Professional Documents

Culture Documents

3 钢筋工程技术交底 (中英)

3 钢筋工程技术交底 (中英)

Uploaded by

fightbymyself0 ratings0% found this document useful (0 votes)

21 views14 pagesOriginal Title

3 钢筋工程技术交底(中英)

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

21 views14 pages3 钢筋工程技术交底 (中英)

3 钢筋工程技术交底 (中英)

Uploaded by

fightbymyselfCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 14

Mombasa-Nairobi Standard Gauge Railway Project

Technical Disclosure Form

技 术 交 底 书

Name of Unit Work House Building Part of Work Major Structure

单位工程名称 房建工程 工程部位 主体结构

Prepared By Affordable housing Received By Steel bar group

编制单位 保障房项目经理部 接收单位 钢筋施工班组

Reinforcing bar

Item to be Disclosed Time of Disclosure

Engineering

交底项目 交底时间

钢筋工程

交底内容: Content of disclosure

一、技术要求 Technical Requirement

(1)由专业工长组织班组学习钢筋混凝土施工及验收规范、钢筋滚扎直螺纹接头技术规程、钢

筋机械连接技术规程等规范并熟悉施工图纸。

(1)The professional forman shall organize all the shifts to study reinforcement concrete construction

and check&acceptance regulation, steel colligation of straight thread joint technical regulation, steel

machine connecting technical regulation, and get familiar with construction drawing.

(2)根据施工图纸编制钢筋加工配料单,并根据钢筋加工单及施工进度计划,编制钢筋进场

计划。

(2)Prepare steel processing list according to construction drawing, and work out steel admission plan

according to steel processing list and construction progress plan.

(3)进行套筒接头作业人员必须经过培训,合格后方可上岗。

(3)Employees to conduct sleeving work shall be trained, and execute the work after being qualified.

(4)所有钢材全部采用大型钢厂生产的钢材,并按批量检查、要有材质保证书。

( 4 ) All steel material applied must be produced from major steel supplier with quality guarantee

certificate and checked by batch.

(5)钢材进场应对外观进行检查,钢筋的表面不得有裂纹、结疤和折迭,表面凸块不得超过横

肋高度,每 1m 的弯曲度不大于 4mm。

(5)It shall check the appearance of steel bars without crack, scab and other defects. The bulge of steel

bar can not be over the height of transverse rib, and tortuosity of steel bar every 1 meter shall not be more

than 4mm.

(6)进场后由试验员根据实际情况取样进行物理性能试验,必要时对其进行化学分析试验,

合格后方可使用。未经复试及经复试不合格的钢材严禁用于工程上。

(6)Tester shall take sample according to the actual condition, conduct the physical property test after

entering the site, and take chemical analysis test when necessary. Steel bars shall be used after being tested

qualified, no applying unqualified or non-rechecked steel material to construction.

(7)钢筋场地必须硬化,并应设有排水坡度。钢筋下面应垫设条墩,以防止钢筋被锈蚀和油

污。

( 7 ) Steel stack yard must be compacted and set with drainage gradient. Set up wood block cushion

under steel stack so as to prevent steel bars from corrosion.

(8)进场的钢筋必须挂标识牌,标识牌必须注明钢筋的规格、生产厂家、重量,并注明是否已

检验合格。

(8)A signboard shall be set for steel material with specification, manufacturer and weight, stating if it

is qualified.

(9)钢筋半成品的存放,按规格、部位分类存放,并做明显的标识。

( 9 ) Semi-finished product of steel bars shall be stored by specification, part and classification with

visibly signboard.

(10)在加工过程中,如发现钢筋脆断、焊接性能不良或力学性能显著不正常等现象,应依据

现行国家标准对该批进场钢筋原材料进行化学成分检验或其它专项检验。

( 10 ) It shall conduct chemical test or special test to the admitted steel bars according to the current

national standard if any crack,bad welding or obvious abnormal mechanical property happens to steel bars

during processing.

(11)钢筋下料前配料单要报工程部审核,并严控下料尺寸。

(11)It shall submit processing list to engineering department for check before charging steel bars and

strictly control the size.

(12)钢筋节点严格按照结构施工图、规范要求施工,不详处参照 11G101 图集。

(12)Steel bar knot construction shall strictly comply with construction drawing and specification, see

the drawing collection 11G101.

(13)钢筋绑扎前必须对工人进行明确分工及绑扎交底。

(13)It shall give the workers specific assignment and colligation disclosure.

二、钢筋加工、安装质量验收要求 Steel Bar Processing and Installation Acceptance Requirement

操作工艺及流程:Operation process and procedure

加工前准备→钢筋除绣→钢筋调直→钢筋切断→钢筋套丝、弯曲成型→检查

Preparation-derust-straightening-cutting- reinforcement set of silk and bending forming-check

1、钢筋加工质量验收标准

1、Reinforcement Processing Acceptance Standard

(1)钢筋加工前需对钢筋原材进行调直、除锈处理。钢筋应平直,无局部曲折,钢筋调直和除

锈可一道完成。

( 1 ) Original reinforcement material must be straightened and derust without local bend before

processing.

(2)统计下料单上的钢筋,统一下料,减少钢筋废料,合理利用每一根钢筋长度。加工时严

格按照下料单上的图形尺寸。

( 2 ) Make a statistic of processing list, reduce reinforcement waste, and apply the length of each

reinforcement reasonably, and process according to the graphic size on charging list.

(3)根据钢筋直径、弯曲角度随时更换轴套。

(3)Replace the shaft sleeve according to reinforcement strightness and bend angle.

2、受力钢筋的弯钩和弯折应符合下列规定:

2、Hook and bend of force reinforcement shall comply with the following requirement:

(1)HPB235 级钢筋的末端应作 180°弯钩,其弯弧内直径 d 不应小于钢筋直径 d 的 2.5 倍,

弯钩的弯后平直部分长度不应小于钢筋直径 d 的 3 倍。

(1)The end of HPB235 reinforcement shall be made to 180°hook, the diameter of internal arc shall not

be less than 2.5 times the diameter of reinforcement, and the length of the straight part after the bend

position of hook shall not less than 3 times the diameter of reinforcement.

(2)当设计要求钢筋末端需做 135°弯钩时,HRB335、HRB400 级钢筋的弯弧内直径 D 不应小

于钢筋直径 d 的 4 倍,弯后平直部分长度应符合设计要求。

(2)The diameter of internal arc of HRB335 and HRB400 reinforcement shall not be less than 4 times

the diameter of the reinforcement when the reinforcement end requires to be made 135°hook according to

the design, and the straight part after the bend position shall comply with the design requirement.

