPAPlaneacion FabrilNo ratings yet

- Mss sp952006 Swaged Nipples and Bull PlugsDocument16 pagesMss sp952006 Swaged Nipples and Bull PlugsDaryna KupriianovaNo ratings yet

- MLT-100 Plastic Coated TubeDocument2 pagesMLT-100 Plastic Coated TubeTan Kang YaoNo ratings yet

- Quality Assurance PlanDocument2 pagesQuality Assurance Planpiyush singhNo ratings yet

- Crosby G-2150Document1 pageCrosby G-2150jdpardoNo ratings yet

- SMAW 9 Week 4 Information SheetDocument3 pagesSMAW 9 Week 4 Information SheetCrauxz de TraxNo ratings yet

- Kopr-Kote TDS 2Document1 pageKopr-Kote TDS 2jesusNo ratings yet

- PCI Express Gen 4 and Gen 5 Card Edge ConnectorsDocument4 pagesPCI Express Gen 4 and Gen 5 Card Edge ConnectorsAlejandro JimenezNo ratings yet

- B 2648 PDFDocument6 pagesB 2648 PDFbcanilkumar007No ratings yet

- SADIP Catalogue, Large Diameters 2007Document62 pagesSADIP Catalogue, Large Diameters 2007diaghanemNo ratings yet

- Aceco Isolator Ball ValveDocument2 pagesAceco Isolator Ball ValveLynn AlgerNo ratings yet

- Heavy-Duty Probe Testers: Accurate Reliable Safe Durable IntuitiveDocument12 pagesHeavy-Duty Probe Testers: Accurate Reliable Safe Durable Intuitivelilo6romeroNo ratings yet

- SSE-QC-ELE-525-Cable LayingDocument3 pagesSSE-QC-ELE-525-Cable LayingBhalsingh JangraNo ratings yet

- Sewing Machine OilDocument1 pageSewing Machine OilSakthi SaravananNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- 4mm IWRCDocument1 page4mm IWRCsaddam4everNo ratings yet

- Green Pin® Bow Shackle BN - Green PinDocument6 pagesGreen Pin® Bow Shackle BN - Green Pinsaddam4everNo ratings yet

- DC FBH 11 TDSDocument1 pageDC FBH 11 TDSsaddam4everNo ratings yet

- Certificate of Examination and Test - Wire Rope Before Being Take Into Use 140707-1Document1 pageCertificate of Examination and Test - Wire Rope Before Being Take Into Use 140707-1saddam4everNo ratings yet

- Thimble 1616Document1 pageThimble 1616saddam4everNo ratings yet

- Electric Hoist CatalogDocument2 pagesElectric Hoist Catalogsaddam4everNo ratings yet

- Certificate of Examination and Test - Wire Rope Before Being Take Into Use 140706-1Document1 pageCertificate of Examination and Test - Wire Rope Before Being Take Into Use 140706-1saddam4everNo ratings yet

- Load Cell 1Document6 pagesLoad Cell 1saddam4everNo ratings yet

- Product CatalogueDocument24 pagesProduct Cataloguesaddam4everNo ratings yet

- SS ItemsDocument1 pageSS Itemssaddam4everNo ratings yet

- Company Profile - VerlindeDocument8 pagesCompany Profile - Verlindesaddam4everNo ratings yet

- Cylinders HiforceDocument5 pagesCylinders Hiforcesaddam4everNo ratings yet

- Cargo Lashing BeltDocument1 pageCargo Lashing Beltsaddam4everNo ratings yet

- Large Dee ShackleDocument1 pageLarge Dee Shacklesaddam4everNo ratings yet

- Construction PaintingDocument8 pagesConstruction PaintingSusan Mabitad100% (1)

- Loctite - Automotive CatalogDocument60 pagesLoctite - Automotive CataloglimalizadoNo ratings yet

- Q F (K, L) K L: (Please Show Complete Solution.)Document4 pagesQ F (K, L) K L: (Please Show Complete Solution.)Karl Simone EsmillaNo ratings yet

