Professional Documents

Culture Documents

T1000 MSDS

T1000 MSDS

Uploaded by

Revita PatriciaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T1000 MSDS

T1000 MSDS

Uploaded by

Revita PatriciaCopyright:

Available Formats

ISO 9001

Quality

Management

Systems

CERTIFIED

FS 740782

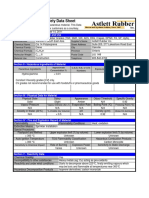

Material Safety Data Sheet

T1000

Elliott Australia’s T1000 is a Type E Glass Fibre – High Bulk borosilicate type. The intended use for this fabric is all high

temperature applications where the need for thermal insulation is required.

Fabric Specifications

Property/Test Method Requirement Tolerance

Fibre type Texturised "E" Glass

Weave Plain

Weight 1150 g/m2 Base fabric

Thickness 2.0mm Nominal

Width 100cm

Finish Vermiculite

Roll length (m) 50

Identification

Other names Fibreglass, Glass fibre

Chemical name Low Alkali, Borosilicate Glass Fibre with an organic size (2.5%)

UN number N/A

Dangerous Goods Class and Subsidiary Non-hazardous

Hazchem code N/A

Hazard class Non-combustible solid

Poisons schedule number N/A

Use Non-asbestos thermal insulation blanket. Welding Blankets, Stress Relieving

Insulation, Furnace Curtains

No better protection. elliotts.net

ISO 9001

Quality

Management

Systems

CERTIFIED

FS 740782

Material Safety Data Sheet

T1000

Technical Data

Physical appearance:

Appearance and odour White fibres with virtually no odour

Boiling point N/A

Melting point >700 deg. C

Vapour pressure -

Vapour density (air = 1) -

Specific gravity (H20 = 1) 2.54

Solubility in water Below 0.01%

Percent volatile by volume (%) -

Evaporation rate (n-butyl acetate = 100) -

Fire and explosion hazard data:

Flash point: (test method/s) May emit smoke briefly between 120°c–180°c

but is unlikely to flash.

Flammable limits in air % by volume Lower: N/A Upper: N/A

Extinguishing media Water (for the packaging materials)

Special fire fighting procedures None

Unusual fire and explosion hazards None

Reactivity data:

Stability Stable

Conditions to avoid None known

Incompatibility (materials to avoid) None known

Hazardous decomposition products None

Hazardous polymerization Will not occur

Elliott Australia Pty Ltd

23 Vauxhall Street, Virginia, QLD 4014 Australia elliotts.net

ISO 9001

Quality

Management

Systems

CERTIFIED

FS 740782

Material Safety Data Sheet

T1000

Health Hazard Information

Health hazard data:

Threshold limit value: *10mg/m3 of total dust or 5mg/m3 of respirable dust (*Nh & Mrc recomm, 1984).

These reinforcement fibres have a filament diameter greater than 6 microns and

are not classified as respirable.

Effects of exposure:

Eye (contact) Dust can cause irritation to eyes. Appropriate eye protection should be worn in

areas where there is likelihood that airborne fibres may contact eyes.

Skin (contact and absorption) Can irritate (largely confined to cutting, trimming and grinding operations)

*see below

Inhalation (breathing) Not respirable but dust masks may be beneficial in areas where high dust levels

occur.

Ingestion (swallowing) Non-toxic (extensive studies have revealed no series effects).

Other health hazards There is no credible evidence of other health problems however it would be wise

to maintain worker exposure at a minimum level, particularly where trimming,

sawing and grinding operations are being conducted.

First aid:

Eye (contact) Flush with water for 15 minutes – get medical assistance if irritation persists.

Skin (contact) None wash, using warm water and mild soap.

Inhalation (breathing) Remove to fresh air. Drink water to clear throat and blow nose to evacuate fibers.

Ingestion (swallowing) Rinse mouth with water. Emetics not necessary unless choking is apparent.

Spills or leak procedures:

Steps to be taken in case material is Prevent the spread of fibreglass dust and avoid dust generation conditions. Those

released or spilled involved in clean up of particulates should use appropriate personal protective

equipment. (See section viii) vacuum clean dusts. If sweeping is necessary, use a

dust suppressant.