(3)钢筋作不大于 90°的弯折时,弯折处的弯弧内直径不应小于钢筋直径的 5 倍。

(3)When reinforcement is bend not more than 90°, the diameter of internal arc shall not be less than 5

times the diameter of steel.

(4)钢筋加工的形状、尺寸应符合设计要求,其偏差应符合下表规定:

(4)Reinforcement shall be processed according to the shape and size required by design.

钢筋加工允许偏差

允许偏差(㎜) Allowable deviation

项 目 Item

GB50204-2002 ZJQ00-SG-002-2003

受力钢筋顺长度方向全长的净尺寸

±10 ±10

Net length of force reinforcement along the length

弯起钢筋的弯折位置 Bend position ±20 ±20

箍筋内净尺寸 Net size within stirrup ±5 ±5

检查数量:按每工作班同一类型钢筋、同一加工设备抽查不应少于 3 件。

Check quantity: sampling check of each type of reinforcement and same processing machine shall not be

less than 3 pieces.

检查方法:钢尺检查。

Check method: Use steel tape to check.

(5)钢筋套丝外观要求牙形饱满,无断牙、秃牙缺陷,且与牙形规的牙形吻合,表面光洁完

整,丝扣圈数应满足要求。

(5)Appearance of reinforcement set of silk is required full of tooth without crack or bare defect, the

tooth shall comply with the shape with complete smooth surface, and the wire fastener travels shall meet

the requirement.

(6)螺纹尺寸长度应满足要求,通规或套筒能顺利旋入螺纹,允许止规与端部螺纹部分施

合,旋入量不应超过纹距。

(6)Thread size shall meet the requirement, go gauge or sleeve can be screwed in the thread smoothly

with screwing distance not more than thread distance, and no-go gauge maybe partly mesh terminal

thread.

(7)套筒外观防锈处理到位。无锈蚀、油污、裂纹、黑皮等缺陷,外形尺寸长度及外径应满足尺

寸公差要求螺纹尺寸通规能顺利旋入,止规从套筒端部旋入量不应超过 3P(P 为螺距)。

( 7 ) Appearance of sleeve shall be treated with derust, no-go gauge shall be screwed in from the

terminal of sleeve with distance not more than 3P (P stands for screw pitch).

2、钢筋的绑扎安装技术要求

2、Technical Requirement of Colligation and Installation of Reinforcement

1)轴心受拉及小偏心受拉杆件的纵筋不得采用绑扎搭接接头。

1)Longitudinal steel of axes and small decentration pulled by pole shall not be colligated and overlapped

with joint.

2)当钢筋的品种、级别或规定需做变更时,应符合规范要求或办理相应的设计变更文件,不

得私自做主,随意变更。

2)When the type and grade of steel or regulation needs to vary, it shall comply with the requirement of

specification or the document of design variation accordingly, no making any variation by own decision.

3)纵向受力钢筋的品种、规格、数量、位置、连接方式、接头位置、接头面积百分率;箍筋、横向

钢筋的品种、规格、数量、间距等必需符合图纸设计和规范要求。

3)The type, specification, quantity, position, connection method, joint position, joint area percentage of

the longitudinal forced steel and the type, specification, quantity and space of transversal steel and stirrup

shall comply with the drawing specification and requirement.

4)纵向钢筋受力的连接方式应符合设计及规范要求,钢筋的接头宜设置在受力较小处,同一

纵向受力钢筋不宜设置两个或两个以上接头。接头末端至钢筋弯起点的距离不应小于钢筋直径的

10d。

4 ) The connection method of longitudinal forced steel shall comply with design and specification, the

steel joint shall be set at the position less forced, and the same longitudinal forced steel had better not set 2

or above joints.The distance between joint terminal and starting point of the bend shall not less than 10d

of steel diameter.

5)当受力钢筋采用机械连接或焊接接头时,在同一构件内的接头宜相互错开。同一 连接区段

的长度为 35d(d 为纵向受力钢筋的较大直径)且不小于 500mm,接头面积百分率应符合设计要

求;当设计无具体要求时,应符合下列规定:

5 )When the forced steel adopts mechanical connection or welding joint, the joints within same frame

member shall be staggered each other. The length of the same connection section shall be 35d (d is the

bigger diameter of the longitudinal steel) and not less than 500mm, and the joint area percentage shall

comply with design requirement; when the design has no specific requirement, it shall comply with the

following stipulation:

① 在受拉区不宜大于 50%;

①It shall not be more than 50% in the pulling area.

② 接头不宜设置在有抗震设防要求的框架梁端,柱端的箍筋加密区;当无法避开时,对等强

度高质量机械连接接头,不应大于 50%。

②Joint had better not be set at frame terminal needing quake proof and intensified area of stirrup at pillar

terminal, when it can’t be avoided, the equivalent strong and heavy mechanical joint shall not be more

than 50%.

6)同一构件中相邻纵向受力钢筋的绑扎搭接接头,宜相互错开,钢筋的横向净距不应小于钢

筋直径,且不应小于 25mm。绑扎搭接接头的搭接区段长度为 1.3L1(L1 为搭接长度),同一区段

接头面积百分率应符合设计要求;当设计无具体要求时应符合不列规定:

6)It is better to stagger the colligation and overlapping joints of adjacent longitudinal forced steel bar of

the same frame member with net transversal distance not less than diameter of steel and not less than

25mm. The overlapping section length of colligation and overlapping joint shall be 1.3L1 (L1 is the length

of overlapping length ), and the area percentage of same section joint shall comply with the design

requirement. When the design has no specific requirement, it shall comply with the following stipulation:

① 梁、板类构件不宜大于 25%; ②柱、墙类构件,不应大于 50%; ③当工程中确有必要增大

接头面积百分率时,对梁类构件,不应大于 50%。

①beam or plate of frame member shall take up less than 25%.

②pillar or wall of frame member shall not more than 50%.

③when the joint percentage needs to increase, beam of frame member shall not be more than 50%.

7)受拉钢筋的最小锚固长度 La 及受拉钢筋的抗震锚固长度 LaE 应符合图纸设计要求及规范

要求。受力钢筋的最小保护层厚度应符合设计和规范的要求。

7)The minimum anchoring length La and shake proof anchoring length LaE of forced steel shall comply

with the drawing design and specification, and the minimum thickness of protection layer shall comply

with design and specification.

8)柱、墙、梁、板的抗震与非抗震构造应符合图纸设计要求及规范的规定。

8)The structure of quake proof and non-quake-proof of pillar, wall, beam and plate shall comply with

design and specification.

