Professional Documents

Culture Documents

K0 38 - Envrnmt Aspects Check List

K0 38 - Envrnmt Aspects Check List

Uploaded by

PRIYESH . K. PRIYANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K0 38 - Envrnmt Aspects Check List

K0 38 - Envrnmt Aspects Check List

Uploaded by

PRIYESH . K. PRIYANCopyright:

Available Formats

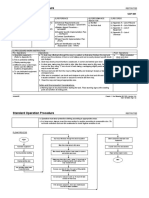

HEALTH, SAFETY & ENVIRONMENT PLAN

Environmental Inspection Checklist

(Note: This form is designed as guide lines for general use and is not exhaustive. Modifications and additions

may be necessary to suit individual projects and to address specific environmental issues and associated

mitigation measures.)

Project: ………………………… Site Location: …………………………... Region ………………..

Construction stage / status during inspection: ……………………………………..

Inspection Date: ………………Inspection Time: …………………… Weather: Dry / Rainy / cold

Inspected by:

1) Name……………………………Designation…………………… Company……………..

2) Name……………………………Designation………………………….Company…………….

3) Name ………………………… Designation………………………….. Company……………

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices,

Yes No* N/A* problems observed, possible cause of

nonconformity and proposed corrective

/ preventative actions.

1. Air Pollution Control

1.1. Are the construction sites watered to

minimize dust being generated?

1.2. Are stockpiles of dusty materials

covered or watered (as applicable)?

1.3. Is the Cement debagging process

undertaken in sheltered areas?

1.4. Are all vehicles carrying dusty loads,

covered/watered over, prior to

leaving the site?

1.5. Are demolition work areas watered?

(e.g. trimming activities by using

breaker)

1.6. Are dusty roads paved and /or sprayed

with water?

1.7. Is the dust being controlled during

percussive drilling or rock breaking?

HEALTH, SAFETY & ENVIRONMENT PLAN

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices, problems

Yes No* N/A* observed, possible cause of nonconformity

and proposed corrective / preventative

actions.

1.8. Are plant and equipment well maintained

(if any black exhaust or smoke is

observed, please indicate the plant

/equipment and location)

1.9. Is dark smoke/exhaust from plant and

equipment, being controlled?

1.10. Are there enclosures around the main

dust-generating activities? (e.g. grout

mixing)

1.11. Are Hoardings (not <2.4m) provided

along boundaries and properly

maintained (any damage / opening

observed, please indicate the location).

1.12. Are speed control measures

displayed/applied? (e.g. speed limit sign)

1.13. Any other observations

(please specify)?

2. Water Pollution Control

2.1. Are water discharge licenses valid?

2.2. Are conditions of the license complied

with? (check the monitoring records and

verify physically)

2.3. Are wastewater treatment systems being

used and properly maintained at site?

(e.g. desalting tank)

2.4. Is the wastewater being discharged to the

storm drains? Is the wastewater being

treated?

2.5. Are measures provided to properly direct

effluent to silt removal facilities? (e.g.

provide earth bunds / U-channels)

2.6. Are u-channels and manholes free of silt

and sediment?

2.7. Are sedimentation traps and tanks free of

silt and sediment?

2.8. Are all manholes at site, covered and

sealed?

HEALTH, SAFETY & ENVIRONMENT PLAN

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices,

Yes No* N/A* problems observed, possible cause of

nonconformity and proposed corrective

/ preventative actions.

2.9. Are sandbags/earth bunds adopted to

prevent washing away of sand/silt

and wastewater to drains, catch pit,

public road and footpath?

2.10. Are vehicles and plants cleaned

before leaving the site?

2.11. Are wheel washing facilities well

maintained to prevent overflow,

flooding, sediment?

2.12. Is sand and silt settled in wheel

washing bay removed?

2.13. Is the public road/area around the

site entrance and site hoarding kept

clean and free of muddy water?

2.14. Is any domestic water being directed

to septic tanks or chemical toilets?

2.15. Others (please specify if any)

3. Noise Control

3.1. Is the CNP (Construction Noise Permit)

applicable / valid for work during

restricted hours?

3.2. Are copies of the valid Construction

Noise Permits posted at site

entrance/exit?

3.3. Do air compressors and generators

operate with doors closed?

3.4. Is idle plant/equipment turned off or

throttled down?

3.5. Do air compressors and hand-held

breakers have valid noise emission

labels (NEL)?

3.6. Are any noise mitigation measures

being adopted (e.g. use noise barrier

/ enclosure) at site?