- Br. Kade Postupak I Ime Preparata Konc. (%) Temp (°C) Miješanje Otopine Materijal Kade Br. Faze (Al I Fe) Vrijeme Obrade PH, ProvodljivostDocument3 pagesBr. Kade Postupak I Ime Preparata Konc. (%) Temp (°C) Miješanje Otopine Materijal Kade Br. Faze (Al I Fe) Vrijeme Obrade PH, ProvodljivostBranko BrezecNo ratings yet

- Case StudyDocument27 pagesCase StudyZewude HirpesaNo ratings yet

- Cakasa (Nigeria) Company Limited: Welding Summary ReportDocument7 pagesCakasa (Nigeria) Company Limited: Welding Summary ReportOgheneruemu EtasNo ratings yet

- 2023MSE-II Handout3Document12 pages2023MSE-II Handout3王竣右No ratings yet

- Cost EstimationDocument10 pagesCost EstimationWOOD UTOPIANo ratings yet

- ASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeDocument7 pagesASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeLiu ZhenguoNo ratings yet

- Mec 132 - Assignment 1Document17 pagesMec 132 - Assignment 1diana tahaNo ratings yet

- CHP-2202-ME-001 R.C - Flow Diagram After Shortlist MeetingDocument1 pageCHP-2202-ME-001 R.C - Flow Diagram After Shortlist MeetingEngineering ServiceNo ratings yet

- 0523 - ABM3000 Batch MillDocument3 pages0523 - ABM3000 Batch MillSilvio Insulza ChoqueNo ratings yet

- L-G Slideway OilDocument2 pagesL-G Slideway OilAdnanNo ratings yet

- Master - J Data SheetDocument1 pageMaster - J Data SheetRonald WongNo ratings yet

- 75TH NGF Exhibitors List of Womens Wear 08.07.2022Document7 pages75TH NGF Exhibitors List of Womens Wear 08.07.2022Harsh PunmiyaNo ratings yet

- Naveed. MOM-140 - Minutes of Weekly Quality Control Meeting 13-Mar-24Document38 pagesNaveed. MOM-140 - Minutes of Weekly Quality Control Meeting 13-Mar-24naveed ahmedNo ratings yet

- Anish Valmiki - 300321845 CVG 5150 Quiz 04Document6 pagesAnish Valmiki - 300321845 CVG 5150 Quiz 04Anish valmikiNo ratings yet

- Axius SC Sanitary Rupture Disc R14301 Datasheet ENDocument3 pagesAxius SC Sanitary Rupture Disc R14301 Datasheet ENeng_823664768No ratings yet

- Adobe Scan 04 Jan 2022Document2 pagesAdobe Scan 04 Jan 2022Garvit SharmaNo ratings yet

- PU Clear LacquerDocument1 pagePU Clear LacquerA.F.M Salman AkterNo ratings yet

- Summer Training Presentation E.R AutoDocument15 pagesSummer Training Presentation E.R AutoRobin ChhabraNo ratings yet

- Evolution of TQM: Total Quality Management Dycbatqm313 Abel C. Reyes January 11, 2020Document12 pagesEvolution of TQM: Total Quality Management Dycbatqm313 Abel C. Reyes January 11, 2020Vea Dela CruzNo ratings yet

- P&ID and Mass Balance Production Waste 130921-B-ModelDocument1 pageP&ID and Mass Balance Production Waste 130921-B-ModelmaizanazaNo ratings yet

- Case Study BoltsDocument14 pagesCase Study BoltsMohamed AnwarNo ratings yet

- Concrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25Document15 pagesConcrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25patel2732sNo ratings yet

- TB-2022-01 PWHT Exemption TableDocument1 pageTB-2022-01 PWHT Exemption TableMuhammad Ghufran KhanNo ratings yet