9)所有现场的钢筋施工必需符合图纸设计要求,结构设计总说明及国家相关规范的规定要

求。

9)All the steel construction shall comply with design drawing, general instruction of structure design and

national specification.

10)未尽事宜应按规范的规定及相应的国家规范执行。

10 ) Matters not covered shall be executed according to the requirement and corresponding national

specification.

11)钢筋安装位置的允许偏差应符合下表规定:

11)The allowable deviation of installation position shall comply with the following stipulation:

允许偏差(mm)Allowable deviation 检验方法

项目 Item

GB50204-2011 ZJQ00-SG-002-2003 Check Method

长、宽 length,

±10 ±10 钢尺检查 steel tape check

width

钢筋网 钢尺量连续 3 挡,取最大

Steelmesh 网眼尺寸 值

±20 ±20

Mesh hole Measure 3 straight,take the

maximum value.

筋骨架 长 Length ±10 ±10 钢尺检查 steel tape check

Steel 宽、高

±5 ±5 钢尺检查 steel tape check

shelf Width, height

间 距 interval ±10 ±10 钢尺量两端、中间各一个

点,取最大值

Measure 1 point of 2

排 距 Row

±5 ±5 sides and middle

受力钢筋 space

respectively by steel tape,

The

take the maximum value.

forced

柱、梁

steel ±5 ±5 钢尺检查 steel tape check

Pillar,

板、墙、壳

plate, wall, ±3 ±3 钢尺检查 steel tape check

crust

钢尺量连续 3 檔,取最大

绑扎箍筋、横向钢筋间

值

距

±20 ±20 Measure 3 straight

Colligate stirrup and

挡,take the maximum

transversal steel distance

value.

钢筋弯起点位置 Bend

20 20 钢尺检查 steel tape check

starting point of steel

构件绑扎的允许偏差和检验方法续表

Complementary Table of Check Method and Allowable Deviation of Frame Member Colligation

项目 允许偏差(mm)Allowable deviation 检验方法

Item GB50204-2002 ZJQ00-SG-002-2003 Check Method

弯钩绑扎接 弯钩朝向应正确,任一绑扎接头的搭接长度均

头 不应小于规定值,且不应大于规定值的 5%。 观察和尺量检查

Hook Hook shall be towards right direction, and any Observe and check by

colligated with joint overlapping length shall not be less than specified tape

joint value and more than 5% of specified value.

数量符合设计要求,弯钩角度和平直段长度符

合规定。 观察和尺量检查

箍 筋

The quantity shall comply with design, hook angle Observe and check by

Stirrup

and flat straight section length shall also meet the tape

stipulation.

备注:1、检查预埋件中心线位置时,应沿纵横两个方向量测,并取其中较大值;

2、表中梁类、板类构件上部纵向受力钢筋保护层厚度的合格点率需达到 90%及

以上,且不得超过表中数值 1.5 倍的尺寸偏差。

Remark: 1.While checking central line position of pre-burial components, measure it by longitudinal

and

transversal direction, and take the bigger value.

2.The qualified point rate of the longitudinally forced steel protection layer thickness on the

beam

and plate of frame member shall reach 90% or above, and not more than 1.5 times size

deviation

with the table.

检查数量:在同一检验批内,对梁、柱,应抽查构件数量的 10%,且不应少于 3 件;对墙和板

按有代表性的自然间抽查 10%,且不少于 3 间;对大空间结构,墙可按相邻轴线间高度 5m 左右划

分检查面,板可按纵横轴线划分检查面,抽查 10%,且不均不少于 3 面

Check quantity: It shall make a sample check by 10% of pillar and beam of frame member and not less

than 3 pieces, by 10% of wall and plate by typical natural room and not less than 3 rooms, by 5m of wall

height between adjacent axes lines, and by 10% of plate by longitudinal and transversal axis line and not

less than 3 faces and uneven.

三、作业流程 Working Procedure

1、柱钢筋安装 Pillar Steel Bar Installation

(1)施工工艺流程 Construction procedure

弹柱子线→剔凿柱混凝土表面浮浆→修理柱子钢筋→套柱箍→搭接绑扎竖向受力筋→画箍筋

间距线→绑箍筋

Lay out the line to pillar-clear the laitance on concrete surface of the pillar-repair pillar steel-pillar

hooping -overlapping and colligation of longitudinal forced steel-drawing space line of stirrup- stirrup

binding

(2)操作工艺 Operational process

1)按图纸要求间距计算好每根柱箍筋数量,先将箍筋套在下层伸出的搭接钢筋上,然后立柱

子钢筋,在搭接长度内绑扣不少于 3 个,绑扣要向柱中心。如果柱子主筋采用光圆钢筋搭接时,角

部弯钩应与范本成 45°角,中间钢筋的弯钩应与范本成 90°角;

1)Calculate the quantity of each stirrup according to the required space of drawing, put stirrup on the

lower overlapping steel extruded first, then set up the pillar steel with colligation at the center of pillar not

less than 3 within overlapping length. If the main steel of pillar adopts smooth round steel to overlapping,

the hook at the foot shall form 45°with model and the hook of middle steel shall form 90°with model.

2)柱子主筋立起后,绑扎接头的搭接长度、接头面积百分率应符合设计要求;

2 ) After the main steel of pillar sets up, overlapping length of binding joint and joint area percentage

shall comply with the design.

3)在立好的柱子竖向钢筋上按图纸要求间距用石笔划出箍筋间距线;

3 ) Use slate pencil to mark out the stirrup space line on the longitudinal steel of the erected steel

according to the drawing.

4)柱箍筋绑扎 Stirrup colligation of pillar

按已划好的箍筋位置线,将已套好的箍筋向上移动,由上往下绑扎,宜采用缠扣绑扎,如下

图所示。

Move up the covered stirrup according to the marked position line and bind it from up to down, it had

better twine and bind it.

箍筋与主筋要垂直,箍筋转角处与主筋交点均要绑扎,主筋与箍筋非转角部分的交点成梅花

形交错绑扎。箍筋的弯钩迭合处应沿柱子竖筋交错布置,并绑扎牢固。

Stirrup shall be vertical with main steel, both the corner of stirrup and main steel intersection shall be

colligated, the main steel and non-corner intersection of stirrup shall be staggered in quincunx and

colligated. The intersection of stirrup hook shall be staggered with longitudinal steel along the pillar and

colligated.