Water disposal method In most cases, woven fibreglass scrap can be disposed of in a sanitary landfill in

accordance with federal, state and local regulations. Check with local authorities

on any questions concerning disposal.

Elliott Australia Pty Ltd

23 Vauxhall Street, Virginia, QLD 4014 Australia elliotts.net

ISO 9001

Quality

Management

Systems

CERTIFIED

FS 740782

Material Safety Data Sheet

T1000

Health Hazard Information

Special protection information

Respiratory protection (specify type) Where dust levels exceed the TLV, use NIOSH approved respirator to protect

against nuisance dusts.

Ventilation (local) Recommended for processing machinery where dust generation is apparent.

Ventilation (exhaust) Recommended for processing machinery where dust generation is apparent.

Mechanical (general) Yes, where local exhaust ventilation is not feasible.

Special: not normally required Other: not normally required

Protection gloves Gloves and barrier creams if necessary.

Eye protection Safety glasses with side shields/goggles.

Other protective clothing or Work aprons or smock are recommended. Wear loose fitting, long sleeved clothing,

equipment niosh approved air supplied or self contained respirator or nonrouting and

emergency situations.

Work/hygienic practices Wash thoroughly after work. Recommend launder work clothes separately and

wipe out washer at end of cycle.

Precautions for Use

Precautions to be taken in handling Store and use in a manner that will prevent airborne particulates in the workplace.

and storing

Other precautions None known.

Other Information

Work/hygiene practices – Wash thoroughly after work. Recommend launder work cloths separately and wipe out clothes

washer after use.

Disclaimer

The information provided herein is believed to be accurate but is not warranted to be, whether it originated

with Elliott Australia or not. The information contained in this Material Data Sheet originates from suppliers,

this information cannot be warranted by Elliott Australia to be correct or appropriate for the recipients

intended use.

Elliott Australia Pty Ltd

23 Vauxhall Street, Virginia, QLD 4014 Australia elliotts.net

You might also like

- Ficha Tecnica Gpps 861FDocument1 pageFicha Tecnica Gpps 861Falvich17No ratings yet

- Unica MGU3.505.18 PDFDocument2 pagesUnica MGU3.505.18 PDFraniaNo ratings yet

- 20) Casement Window SectionsDocument21 pages20) Casement Window SectionsMinal Agarwal0% (1)

- CQ of Rock Wool Board 120kgDocument1 pageCQ of Rock Wool Board 120kgTan PhanNo ratings yet

- Dupont Zytel 70G30L NC010Document2 pagesDupont Zytel 70G30L NC010Dario de SantiagoNo ratings yet

- Baypren 111: Rubber Business Group RubberDocument2 pagesBaypren 111: Rubber Business Group RubberTmacNo ratings yet

- Vitralit 1650 English Tds Panacol AdhesiveDocument4 pagesVitralit 1650 English Tds Panacol Adhesivetito3007No ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- Elliotts Pds - Welding Blankets HSB t1000 1Document1 pageElliotts Pds - Welding Blankets HSB t1000 1Revita PatriciaNo ratings yet

- Polyamide Carbon Fiber: DissipativeDocument2 pagesPolyamide Carbon Fiber: DissipativeLeonardo MurilloNo ratings yet

- PVB ArchitecturalDocument2 pagesPVB Architecturalma627228909No ratings yet

- MedixDocument2 pagesMedixรอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- Abs Absolac 300Document2 pagesAbs Absolac 300ShrikantNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Absolac 300 Ineos AbsDocument2 pagesAbsolac 300 Ineos Absadrian4santanaNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- Material Safety Data Sheet: Section I - Material Identification and UseDocument2 pagesMaterial Safety Data Sheet: Section I - Material Identification and UseBharat ChatrathNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Fortron 1120LDocument2 pagesFortron 1120LdanielNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- Ds 5600 LD enDocument2 pagesDs 5600 LD enMarek KamenickyNo ratings yet