- Uny Marine - Polyurethane Finish (Findotek)Document1 pageUny Marine - Polyurethane Finish (Findotek)Hendy S LeksonoNo ratings yet

- Gemini Twin Line ParalelaDocument1 pageGemini Twin Line ParalelaMary Huaylla ANo ratings yet

- RUKO Hole Saws CMSDocument15 pagesRUKO Hole Saws CMSjoaomachadoNo ratings yet

- BENCHMADE 2010 (Knife Catalogue) (Z-Library)Document72 pagesBENCHMADE 2010 (Knife Catalogue) (Z-Library)nikkojazzNo ratings yet

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Uploaded by

saddam4everOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Master Links: Grade 80 A-347 Welded Master Link Assembly With Engineered Flat

Uploaded by

saddam4everCopyright:

Available Formats

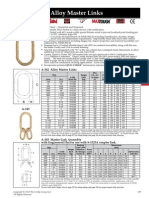

MASTER LINKS

A-347 •

•

Alloy steel — Quenched & Tempered.

Individually Proof Tested to values shown, with certification.

1

2

• Design Factor of 5 to 1.

• Proof Tested with 70% inside width special fixtures sized to

prevent localized point loading per EN1677.

3

• Each main link is marked with Product Identification Code

(PIC) for material traceability, Grade, CE, chain size and the

"CG" (Crosby Group). Each sublink is marked with traceability

code.

• A-347 master links are type approved to DNV Certification

Notes 2.7-1- Offshore Containers. These Crosby master links

4

are 100% proof tested. Every batch is impact tested. The tests

are conducted by Crosby and 3.1 test certification is available

upon request.

5

• Engineered Flat for use with S-1325A coupler link.

• Fatigue rated to 20,000 cycles at 1.5 times the Working Load

Limit.

6

• Meets or exceeds all requirements of ASME B30.26 including

identification, ductility, design factor, proof load and

temperature requirements. Importantly, these links meet

7

other critical performance requirements including fatigue life,

impact properties and material traceability, not addressed by

ASME B30.26.

8

• Available only in EMEA.

Grade 80 A-347 Welded Master Link Assembly with Engineered Flat

Grade 100 Grade 80 Dimensions (in) Engineered

9

Chain Sling Chain Sling Flat Size for

Stock No.

Weight

Each

(lb)

Three / Four

(in)

Three / Four

Legs Chain Size Legs Chain Size

(in)

WLL

(lb)

Proof

Load

(lb) A B C D E F G

S1325A

Chain Size

(in)