柱基、柱顶和梁柱交接处箍筋间距应按设计要求加密。柱上下两端箍筋应加密,加密区长度及

加密区内箍筋间距应符合设计图纸要求。如设计要求箍筋设拉筋时,拉筋应钩住箍筋。

Stirrup space at the intersection of pillar foundation,pillar top and beam shall be intensified according to

the design, as well as of the ends of pillar with length of intensified section and stirrup space within

intensified section complying with the drawing. If the design requires to set up pulling steel, it shall hook

the stirrup.

柱筋保护层厚度应符合规范要求,垫块应绑在柱筋外皮上,间距为 1000mm。

The thickness of protection layer of pillar steel shall comply with the specification, the cushion block shall

be fastened on the pillar steel with space 1000mm.

2、梁钢筋安装 Beam Steel Installation

(1)施工工艺流程 Construction Process

1)模内绑扎:画主次梁箍筋间距→放主次梁箍筋→穿主梁底筋及弯起筋→穿次梁底筋并与箍

筋固定→穿主梁上层纵向架立筋→按箍筋间距绑扎→穿次梁上层纵向钢筋→按箍筋间距绑扎

1)In-formwork colligation: draw out the space of the beam stirrup-lay out the stirrup of beam-put on the

bottom steel of main beam and bend steel-put on the bottom steel of sub-beam and fix stirrup-put up

longitudinal erected steel of upper layer of main beam-colligate steel according to the stirrup space-put on

upper longitudinal steel of sub-beam-colligate steel according to the stirrup space

2)模外绑扎:画箍筋间距→在主次梁范本上口铺横杆数根→在横杆上面放箍筋→穿主梁底筋

→穿次梁底筋→穿主梁面筋→按箍筋间距绑扎→穿次梁面筋→按箍筋间距绑扎→抽出横杆落钢筋

骨架与梁模内

2)Out-formwork colligation: Draw out stirrup space-pave some transversal pole on beam model-set up

stirrup on transversal pole-put on the bottom steel of main beam-put on the bottom steel of sub-beam -put

on face steel of main beam-colligate steel according to the stirrup space-put on face steel of sub-beam -

colligate steel according to the stirrup space-pull out transversal pole and put in the steel skeleton and

beam formwork.

(2)操作工艺 Operation Process

1)在梁侧范本上画出箍筋间距,摆放箍筋;

1)Draw out the stirrup space on the model by the beam and distribute the stirrup.

2)先穿主梁的底筋及弯起钢筋,将箍筋按已画好的间距逐个分开;穿次梁底筋及弯起钢筋,

并套好箍筋;放主次梁架立筋;隔一定间距将架立筋与箍筋绑扎牢固;调整箍筋间距使间距符合

设计要求,绑扎架立筋,再绑扎主筋,主次梁同时配合进行。

2)Put on the bottom steel and bend-up steel of main beam first, separate the stirrup one by one by the

space drawn out. Put on the bottom steel and bend-up steel of sub-beam, and sleeve the stirrup. Colligate

the erected steel with stirrup firmly by a certain space, regulate the space to meet the design, colligate the

erected steel first and then the main steel. The main beam and sub-beam shall be conducted at same time.

3)梁箍筋弯钩布置于梁受压侧,沿梁长度方向交错布置。

3)The hook of beam stirrup shall be staggered and arranged at the forced side of beam along the beam

length.

4)框架梁面筋应贯穿中间节点,梁底筋伸入中间节点锚固长度及伸过中心线的长度要符合设

计要求。框架梁纵向钢筋在端节点内的锚固长度也要符合设计要求;

4)Face steel of frame beam shall be through the middle knots, the anchoring length that bottom steel of

beam stretches into center line shall comply with the design, as well as the anchoring length in the knot of

longitudinal steel of frame beam.

5)绑扎梁面筋的箍筋宜用套扣法绑扎

5)Stirrup of beam face steel colligation had better adopt sleeve-fastening method.

6)箍筋在迭合处的弯钩,在梁中应交错绑扎,箍筋弯钩为 135°,平直部分长度为 10d,如做

成封闭箍筋时,单面焊缝长度为 5d。

6)The hook at intersection of stirrup shall be staggered and colligated in the beam with 135°hook and

flat straight section length 10d. The length of single face welding joint shall be 5d when it is made into

close stirrup.

7)梁端第一个箍筋应设置在距离柱节点边缘 50mm 处。梁端与柱交接处箍筋应加密,其间距

与加密区长度均要符合设计要求。

7)The first stirrup of the end of beam shall be set at 50mm away from pillar knot, and intersection of

beam end and pillar shall be intensified with both space and length of intensified section complying with

design.

8)在主次梁受力筋下均应垫垫块,保证保护层厚度。受力筋为双排时,可用短钢筋垫在两层

钢筋之间,钢筋排距应符合设计要求;

8 ) It shall set up a cushion block under both of main beam and sub-beam to ensure the thickness of

protection layer, and fix short steel between two layers of steel with the space complying with the design

if the forced steel has two rows.

9)梁筋的搭接:搭接长度末端与钢筋弯折处的距离不得小于钢筋直径的 10 倍。接头不宜位于

构件的最大弯矩处,搭接处应在中心和两端扎牢。

9)Overlapping of beam steel: The distance between overlapping length end and bending position of steel

shall not be less 10 time of steel diameter, joint had better not set at the maximum bending moment of

component and overlapping position shall be set at center, colligating with the two ends.

3、板钢筋安装 Plate Steel Bar Installation

(1)施工工艺流程 Construction process

清理模板→模板上划出板底筋布置线→绑板底筋→绑板负弯矩筋

Clean formwork-mark out the distributing line of plate bottom steel on formwork-colligate plate bottom

steel-colligate negative bending moment steel of plate

(2)操作工艺 Operational process

1)清理范本上的杂物,用粉笔在范本上划好主筋及分布筋间距线;

1)Clear away the sundries on the model, and use chalk to mark out the main steel and the space line of

distribution steel on the model.

2)按划好的间距线,先摆放受力主筋,后放分布筋。预埋件、电线管、预留孔等及时配合安

装;

2 ) Arrange the main forced steel according the space line marked out and then distribution steel, and

install the pre-burial piece, wire tube, reserve hole in time.

3)在现浇板中有板带梁时,应先绑板带梁钢筋,再摆放板钢筋;

3)It shall colligate the plate belt beam steel and then set up plate steel, when there is plate belt beam in

on-site casting plate.