3.7. Are silenced

equipment being utilized at

site?

HEALTH, SAFETY & ENVIRONMENT PLAN

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices,

Yes No* N/A* problems observed, possible cause of

nonconformity and proposed corrective

/ preventative actions.

3.8. Others (please if any )

4. Waste Management

4.1. Is the site kept clean and tidy? (e.g.

litter free, good housekeeping)

4.2. Are separate chutes used for inert and

non-inert wastes?

4.3. Are separate labelled containers /

areas provided for facilitating

recycling and waste segregation?

4.4. Are construction waste / recyclable

waste and general refuse removed

off site regularly?

4.5. Are construction waste collected and

disposed of properly by licensed

collectors?

4.6. Are chemical wastes, if any, collected

and disposed of properly by licensed

collectors?

4.7. Does chemical waste producer license

cover all major chemical wastes

produced on site?

4.8. Are chemical wastes properly stored

and labelled?

4.9. Are oil drums and plant / equipment

provided with drip trays?

4.10. Are drip trays free of oil and water?

4.11. Is there any oil spillage?

4.12. Is clean-up of such contaminated soil

done immediately?

4.13. Is litter, foam or other objectionable

matter cleaned regularly from

nearby drain/sewer?

4.14. Are registered professionals handling

existing asbestos wastes (if any &

where applicable)?

HEALTH, SAFETY & ENVIRONMENT PLAN

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices,

Yes No* N/A* problems observed, possible cause of

nonconformity and proposed corrective

/ preventative actions.

4.15. Others (please specify if any )

5. Storage of Chemicals and Dangerous Goods

5.1. Are chemicals stored and labelled

properly?

5.2. Does storage of DG comply with

license conditions (include types and

quantities if DG store is available,

check the DG store license)?

5.3. Are there proper measures to control

oil and other chemical spillages

during maintenance? (e.g.

provide drip trays)

5.4. Are the spill kits / sand / saw dust

used for absorbing chemical spillage,

readily accessible?

5.5. Others (please specify if any)

6. Protection of Flora, Fauna and Historical Heritage

6.1. Are disturbance to terrestrial flora

minimized (e.g. plants to be

preserved)?

6.2. Are disturbance to terrestrial fauna

minimized (if rare species

identified)?

6.3. Are there any historical heritages that

exist on or are affected by, the

project site?

6.4. If yes, are appropriate measures being

taken to preserve the same?

6.5. Others (please specify)

HEALTH, SAFETY & ENVIRONMENT PLAN

7. Resource Conservation

7.1. Is recycled water (wherever possible)

being used for dust suppression?

Implemented? Remarks

1. * Give valid reasons.

Inspection Items 2. Specify good practices,

Yes No* N/A* problems observed, possible cause of

nonconformity and proposed corrective

/ preventative actions.

7.2. Is wastage of water (e.g. pipe leakage)

being prevented?

7.3. Are diesel-powered plants and

equipment’s shut off while not in use

to reduce excessive use and air

pollution?

7.4. Are energy conservation practices

adopted?

7.5. Are metal or other alternatives used to

minimize the use of timber?

7.6. Are materials stored in good condition

to prevent deterioration and

wastage (e.g. covered, separated)?

7.7. Are pesticides used under the

requirement of Agriculture, Fishers

and Conservation Department?

7.8. Others (please specify if any)

8. Any other observations (please specify)

8.1.

8.2.

Any other related issues or comments:

Inspectors:

Signature/date……………………………………….Designation………………………….. Company………………………………

M Moser Reviewed and

Accepted ………………. Rejected ……… ….

Signature/date/Time……………………………………….Designation……………….

You might also like

- HYD 20 - HIRA Cable Laying and TerminationDocument8 pagesHYD 20 - HIRA Cable Laying and TerminationPRIYESH . K. PRIYANNo ratings yet

- Basic GMP Checklist For Pharmaceutical PlantsDocument30 pagesBasic GMP Checklist For Pharmaceutical PlantsPrem Goel100% (10)

- Revised Site Audit TemplateDocument4 pagesRevised Site Audit TemplateLucian100% (1)

- Inspection Checklist Drill Rig PDFDocument2 pagesInspection Checklist Drill Rig PDFAbdo Ojaimy100% (2)

- Cat 3508 B Main EnginesDocument148 pagesCat 3508 B Main EnginesAnandOjha95% (43)

