Professional Documents

Culture Documents

Refractory Concrete Inspection Record: Item Description of Check Subcontractor Client

Refractory Concrete Inspection Record: Item Description of Check Subcontractor Client

Uploaded by

VPN Network0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

C001.doc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views1 pageRefractory Concrete Inspection Record: Item Description of Check Subcontractor Client

Refractory Concrete Inspection Record: Item Description of Check Subcontractor Client

Uploaded by

VPN NetworkCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

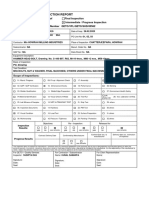

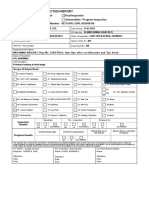

Refractory Concrete Inspection Record

Tag Description: Tag No.:

P. O. No.: Inspection Classification Area/Unit:

Subcontractor: Subcontractor Client Turnover System:

Work Package: Other Sub – System:

Item Description of Check Subcontractor Client

01 Receive operations/inspection complete

Refractory Brand:

02 Refractory used did not exceed shelf life recommended by vendor

03 Metal surface cleaned in accordance with specifications

04 All surfaces and forms sealed and pre-wetted

05 Anchors installed in accordance with project drawings, welding visually

inspected and random anchors hammer-tested

06 Mix procedure in accordance with manufacturer’s recommendations

Mixing Method:

07 Placement procedures inspected and in accordance with specifications

Placement equipment: Placement

method:

Placement completed in days for this equipment

08 Curing was observed to be performed in accordance with specifications

Curing Temperature Data:

Outside Ambient: In place refractory:

Inside Ambient: In place 24 hours:

Curing method used:

Drying performed by:

Firing performed by:

09 Refractory consistency (ball-in-hand) test performed during grouting

10 Hammer test soundness performed on cured concrete surface

11 In-place thickness measurements on fresh refractory

Sampling locations

Average thickness: inches

Remarks:

Company

Name:

Signature:

Date:

C001.doc

You might also like

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Quality Assurance Plan FOR: Refractory MaterialsDocument2 pagesQuality Assurance Plan FOR: Refractory MaterialsPooja TripathiNo ratings yet

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- Base PlateDocument1 pageBase PlateVPN NetworkNo ratings yet

- Epoxy Resin Grout Inspection RecordDocument1 pageEpoxy Resin Grout Inspection RecordVPN NetworkNo ratings yet

- By Akhilesh CHECKLIST - For AllDocument15 pagesBy Akhilesh CHECKLIST - For AllankurNo ratings yet

- BG-CL-PRJ-003 Checklist For Piling WorksDocument1 pageBG-CL-PRJ-003 Checklist For Piling Worksprabhakaran gurunathanNo ratings yet

- No. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryDocument1 pageNo. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryKuljinder VirdiNo ratings yet

- Ir562 Hmi 28.02.23Document2 pagesIr562 Hmi 28.02.23Pinki Mitra DasNo ratings yet

- Soil Inspection ChecklistDocument1 pageSoil Inspection ChecklistVPN NetworkNo ratings yet

- Building Metal Siding and Roofing ChecklistDocument1 pageBuilding Metal Siding and Roofing ChecklistVPN NetworkNo ratings yet

- Structural Steel Inspection Checklist Report NoDocument1 pageStructural Steel Inspection Checklist Report Nosarsan nedumkuzhi maniNo ratings yet

- Cathodic Protection Inspection ChecklistDocument1 pageCathodic Protection Inspection ChecklistVPN NetworkNo ratings yet

- Combined Area Acceptance: Item Description of Check Subcontractor ClientDocument1 pageCombined Area Acceptance: Item Description of Check Subcontractor ClientVPN NetworkNo ratings yet

- Combined Area Acceptance: Item Description of Check Subcontractor ClientDocument1 pageCombined Area Acceptance: Item Description of Check Subcontractor ClientVPN NetworkNo ratings yet

- Buildings Water Proofing and Damp Proofing ChecklistDocument1 pageBuildings Water Proofing and Damp Proofing ChecklistVPN NetworkNo ratings yet

- Assessment Procedure Welding Report FormDocument23 pagesAssessment Procedure Welding Report Formssierro100% (1)

- Masonry (Brickwork) ChecklistDocument1 pageMasonry (Brickwork) ChecklistVPN NetworkNo ratings yet