- Szen P84500NDocument1 pageSzen P84500NASIF RAOUFNo ratings yet

- Pa66-R10g25 Tds-Iso-EngDocument2 pagesPa66-R10g25 Tds-Iso-EngTRUONGNo ratings yet

- PDS Anderol 750Document2 pagesPDS Anderol 750Hiram GarciaNo ratings yet

- Baypren 611Document2 pagesBaypren 611TmacNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Data Sheet EL-Lene H1000PC Rev - Feb - 09Document2 pagesData Sheet EL-Lene H1000PC Rev - Feb - 09kuntasee.duckNo ratings yet

- Matt80 HM100 WG62Document2 pagesMatt80 HM100 WG62Mahmud RezaNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Safe - N - Silent Pro Product Data Sheet IndiaDocument2 pagesSafe - N - Silent Pro Product Data Sheet IndiaMd Farid AhmedNo ratings yet

- Baypren 510: Rubber Business Group RubberDocument2 pagesBaypren 510: Rubber Business Group RubberTmacNo ratings yet

- EVO Type T - AnsellDocument6 pagesEVO Type T - Ansellkhon thaiNo ratings yet

- Tds Heraform r900 Nat EngDocument2 pagesTds Heraform r900 Nat EngSenophoeNo ratings yet

- Interpon 600 AM - AkzoNobelDocument3 pagesInterpon 600 AM - AkzoNobelJoão Gilberto Vedana JúniorNo ratings yet

- Feydom Fabric Sheet VelareDocument1 pageFeydom Fabric Sheet VelareElisabeta Mihaela StanescuNo ratings yet

- PVB SolarDocument2 pagesPVB Solarma627228909No ratings yet

- Tds of Interpon RDX Plus-Al180cs-EnDocument4 pagesTds of Interpon RDX Plus-Al180cs-EnjmcastellviNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Econamid FL 6B30Document2 pagesEconamid FL 6B30Jagadeesh WaranNo ratings yet

- Feydom Fabric Sheet VelareDocument1 pageFeydom Fabric Sheet VelareAmaliaNo ratings yet

- EU - TDS - Interpon D2525 STF TextureDocument3 pagesEU - TDS - Interpon D2525 STF TextureWilson ThomasNo ratings yet

- Moly KoteDocument2 pagesMoly KoteNagaraju PanguluriNo ratings yet

- TDS Ral9003 SGDocument2 pagesTDS Ral9003 SGfawazNo ratings yet

- ULTRAMID Sup ® Sup +A3HG7Document3 pagesULTRAMID Sup ® Sup +A3HG7torksss123No ratings yet

- CRP 100NDocument2 pagesCRP 100NbaharehestekiNo ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- TDS KL 2700Document3 pagesTDS KL 2700Agenk VambudyNo ratings yet

- PVC - Food & Pharmaceutical UseDocument3 pagesPVC - Food & Pharmaceutical UseARINDAM SETTNo ratings yet

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- 300.024 Lustran Elite 1891Document2 pages300.024 Lustran Elite 1891Enrique ChavezNo ratings yet

- Datasheet - TB 250 IR enDocument2 pagesDatasheet - TB 250 IR enMiles JohnsonNo ratings yet

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 pagesCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaNo ratings yet

- Calon:Arlon Series - 2100 - PIB - ENG - FEB19 - 1Document3 pagesCalon:Arlon Series - 2100 - PIB - ENG - FEB19 - 1allthingsinglassNo ratings yet

- Steripleat Vent: Sterile Tank Vent FiltrationDocument3 pagesSteripleat Vent: Sterile Tank Vent FiltrationPraful IngleNo ratings yet

- Iron Oxide Red S130MDocument2 pagesIron Oxide Red S130MRicardo Antonio García QuispeNo ratings yet

- IPS E.max Lithium Disilicate Scientific DocumentDocument16 pagesIPS E.max Lithium Disilicate Scientific DocumentIvoclar Vivadent100% (4)

- Structural Design and Test Factors of Safety For Spaceflight HardwareDocument20 pagesStructural Design and Test Factors of Safety For Spaceflight HardwareAmd MhmdNo ratings yet

- Pasterized HoneyDocument22 pagesPasterized HoneyLarisa Mihaela Giura100% (1)