4)绑扎板筋时采用顺扣或八字扣,除外围两根钢筋的相交点应全部绑扎外,其余各点可交错

绑扎(双向板相交点需全部绑扎)。如板为双层钢筋,两层钢筋之间需加马凳筋,以确保上下层钢

筋位置的正确。负弯矩筋每个相交点均要绑扎;

4 ) It shall adopt clockwise fastening or 八 shaped fastening as colligating plate steel, except that the

intersections of external two steel bars shall be all colligated, the rest intersection shall be staggered and

colligated (all two-way plate intersections shall be all colligated). It shall set up stirrup steel to ensure the

position of both upper and lower steel right if the plate is double steel. Each intersection of negative

bending moment shall be colligated.

5)板底筋加设大理石或砂浆垫块,间距 1m,垫块厚度等于设计保护层厚度。钢筋搭接长度与

搭接位置的要求与前面所述梁相同。

5 ) It shall set up marble or mortar cushion block under the plate bottom steel with space 1m, and the

thickness shall same with the thickness of the protection layer. The steel overlapping length and position

shall be same with the forgoing.

4、剪力墙钢筋安装 Installation of Shear Wall Steel

(1)施工工艺流程 Construction Process

弹墙体线→剔凿墙体混凝土浮浆→修正预留搭接筋→绑纵向筋→绑横向筋→绑拉筋或支撑筋。

Mark out wall line-clear the laitance on the wall-correct the reserved overlapping steel-longitudinal steel

colligation-transversal steel colligation-colligate pulling steel or support steel.

(2)操作工艺 Operational Process

1)将预留钢筋调直理顺,并将表面砂浆等杂物清理干净。先立 2~4 根纵向筋,并划好横向筋

分文件标志,然后于下部及齐胸处绑两根定位水平筋,并在横筋上划好分文件标志,然后绑其余

纵向筋,最后绑其余横筋。如剪力墙中有暗梁、暗柱时,应先绑暗梁、暗柱,再绑周围横筋。

1)Straighten the reserved steel and clean the surface laitance and other sundries. Erect 2-4 longitudinal

steel bars, make a file mark on transversal steel, fasten 2 location level steel at the bottom and middle up,

make a file mark on longitudinal steel, and colligate the rest transversal steel. If there are hidden beam and

hidden pillar in shear wall, colligate the hidden beam and pillar, and then the nearby transversal steel.

2)剪力墙钢筋绑扎完后,把垫块或垫圈固定好确保钢筋保护层厚度。

2)Fix the cushion block or backup ring, to ensure the thickness of steel protection layer after colligation

of the shear wall steel.

3)剪力墙的纵向钢筋每段钢筋的长度不宜超过 4m(钢筋的直径≤12mm)或 6m(钢筋的直

径>12mm),水平段每段长度不宜超过 8m,以利于绑扎。

3 ) The length of each section of longitudinal steel of shear wall had better not more than 4m (steel

diameter≤12mm ) or 6m (Steel diameter >12m,) the length of each section of level section had better

not more than 8m so as to colligate easily.

4)剪力墙的钢筋网绑扎时全部钢筋的交叉点要扎牢,绑扎时相邻绑扎点的铁丝扣成八字形,

一面网片歪斜变形。

4)All the steel intersection shall be fastened as colligating the steel net of shear wall, the steel wire of

adjacent colligation points shall be fastened in the form of 八 with a side of the net inclined and deformed

as colligation.

5)剪力墙水平分布筋的搭接长度不应小于 1.2la(la 为钢筋锚固长度)。同排水平分布筋的搭

接接头之间及上下相邻水平分布筋的搭接接头之间沿水平方向的净间距不宜小于 500mm,搭接采

用焊接时应符合《钢筋焊接及验收规程》(JGJ18-2003)规定。

5)The overlapping length of horizontal distributed steel of shear wall shall not be less than 1.2la (la is

the length of steel anchoring ), it had better not less than 500mm for the horizontal net space between the

overlapping joints of horizontal distributed steel in same row and the vertical adjacent distributed steel.

When overlapping adopts welding joint, it shall comply with the stipulation of (JGJ18-2003), Steel

Welding and Acceptance Regulation.

6)剪力墙竖向分布筋连接时应符合 11G101-1 中剪力墙身竖向分布钢筋连接构造;剪力墙竖

向底部筋锚入梁内的构造应按照 11G101-1 中的规定严格执行。

6 ) The vertical distributed steel joint of shear wall shall comply with the joint structure of vertical

distributed steel of shear wall in 11G101-1, and vertical bottom steel of shear wall anchored in structure

shall be executed according to the stipulation of 11G101-1.

7)剪力墙分布钢筋的锚固:剪力墙水平分布筋应伸至墙端,并向内水平弯折 10d 后截断,其

中 d 为水平分布钢筋直径。

7 ) Distributed steel anchoring of shear wall: The transversal distributed steel of shear wall shall be

extended to the end of wall, horizontally bent 10d towards internal and cut off, and d is the diameter of

horizontal distributed steel.

8)当剪力墙端部有翼墙或转角墙时,内墙两侧的水平分布钢筋和外墙内侧的水平分布钢筋应

伸至翼墙或转角墙外边,并分别向两侧水平弯折后截断,其水平弯折长度不宜小于 15d。在转角墙

处,外墙外侧的水平分布钢筋应在墙端外角处弯入翼墙,并于翼墙外侧水平分布钢筋搭接,搭接

长度为 1.2la。带边框的剪力墙,其水平和竖向分布筋宜分别贯穿柱、梁或锚固在柱、梁内。

8)When the end of shear wall has a wing wall or corner wall, the horizontal distributed steel of 2 sides of

internal wall and the internal horizontal distributed steel of external wall shall be extended to wing wall or

outside of corner wall, and bent towards to the two sides and cut off with the horizontal bending length

not less than 15d. The horizontal distributed steel outside of external wall in the corner wall shall be bent

into wing wall at the end of wall, and overlapped with the horizontal distributed steel outside of wing wall

with the length 1.2la. The horizontal and vertical distributed steel of shear wall with frame shall be

through pillar and beam, or anchored in the pillar and beam.

9)剪力墙洞口连梁应沿全长配置箍筋,箍筋直径不宜小于 6mm,间距不宜大于 150mm。在顶

层洞口连梁纵向钢筋伸入墙内的锚固长度范围内,应设置间距不大于 150mm 的箍筋,箍筋直径与

该连梁跨内箍筋直径相同。同时,门窗洞边的竖向钢筋应按受拉钢筋锚固在顶层连梁高度范围内。

9)The connection beam of the shear wall hole shall be fixed with stirrup along the whole length with the

stirrup diameter not less than 6mm and space not more than 150mm, and the vertical steel of connection

beam in top hole shall be extended into the scope of the anchoring length inside the wall with the space

not more than 150mm of the stirrup, and stirrup diameter shall be same with that inside span of connection

beam, meanwhile, The vertical steel by the hole of door and window shall be anchored in the scope of the

height of top layer connection beam according to the pulled steel.