- Structural Steel Inspection ChecklistDocument1 pageStructural Steel Inspection ChecklistVPN NetworkNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- Qap - LR BendDocument1 pageQap - LR BendSachin KumarNo ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Packaged Equipment Function Checklist: Item Description of Check SubcontractorDocument1 pagePackaged Equipment Function Checklist: Item Description of Check SubcontractorVPN NetworkNo ratings yet

- 5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Document29 pages5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Rupesh KumarNo ratings yet

- Check List For Installation of External Fire Hydrant PDFDocument1 pageCheck List For Installation of External Fire Hydrant PDFvishalkadam57No ratings yet

- ITR INL (Insulation)Document2 pagesITR INL (Insulation)mahmoudNo ratings yet

- F020A-QC Matl Inspn CHK ListDocument1 pageF020A-QC Matl Inspn CHK ListGaneshpandianNo ratings yet

- F037-QC MEP Sprinkler System Hydro Test CHK ListDocument5 pagesF037-QC MEP Sprinkler System Hydro Test CHK ListGopal Nagal - PadamsNo ratings yet

- InspectorDocument5 pagesInspectorVictor DvornikovNo ratings yet

- Electrical Heat Tracing Inspection ChecklistDocument1 pageElectrical Heat Tracing Inspection ChecklistVPN NetworkNo ratings yet

- Test Request Form Concrete Section: (Trial Mix)Document1 pageTest Request Form Concrete Section: (Trial Mix)Nimish MadananNo ratings yet

- 16.06 Civil Works ChecklistDocument145 pages16.06 Civil Works Checklistashutosh65361No ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196sudipta dasNo ratings yet

- Project: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoDocument24 pagesProject: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoNay Win MaungNo ratings yet

- Switching Units - HV Switchgear Inspection Checklist: Item Description of Check SubcontractorDocument1 pageSwitching Units - HV Switchgear Inspection Checklist: Item Description of Check SubcontractorVPN NetworkNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- BL 02 FM200 T&C CommentsDocument1 pageBL 02 FM200 T&C CommentsMaged Lotfy Abdel-aalNo ratings yet

- BGC Construction Surveillance Checklist: Activity Description Results Accepted Yes NoDocument1 pageBGC Construction Surveillance Checklist: Activity Description Results Accepted Yes NoAhmedNo ratings yet

- AHU Pre-Commissioning Check ListDocument8 pagesAHU Pre-Commissioning Check ListSHAHBAZNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Internal INSPECTION Checklist REPORTDocument1 pageInternal INSPECTION Checklist REPORTThom RayNo ratings yet

- Checklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationDocument28 pagesChecklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationThang Tran VietNo ratings yet

- Doors and Hatches (Offshore Facilites) Inspection ChecklistDocument1 pageDoors and Hatches (Offshore Facilites) Inspection ChecklistVPN NetworkNo ratings yet

- Inspection Flash Report: ITP No. & SL No: W20015-ITP-001& 12,13Document2 pagesInspection Flash Report: ITP No. & SL No: W20015-ITP-001& 12,13Fahad AhmadNo ratings yet

- Forging Process Audit Check ListDocument15 pagesForging Process Audit Check ListKeerthivasan NNo ratings yet

- Plaster ChecklistDocument1 pagePlaster ChecklistVPN NetworkNo ratings yet

- Form 02 Crane Inspection FormDocument2 pagesForm 02 Crane Inspection FormDenny SyafwalufiNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197sudipta dasNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProcedureBharat BhoirNo ratings yet

- Heat Treatment Process AuditDocument2 pagesHeat Treatment Process AuditVishram VaidyaNo ratings yet

- Ork DCC Mas Id 003Document9 pagesOrk DCC Mas Id 003Phea RomNo ratings yet

- 60-Request For Field Water Test of WindowsDocument1 page60-Request For Field Water Test of WindowsConstruction UpdatePHNo ratings yet

- Construction Quality Checklist 1.1Document22 pagesConstruction Quality Checklist 1.1lowiyaun100% (1)

- CQM Quality Preparatory SampleDocument5 pagesCQM Quality Preparatory Sampleabdalla el-saadaneyNo ratings yet

- Prefab Wall Element Systems ChecklistDocument1 pagePrefab Wall Element Systems ChecklistVPN NetworkNo ratings yet

- Final Welding Inspection ReportDocument1 pageFinal Welding Inspection ReportKish Shan S SubediNo ratings yet