- SIDEROS - Dust CollectorsDocument2 pagesSIDEROS - Dust CollectorsDaniel Austin100% (1)

- Internal Audit Checklist PRODUCTIONDocument6 pagesInternal Audit Checklist PRODUCTIONRavi Baghel100% (3)

- Site Environmental ChecklistDocument6 pagesSite Environmental ChecklistSherif MahmoudNo ratings yet

- EHS Inspection ChecklistDocument8 pagesEHS Inspection ChecklistpremNo ratings yet

- SOP 001 Dust MoppingDocument2 pagesSOP 001 Dust MoppingMade GileeNo ratings yet

- Environmental Site Inspection Checklist MVLDocument6 pagesEnvironmental Site Inspection Checklist MVLraghu0999No ratings yet

- Environmental Inspection ChecklistDocument6 pagesEnvironmental Inspection ChecklistAhmed Salah El DinNo ratings yet

- Environmental Site Inspection ChecklistDocument6 pagesEnvironmental Site Inspection ChecklistAhmad Mensa100% (5)

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/ADocument6 pagesEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/Asoliman fathyNo ratings yet

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlDocument6 pagesEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyNo ratings yet

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlDocument6 pagesEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyNo ratings yet

- 03 Enviromental InspectionDocument3 pages03 Enviromental InspectionMohamad YuhaizadNo ratings yet

- Weekly Environmental Report: Riyadh City South Phase 5Document4 pagesWeekly Environmental Report: Riyadh City South Phase 5Venkadesh Periathambi100% (1)

- FM-SUS-0800-04 Site Environmental CheckDocument3 pagesFM-SUS-0800-04 Site Environmental CheckdavidburkepsNo ratings yet

- Inspeksi TambangDocument6 pagesInspeksi TambangAchmad RifaniNo ratings yet

- Ef Ei04 01Document7 pagesEf Ei04 01TAHER AMMARNo ratings yet

- iNSPECTION CHEKLISTDocument3 pagesiNSPECTION CHEKLISTShrikant UtekarNo ratings yet

- Commissioning Checklist - FinalDocument2 pagesCommissioning Checklist - Finalnaresh reddy. mNo ratings yet

- ARB Construction Site Inspection ChecklistDocument5 pagesARB Construction Site Inspection ChecklistOjullaIsaacNo ratings yet

- Hse-027 - Environmental Site Inspection - ChecklistDocument4 pagesHse-027 - Environmental Site Inspection - ChecklistyahiyaNo ratings yet

- ESHS Daily Tracking Tool: Appendix 9Document4 pagesESHS Daily Tracking Tool: Appendix 9George LumiisaNo ratings yet

- GCPD-Laydown Yard Checklist-SafelifeDocument5 pagesGCPD-Laydown Yard Checklist-SafelifeMuhammad TariqNo ratings yet

- Environmental ControlsDocument3 pagesEnvironmental Controlstariq1987No ratings yet

- Environmental AuditDocument5 pagesEnvironmental AuditAnsarMahmoodNo ratings yet

- HSE Visit Walkabout ChecklistDocument4 pagesHSE Visit Walkabout ChecklistEric T100% (1)

- Asia ERC Template Sept 9 2015Document8 pagesAsia ERC Template Sept 9 2015naveed ahmedNo ratings yet

- Environmental Compliance ChecklistDocument5 pagesEnvironmental Compliance ChecklistNIJESH100% (1)

- Monthly HSSE Inspection ChecklistDocument5 pagesMonthly HSSE Inspection ChecklistEric TNo ratings yet

- Ohs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormDocument6 pagesOhs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormSiddiqui100% (1)

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Construction Safety Audit ChecklistDocument7 pagesConstruction Safety Audit Checklistamit sikkaNo ratings yet

- Workplace - Inspection Checklist UpdatedDocument8 pagesWorkplace - Inspection Checklist UpdatedNate JamesNo ratings yet

- IKK Asphalt Batch Plant Recommissioning Checklist - May 2022Document6 pagesIKK Asphalt Batch Plant Recommissioning Checklist - May 2022Idris Adeshina AdeniranNo ratings yet

- Environmental Audit DOWADocument10 pagesEnvironmental Audit DOWAsamuelNo ratings yet

- GMP ChecklistDocument10 pagesGMP Checklistkang adeNo ratings yet

- Site Investigation ReportDocument11 pagesSite Investigation ReportyousefzkrNo ratings yet