10)混凝土浇筑前,对伸出墙体的钢筋进行修整,并绑扎两道临时水平钢筋固定伸出竖向筋

的间距。墙体混凝土浇筑时派专人看管钢筋,浇筑完成后,立即对伸出钢筋进行校正,校正完毕后

用定位钢筋网片进行定位,保证竖向钢筋的位置、间距和排距准确。定位钢筋用 Φ16 钢筋焊接成

型。

10)It shall repair the steel extruded out of the wall before casting concrete, and colligate the 2 temporary

transversal steel to fix the extruded vertical space. Appoint a person to watch the steel as casting concrete

to wall. Immediately correct the steel extruded after casting, and use the steel net to locate,ensuring the

position,space, row space of steel right. It shall use steel Φ16 as location steel to weld into the form.

5、楼梯钢筋安装 Steel Installation of Staircase

(1)施工工艺流程 Construction Process

划好位置线→绑主筋→绑分布筋→绑踏步筋

Mark out location line-colligate main steel-colligate distribution steel-colligate mark steel

(2)操作工艺 Operational Process

1)在楼梯底板上划出主筋和分布筋的位置线;

1)Mark out the position line of main steel and distribution steel on the bottom plate of staircase.

2)根据设计图纸中主筋、分布筋的方向,先绑扎主筋后绑扎分布筋,每个交点均要绑扎。如有

楼梯梁时,先绑梁后绑板筋,板筋要锚固到梁内;

2 ) Colligate the main steel and then the distribution steel according to direction of main steel and

distribution steel of drawing, and all the intersection shall be colligated. If there is any staircase beam,

colligate the beam and then plate steel, and all the plate steel shall be anchored into the beam.

3)底板筋绑完,待踏步范本支好后,再绑扎踏步钢筋。主筋接头数量和位置均要符合设计和

施工质量验收规范的规定。

3)After the colligation of bottom plate steel and support of mark model, colligate the mark steel, and the

quatity and position of the main steel joints shall comply with design and the requirement of construction

quality acceptance regulation.

四、施工注意事项 Construction Attentions

(1)楼板的弯起钢筋、负弯矩钢筋绑扎好后,不准踩在上面行走,浇筑混凝土前,在钢筋上

搭设跳板,以保持钢筋原有形状,并派钢筋工专门负责修理。

(1)After colligation of bend-up steel of floor and negative bending moment, no passing on it. Set up a

plate on steel to ensure the original shape of the steel before casting concrete, and send a steel fixer to

repair.

(2)浇筑砼时禁止碰撞预埋件及洞口。

(2)No hitting the pre-burial piece or the hole as casting concrete.

(3)现浇板浇筑混凝土时,采用拉线、打点等方法控制现浇板混凝土的标高、厚度和平整度,

使之符合规范要求,防止负筋保护层厚度尺寸超差。

(3)It shall adopt the method of pulling line and making point to controlling the elevation, thickness and

evenness of the on-site casting slab as on-site casting concrete in order to comply with the specification,

preventing the negative protection layer thickness and size from exceeding the allowable tolerance.

(4)钢筋加工前,首先对进场的钢筋原材进行试验,复试合格、质保数据齐全后方可加工,

加工成型的钢筋分类堆码整齐。

( 4 ) It shall carry out the test of raw material of steel before processing steel till the data of re-test

qualified and quality guarantee completed, and the formed steel shall be piled up by classification in good

order.

(5)施工前钢筋施工班组长必须对施工顺序、操作方法和要求向操作人员详细交底,施工过

程中对钢筋规格、数量、位置随时进行复核检查。要特别注意对一些较复杂部位的钢筋规格、数量、

位置随时进行复核检查,梁柱节点严禁漏放箍筋。

(5)The headman of construction team shall make a detailed disclosure of construction order, operation

method and construction requirement to the operator before construction, check the specification, quantity

and position at any time during construction, and give special attention to the complicated part. No

missing to put the stirrup to the knot of beam and pillar..

(6)钢筋的保护层厚度依设计图纸规定进行。同一截面钢筋的接头数量应符合规范要求。

(6)The thickness of steel protection layer shall comply with the design drawing, and the quantity of

joints on same profile shall comply with the specification.

(7)严格控制柱插筋的位置,避免发生钢筋位移及规格与设计图纸不符,柱钢筋绑扎前必须

清理根部的水泥浆,清理干净后方可进行绑扎,并注意竖筋的垂直度,不得在倾斜的情况下绑扎

水平筋及箍筋。柱的插筋上绑扎一个柱箍,将插筋上部连成一片防止任意移位及弯曲。

(7)Strictly control the position of pillar joint bar in order that the steel displacement and specification

can meet the design, clear the mortar on the root before colligation of pillar steel and keep the verticality

of vertical steel, no colligating transversal steel and stirrup as the vertical steel inclines. Colligate a stirrup

to pillar joint bar, and connect the upper joint bar into a whole to avoid displacement or bend.

(8)柱子钢筋采用定位措施,一般采用定位卡在浇筑混凝土前将定位卡套在柱筋顶端,用绑

扣将柱筋紧靠在定位卡上,控制钢筋间距位置,下部用塑料垫块控制保护层厚度。

( 8)It shall take a location measure to the pillar steel, normally sleeve the location pin on the top of

pillar steel before casting concrete, use fastening to put the pillar steel on the location pin closely, control

the space and position of the steel, and use the plastic cushion pad to control the thickness of protection

layer under the bottom.

(9)工程上的钢筋不得任意代换,根据实际情况确需调整时必须由技术部门与设计院商量同

意后方可实施,并办妥技术核定单。

( 9 ) The steel in the construction shall not be replaced casually, the adjustment shall be executed

according the actual condition once both the technical department and design institute consent if

necessary, and process the technical pass.

(10)钢筋搭接处,应在中心和两端用扎丝扎牢;梁主筋与箍筋的接触点全部用扎丝扎牢,

墙板、楼板双向受力钢筋的相交点必须全部扎牢;上述非双向配置的钢筋相交点,除靠近外围两行

钢筋的相交点全部扎牢外,中间可按梅花形交错绑扎牢固。

( 10 ) It shall use steel wire to fasten the two ends and center at steel overlapping, as well as the

intersection of main steel of beam and stirrup, and colligate the intersection of two-way forced steel of

wall plate and floor plate. The forgoing non- two-way fixed steel intersection and the middle shall be

staggered and fastened except colligation of the external 2 lines of steel intersection.