- Lightfastness Studies of Waterbased InkjetDocument8 pagesLightfastness Studies of Waterbased Inkjetnikopigni2No ratings yet

- Glass Presentation ..Document15 pagesGlass Presentation ..JEETNo ratings yet

- Silicate IndustryDocument40 pagesSilicate IndustryTamiru DerejeNo ratings yet

- A Project On Dealers Perception On Kajaria Ceramics CoimbatoreDocument47 pagesA Project On Dealers Perception On Kajaria Ceramics CoimbatoreMohamed SanferNo ratings yet

- O2 Barrier in Heat SetDocument7 pagesO2 Barrier in Heat SetShiv7_som784No ratings yet

- PIP INEG1000 Insulation Design and Type Codes 1999-04Document35 pagesPIP INEG1000 Insulation Design and Type Codes 1999-04asvasan5554No ratings yet

- 03 - Next Generation Interlayer Solutions For Head-Up DisplaysDocument22 pages03 - Next Generation Interlayer Solutions For Head-Up DisplaysProvappiNo ratings yet

- Catalog e PDFDocument253 pagesCatalog e PDFNguyễn Quí ThànhNo ratings yet

- BS 7159 (1989) Design and Construction of Glass Reinforced Plastics (GRP) Piping Systems For Individual Plants or SitesDocument1 pageBS 7159 (1989) Design and Construction of Glass Reinforced Plastics (GRP) Piping Systems For Individual Plants or Sitesvijay1911No ratings yet

- UNIT 1 PPT 2Document30 pagesUNIT 1 PPT 2neha yarrapothuNo ratings yet

- Curriculum Map Grade 3 Scince Quarter 1Document12 pagesCurriculum Map Grade 3 Scince Quarter 1Gremel IntapayaNo ratings yet

- Digital Assignment Name:Iyyavu.M REG - NO:17BIT0349 Course:Eee1018 - Nanotechnology Fundamentals and Its Applications SLOT:G2+TG2Document4 pagesDigital Assignment Name:Iyyavu.M REG - NO:17BIT0349 Course:Eee1018 - Nanotechnology Fundamentals and Its Applications SLOT:G2+TG2Ayyavu MNo ratings yet

- Cement, Gypsum Product, Quartz SandDocument14 pagesCement, Gypsum Product, Quartz SandHuda FauziNo ratings yet

- Journal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteDocument8 pagesJournal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteAngle JudieNo ratings yet

- Performance: Unparalleled Micro-XrfDocument2 pagesPerformance: Unparalleled Micro-Xrftaufiq_hidayat_1982No ratings yet

- Natural Science: Natural Science 1 Learning Lab Is A Collective WorkDocument104 pagesNatural Science: Natural Science 1 Learning Lab Is A Collective WorkSusana BebNo ratings yet

- Add Math Project 2012 SabahDocument32 pagesAdd Math Project 2012 SabahIrsyadNo ratings yet

- C1071Document4 pagesC1071dinhtung22100% (1)

- Ighina Elios Magnetic AtomDocument47 pagesIghina Elios Magnetic AtomCalzaPupazzo100% (1)

- MPL-P142 - 6316345 - Vol.2 Sec. 9 General Specifications-Aluminum WorksDocument63 pagesMPL-P142 - 6316345 - Vol.2 Sec. 9 General Specifications-Aluminum WorksanishNo ratings yet

- Infosheet ImaginDocument23 pagesInfosheet ImaginsardusiNo ratings yet

- True GDM-19TDocument2 pagesTrue GDM-19Twsfc-ebayNo ratings yet

- Basic Wedling To LearnerDocument20 pagesBasic Wedling To LearnerRockiBalaNo ratings yet

- SECTION 08800 Glazing Part 1 - General 1.1 SummaryDocument20 pagesSECTION 08800 Glazing Part 1 - General 1.1 SummaryIm ChinithNo ratings yet

- CatalogueDocument19 pagesCatalogueHaitham Salama GhareebNo ratings yet

- D28G0300 enDocument1 pageD28G0300 enAirika BalqizNo ratings yet