- Registered Starting Material Auditing Guide: Annex 1 - Aide MémoireDocument23 pagesRegistered Starting Material Auditing Guide: Annex 1 - Aide MémoireMohab Ameen AldesoukiNo ratings yet

- Compliance Checklist - HSE-OH-ST07 Cont Welfare MGMTDocument5 pagesCompliance Checklist - HSE-OH-ST07 Cont Welfare MGMTjerinNo ratings yet

- General Workplace InspectionDocument12 pagesGeneral Workplace InspectionMark AlaliboNo ratings yet

- GMP Audit v14.09 Scope OutlineDocument17 pagesGMP Audit v14.09 Scope OutlinesuthaNo ratings yet

- Environmental ChecklistDocument2 pagesEnvironmental ChecklistpuneetNo ratings yet

- GMP Checklist: Location and SurroundingsDocument30 pagesGMP Checklist: Location and SurroundingsMv PatelNo ratings yet

- Standard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INCDocument4 pagesStandard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INCJaijeev PaliNo ratings yet

- BTSO-SG-002A - Manned Vessel Confined Space Entry ChecklistDocument2 pagesBTSO-SG-002A - Manned Vessel Confined Space Entry ChecklistThinh TranNo ratings yet

- Wan Bao Construction Limited: Environmental InstructionDocument39 pagesWan Bao Construction Limited: Environmental InstructionTakudzwa Valeria ChiutanyiNo ratings yet

- Checklist For 5-Star Safety Documentation-SOADocument15 pagesChecklist For 5-Star Safety Documentation-SOAYASIRNo ratings yet

- SOP A04 ventilationDocument4 pagesSOP A04 ventilationCinthia Franco SalinasNo ratings yet

- 4.tool - Environmental & OccupationalHealthDocument6 pages4.tool - Environmental & OccupationalHealthShanikaweerNo ratings yet

- Waste Management Procedure: Project Jorf Lasfar Units 5&6Document16 pagesWaste Management Procedure: Project Jorf Lasfar Units 5&6Mohamed HadjkacemNo ratings yet

- GMP Who GuidelineDocument30 pagesGMP Who Guidelinedevang asherNo ratings yet

- EOCOP 1 : Environment of Care Site Survey-Outpatient AreasDocument6 pagesEOCOP 1 : Environment of Care Site Survey-Outpatient AreasvengielNo ratings yet

- Building (Office) OHS Audit-Assessmnt Form (KF)Document9 pagesBuilding (Office) OHS Audit-Assessmnt Form (KF)bayu arwiansyah100% (2)

- Summer Plan - Inspection ChecklistDocument3 pagesSummer Plan - Inspection ChecklistFRAHIM HAIDERNo ratings yet

- Astm D4700-15Document16 pagesAstm D4700-15adolfo camayoNo ratings yet

- JOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentDocument7 pagesJOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentOrdu Henry Onyebuchukwu100% (1)

- Assignment Sbev 3103 Sem Jan-2022-Tanasilan A.danabaluDocument13 pagesAssignment Sbev 3103 Sem Jan-2022-Tanasilan A.danabalutanaNo ratings yet

- Emp MonitoringDocument30 pagesEmp MonitoringZay Yan HtetNo ratings yet

- KA 43 Excavator Safety ChecklistDocument1 pageKA 43 Excavator Safety ChecklistPRIYESH . K. PRIYANNo ratings yet

- R 12 Hot Work Permit FormatDocument2 pagesR 12 Hot Work Permit FormatPRIYESH . K. PRIYANNo ratings yet

- Cable Laying &termination HIRADocument66 pagesCable Laying &termination HIRAPRIYESH . K. PRIYANNo ratings yet

- Wall Tile Fixing-Risk AssessmentDocument3 pagesWall Tile Fixing-Risk AssessmentPRIYESH . K. PRIYANNo ratings yet

- Check List For Legal Compliance by ContractorDocument2 pagesCheck List For Legal Compliance by ContractorPRIYESH . K. PRIYANNo ratings yet

- Tower Crane Maintenance ChecklistDocument2 pagesTower Crane Maintenance ChecklistPRIYESH . K. PRIYANNo ratings yet

- Lux Level CheckingDocument1 pageLux Level CheckingPRIYESH . K. PRIYANNo ratings yet

- Emergency Vehicle ChecklistDocument1 pageEmergency Vehicle ChecklistPRIYESH . K. PRIYANNo ratings yet

- KA 40 Pic-Checklist For Generator (DG)Document2 pagesKA 40 Pic-Checklist For Generator (DG)PRIYESH . K. PRIYANNo ratings yet