(11)钢筋的绑扎搭接及锚固除按规范要求外还须满足抗震设计规范要求。钢筋绑扎时如遇预

留洞、预埋件、管道位置须割断妨碍的钢筋,要按图纸要求留加强筋,必要时会同有关人员研究协

商,严禁任意拆、移、割。

(11)The colligation overlapping and anchoring shall also meet the quake proof requirement. It shall cut

off the steel as there is a reserved hole, pre-burial piece or pipeline affecting the steel,and reserve stiffener

according to the drawing. Discuss with related personnel as necessary, no piecing out, moving or cutting

off casually.

(12)钢筋制作前,必须有下料单,特殊复杂的钢筋先放大样,经校核无误后方可大量制作。

( 12 ) Make the steel after receiving the processing order, make the amplified sample for the special

complicated steel, make in batch after crosscheck right.

(13)钢筋的制作必须严格按图纸、规范标准施工,接头位置必须错开,搭接长度及锚固长度

必须严格控制,当锚固长度不够时,设 90°弯钩来解决。因本工程为所有箍筋均作 135°弯钩,平直

长度必须满足≥10d。

(13)Make steel strictly complying with drawing and specification, and stagger the joint position.

The overlapping length and anchoring length shall be strictly controlled, when the anchoring length is

less, set up a hook to solve the problem. Because all the stirrup shall be set 135°hook in this construction,

the flat straight length shall be≥10d.

Discloser Review Check

交底人 复核 审核

Disclosee: (To use Attendance Form when necessary)

接收人:(接收人较多时可附接收签到表)

Note:Disclose must personally sign, it is strictly prohibited are signed by others

注:接交底人必须亲自签字,严禁由他人代签。

You might also like

- Spare Parts Catalogue - D2876 LE301 - EngDocument138 pagesSpare Parts Catalogue - D2876 LE301 - EngGeorge Domusciu90% (10)

- Guide To Design of Anchors Bolts and Other Steel EmbedmentsDocument14 pagesGuide To Design of Anchors Bolts and Other Steel Embedmentsvinku90% (1)

- فحص بلدية دبيDocument33 pagesفحص بلدية دبيFredj Kriaa67% (3)

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- SEBU6250-30 Specs Dec 20Document158 pagesSEBU6250-30 Specs Dec 20Afandiquokka100% (1)

- PT Works Material Specification (22apr2021) IESDocument54 pagesPT Works Material Specification (22apr2021) IESYeoh chun yenNo ratings yet

- Method Statement FOR Steel Reinforcement: ProjectDocument5 pagesMethod Statement FOR Steel Reinforcement: ProjectKelvin Lau67% (3)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Cross Arm Galvanized StandardDocument19 pagesCross Arm Galvanized StandardprabathnilanNo ratings yet

- Switch Yard Aluminum Bus Bar Piping Construction (Welding Part)Document11 pagesSwitch Yard Aluminum Bus Bar Piping Construction (Welding Part)Ren SalazarNo ratings yet

- 2 模板工程技术交底 (中英)Document12 pages2 模板工程技术交底 (中英)fightbymyselfNo ratings yet

- Eng 钢筋安装检验批Document9 pagesEng 钢筋安装检验批lamintun109.110.111No ratings yet

- MS For Reinforcement WorksDocument9 pagesMS For Reinforcement WorksShan THALANo ratings yet

- Essar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1Document17 pagesEssar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1ashish_rocksNo ratings yet

- BTS Installation Check Standard - GuideV2.0Document129 pagesBTS Installation Check Standard - GuideV2.0ihi_aunas7439No ratings yet

- Cross Arm Un Galvanized StandardDocument17 pagesCross Arm Un Galvanized StandardprabathnilanNo ratings yet

- Bar Bending ScheduleDocument5 pagesBar Bending ScheduleAnton_Young_1962100% (2)

- 05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsDocument7 pages05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsuddinnadeemNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationMelkamu DemewezNo ratings yet

- Method Statement of AbutmentDocument8 pagesMethod Statement of AbutmentSaeed Ahmed SoomroNo ratings yet

- Checklist For 33kV HG Fuse Structure Design & DrawingDocument4 pagesChecklist For 33kV HG Fuse Structure Design & DrawingRupesh KhandekarNo ratings yet

- Structural Steel & Shop DrawingsDocument43 pagesStructural Steel & Shop DrawingsDIOGO FRANCO PUREZA100% (1)

- Specification OF Reinforcement Bars: Project Management-IiDocument23 pagesSpecification OF Reinforcement Bars: Project Management-IiLizel MadriagaNo ratings yet

- Cutting and Bending of BarsDocument5 pagesCutting and Bending of BarsTana RobinNo ratings yet

- (4.20 4.21) Cement Silo-User ManualDocument29 pages(4.20 4.21) Cement Silo-User Manualعبد الرحمن قاسم البناءNo ratings yet

- Layout of Oil & Heavy Berth Dolphin CatwalkDocument11 pagesLayout of Oil & Heavy Berth Dolphin CatwalkJoel Jeffery SarkarNo ratings yet

- Technical Specifications: Scope of WorkDocument19 pagesTechnical Specifications: Scope of WorknathanieldagsaNo ratings yet

- Structure Calculation Connection Design For Alar HotelDocument63 pagesStructure Calculation Connection Design For Alar Hotelmilenaglisic1121No ratings yet

- Quality Supervision of Soil Nails 2016-09-4Document5 pagesQuality Supervision of Soil Nails 2016-09-4Vince KongNo ratings yet

- Checklist For 33kV Bus Duct Structure Design & DrawingDocument4 pagesChecklist For 33kV Bus Duct Structure Design & DrawingRupesh KhandekarNo ratings yet

- 1062Document13 pages1062katchaniNo ratings yet

- Checklist For Wave Trap Structure Design & DrawingDocument4 pagesChecklist For Wave Trap Structure Design & DrawingRupesh KhandekarNo ratings yet

- Opss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesDocument16 pagesOpss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Anchor Anchor Anchor Anchor Anchor Anchor Anchor AnchorDocument1 pageAnchor Anchor Anchor Anchor Anchor Anchor Anchor AnchorAlemtideg AlemayehuNo ratings yet

- CE-515: Design of Steel Structures: Shear StrengthDocument12 pagesCE-515: Design of Steel Structures: Shear StrengthZiaullahNo ratings yet