10

1257755 2.4 - 6mm 7,000 17,632 0.51 2.36 4.72 0.51 4.72 2.36 0.26 6mm

1257762

1257832

3.5

3.9

6mm

6mm

6mm, 9/32

9/32

9,000

9,200

22,701

23,362

0.67

0.75

3.54

3.54

6.30

6.30

0.51

0.51

4.72

4.72

2.36

2.36

0.26

0.26

6mm

9/32 11

1258058 7.3 5/16, 9/32 5/16 15,400 38,570 0.87 3.94 7.09 0.67 6.30 3.54 0.33 3/8

1258067

1258049

8.9

8.4

5/16, 9/32

5/16

5/16

3/8

15,400

18,700

38,570

46,725

0.87

0.87

5.71

3.94

10.83

7.09

0.67

0.75

6.30

6.30

3.54

3.54

0.33

0.33

3/8

3/8 12

1258076 10.1 5/16 3/8 19,600 49,149 0.98 4.53 8.27 0.75 6.30 3.54 0.33 3/8

1258102

1258142

11.4

15.6

5/16

3/8

3/8

1/2

19,600

31,900

49,149

80,005

0.98

1.10

5.71

5.71

10.83

10.83

0.75

0.87

6.30

7.09

3.54

3.94

0.33

0.41

3/8

1/2 13

1258182 21.2 3/8 1/2 37,400 93,670 1.26 5.71 10.83 0.98 8.27 4.53 0.53 5/8

1258185

1258187

28

40.6

1/2

5/8

5/8

5/8

52,000

61,900

130,036

154,941

1.42

1.57

6.10

5.51

11.22

10.63

1.10

1.26

7.48

10.83

4.33

5.71

0.53

0.66

5/8

- 14

1258402 58.6 5/8 3/4 84,400 211,143 1.77 7.09 13.39 1.42 11.22 6.10 - -

1258471

1258491

78.2

134.6

3/4

7/8

7/8

1

99,200

147,600

247,950

369,170

2.01

2.17

8.46

7.99

15.35

15.98

1.57

2.01

10.63

15.35

5.51

8.46

-

-

-

- 15

5:1 Design Factor. Applications with wire rope and synthetic sling generally require a Design Factor of 5. Based on single leg sling (in-line load), or resultant load on multiple legs with

16

an included angle less than or equal to 120 degrees. Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9. Chain slings require that the Design

Factor be 4:1. Refer to applications & warnings to determine product's actual Ultimate Load. There are no manufactured flats on links over 1 1/4" (32mm).

APPLICATION AND WARNING INFORMATION

17

SECTION 17

Copyright © 2023 The Crosby Group LLC All Rights Reserved 137

You might also like

- Welded Master Links With Engineered FlatDocument1 pageWelded Master Links With Engineered FlatjpriceNo ratings yet

- Grillete S-281Document1 pageGrillete S-281Franco Gaston (GR industrial S.R.L.)No ratings yet

- Crosby US 422TDocument1 pageCrosby US 422Tcyril87No ratings yet

- Cold Tuff Fittings: Master LinksDocument1 pageCold Tuff Fittings: Master LinksYOGESH GOPALNo ratings yet

- Grade 100 Alloy Master Links: A-1370 Reeving LinkDocument1 pageGrade 100 Alloy Master Links: A-1370 Reeving LinkKonstantinos SynodinosNo ratings yet

- cb0369 Reid Reidbrace Technical Data Sheet - Nov - 2021 Pin and Clips WebDocument8 pagescb0369 Reid Reidbrace Technical Data Sheet - Nov - 2021 Pin and Clips WebsteventNo ratings yet

- Load Securement: Crosby LEBUS L-140 Standard Ratchet Type Load BindersDocument1 pageLoad Securement: Crosby LEBUS L-140 Standard Ratchet Type Load BindersCarla Flores QuintanaNo ratings yet

- PS PS-1250 DatasheetDocument2 pagesPS PS-1250 DatasheetJose Alberto López MacíasNo ratings yet

- Unit 3a Welding InspectionDocument15 pagesUnit 3a Welding InspectionMarcell John TamioNo ratings yet

- QAP Highmast 42672 D6ac45Document2 pagesQAP Highmast 42672 D6ac45Kritika Chaudhary Chandra MohanNo ratings yet

- Katalog Koncowki Rurowe ABB Wersja en 08.2017Document36 pagesKatalog Koncowki Rurowe ABB Wersja en 08.2017nnNo ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- HVA Capsule Adhesive Anchor Product Data 814698Document20 pagesHVA Capsule Adhesive Anchor Product Data 814698Teodoro MendezNo ratings yet

- Cold Tuff Master LinkDocument1 pageCold Tuff Master LinkSelamet MirantoNo ratings yet

- Assessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015Document31 pagesAssessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015امين100% (2)

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Features: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesDocument2 pagesFeatures: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesKva MurphyNo ratings yet

- ClareDocument9 pagesClareAbdelkader DraïNo ratings yet

- PS-1270F1 Ficha TécnicaDocument2 pagesPS-1270F1 Ficha TécnicaFernando TapiaNo ratings yet

- Battery Performance Specifications: Telecommunications Nebs CompliantDocument6 pagesBattery Performance Specifications: Telecommunications Nebs Compliantlucien altidorNo ratings yet

- Anel A-344 - 67T - CrosbyDocument1 pageAnel A-344 - 67T - CrosbyBeatriz SantosNo ratings yet