- Rfi-001 PlatformDocument1 pageRfi-001 PlatformVPN NetworkNo ratings yet

- Rfi 001 PlatformDocument13 pagesRfi 001 PlatformVPN NetworkNo ratings yet

- IC Multiple Project Dashboard Tracking 11362Document15 pagesIC Multiple Project Dashboard Tracking 11362VPN NetworkNo ratings yet

- Project QA QC RequirementDocument25 pagesProject QA QC RequirementVPN NetworkNo ratings yet

- 41.Exhibit-41.Welder Continuity LogDocument2 pages41.Exhibit-41.Welder Continuity LogVPN NetworkNo ratings yet

- Vessel Tool Sign Out-In SheetDocument3 pagesVessel Tool Sign Out-In SheetVPN NetworkNo ratings yet

- Maaden Safety - Code of EthicsDocument4 pagesMaaden Safety - Code of EthicsVPN NetworkNo ratings yet

- BPVC - Viii-1 - Uv-1 .Document1 pageBPVC - Viii-1 - Uv-1 .VPN NetworkNo ratings yet

- Refinery Maintenance Contractors Weekly Report 2020Document2 pagesRefinery Maintenance Contractors Weekly Report 2020VPN NetworkNo ratings yet

- 17-Construction QA QC-Qualification of WeldersDocument5 pages17-Construction QA QC-Qualification of WeldersVPN NetworkNo ratings yet

- 1-Construction QA QC-CivilDocument33 pages1-Construction QA QC-CivilVPN NetworkNo ratings yet

- Post Weld Heat Treat - FormulaDocument20 pagesPost Weld Heat Treat - FormulaVPN NetworkNo ratings yet

- R 4form - NB 231Document1 pageR 4form - NB 231VPN NetworkNo ratings yet

- Miscellaneous EquipmentDocument1 pageMiscellaneous EquipmentVPN NetworkNo ratings yet

- Packaged Equipment Function Checklist: Item Description of Check SubcontractorDocument1 pagePackaged Equipment Function Checklist: Item Description of Check SubcontractorVPN NetworkNo ratings yet

- R 3form - NB 230Document2 pagesR 3form - NB 230VPN NetworkNo ratings yet

- Lifting Equipment - GeneralDocument1 pageLifting Equipment - GeneralVPN NetworkNo ratings yet

- Pressure Safety Valve Test RecordDocument1 pagePressure Safety Valve Test RecordVPN NetworkNo ratings yet

- Doors and Hatches (Offshore Facilites) Inspection ChecklistDocument1 pageDoors and Hatches (Offshore Facilites) Inspection ChecklistVPN NetworkNo ratings yet

- 1A-Quality Manual IntroductionDocument1 page1A-Quality Manual IntroductionVPN NetworkNo ratings yet

- Packaged Equipment Inspection: Item Description of Check SubcontractorDocument1 pagePackaged Equipment Inspection: Item Description of Check SubcontractorVPN NetworkNo ratings yet

- Concrete: Repair Work Inspection Checklist: CompanyDocument1 pageConcrete: Repair Work Inspection Checklist: CompanyVPN NetworkNo ratings yet

- Pedestal Crane: Item Description of Check Subcontractor ClientDocument1 pagePedestal Crane: Item Description of Check Subcontractor ClientVPN NetworkNo ratings yet

- Pile Driving Inspection Record: Depth in Feet Blows Per Foot Depth in Feet Blows Per Foot Depth in Feet Blows Per FootDocument1 pagePile Driving Inspection Record: Depth in Feet Blows Per Foot Depth in Feet Blows Per Foot Depth in Feet Blows Per FootVPN NetworkNo ratings yet

- Torque Wrench Calibration LogDocument1 pageTorque Wrench Calibration LogVPN NetworkNo ratings yet

- Nuclear Density Test Report - Bituminous ConcreteDocument1 pageNuclear Density Test Report - Bituminous ConcreteVPN NetworkNo ratings yet

- Bituminous Concrete Compaction: (AASHTO T 230)Document1 pageBituminous Concrete Compaction: (AASHTO T 230)VPN NetworkNo ratings yet

- Area Completion: Item Description of Check Subcontractor ClientDocument1 pageArea Completion: Item Description of Check Subcontractor ClientVPN NetworkNo ratings yet

- Structural Steel Inspection ChecklistDocument1 pageStructural Steel Inspection ChecklistVPN NetworkNo ratings yet

- Building Inspection and Test ChecklistDocument1 pageBuilding Inspection and Test ChecklistVPN NetworkNo ratings yet