- Bar Bending ScheduleDocument5 pagesBar Bending ScheduleAbdulkadirNo ratings yet

- STUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Document10 pagesSTUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Mark Darrel AranasNo ratings yet

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNo ratings yet

- CHAPTER 9b - BearingsDocument6 pagesCHAPTER 9b - Bearings李明环No ratings yet

- Bored Cast in Situ Method LogyDocument77 pagesBored Cast in Situ Method LogySujan RajkumarNo ratings yet

- Fabrication of Structural Steel WorkDocument16 pagesFabrication of Structural Steel WorkyogeswaranNo ratings yet

- 2 R-ME-MS-002 Method Statement of Penstock InstallationDocument23 pages2 R-ME-MS-002 Method Statement of Penstock Installationrotimi olalekan fatai100% (1)

- Checklist For BPI Structure Design & DrawingDocument4 pagesChecklist For BPI Structure Design & DrawingRupesh KhandekarNo ratings yet

- Rail-Steel Deformed and Plain Bars For Concrete ReinforcementDocument4 pagesRail-Steel Deformed and Plain Bars For Concrete ReinforcementmjgutierrezperaltaNo ratings yet

- Reinforcing SteelDocument8 pagesReinforcing SteelPrittam Kumar JenaNo ratings yet

- DIP-NOR-022 - Suministro de Estructura Metálica - Es.enDocument24 pagesDIP-NOR-022 - Suministro de Estructura Metálica - Es.enSUJAL SHAH - SKIPPER LIMITEDNo ratings yet

- 1 混凝土工程施工技术交底 (中英)Document10 pages1 混凝土工程施工技术交底 (中英)fightbymyselfNo ratings yet

- Opss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesDocument29 pagesOpss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Part S30Fabrication Structural Steelwork ContentsDocument7 pagesPart S30Fabrication Structural Steelwork ContentsFerhat KahveciNo ratings yet

- What Are The Mechanical Properties of Structural Steel?: Resistence To Deformation Based UponDocument5 pagesWhat Are The Mechanical Properties of Structural Steel?: Resistence To Deformation Based UponEni VinoNo ratings yet

- Ikeda - DEVELOPMENT OF HYBRID PRESTRESSED CONCRETE BRIDGES WITH CORRUGATED STEEL WEB CONSTRUCTIONDocument15 pagesIkeda - DEVELOPMENT OF HYBRID PRESTRESSED CONCRETE BRIDGES WITH CORRUGATED STEEL WEB CONSTRUCTIONPierre MonchaninNo ratings yet

- Painting Process and Rules 涂装工艺: Cssc Xijiang Shipbuilding Co.,LtdDocument18 pagesPainting Process and Rules 涂装工艺: Cssc Xijiang Shipbuilding Co.,LtdHasib Ul Haque AmitNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- JC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)Document15 pagesJC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)sharedfilepcNo ratings yet

- MGB Carb ArticleUploadDocument1 pageMGB Carb ArticleUploadHarold BeekhuizenNo ratings yet

- Engine HandoutsDocument9 pagesEngine HandoutsJohn Albert FelicesNo ratings yet

- Or Lights-Preventive Maintenance-Wearing Parts Replacement Cycle-En-GlobalDocument17 pagesOr Lights-Preventive Maintenance-Wearing Parts Replacement Cycle-En-GlobalDaniel SchererNo ratings yet

- Artigo Erros Relevantes Ensaios Tensao MetaisDocument5 pagesArtigo Erros Relevantes Ensaios Tensao MetaisbiancogallazziNo ratings yet

- Renault BasicDocument84 pagesRenault BasicDaghe De Sblock80% (5)

- Guideline For Hand Held Shear Vane TestDocument11 pagesGuideline For Hand Held Shear Vane Teststavros_stergNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- C StrucAnalysis Wong Jan17 1Document4 pagesC StrucAnalysis Wong Jan17 1Hattori HanzoNo ratings yet

- Tank Dimensions Liquid Level Liq. Level To Dia. Ratio Typical Mixer Budget PriceDocument6 pagesTank Dimensions Liquid Level Liq. Level To Dia. Ratio Typical Mixer Budget PriceeleyaysieyM.No ratings yet

- Commissioning Procedure Vagen Screw Conveyor With Check ListDocument3 pagesCommissioning Procedure Vagen Screw Conveyor With Check Listrahmankhan823100% (1)

- Bray Product LineDocument6 pagesBray Product LineShag ShaggyNo ratings yet

- Test 2 DJJ50203 Sesi I-23-24Document4 pagesTest 2 DJJ50203 Sesi I-23-24AmmarNo ratings yet

- Standart Rodamientos Doble HileraDocument2 pagesStandart Rodamientos Doble HileracarlosNo ratings yet

- Series 2000 - Magnahelic Differential Pressure GaugeDocument2 pagesSeries 2000 - Magnahelic Differential Pressure GaugeKoteswara RaoNo ratings yet

- CLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration CycleDocument7 pagesCLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration CycleSiti Hajar MohamedNo ratings yet

- College of Engineering and Technology: Course Code: Course Title Course DescriptionDocument5 pagesCollege of Engineering and Technology: Course Code: Course Title Course DescriptionOrley G FadriquelNo ratings yet

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- Mechanical Engineering S6 - RemovedDocument149 pagesMechanical Engineering S6 - RemovedAnish SukumaranNo ratings yet

- SRG Major Test Paper 31-12-2023Document52 pagesSRG Major Test Paper 31-12-2023pal018488No ratings yet

- Chassis Cab: Super DutyDocument17 pagesChassis Cab: Super DutyJoeNo ratings yet

- TATT 100Level1Manual1 11Document649 pagesTATT 100Level1Manual1 11Patrick ByronNo ratings yet

- Robustness of Car Parks Against Localised Fire (Robustfire)Document143 pagesRobustness of Car Parks Against Localised Fire (Robustfire)Batuhan DerNo ratings yet

- Sol T4Document7 pagesSol T4Sohini RoyNo ratings yet

- HPI Catalog - Pumps - GeneralDocument131 pagesHPI Catalog - Pumps - GeneralMichi MichiNo ratings yet

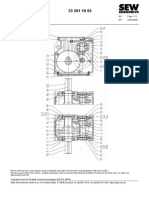

- Parts List 33 261 16 95: Helical-Bevel Gear Unit K97Document3 pagesParts List 33 261 16 95: Helical-Bevel Gear Unit K97Edmundo JavierNo ratings yet

- Smaw Bco 9Document15 pagesSmaw Bco 9Michael Angelo LumanogNo ratings yet