- LxemDocument10 pagesLxemtgghareebNo ratings yet

- GE50 Series 40 and Series 46 HeavyDuty SingleStage Pressure Regulators EnglishDocument2 pagesGE50 Series 40 and Series 46 HeavyDuty SingleStage Pressure Regulators EnglishVijo JoseNo ratings yet

- Chapter01 ShacklesDocument48 pagesChapter01 Shacklescalculus pussNo ratings yet

- Turnbuckles, Swivels, & Hoist RingsDocument5 pagesTurnbuckles, Swivels, & Hoist RingscelonevesNo ratings yet

- wedge anchoring clamps Σελίδα 48 και 49Document1 pagewedge anchoring clamps Σελίδα 48 και 49Konstantinos SynodinosNo ratings yet

- RJ45 CAT.5e For PROFINET: Approvals Application AdvantageDocument1 pageRJ45 CAT.5e For PROFINET: Approvals Application Advantageindra putraNo ratings yet

- American Welding SocietyDocument56 pagesAmerican Welding SocietyJUAN RAMOSNo ratings yet

- Shield - Gas Engine Oil Low Ash - Sae 40: Typical Physical PropertiesDocument1 pageShield - Gas Engine Oil Low Ash - Sae 40: Typical Physical Propertiesdave fowlerNo ratings yet

- Module Weld Subsequent Filling PassDocument10 pagesModule Weld Subsequent Filling Passbarry bonzoNo ratings yet

- LESER India Catalogue Type 526 IC API Series PDFDocument12 pagesLESER India Catalogue Type 526 IC API Series PDFyg89No ratings yet

- Vishay Bccomponents: FeaturesDocument18 pagesVishay Bccomponents: FeaturesJose cuelloNo ratings yet

- HG-228 Esticador CrosbyDocument1 pageHG-228 Esticador CrosbyBeatriz SantosNo ratings yet

- WE-Aly-PLSec1-02-09-2010 Rev.1Document1 pageWE-Aly-PLSec1-02-09-2010 Rev.1Ahmed AlyNo ratings yet

- API 6D Valves Bonney Forge PDFDocument12 pagesAPI 6D Valves Bonney Forge PDFSQUALO_122No ratings yet

- 25kv Class Fused Loadbreak Elbow Connector Catalog Ca650070enDocument8 pages25kv Class Fused Loadbreak Elbow Connector Catalog Ca650070enHugo OsunaNo ratings yet

- PNR Porcelain Bushing Brochure 33209 EN A4 202112 R002Document9 pagesPNR Porcelain Bushing Brochure 33209 EN A4 202112 R002setiyawanNo ratings yet

- Saudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingDocument5 pagesSaudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingMahrouz MadoNo ratings yet

- LCOM Spec SheetDocument4 pagesLCOM Spec SheetGabrielGrecoNo ratings yet

- Catalog: Flanged Safety Relief Valves Series 526 CCDocument12 pagesCatalog: Flanged Safety Relief Valves Series 526 CCSuelen SobrinhoNo ratings yet

- Avago HSMS 2820 TR1G DatasheetDocument14 pagesAvago HSMS 2820 TR1G DatasheetTanko SuleNo ratings yet

- VDF Weg DibDocument44 pagesVDF Weg DibSame HeidernNo ratings yet

- CHAPADocument2 pagesCHAPAPlaneacion FabrilNo ratings yet

- Mss sp952006 Swaged Nipples and Bull PlugsDocument16 pagesMss sp952006 Swaged Nipples and Bull PlugsDaryna KupriianovaNo ratings yet

- MLT-100 Plastic Coated TubeDocument2 pagesMLT-100 Plastic Coated TubeTan Kang YaoNo ratings yet

- Quality Assurance PlanDocument2 pagesQuality Assurance Planpiyush singhNo ratings yet