- Fire Extinguisher Inspection 01Document1 pageFire Extinguisher Inspection 01PRIYESH . K. PRIYANNo ratings yet

- R 02 Fitouts General Work PermitDocument1 pageR 02 Fitouts General Work PermitPRIYESH . K. PRIYANNo ratings yet

- Checklist For Sling InspectionDocument1 pageChecklist For Sling InspectionPRIYESH . K. PRIYANNo ratings yet

- Material Safety Data Sheet Synthetic Black Iron Oxide (Group II)Document6 pagesMaterial Safety Data Sheet Synthetic Black Iron Oxide (Group II)ikanurdiantiNo ratings yet

- Fugitive Dust Control PlanDocument3 pagesFugitive Dust Control Plangabinuang100% (1)

- Apr 2017Document45 pagesApr 2017prasanta_bbsrNo ratings yet

- IQ Analytical BalanceDocument10 pagesIQ Analytical BalanceMohsin AliNo ratings yet

- RSPDocument5 pagesRSPKamil KhanNo ratings yet

- Filtros de Aire UHE (Ultra High Efficiency) CATDocument2 pagesFiltros de Aire UHE (Ultra High Efficiency) CATgerardoNo ratings yet

- 03 Acacia MEPF Final Mechanical Technical SpecsDocument256 pages03 Acacia MEPF Final Mechanical Technical SpecsPamela LicayanNo ratings yet

- TB016 Operators Manual TakeuchiDocument214 pagesTB016 Operators Manual TakeuchiDaniel William Hill100% (3)

- EFFEX Product-Guide-Extraction English LowDocument16 pagesEFFEX Product-Guide-Extraction English LowXIN NIUNIUNo ratings yet

- Installation and Maintenance Instructions: Oil and Gas-Fired Boilers Logano G215 USDocument72 pagesInstallation and Maintenance Instructions: Oil and Gas-Fired Boilers Logano G215 UScarlosNo ratings yet

- MSDS White Sugar PDFDocument5 pagesMSDS White Sugar PDFMohammed Osman SultaniNo ratings yet

- Filters and Filtration: A A A A ADocument6 pagesFilters and Filtration: A A A A ASyamsul IrmaNo ratings yet

- NTPC Safety RulesDocument109 pagesNTPC Safety RulesVivek Kakkoth100% (2)

- Miele Floor Care BrochureDocument88 pagesMiele Floor Care BrochureBrent SmithNo ratings yet

- DUST CONTROL HANDBOOK FOR MINERALS PROCESSING by Martin Marietta Laboratories 1987Document176 pagesDUST CONTROL HANDBOOK FOR MINERALS PROCESSING by Martin Marietta Laboratories 1987Ferudun AkyolNo ratings yet

- SSPC Guide 16Document13 pagesSSPC Guide 16mithileshNo ratings yet

- Nebosh Igc2 QaDocument12 pagesNebosh Igc2 Qaselvaprpc50% (2)

- Material Safety Data Sheet: Polyethylene TerephthalateDocument4 pagesMaterial Safety Data Sheet: Polyethylene Terephthalatesaeful anwar100% (1)

- Manual Aspiradora LG Luv200rDocument75 pagesManual Aspiradora LG Luv200rrukaiserNo ratings yet

- Risk Assessment Workbook For Mines PDFDocument64 pagesRisk Assessment Workbook For Mines PDFHamit AydınNo ratings yet

- 31st Meeting of MinutesDocument9 pages31st Meeting of MinutesSiva JeevaNo ratings yet

- GMW14527 - Body Dust IntrusionDocument9 pagesGMW14527 - Body Dust IntrusionScott KramerNo ratings yet

- Household Services: Making Beds and CotsDocument10 pagesHousehold Services: Making Beds and CotsGlenda Oliveros PelarisNo ratings yet

- Fungus: How To Prevent Growth and Remove It From Optical ComponentsDocument1 pageFungus: How To Prevent Growth and Remove It From Optical Componentsmuhammad FikriNo ratings yet

- MSDS MASQUOL EDTA NaDocument10 pagesMSDS MASQUOL EDTA NaEstevan huertasNo ratings yet

- EMW Filtertechnik - GT (GB)Document9 pagesEMW Filtertechnik - GT (GB)Nguyễn Kim HùngNo ratings yet

- Combustible Dust ChecklistDocument2 pagesCombustible Dust ChecklistAbdus SamadNo ratings yet