- Crosby G-2150Document1 pageCrosby G-2150jdpardoNo ratings yet

- SMAW 9 Week 4 Information SheetDocument3 pagesSMAW 9 Week 4 Information SheetCrauxz de TraxNo ratings yet

- Kopr-Kote TDS 2Document1 pageKopr-Kote TDS 2jesusNo ratings yet

- PCI Express Gen 4 and Gen 5 Card Edge ConnectorsDocument4 pagesPCI Express Gen 4 and Gen 5 Card Edge ConnectorsAlejandro JimenezNo ratings yet

- B 2648 PDFDocument6 pagesB 2648 PDFbcanilkumar007No ratings yet

- SADIP Catalogue, Large Diameters 2007Document62 pagesSADIP Catalogue, Large Diameters 2007diaghanemNo ratings yet

- Aceco Isolator Ball ValveDocument2 pagesAceco Isolator Ball ValveLynn AlgerNo ratings yet

- Heavy-Duty Probe Testers: Accurate Reliable Safe Durable IntuitiveDocument12 pagesHeavy-Duty Probe Testers: Accurate Reliable Safe Durable Intuitivelilo6romeroNo ratings yet

- SSE-QC-ELE-525-Cable LayingDocument3 pagesSSE-QC-ELE-525-Cable LayingBhalsingh JangraNo ratings yet

- Sewing Machine OilDocument1 pageSewing Machine OilSakthi SaravananNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- 4mm IWRCDocument1 page4mm IWRCsaddam4everNo ratings yet

- Green Pin® Bow Shackle BN - Green PinDocument6 pagesGreen Pin® Bow Shackle BN - Green Pinsaddam4everNo ratings yet

- DC FBH 11 TDSDocument1 pageDC FBH 11 TDSsaddam4everNo ratings yet

- Certificate of Examination and Test - Wire Rope Before Being Take Into Use 140707-1Document1 pageCertificate of Examination and Test - Wire Rope Before Being Take Into Use 140707-1saddam4everNo ratings yet

- Thimble 1616Document1 pageThimble 1616saddam4everNo ratings yet

- Electric Hoist CatalogDocument2 pagesElectric Hoist Catalogsaddam4everNo ratings yet

- Certificate of Examination and Test - Wire Rope Before Being Take Into Use 140706-1Document1 pageCertificate of Examination and Test - Wire Rope Before Being Take Into Use 140706-1saddam4everNo ratings yet

- Load Cell 1Document6 pagesLoad Cell 1saddam4everNo ratings yet

- Product CatalogueDocument24 pagesProduct Cataloguesaddam4everNo ratings yet

- SS ItemsDocument1 pageSS Itemssaddam4everNo ratings yet

- Company Profile - VerlindeDocument8 pagesCompany Profile - Verlindesaddam4everNo ratings yet

- Cylinders HiforceDocument5 pagesCylinders Hiforcesaddam4everNo ratings yet

- Cargo Lashing BeltDocument1 pageCargo Lashing Beltsaddam4everNo ratings yet

- Large Dee ShackleDocument1 pageLarge Dee Shacklesaddam4everNo ratings yet

- Construction PaintingDocument8 pagesConstruction PaintingSusan Mabitad100% (1)

- Loctite - Automotive CatalogDocument60 pagesLoctite - Automotive CataloglimalizadoNo ratings yet

- Q F (K, L) K L: (Please Show Complete Solution.)Document4 pagesQ F (K, L) K L: (Please Show Complete Solution.)Karl Simone EsmillaNo ratings yet

- Br. Kade Postupak I Ime Preparata Konc. (%) Temp (°C) Miješanje Otopine Materijal Kade Br. Faze (Al I Fe) Vrijeme Obrade PH, ProvodljivostDocument3 pagesBr. Kade Postupak I Ime Preparata Konc. (%) Temp (°C) Miješanje Otopine Materijal Kade Br. Faze (Al I Fe) Vrijeme Obrade PH, ProvodljivostBranko BrezecNo ratings yet

- Case StudyDocument27 pagesCase StudyZewude HirpesaNo ratings yet

- Cakasa (Nigeria) Company Limited: Welding Summary ReportDocument7 pagesCakasa (Nigeria) Company Limited: Welding Summary ReportOgheneruemu EtasNo ratings yet

- 2023MSE-II Handout3Document12 pages2023MSE-II Handout3王竣右No ratings yet

- Cost EstimationDocument10 pagesCost EstimationWOOD UTOPIANo ratings yet

- ASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeDocument7 pagesASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeLiu ZhenguoNo ratings yet

- Mec 132 - Assignment 1Document17 pagesMec 132 - Assignment 1diana tahaNo ratings yet

- CHP-2202-ME-001 R.C - Flow Diagram After Shortlist MeetingDocument1 pageCHP-2202-ME-001 R.C - Flow Diagram After Shortlist MeetingEngineering ServiceNo ratings yet

- 0523 - ABM3000 Batch MillDocument3 pages0523 - ABM3000 Batch MillSilvio Insulza ChoqueNo ratings yet

- L-G Slideway OilDocument2 pagesL-G Slideway OilAdnanNo ratings yet

- Master - J Data SheetDocument1 pageMaster - J Data SheetRonald WongNo ratings yet

- 75TH NGF Exhibitors List of Womens Wear 08.07.2022Document7 pages75TH NGF Exhibitors List of Womens Wear 08.07.2022Harsh PunmiyaNo ratings yet

- Naveed. MOM-140 - Minutes of Weekly Quality Control Meeting 13-Mar-24Document38 pagesNaveed. MOM-140 - Minutes of Weekly Quality Control Meeting 13-Mar-24naveed ahmedNo ratings yet

- Anish Valmiki - 300321845 CVG 5150 Quiz 04Document6 pagesAnish Valmiki - 300321845 CVG 5150 Quiz 04Anish valmikiNo ratings yet

- Axius SC Sanitary Rupture Disc R14301 Datasheet ENDocument3 pagesAxius SC Sanitary Rupture Disc R14301 Datasheet ENeng_823664768No ratings yet

- Adobe Scan 04 Jan 2022Document2 pagesAdobe Scan 04 Jan 2022Garvit SharmaNo ratings yet

- PU Clear LacquerDocument1 pagePU Clear LacquerA.F.M Salman AkterNo ratings yet

- Summer Training Presentation E.R AutoDocument15 pagesSummer Training Presentation E.R AutoRobin ChhabraNo ratings yet

- Evolution of TQM: Total Quality Management Dycbatqm313 Abel C. Reyes January 11, 2020Document12 pagesEvolution of TQM: Total Quality Management Dycbatqm313 Abel C. Reyes January 11, 2020Vea Dela CruzNo ratings yet

- P&ID and Mass Balance Production Waste 130921-B-ModelDocument1 pageP&ID and Mass Balance Production Waste 130921-B-ModelmaizanazaNo ratings yet

- Case Study BoltsDocument14 pagesCase Study BoltsMohamed AnwarNo ratings yet

- Concrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25Document15 pagesConcrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25patel2732sNo ratings yet

- TB-2022-01 PWHT Exemption TableDocument1 pageTB-2022-01 PWHT Exemption TableMuhammad Ghufran KhanNo ratings yet

- Uny Marine - Polyurethane Finish (Findotek)Document1 pageUny Marine - Polyurethane Finish (Findotek)Hendy S LeksonoNo ratings yet

- Gemini Twin Line ParalelaDocument1 pageGemini Twin Line ParalelaMary Huaylla ANo ratings yet

- RUKO Hole Saws CMSDocument15 pagesRUKO Hole Saws CMSjoaomachadoNo ratings yet

- BENCHMADE 2010 (Knife Catalogue) (Z-Library)Document72 pagesBENCHMADE 2010 (Knife Catalogue) (Z-Library)nikkojazzNo ratings yet